Grinnell Grooved Standard Specifications Roll and Cut Groove for ...

Grinnell Grooved Standard Specifications Roll and Cut Groove for ...

Grinnell Grooved Standard Specifications Roll and Cut Groove for ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500<br />

www.tyco-fire.com<br />

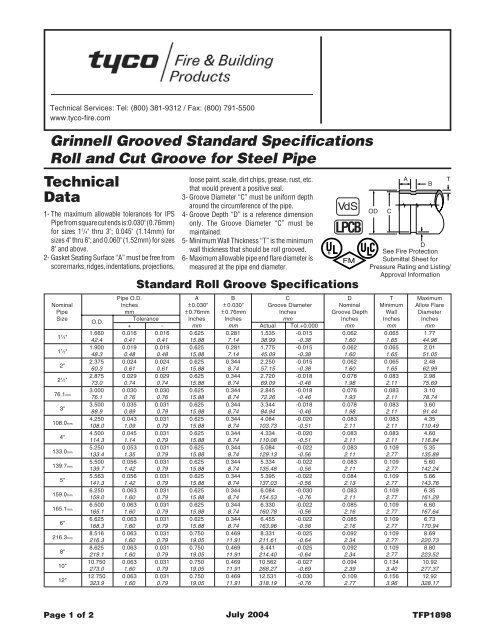

<strong>Grinnell</strong> <strong><strong>Groove</strong>d</strong> <strong>St<strong>and</strong>ard</strong> <strong>Specifications</strong><br />

<strong>Roll</strong> <strong>and</strong> <strong>Cut</strong> <strong>Groove</strong> <strong>for</strong> Steel Pipe<br />

Technical<br />

Data<br />

1- The maximum allowable tolerances <strong>for</strong> IPS<br />

Pipe from square cut ends is:0.030" (0.76mm)<br />

<strong>for</strong> sizes 1 1 /4" thru 3"; 0.045" (1.14mm) <strong>for</strong><br />

sizes 4" thru 6"; <strong>and</strong> 0.060" (1.52mm) <strong>for</strong> sizes<br />

8" <strong>and</strong> above.<br />

2- Gasket Seating Surface “A” must be free from<br />

score marks, ridges, indentations, projections,<br />

loose paint, scale, dirt chips, grease, rust, etc.<br />

that would prevent a positive seal.<br />

3- <strong>Groove</strong> Diameter “C” must be uni<strong>for</strong>m depth<br />

around the circumference of the pipe.<br />

4- <strong>Groove</strong> Depth “D” is a reference dimension<br />

only. The <strong>Groove</strong> Diameter “C” must be<br />

maintained.<br />

5- Minimum Wall Thickness “T” is the minimum<br />

wall thickness that should be roll grooved.<br />

6- Maximum allowable pipe end flare diameter is<br />

measured at the pipe end diameter.<br />

Vd S<br />

LPCB<br />

<strong>St<strong>and</strong>ard</strong> <strong>Roll</strong> <strong>Groove</strong> <strong>Specifications</strong><br />

OD<br />

C<br />

A<br />

D<br />

See Fire Protection<br />

Submittal Sheet <strong>for</strong><br />

Pressure Rating <strong>and</strong> Listing/<br />

Approval In<strong>for</strong>mation<br />

Pipe O.D. A B C D T Maximum<br />

Nominal Inches +_ 0.030" +_ 0.030" <strong>Groove</strong> Diameter Nominal Minimum Allow Flare<br />

Pipe mm +_ 0.76mm +_ 0.76mm Inches <strong>Groove</strong> Depth Wall Diameter<br />

Size Tolerance Inches Inches mm Inches Inches Inches<br />

O.D.<br />

+ - mm mm Actual Tol.+0.000 mm mm mm<br />

1 1 ⁄4"<br />

1 1 ⁄2"<br />

2"<br />

2 1 ⁄2"<br />

76.1mm<br />

3"<br />

108.0mm<br />

4"<br />

133.0mm<br />

139.7mm<br />

5"<br />

159.0mm<br />

165.1mm<br />

6"<br />

216.3mm<br />

8"<br />

10"<br />

12"<br />

1.660<br />

1.900<br />

2.375<br />

2.875<br />

3.000<br />

3.500<br />

4.250<br />

4.500<br />

5.250<br />

5.500<br />

5.563<br />

6.250<br />

6.500<br />

6.625<br />

8.516<br />

8.625<br />

10.750<br />

12.750<br />

0.016<br />

0.019<br />

0.024<br />

0.029<br />

0.030<br />

0.035<br />

0.043<br />

0.045<br />

0.053<br />

0.056<br />

0.056<br />

0.063<br />

0.063<br />

0.063<br />

0.063<br />

0.063<br />

0.063<br />

0.063<br />

0.016<br />

0.019<br />

0.024<br />

0.029<br />

0.030<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.750<br />

0.750<br />

0.750<br />

0.750<br />

0.281<br />

0.281<br />

0.344<br />

0.344<br />

0.344<br />

0.344<br />

0.344<br />

0.344<br />

0.344<br />

0.344<br />

0.344<br />

0.344<br />

0.344<br />

0.344<br />

0.469<br />

0.469<br />

0.469<br />

0.469<br />

1.535<br />

1.775<br />

2.250<br />

2.720<br />

2.845<br />

3.344<br />

4.084<br />

4.334<br />

5.084<br />

5.334<br />

5.395<br />

6.084<br />

6.330<br />

6.455<br />

8.331<br />

8.441<br />

10.562<br />

12.531<br />

-0.015<br />

-0.015<br />

-0.015<br />

-0.018<br />

-0.018<br />

-0.018<br />

-0.020<br />

-0.020<br />

-0.022<br />

-0.022<br />

-0.022<br />

-0.030<br />

-0.022<br />

-0.022<br />

-0.025<br />

-0.025<br />

-0.027<br />

-0.030<br />

0.062<br />

0.062<br />

0.062<br />

0.078<br />

0.076<br />

0.078<br />

0.083<br />

0.083<br />

0.083<br />

0.083<br />

0.084<br />

0.083<br />

0.085<br />

0.085<br />

0.092<br />

0.092<br />

0.094<br />

0.109<br />

0.065<br />

0.065<br />

0.065<br />

0.083<br />

0.083<br />

0.083<br />

0.083<br />

0.083<br />

0.109<br />

0.109<br />

0.109<br />

0.109<br />

0.109<br />

0.109<br />

0.109<br />

0.109<br />

0.134<br />

0.156<br />

1.77<br />

2.01<br />

2.48<br />

2.98<br />

3.10<br />

3.60<br />

4.35<br />

4.60<br />

5.35<br />

5.60<br />

5.66<br />

6.35<br />

6.60<br />

6.73<br />

8.69<br />

8.80<br />

10.92<br />

12.92<br />

42.4<br />

48.3<br />

60.3<br />

73.0<br />

76.1<br />

88.9<br />

108.0<br />

114.3<br />

133.4<br />

139.7<br />

141.3<br />

159.0<br />

165.1<br />

168.3<br />

216.3<br />

219.1<br />

273.0<br />

323.9<br />

0.41<br />

0.48<br />

0.61<br />

0.74<br />

0.76<br />

0.89<br />

1.09<br />

1.14<br />

1.35<br />

1.42<br />

1.42<br />

1.60<br />

1.60<br />

1.60<br />

1.60<br />

1.60<br />

1.60<br />

1.60<br />

0.41<br />

0.48<br />

0.61<br />

0.74<br />

0.76<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

19.05<br />

19.05<br />

19.05<br />

19.05<br />

7.14<br />

7.14<br />

8.74<br />

8.74<br />

8.74<br />

8.74<br />

8.74<br />

8.74<br />

8.74<br />

8.74<br />

8.74<br />

8.74<br />

8.74<br />

8.74<br />

11.91<br />

11.91<br />

11.91<br />

11.91<br />

38.99<br />

45.09<br />

57.15<br />

69.09<br />

72.26<br />

84.94<br />

103.73<br />

110.08<br />

129.13<br />

135.48<br />

137.03<br />

154.53<br />

160.78<br />

163.96<br />

211.61<br />

214.40<br />

268.27<br />

318.19<br />

-0.38<br />

-0.38<br />

-0.38<br />

-0.46<br />

-0.46<br />

-0.46<br />

-0.51<br />

-0.51<br />

-0.56<br />

-0.56<br />

-0.56<br />

-0.76<br />

-0.56<br />

-0.56<br />

-0.64<br />

-0.64<br />

-0.69<br />

-0.76<br />

1.60<br />

1.60<br />

1.60<br />

1.98<br />

1.93<br />

1.98<br />

2.11<br />

2.11<br />

2.11<br />

2.11<br />

2.13<br />

2.11<br />

2.16<br />

2.16<br />

2.34<br />

2.34<br />

2.39<br />

2.77<br />

1.65<br />

1.65<br />

1.65<br />

2.11<br />

2.11<br />

2.11<br />

2.11<br />

2.11<br />

2.77<br />

2.77<br />

2.77<br />

2.77<br />

2.77<br />

2.77<br />

2.77<br />

2.77<br />

3.40<br />

3.96<br />

44.96<br />

51.05<br />

62.99<br />

75.69<br />

78.74<br />

91.44<br />

110.49<br />

116.84<br />

135.89<br />

142.24<br />

143.76<br />

161.29<br />

167.64<br />

170.94<br />

220.73<br />

223.52<br />

277.37<br />

328.17<br />

B<br />

T<br />

Page 1 of 2<br />

July 2004<br />

TFP1898

Page 2 of 2<br />

Technical<br />

Data<br />

1- The maximum allowable tolerances <strong>for</strong> IPS<br />

Pipe from square cut ends is:0.030" (0.76mm)<br />

<strong>for</strong> sizes 1 1 /4" thru 3"; 0.045" (1.14mm) <strong>for</strong><br />

sizes 4" thru 6"; <strong>and</strong> 0.060" (1.52mm) <strong>for</strong> sizes<br />

8" <strong>and</strong> above.<br />

2- Gasket Seating Surface “A” must be free from<br />

score marks, ridges, indentations, projections,<br />

loose paint, scale, dirt chips, grease, rust, etc.<br />

that would prevent a positive seal.<br />

3- <strong>Groove</strong> Diameter “C” must be uni<strong>for</strong>m depth<br />

around the circumference of the pipe.<br />

4- <strong>Groove</strong> Depth “D” is a reference dimension<br />

only. The <strong>Groove</strong> Diameter “C” must be<br />

maintained.<br />

5- Minimum Wall Thickness “T” is the minimum<br />

wall thickness that should be cut grooved.<br />

Vd S<br />

LPCB<br />

<strong>St<strong>and</strong>ard</strong> <strong>Cut</strong> <strong>Groove</strong> <strong>Specifications</strong><br />

OD<br />

C<br />

A<br />

TFP1898<br />

D<br />

See Fire Protection<br />

Submittal Sheet <strong>for</strong><br />

Pressure Rating <strong>and</strong> Listing/<br />

Approval In<strong>for</strong>mation<br />

Pipe O.D. A B C D T<br />

Nominal Inches +_ 0.030" +_ 0.030" <strong>Groove</strong> Diameter Nominal Minimum<br />

Pipe mm +_ 0.76mm +_ 0.76mm Inches <strong>Groove</strong> Depth Wall<br />

Size Tolerance Inches Inches mm Inches Inches<br />

O.D.<br />

+ - mm mm Actual Tol.+0.000 mm mm<br />

1 1 ⁄4"<br />

1 1 ⁄2"<br />

2"<br />

2 1 ⁄2"<br />

76.1mm<br />

3"<br />

108.0mm<br />

4"<br />

133.0mm<br />

139.7mm<br />

5"<br />

159.0mm<br />

165.1mm<br />

6"<br />

216.3mm<br />

8"<br />

10"<br />

12"<br />

1.660<br />

1.900<br />

2.375<br />

2.875<br />

3.000<br />

3.500<br />

4.250<br />

4.500<br />

5.250<br />

5.500<br />

5.563<br />

6.250<br />

6.500<br />

6.625<br />

8.516<br />

8.625<br />

10.750<br />

12.750<br />

0.016<br />

0.019<br />

0.024<br />

0.029<br />

0.030<br />

0.035<br />

0.042<br />

0.045<br />

0.052<br />

0.056<br />

0.056<br />

0.063<br />

0.063<br />

0.063<br />

0.063<br />

0.063<br />

0.063<br />

0.063<br />

0.016<br />

0.019<br />

0.024<br />

0.029<br />

0.030<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.031<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.625<br />

0.750<br />

0.750<br />

0.750<br />

0.750<br />

0.313<br />

0.313<br />

0.313<br />

0.313<br />

0.313<br />

0.313<br />

0.375<br />

0.375<br />

0.375<br />

0.375<br />

0.375<br />

0.375<br />

0.375<br />

0.375<br />

0.438<br />

0.438<br />

0.500<br />

0.500<br />

1.535<br />

1.775<br />

2.250<br />

2.720<br />

2.845<br />

3.344<br />

4.084<br />

4.334<br />

5.084<br />

5.334<br />

5.395<br />

6.084<br />

6.330<br />

6.455<br />

8.331<br />

8.441<br />

10.562<br />

12.531<br />

-0.015<br />

-0.015<br />

-0.015<br />

-0.018<br />

-0.018<br />

-0.018<br />

-0.020<br />

-0.020<br />

-0.020<br />

-0.020<br />

-0.022<br />

-0.022<br />

-0.022<br />

-0.022<br />

-0.025<br />

-0.025<br />

-0.027<br />

-0.030<br />

0.062<br />

0.062<br />

0.062<br />

0.078<br />

0.076<br />

0.078<br />

0.083<br />

0.083<br />

0.083<br />

0.083<br />

0.084<br />

0.083<br />

0.085<br />

0.085<br />

0.092<br />

0.092<br />

0.094<br />

0.109<br />

0.140<br />

0.145<br />

0.154<br />

0.188<br />

0.188<br />

0.188<br />

0.203<br />

0.203<br />

0.203<br />

0.203<br />

0.203<br />

0.219<br />

0.219<br />

0.219<br />

0.238<br />

0.238<br />

0.250<br />

0.279<br />

42.4<br />

48.3<br />

60.3<br />

73.0<br />

76.1<br />

88.9<br />

108.0<br />

114.3<br />

133.0<br />

139.7<br />

141.3<br />

159.0<br />

165.1<br />

168.3<br />

216.3<br />

219.1<br />

273.0<br />

323.9<br />

0.41<br />

0.48<br />

0.61<br />

0.74<br />

0.76<br />

0.89<br />

1.07<br />

1.14<br />

1.32<br />

1.42<br />

1.42<br />

1.60<br />

1.60<br />

1.60<br />

1.60<br />

1.60<br />

1.60<br />

1.60<br />

0.41<br />

0.48<br />

0.61<br />

0.74<br />

0.76<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

0.79<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

15.88<br />

19.05<br />

19.05<br />

19.05<br />

19.05<br />

7.95<br />

7.95<br />

7.95<br />

7.95<br />

7.95<br />

7.95<br />

9.53<br />

9.53<br />

9.53<br />

9.53<br />

9.53<br />

9.53<br />

9.53<br />

9.53<br />

11.13<br />

11.13<br />

12.70<br />

12.70<br />

38.99<br />

45.09<br />

57.15<br />

69.09<br />

72.26<br />

84.94<br />

103.73<br />

110.08<br />

129.13<br />

135.48<br />

137.03<br />

154.53<br />

160.78<br />

163.96<br />

211.61<br />

214.40<br />

268.27<br />

318.19<br />

-0.38<br />

-0.38<br />

-0.38<br />

-0.46<br />

-0.46<br />

-0.46<br />

-0.51<br />

-0.51<br />

-0.51<br />

-0.51<br />

-0.56<br />

-0.56<br />

-0.56<br />

-0.56<br />

-0.64<br />

-0.64<br />

-0.69<br />

-0.76<br />

1.60<br />

1.60<br />

1.60<br />

1.98<br />

1.93<br />

1.98<br />

2.11<br />

2.11<br />

2.11<br />

2.11<br />

2.13<br />

2.11<br />

2.16<br />

2.16<br />

2.34<br />

2.34<br />

2.39<br />

2.77<br />

3.56<br />

3.68<br />

3.91<br />

4.78<br />

4.78<br />

4.78<br />

5.16<br />

5.16<br />

5.16<br />

5.16<br />

5.16<br />

5.56<br />

5.56<br />

5.56<br />

6.05<br />

6.05<br />

6.35<br />

7.09<br />

B<br />

T<br />

General Notes: It is the Designer’s responsibility to select products suitable <strong>for</strong> the intended service <strong>and</strong> to ensure<br />

that pressure ratings <strong>and</strong> per<strong>for</strong>mance data is not exceeded. Always read <strong>and</strong> underst<strong>and</strong> the installation<br />

instructions (IH-1000). Never remove any piping component or correct or modify any piping deficiencies without<br />

first depressurizing <strong>and</strong> draining the system. Material <strong>and</strong> gasket selection should be verified to be compatible<br />

<strong>for</strong> the specific application.<br />

TYCO FIRE PRODUCTS, 451 North Cannon Avenue, Lansdale, Pennsylvania 19946<br />

Certified Company<br />

Printed U.S.A.