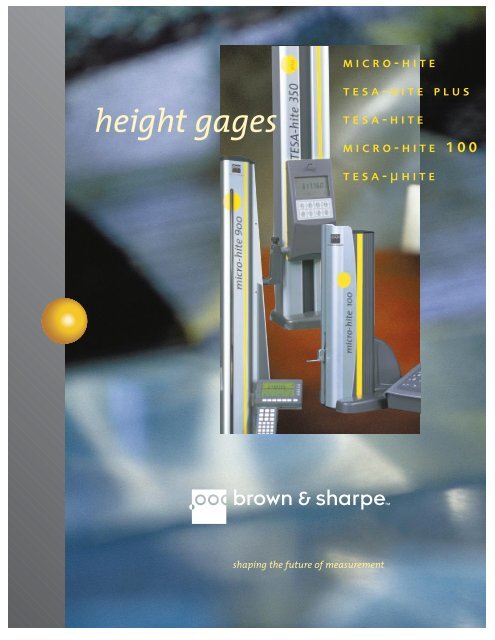

height gages

height gages

height gages

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MICRO-HITE<br />

TESA-HITE<br />

PLUS<br />

<strong>height</strong> <strong>gages</strong><br />

TESA-HITE<br />

MICRO-HITE 100<br />

TESA-µHITE<br />

shaping the future of measurement

Quality • Simplicity • Accuracy • Variety<br />

Brown & Sharpe the leaders in El<br />

Measuring Range:<br />

0-14 in/0-350 mm<br />

Accuracy:<br />

± 0006 in/± 0.015 mm<br />

Resolution:<br />

Standard: .0002 in/0.005 mm<br />

Scribing: .0005 in/0.01 mm<br />

Calibration: .0001 in/0.001 mm<br />

Range:<br />

4 in/100 mm<br />

Resolution:<br />

.00001 in/0.0001 mm<br />

switchable to<br />

.0001 in/0.001 mm<br />

Accuracy:<br />

Max. perm. Error with<br />

standard accessories:<br />

- Axial .00005 in/1 µm<br />

- Radial .0001 in/2 µm<br />

Measuring Range:<br />

0-24 in/0-600 mm<br />

Accuracy:<br />

±.0008 in/±0.020 mm<br />

Resolution:<br />

Standard: .0002 in/0.005 mm<br />

Scribing: .0005 in/0.01 mm<br />

Calibration: .0001 in/0.001 mm<br />

Measuring Range:<br />

0-14 in/0-350 mm<br />

Accuracy:<br />

± .0003 in/± 7 µm<br />

Resolution:<br />

Standard: .0002 in/0.005 mm<br />

Scribing: .0005 in/0.01 mm<br />

Calibration: .0001 in/0.001 mm<br />

Measuring Range:<br />

0-24 in/0-600 mm<br />

Accuracy:<br />

±.0004 in/±10 µm<br />

Resolution:<br />

Standard: .0002 in/0.005 mm<br />

Scribing: .0005 in/0.01 mm<br />

Calibration: .0001 in/0.001 mm

ctronic Height Gage Measurement<br />

Measuring Range:<br />

0-36 in/0-920 mm<br />

Accuracy:<br />

±0.0002 in (±0.00045 mm)<br />

Resolution:<br />

0-36 in (0-920 mm)<br />

Measuring Range:<br />

0-24 in/0-615 mm<br />

Accuracy:<br />

±0.00018 in (±0.00040<br />

mm)<br />

Resolution:<br />

0-24 in (0-615 mm)<br />

Measuring Range:<br />

0-14 in/0-365 mm<br />

Accuracy:<br />

±0.00014 in (±0.00030 mm)<br />

Resolution:<br />

0-14 in (0-365 mm)<br />

Measuring Range:<br />

4 in/100 mm<br />

Accuracy:<br />

.0001 in/2 µm<br />

Resolution:<br />

.00001 in/0.0001 mm<br />

switchable to<br />

.0001 in/0.001 mm<br />

3

micro-hite<br />

Rechargeable battery<br />

pack operation<br />

Rugged cast iron<br />

and stainless steel<br />

construction<br />

THE ULTIMATE IN SPEED & ACCURACY<br />

Two-dimensional measurement with a single-axis <strong>height</strong> gage is made simple with<br />

MICRO-HITE 1D/2D <strong>height</strong> gage technology from Brown & Sharpe. The second dimension,<br />

along with rapid measuring speed, a stand-alone design, and a user-friendly interface have<br />

made the MICRO-HITE the market leader in its class and opened up a world of inspection<br />

capabilities for you.<br />

TWO-DIMENSIONAL<br />

MEASUREMENT<br />

Until now, you needed a coordinate<br />

measuring machine to efficiently<br />

handle two-dimensional measurement<br />

requirements, but that requires a substantial<br />

capital investment and a commitment<br />

to extended operator training. With the<br />

MICRO-HITE 1D/2D electronic <strong>height</strong> gage,<br />

you can easily measure in two dimensions<br />

in either rectangular or polar coordinates.<br />

Just measure the feature or features,<br />

rotate the part through a known angle,<br />

and measure the same features again<br />

on a new axis. The MICRO-HITE gage’s<br />

new electronic software is programmed to<br />

calculate the two-dimensional measurement.<br />

It’s that simple.<br />

RS232-C Interface<br />

Rapid transverse<br />

and fine adjustment<br />

High-Accuracy<br />

Measuring System<br />

Air-cushion<br />

movement<br />

IG 13 PROBE<br />

Perpendicularity, straightness and angle<br />

of incline are calculated directly when using<br />

the IG 13 digital probe.<br />

D YNAMIC PROBES WITH<br />

OPERATOR SIGNALS<br />

The new probing system when used in the<br />

automatic mode will capture the high and<br />

low culminating points of cylinders for I.D.<br />

and O.D. calculations. Acoustic<br />

as well as a visual signal will confirm the<br />

measured values have been registered.<br />

DIODE CHAIN DISPLAY<br />

An independent electronic measuring<br />

system divides a colorful diode chain into 12<br />

parts to facilitate the manual locating<br />

of the probe at the culminating point of<br />

curved surfaces.<br />

LINE PRINTER<br />

Compact line printer, an integral part<br />

of the 1D/2D control panels, is always<br />

available for hard copy printouts. The Tesa<br />

SPC Printer is available as an option for<br />

the 1D control panel when a hard copy<br />

printout is required.<br />

Straight regression line<br />

Straightness error<br />

Culminating Point<br />

4

EASY-TO-USE<br />

MEASURING POWER<br />

The MICRO-HITE <strong>height</strong> gage’s dedicated<br />

dimensional function programs make<br />

measuring quick, easy and accurate.<br />

Even complex measurements are easy<br />

to execute with the MICRO-HITE system’s<br />

computer power. The MICRO-HITE 1D/2D<br />

electronic <strong>height</strong> gage measures external,<br />

internal and distance dimensions as well<br />

as perpendicularity, flatness, straightness,<br />

centers and diameters. In addition, the<br />

MICRO-HITE system calculates deviations<br />

and feature relationships, automatically. With<br />

its two-dimensional measuring capability, the<br />

MICRO-HITE gage can determine<br />

concentricity or express the relationship<br />

between holes, patterns, or features on a<br />

part in polar or rectangular coordinates.<br />

Additional measurement capabilities include<br />

determining the minimum/maximum of bolt<br />

circles. For all of its measuring power, the<br />

MICRO-HITE 1D/2D gage is simple to use.<br />

Its new keypad and interactive LC display<br />

are specifically designed to guide operators<br />

smoothly and efficiently through<br />

measurement operations.<br />

EFFICIENT STAND-ALONE<br />

DESIGN<br />

The MICRO-HITE 1D/2D <strong>height</strong> gage<br />

moves on a cushion of air generated by a<br />

completely self-contained pneumatic system.<br />

Two battery packs are provided so that one<br />

can be recharged while the other is in use,<br />

providing continuous operation without<br />

cumbersome power cords and air supply<br />

lines to clutter up your surface plate. In both<br />

design and operation, the MICRO-HITE<br />

gage is efficient and accurate for simple or<br />

complex measurement requirements in one<br />

or two dimensions. Three control panel options<br />

1D, 1D/2D, or programmable 1D/2D mean<br />

there is a MICRO-HITE designed specifically<br />

to meet your application requirements.<br />

C ONTROL PANEL “1D”<br />

A simple to use keyboard runs a complete<br />

“1D” measurement program. Easy to follow<br />

measurement icons and bold print measurement<br />

readings on the display guide the user<br />

and enhance the ease of operation.<br />

C ONTROL PANEL “1D/2D”<br />

In addition to incorporating all the<br />

capabilities of the “1D” control panel, the<br />

“1D/2D” control panel allows the generation<br />

of cartesian coordinates or polar coordinates<br />

to provide simple solutions to complex<br />

measuring problems.<br />

“1D/2D” PROGRAMMABLE<br />

The Power Panel incorporates all the<br />

measuring capabilities of the “1D” and<br />

“1D/2D” control panels plus has the ability<br />

to learn measuring programs and store them<br />

on memory cards. The large display provides<br />

more information in a friendly easily understood<br />

format. Minimal learning time for<br />

complex part inspection and programming.<br />

Red, Orange and Green signal lights indicate<br />

measured feature relative to preprogrammed<br />

tolerances. Ideal for first part, production<br />

and receiving inspection.<br />

P1 Power Panel<br />

1D/2D Control Panel<br />

1D Control Panel<br />

5

tesa-hite plus<br />

Automatic calculation<br />

of measurement<br />

dimensions<br />

Programmed routines<br />

to speed and<br />

simplify complex<br />

measurements<br />

Rapid traverse crank<br />

with fine feed knob<br />

for positioning the<br />

measuring head<br />

and capturing the<br />

measurement<br />

ALL THE FEATURES OF TESA-HITE<br />

WITH ADDITIONAL ACCURACY.<br />

Now you can raise your standards for measuring precision and performance without raising<br />

your budget. TESA-HITE ® PLUS has all the capabilities and more of full-featured electronic<br />

<strong>height</strong> <strong>gages</strong> – at a price that’s well within reach.<br />

The TESA-HITE PLUS utilizes the proven high accuracy measuring system of the MICRO-HITE.<br />

The higher accuracy measurements achieved by an opto-electronic sensor moving over a<br />

high accuracy glass scale on Precision Vertical Guides. The guide system and drive system<br />

are separate so that there is no influence one the the other. TESA-HITE PLUS comes with a<br />

rechargeable battery pack.<br />

HIGHER ACCURACY<br />

TESA-HITE PLUS is fast and functional,<br />

too. You’ll measure accurately to ±.0003 in/<br />

±0.007 mm with the 14 inch<br />

and ±.0004 in/±0.010 mm with the 24 inch.<br />

C L<br />

C L<br />

E▲<br />

▲<br />

▲<br />

▲<br />

➤<br />

➤<br />

➤<br />

➤<br />

▲<br />

h1<br />

h2<br />

With Two Probe Hits<br />

Datum<br />

The repeatability of both models is .0002 in/<br />

0.005 mm. It’s the universal gage for use in<br />

your quality assurance lab, inspection<br />

department, or right at the machine.<br />

AUTOMATICALLY CALCULATES MEASUREMENTS FOR YOU!<br />

No more math. No more manual calculation errors. TESA-HITE and TESA-HITE PLUS<br />

automatically calculate measurement dimensions to save you time and ensure accuracy.<br />

The tool even determines the gage head constant to eliminate time-consuming set-up —<br />

so you can raise your standards for increased inspection productivity.<br />

Manual or automatic<br />

transfer of the<br />

measurements via<br />

an opto-coupled<br />

RS-232 port directly<br />

to a PC or printer<br />

0.0<br />

E<br />

h1<br />

Datum<br />

F1 F2 F3 F4<br />

PRINT<br />

mm<br />

in<br />

ON<br />

OFF<br />

E<br />

➤<br />

➤<br />

▲<br />

h1<br />

h2<br />

Datum<br />

Transfer of a<br />

measured value<br />

to a peripheral<br />

Unit selection<br />

Switch on/<br />

Switch off<br />

Cancellation of last<br />

function or probing<br />

6<br />

The lower four keys are single function keys<br />

and are clearly designated.

SPC/SQC Integration.<br />

Manual or automatic<br />

transfer of the<br />

measurements via<br />

an opto-coupled<br />

RS-232 port directly<br />

to a PC or printer.<br />

INTERACTIVE LC DISPLAY<br />

Easy to understand. Interactive LC display keeps you fully informed.<br />

“Just a glance” indicates numerical values for the feature being<br />

measured. Graphic icons that are easily recognized and quickly<br />

learned indicate the functions that have been selected and the<br />

options that are available using just four function keys.<br />

Single Probe<br />

Contact<br />

Two Probe<br />

Contact<br />

Preset Indirect<br />

Reference<br />

Continuous<br />

Display<br />

Difference of<br />

the Last Two<br />

Displayed Values<br />

F AST, SIMPLE MEASUREMENT PROGRAMS.<br />

TESA-HITE features programmed routines for the most commonly<br />

used measurement functions. So you can make complex measurements<br />

faster, more accurately and far more efficiently than ever before.<br />

Point-to-Point Program<br />

Establish zero at any point and subsequent measurements<br />

are automatically calculated from the zero reference. Press<br />

the Delta key to recover the difference between any two<br />

measurements previously taken. Effortlessly.<br />

Centerline-to-Centerline Program<br />

Calculates center-to-center distances between grooves,<br />

holes, studs, and other features on a workpiece. Automatically.<br />

Indirect Reference Program<br />

Enter numerical values for a reference plane which<br />

cannot be directly contacted by the probe, TESA-HITE<br />

and TESA-HITE PLUS measures distances from the indirect<br />

reference to any surface of the workpiece. Precisely.<br />

Fast, accurate positioning.<br />

Rapid traverse crank with fine feed knob<br />

for positioning the measuring head and<br />

capturing the measurement.<br />

Adapts to your measuring<br />

needs … anywhere.<br />

Rugged probe holder<br />

and built-in touch-trigger<br />

function captures the<br />

measurement on-the-fly.<br />

7

tesa-hite<br />

Automatic calculation<br />

of measurement<br />

dimensions<br />

Programmed routines<br />

to speed and<br />

simplify complex<br />

measurements<br />

Rapid traverse crank<br />

with fine feed knob<br />

for positioning the<br />

measuring head<br />

and capturing the<br />

measurement<br />

Manual or automatic<br />

transfer of the<br />

measurements via<br />

an opto-coupled<br />

RS-232 port directly<br />

to a PC or printer<br />

RAISING THE STANDARDS FOR<br />

ELECTRONIC HEIGHT GAGE<br />

MEASUREMENT.<br />

The new Tesa-Hite’s on-board microprocessor can correct for the probe size, calculate the size<br />

of slots and projections, and determine the centerlines of features. The TESA-HITE offers three<br />

different measuring modes to suit the task – from simple scribing to sophisticated inspection.<br />

These measuring functions are:<br />

• Measurement in one direction without concern for size of the probe<br />

• Bi-direction measurement with correction to account for the size of the probe. This is<br />

function used for rapid measurement of external and internal dimensions and centerlines.<br />

• Continuous display with reduced resolution for scribing tasks.<br />

The measuring functions are controlled by a keyboard with only eight keys. Four keys are<br />

single function keys and are clearly designated as “ON/OFF”, “INCH/MM”, “CANCEL” and<br />

“PRINT”. The other four are function keys that correspond to graphic icons in the LC Display.<br />

Some of the important features and benefits of the new TESA-HITE include:<br />

• Resolution of .0002" (0.005 mm) in the normal measuring mode<br />

• Resolution of .0005" (0.01 mm) in the scribing mode. An accessory scriber is<br />

available for the probe holder<br />

• Large LC Display with .5" (12 mm) tall digits is easy to read<br />

• Rapid traverse crank with fine feed knob for positioning the measuring head<br />

• Rugged probe holder and built-in touch-trigger function<br />

• Manual or automatic transfer of the measurements via an opto-coupled RS-232<br />

port directly to a PC or printer<br />

• Runs for up to 2000 hours using readily available “AA” alkaline batteries.<br />

Auto-off function extends battery life<br />

• Internal diameters can be quickly determined with the use of the optional<br />

“QUICK-CENTER” accessory probe system<br />

• Outside diameters are efficiently measured with the aid of the accessory<br />

cylindrical probe<br />

• Solidly constructed from cast iron and corrosion protected steels<br />

• A wide variety of standard probes available for many measuring problems.<br />

TESA QUICK CENTER<br />

Measuring accessory to<br />

automatically establish the<br />

culminating point of a bore.<br />

(See page 15 for complete<br />

information.)<br />

8

F AST, SIMPLE MEASUREMENT PROGRAMS<br />

TESA-HITE features programmed routines for the most commonly used measurement<br />

functions. So you can make complex measurements faster, more accurately and far<br />

more efficiently than ever before.<br />

POINT-TO-POINT PROGRAM<br />

Establish zero at any point and subsequent measurements are automatically calculated<br />

from the zero reference. Press the Delta key to recover the difference between any two<br />

measurements previously taken. Effortlessly.<br />

CENTERLINE-TO-CENTERLINE<br />

Calculates center-to-center distances between grooves, holes, studs and other features<br />

on a workpiece. Automatically.<br />

INDIRECT REFERENCE PROGRAM<br />

Enter numerical values for a reference plane which cannot be directly contacted by the<br />

probe and the TESA-HITE measures distances from the indirect reference to any surface<br />

of the workpiece. Precisely.<br />

Measuring functions are the<br />

same for the TESA-HITE and the<br />

TESA-HITE PLUS. See page 6<br />

and 7 for complete information.<br />

9

micro-hite 100<br />

Range:<br />

4 in/100 mm<br />

Accuracy:<br />

.0001 in/2 µm<br />

MICRO-HITE 100<br />

The new motorized mini-<strong>height</strong> gauge MICRO-HITE 100 with incremental measuring<br />

system and Brown & Sharpe’s metrology experience, condensed and miniaturized,<br />

for an unequalled precision. This fine <strong>height</strong> gauge is made to measure small-sized<br />

workpieces. It’s the ideal solution for inspecting right next to the production floor<br />

or even in inspection laboratories.<br />

■ Provides high measurement accuracy guaranteed by the measuring system, which includes<br />

a long-term stability glass scale, as well as the high resolution of the measurement signal.<br />

■ Measures lengths in the form of internal, external, <strong>height</strong>, depth and distance dimensions.<br />

Outputs the position and diameter of bores in one coordinate.<br />

■ Motor-driven measuring movements allow fast, reliable probing of the measuring points<br />

with a constant measuring force.<br />

Resolution:<br />

.00001 in/0.0001 mm<br />

switchable to<br />

.0001 in/0.001 mm<br />

10

tesa-µhite<br />

Range:<br />

4 in/100 mm<br />

Resolution:<br />

.00001 in/0.0001 mm<br />

switchable to<br />

.0001 in/0.001 mm<br />

TESA-µHITE<br />

The new motorized probe TESA-µHITE with incremental measuring system and Brown<br />

& Sharpe’s metrology experience, condensed and miniaturized, for an unequalled precision.<br />

This fine incremental probe is made to measure small-sized workpieces. It’s the ideal solution<br />

for inspecting right next to the production floor or even in inspection laboratories.<br />

■ Provides high measurement accuracy guaranteed by the measuring system,<br />

which includes a long-term stability glass scale, as well as the high resolution of the<br />

measurement signal.<br />

■ Measures lengths in the form of internal, external, <strong>height</strong>, depth and distance dimensions.<br />

Outputs the position and diameter of bores in one coordinate.<br />

■ Motor-driven measuring movements allow fast, reliable probing of the measuring points<br />

with a constant measuring force.<br />

Accuracy:<br />

Max. perm. Error with<br />

standard accessories:<br />

- Axial .00005 in/1 µm<br />

- Radial .0001 in/2 µm<br />

11

specifications and ordering information<br />

MICRO-HITE 1D & 1D/2D ELECTRONIC HEIGHT GAGE<br />

Accuracy<br />

14" Model ±0.00014" ±0.00030 mm<br />

24" Model ±0.00018" ±0.00040 mm<br />

36" Model ±0.0002" ±0.00045 mm<br />

Repeatability<br />

±2s = 0.0001" 0.003mm<br />

Maximum Perpendicularity Error<br />

14" Model 0.00024" 0.006mm<br />

24" Model 0.00032" 0.008mm<br />

36" Model 0.00048" 0.012mm<br />

Digit Display<br />

Type: Liquid Crystal Display (LCD)<br />

Resolution: 0.000020" (0.0005mm)<br />

Measuring Head<br />

Max. Displacement Speed:10"/sec (250mm/sec)<br />

Probe Displacement: ±0.315" (±8mm)<br />

ORDERING INFORMATION<br />

Measuring System<br />

Opto-electronic sensor precision glass scale<br />

Gage Movement<br />

Air cushion movement for easy,precise<br />

positioning<br />

Battery Packs<br />

For continuous operation, one battery pack<br />

supplies full-shift power while the second set is<br />

being recharged. Batteries may be recharged on<br />

or off-line<br />

Dynamic Probes<br />

Trigger-switch probe mechanism for “on-the-fly”<br />

bidirectional measurements<br />

Description Measuring Application Range Tool EDP<br />

Range (With extension) No. No.<br />

14" MICRO-HITE "1D" 0-14" (0-365mm) 0-22" (0-575mm) 599-1011-14-1D 86543<br />

14" MICRO-HITE "1D/2D" 0-14" (0-365mm) 0-22" (0-575mm) 599-1011-14-2D 86546<br />

14" MICRO-HITE "1D/2D" Power Panel 0-14" (0-365mm) 0-22" (0-575mm) 599-1011-14-P1 26871<br />

24" MICRO-HITE "1D" 0-24" (0-615mm) 0-32" (0-825mm) 599-1011-24-1D 86544<br />

24" MICRO-HITE "1D/2D" 0-24" (0-615mm) 0-32" (0-825mm) 599-1011-24-2D 86547<br />

24" MICRO-HITE "1D/2D" Power Panel 0-24" (0-615mm) 0-32" (0-825mm) 599-1011-24-P1 26872<br />

36" MICRO-HITE "1D" 0-36" (0-920mm) 0-44" (0-1130mm) 599-1011-36-1D 86545<br />

36" MICRO-HITE "1D/2D" 0-36" (0-920mm) 0-44" (0-1130mm) 599-1011-36-2D 86548<br />

36" MICRO-HITE "1D/2D" Power Panel 0-36" (0-920mm) 0-44" (0-1130mm) 599-1011-36-P1 26873<br />

ACCESSORIES*<br />

Tesa SPC Printer 64.90000 87359<br />

Digital Probe 1G 13 with mounting adapter 599-1011-230 86552<br />

Connecting Cable for Printer (Tesa SPC Printer) 47.61023 41271<br />

Simple Printer (for “1D” models only) 599-1011-275-2 87239<br />

Adapter (for connecting Simple Printer to “1D” models) DADPTAT9M25F 86603<br />

Practice Piece for 2D Software 599-1011-119-05 25088<br />

Every MICRO-HITE gage is supplied with two rechargeable battery sets in holders, a battery charger, one standard 5mm dia. ball tip probe, one<br />

probe holder, (73mm length), one setting standard, one dust cover, one instruction manual and one roll of printing paper with 1D/2D models.<br />

Complete set of accessories 599-1011-200 51650<br />

Extra printer paper: 5 rolls, 2.25" (57mm wide) 599-1011-15 25129<br />

*Individual accessories, probes and holders are available through local Brown & Sharpe MICRO-HITE distributors.<br />

12

TESA-HITE AND TESA-HITE PLUS<br />

Specifications-Standard Tesa-Hite ®<br />

07.90041 07.90042<br />

Measuring Range: 0-14"/0-350mm 0-24"/0-600mm<br />

Accuracy: ±.0006"/±0.015mm ±.0008"/±0.020mm<br />

Resolution: Standard: .0002"/0.005mm<br />

Scribing:<br />

.0005"/0.01mm<br />

Calibration:<br />

.0001"/0.001mm<br />

Repeatability:<br />

.0002/0.005mm<br />

Power Supply: 4 non-rechargeable 1.5V AA batteries<br />

Battery Life: 1 year (2000 working hours)<br />

ORDERING INFORMATION‡<br />

TESA-HITE with 14" (350mm) Measuring Range 07.90041<br />

TESA-HITE with 24" (600mm) Measuring Range 07.90042<br />

‡TESA-HITE is supplied with a standard probe holder, a<br />

Ø 5mm ball probe, a setting block, 4 “AA” alkaline batteries<br />

and an operation booklet.<br />

TESA-HITE PLUS with 14" (350mm) Measuring Range 07.90051<br />

TESA-HITE PLUS with 24" (600mm) Measuring Range 07.90052<br />

‡TESA-HITE PLUS is supplied with QUICK-CENTER and 10mm probe,<br />

a standard probe holder, a Ø 5mm ball probe, a setting block,<br />

Ni-CI 6 V 0,5, and external charging unit.<br />

Specifications-Tesa-Hite ® Plus<br />

07.90051 07.90052<br />

Measuring Range: 0-14"/0-350 mm 0-24"/0-600 mm<br />

Accuracy: ±.0003"/±0.007 mm ±.0004"/±0.010 mm<br />

Resolution: Standard: .0002"/0.005 mm<br />

Scribing:<br />

.0005"/0.01 mm<br />

Calibration:<br />

.0001"/0.001 mm<br />

Repeatability:<br />

0002/0.005 mm<br />

Perpendicularity: .0006"/0.015 mm .0008"/0.020 mm<br />

QUICK-CENTER<br />

& 10mm probe: Included Included<br />

Power Supply: Ni-CI 6 V 0,5<br />

Battery Life: 50 hours before it needs to be recharged<br />

5 hours to recharge. TESA-HITE PLUS can<br />

be used while charging.Up to 500 charges<br />

if used properly. 115V charger included<br />

with unit.<br />

Accessory Set<br />

No. 599-9004-200<br />

ACCESSORY SET INCLUDES:<br />

Carbide tipped scriber fits the probe holder 599-9004-165<br />

Adapter for test indicators fits the probe holder 599-9004-166<br />

Cylindrical probe tip for outside diameters 599-9004-218<br />

Universal Probe Shank; accepts BesTest points 599-1011-212<br />

BesTest point with .040" (1mm) dia. carbide ball 599-7030-40<br />

BesTest point with .080" (2mm) dia. carbide ball 599-7030-80<br />

BesTest point with .120" (3mm) dia. carbide ball 599-7030-120<br />

Depth Gage Holder with Adjustable Pin 599-9004-219<br />

OPTIONAL ACCESSORY ITEMS<br />

QUICK-CENTER device for measuring internal diameters 07.90018<br />

Probe for QUICK-CENTER .400" (10mm) 07.60134<br />

Probe for QUICK-CENTER .200" (5mm) 07.60135<br />

Data cable opto-coupled RS-232 to PC (9 pin) 47.61046<br />

Note: See the Height Gages section in the<br />

Brown & Sharpe Metrology Equipment<br />

Catalog for more information on probes<br />

and accessories for special applications.<br />

13

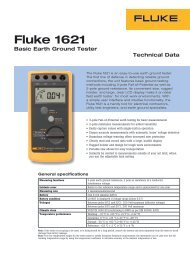

MICRO-HITE 100<br />

TESA-µHITE<br />

Measuring span<br />

4 in/100 mm<br />

Max. perm.Error with<br />

standard accessories .0001 in/2 µm<br />

Repeatability limit ≤.00004 in/1 µm<br />

Resolution<br />

.00001 in/0.0001 mm , switchable<br />

to .0001 in/0.001 mm<br />

Measuring force 1N switchable to 0.63N<br />

Motorized movement speed<br />

Control panel<br />

Data output RS 232<br />

Operating temperature<br />

Storage temperature<br />

Mass<br />

30 mm/s –10 mm/s – 5 mm/s<br />

Extremely simple to use, large LCD<br />

field for the display of measured<br />

values and information s symbols.<br />

5˚ C to 40˚ C<br />

-10˚ C to 60˚ C<br />

9.9 Kg<br />

Degree of protection IP 50<br />

Electromagnetic compatibility EN50081-1, EN50081-2<br />

EN50082-1, EN50082-2<br />

Identification<br />

Individual serial number<br />

ORDERING INFORMATION<br />

MICRO-HITE 100 basis unit, complete with 07.90048<br />

control panel and standard accessories, composed of:<br />

- Radial head holder ø 4 mm<br />

- Measuring insert with tungsten carbide<br />

- Reference piece<br />

- Universal adapter 100-240V<br />

- Measuring protocol declaration of conformity and instruction manual<br />

OPTIONAL ACCESSORIES<br />

Universal head holder 07.60199<br />

Measuring insert with tungsten carbide ø 5 mm 07.60200<br />

Measuring insert with tungsten carbide ø 3 mm 07.60201<br />

RS232 connecting cable MICRO-HITE 100 to TESA<br />

Printer SPC or PC (SUB-D 9polig m/f) 47.61052<br />

Rechargeable Battery 07.60202<br />

Measuring span<br />

4 in/100 mm<br />

Max. perm. Error with standard accessories:<br />

- Axial .00005 in/1 µm<br />

- Radial .0001 in/2 µm<br />

Repeatability limit:<br />

- Axial ≤.00002 in/0.5 µm<br />

- Radial ≤.00004 in/1 µm<br />

Resolution<br />

.00001 in/0.0001 mm, switchable<br />

to .0001 in/0.001 mm<br />

Measuring force<br />

Motorized movement speed<br />

Control panel<br />

Data output RS 232<br />

Operating temperature<br />

Storage temperature<br />

Mass<br />

1 N switchable to 0.63 N<br />

30 mm/s – 10 mm/s – 5 mm/s<br />

Extremely simple to use, large<br />

LCD field for the display of<br />

measured values and<br />

information’s symbols.<br />

5˚ C to 40˚ C<br />

-10˚ C to 60˚ C<br />

25 Kg<br />

Degree of protection IP 50<br />

Electromagnetic compatibility EN50081-1, EN50081-2,<br />

EN50082-1, EN50082-2<br />

Identification:<br />

Individual serial number<br />

ORDERING INFORMATION<br />

TESA-µHITE basis unit, complete with measuring stand, 07.90049<br />

control panel and standard accessories, composed of:<br />

- Axial head holder M2,5 with tungsten carbide tip ø 3 mm<br />

- Radial measuring insert with tungsten carbide ø 5 mm<br />

- Reference piece<br />

- Universal adapter 100-240 V<br />

- Measuring protocol, declaration of conformity and instruction manual<br />

OPTIONAL ACCESSORIES<br />

- Axial head holder M1,4 07.60194<br />

- Axial head holder M2,5 07.60195<br />

- Axial head holder M3 07.60196<br />

- Radial measuring insert with<br />

tungsten carbide ÿ 5 mm 07.60197<br />

- Radial head holder ÿ 4 mm 07.60198<br />

Universal head holder 07.60199<br />

Measuring insert with tungsten carbide ø 5 mm 07.60200<br />

Measuring insert with tungsten carbide ø 3 mm 07.60201<br />

RS232 connecting cable TESA-µHITE<br />

to TESA Printer SPC or PC (SUB-D 9polig m/f)47.61052<br />

Rechargeable Battery 07.60202<br />

14

Quick-Center<br />

The QUICK-CENTER<br />

Probe enables<br />

diameters from<br />

.280" (7mm) through<br />

3.200" (80mm)<br />

and center lines<br />

to be calculated<br />

simultaneously<br />

without the need<br />

to tram for the high<br />

and low point of<br />

the diameter.<br />

AUTOMATICALLY LOCATES THE<br />

CENTER POINT, QUICKLY AND EASILY.<br />

The unique design of QUICK-CENTER utilizes precision anti-friction bearings that allow the<br />

probe to float to the lowest point in a bore when a measuring force is applied. The automated<br />

centering of the probe eliminates the use of the analog meter to find the low point for center<br />

location. It also eliminates the need to compensate for the air bearing lift on systems that use<br />

an electronic latch when tramming.<br />

FEATURES:<br />

• QUICK-CENTER body to automatically establish low point of bore. Part # 07.90018<br />

• Probe with 10mm bearing diameter.<br />

Application range .700" - 3.15"/18 - 80 mm. Part # 07.60134<br />

or<br />

Probe with 5mm bearing diameter.<br />

Application range .272 - 1.00/7 - 25 mm. Part # 07.60135<br />

Measurement uncertainty: As compared to probe contacts made using a rigid probe -<br />

for example, the 5mm diameter tungsten carbide ball tip (No. 07.60062) from the<br />

standard equipment - measurements performed with TESA QUICK-CENTER have<br />

a larger dispersion range.<br />

Repeatability of the measured values is the following:<br />

± 2s ≤ 5µm/.0002 inch when using QUICK-CENTER.<br />

This compares to a repeatability of ± 2s ≤ 5µm/.0001 inch when using the rigid probe.<br />

15

For repair and calibration of <strong>height</strong> <strong>gages</strong>,<br />

or any Brown & Sharpe precision tool<br />

products, please contact:<br />

Brown & Sharpe Service Department<br />

200 Frenchtown Road<br />

North Kingstown, RI 20852<br />

Phone 1-800-283-3600 (Option 1)<br />

401-886-2244<br />

Fax 401-886-2485<br />

World Headquarters<br />

200 Frenchtown Road<br />

North Kingstown, RI 02852-1700<br />

Tel: (800) 283-3600 Fax: (401) 886-2553<br />

shaping the future of measurement<br />

PTI-540