Garrett Catalog - RB Racing

Garrett Catalog - RB Racing

Garrett Catalog - RB Racing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Garrett</strong> ® -Sponsored Drivers<br />

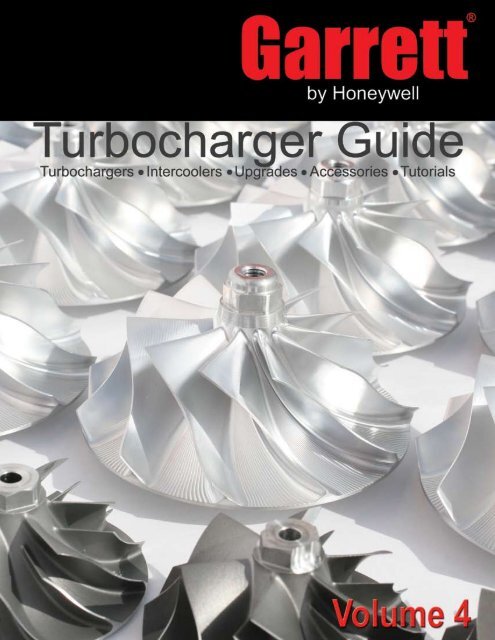

<strong>Garrett</strong> ®<br />

by Honeywell<br />

<br />

www.TurboBy<strong>Garrett</strong>.com<br />

Honeywell

<strong>Garrett</strong> ®<br />

by Honeywell<br />

Table of Contents<br />

Why <strong>Garrett</strong> ® ? - History and Testing.................................................pg 4<br />

<strong>Garrett</strong> ® Technology..........................................................................pg 5<br />

Turbo Basics.....................................................................................pg 6<br />

Turbo Tech; How to Choose the Right Turbo - Gasoline ..................pg 9<br />

Turbo Tech; How to Choose the Right Turbo - Diesel.......................pg 13<br />

Turbo System Optimization ..............................................................pg 16<br />

Troubleshooting.................................................................................pg 19<br />

Displacement Charts ........................................................................pg 20<br />

<strong>Garrett</strong> ® GT & GTX Turbochargers...................................................pg 21<br />

T-Series Ball Bearing Upgrades........................................................pg 76<br />

Mitsubishi Evolution X Upgrade Kit...................................................pg 77<br />

Diesel PowerMax TM Upgrade Kits.....................................................pg 78<br />

Drag <strong>Racing</strong>-Specific Turbos............................................................pg 81<br />

Turbocharger Connection Sizes & Dimensions.................................pg 82<br />

Wastegates & Blow-Off Valves.........................................................pg 87<br />

<strong>Garrett</strong> ® Accessories.........................................................................pg 88<br />

Intercoolers.......................................................................................pg 89<br />

<strong>Garrett</strong> ® GT Turbocharger Index.......................................................pg 90<br />

Honeywell<br />

www.TurboBy<strong>Garrett</strong>.com

Why <strong>Garrett</strong> ® ?<br />

<strong>Garrett</strong> ®<br />

by Honeywell<br />

<strong>Garrett</strong> ® History<br />

The heritage of the turbo business began in 1936 when<br />

young Cliff <strong>Garrett</strong> formed his company in a tiny, one-room<br />

office in Los Angeles. With encouragement and financial<br />

support from friends like Jack<br />

Northrop and Harry Wetzel, plus<br />

$5,000 he borrowed on his own,<br />

<strong>Garrett</strong> founded the company that<br />

would later become the <strong>Garrett</strong><br />

Corporation. Number of employees:<br />

1. Number of customers: 1.<br />

Today, that business couldn’t<br />

be more different. Over time, the<br />

turbocharging business spun off to<br />

establish itself as a serious player<br />

in the engine boosting industry.<br />

<strong>Garrett</strong> ® product is produced by over 6,000 employees and<br />

serves the leading global engine and vehicle manufacturers,<br />

including Audi, BMW, Chrysler, Daimler Benz, DDC, Fiat,<br />

Ford, General Motors, International Truck Co, Nissan,<br />

Peugeot, Renault, Saab and Volkswagen.<br />

Through names such as AiResearch, AlliedSignal, and the<br />

Honeywell of today, <strong>Garrett</strong> ® has sustained its reputation for<br />

revolutionizing turbocharger technologies generation after<br />

generation. From its long list of industry firsts to its leadingedge<br />

patented dual-ball bearing turbos for high performance<br />

vehicles, <strong>Garrett</strong> ® develops and manufactures the same<br />

cutting-edge boosting expertise that goes into all <strong>Garrett</strong> ®<br />

products. The fact that <strong>Garrett</strong> ® turbochargers are the<br />

preferred choice of leading original equipment manufacturers<br />

and many top race teams in World Rally, American Le Mans,<br />

24 Hours of Le Mans, and Pikes Peak is a telling example.<br />

Today, <strong>Garrett</strong> ® continues to redefine the art and science<br />

of boosting technology with advanced air management<br />

systems for the full spectrum of modern engines. With over<br />

30,000 turbos produced EVERY DAY, you know the <strong>Garrett</strong> ®<br />

name is one you can trust.<br />

<strong>Garrett</strong> ® Testing<br />

A turbocharger is a highly technical product that requires<br />

superior design and intensive capital to produce. It must<br />

meet the most severe requirements that only a world-class<br />

manufacturer like Honeywell’s <strong>Garrett</strong> ® brand can achieve.<br />

<strong>Garrett</strong> ® is one of the few brands that subjects its turbos<br />

to several OE qualification tests that ensure that “<strong>Garrett</strong>” is<br />

only stamped on safe and reliable turbos! Some of these<br />

tests include:<br />

* On-Engine Durability - A 1,000-hour general turbocharger<br />

durability test that is run on-engine in an engineering<br />

laboratory.<br />

* Compressor & Turbine Housing Containment - A compressor/turbine<br />

wheel is set to “hub” burst at a specific speed.<br />

No portion of the wheel is allowed to penetrate a “containment<br />

shroud” surrounding the turbocharger; a test to ensure<br />

safety.<br />

* Shaft Motion - The<br />

maximum tolerances<br />

of the bearing system<br />

are tested for rotordynamic<br />

stability beyond<br />

the maximum<br />

turbocharger operating<br />

speed. This means no<br />

bearing problems and<br />

a long turbo life.<br />

* Compressor & Turbine Performance - The entire operating<br />

range of both the compressor and turbine are mapped on a<br />

“Performance Gas Stand.” These test cells are calibrated to<br />

strict standards to assure accuracy and consistency.<br />

* Heat Soakback - A turbocharger instrumented with thermocouples<br />

is taken<br />

beyond maximum operating<br />

temperature<br />

and shut down hard!<br />

Repeat this test four<br />

more times and make<br />

sure maximum temperatures<br />

stay within<br />

strict limits to avoid oil<br />

“coking” or build up inside<br />

the center housing. This is particularly critical for high<br />

temperature gasoline applications.<br />

* Thermal Cycle - A 200-hour endurance test that cycles the<br />

turbocharger from low temperature to “glowing red” every 10<br />

minutes. To ensure long turbo life, no cracking of the turbine<br />

housing or distortion of the heat shroud is accepted.<br />

* Rotor Inertia - A measurement made to document the rotational<br />

inertia of the compresor and turbine wheels. <strong>Garrett</strong> ®<br />

brand products are known for their high flow / low inertia<br />

characteristics.<br />

Vistit www.TurboBy<strong>Garrett</strong>.com for complete test list.<br />

<br />

www.TurboBy<strong>Garrett</strong>.com<br />

Honeywell

<strong>Garrett</strong> ®<br />

by Honeywell<br />

<strong>Garrett</strong> ® Technology<br />

<strong>Garrett</strong> ® GTX Turbochargers<br />

The next step in the evolution of the turbocharger is here!<br />

<strong>Garrett</strong> ® GTX Turbos feature all new compressor wheels with<br />

next generation aerodynamics and improved efficiency to<br />

deliver wicked performance!<br />

<strong>Garrett</strong> ® GTX Turbochargers provide higher flow and greater<br />

boost pressure ratios beyond the world-class <strong>Garrett</strong> ® GT<br />

Series compressor wheels.<br />

* 10%+ Gain in flow over traditional GT compressor<br />

wheel designs<br />

* 10%+ Higher pressure ratio compared to traditional GT<br />

compressor wheel designs<br />

* Forged, fully machined wheels<br />

(billet) for expedited release<br />

* 11 Full-blade design for<br />

improved efficiency and ultra<br />

quiet operation<br />

* Outline interchangeable with<br />

<strong>Garrett</strong> ® GT Series turbos<br />

* <strong>Garrett</strong> ® OE-quality for<br />

unbeatable reliability<br />

<strong>Garrett</strong> ® Dual Ball Bearing<br />

The journal bearing has long been the workhorse of the<br />

turbocharger. However, in the 1990’s, <strong>Garrett</strong> ® engineers developed<br />

a radically new and extremely efficient turbocharger.<br />

With wheel and bearing advances that provide crisp and strong<br />

throttle response up to 15% faster than traditional bearings, a<br />

<strong>Garrett</strong> ® turbo will accelerate your vehicle more quickly than<br />

ever.<br />

The patented dual ball bearing design also requires less oil to<br />

provide adequate lubrication. This in turn lowers oil volume and<br />

the chances for seal leakage. The lessened need for oil also<br />

makes the bearings more tolerant to marginal lube conditions<br />

and diminishes the possibility of turbocharger failure on engine<br />

shut down.<br />

The <strong>Garrett</strong> ® dual ball bearing cartridge gives better damping<br />

and control over shaft motion allowing enhanced reliability for both everyday and extreme driving conditions. The opposed<br />

angular contact bearing cartridge eliminates the need for the thrust bearing, commonly the weak link in the turbo bearing<br />

system. The bearing system in the GT turbocharger allows for improved shaft stability and less drag throughout the speed<br />

range.<br />

While T-series turbos typically contain 54 components, GT turbos have an average of only 29. The 45% decrease in parts<br />

diminishes the opportunity for failure and results in smoother operation.<br />

A <strong>Garrett</strong> ® Turbo for Your Vehicle?<br />

<strong>Garrett</strong> ® is the only brand to offer a searchable database for turbo kits using its product.<br />

Visit www.TurboBy<strong>Garrett</strong>.com and enter your vehicle into our Turbo Application Search Engine (TASE) to find a turbo kit<br />

available for it using <strong>Garrett</strong> ® turbochargers!<br />

Honeywell<br />

www.TurboBy<strong>Garrett</strong>.com

Turbo Basics<br />

<strong>Garrett</strong> ®<br />

by Honeywell<br />

How a Turbo System Works<br />

Engine power is proportional to the<br />

amount of air and fuel that can get into<br />

the cylinders. All else being equal,<br />

larger engines flow more air and as<br />

such will produce more power.<br />

If we want our small engine to<br />

perform like a big engine, or simply<br />

make our bigger engine produce<br />

more power, our ultimate objective is<br />

to draw more air into the cylinder. By<br />

installing a <strong>Garrett</strong> ® turbocharger, the<br />

power and performance of an engine<br />

can be dramatically increased.<br />

The layout of the turbocharger<br />

in a given application is critical to a<br />

properly performing system.<br />

So how does a turbocharger get<br />

more air into the engine? Let us first<br />

look at the schematic to the upper<br />

right.<br />

• Ambient air passes through the air<br />

filter (not shown) before entering the<br />

compressor [1].<br />

• The air is then compressed which<br />

raises the air’s density<br />

(mass / unit volume) [2].<br />

• Many turbocharged engines have a<br />

charge air cooler (aka intercooler)<br />

[3] that cools the compressed air to<br />

further increase its density and to<br />

increase resistance to detonation.<br />

• After passing through the intake<br />

manifold [4], the air enters<br />

the engine’s cylinders, which<br />

contain a fixed maximum<br />

volume. Since the air is at an<br />

elevated density, each cylinder<br />

can contain an increased mass<br />

of air. Higher air mass flow<br />

rate allows a higher fuel flow<br />

rate (with similar air/fuel ratio).<br />

Combusting more fuel results in<br />

more power being produced for<br />

a given size or displacement.<br />

• After the fuel is burned in<br />

the cylinder, it is expelled<br />

during the cylinder’s exhaust<br />

stroke into the exhaust manifold<br />

[5].<br />

• The high temperature gas<br />

then continues on to the<br />

turbine [6]. The turbine creates<br />

backpressure on the engine<br />

which means engine exhaust<br />

pressure is higher than<br />

atmospheric pressure.<br />

• A pressure and temperature<br />

drop occurs (expansion) across<br />

the turbine [7], which harnesses<br />

the energy of the exhaust gas to<br />

provide the power necessary to drive<br />

the compressor.<br />

What are the Components of a<br />

Turbocharger?<br />

• Compressor Housing<br />

• Turbine Housing<br />

• Center Housing and Rotating<br />

Assembly (CHRA)<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Compressor Wheel<br />

Turbine Wheel Assembly<br />

(wheel and shaft)<br />

Backplate<br />

Bearing System<br />

Oil Inlet<br />

Oil Outlet<br />

<br />

www.TurboBy<strong>Garrett</strong>.com<br />

Honeywell

<strong>Garrett</strong> ®<br />

by Honeywell<br />

Turbo Basics<br />

How Do I Choose the Right Turbo?<br />

Selecting the proper turbocharger for your specific<br />

application requires many inputs. With decades of collective<br />

turbocharging experience, the <strong>Garrett</strong> ® Performance<br />

Distributors can assist in selecting the right turbocharger for<br />

your application.<br />

The primary input in determining which turbocharger<br />

is appropriate is to have a target horsepower in mind.<br />

This should be as realistic as possible for the application.<br />

Remember that engine power is generally proportional to<br />

air and fuel flow. Thus, once you have a target power level<br />

identified, you begin to hone in on the turbocharger size,<br />

which is highly dependent on air flow requirements.<br />

Other important factors include the type of application. An<br />

autocross car, for example, requires rapid boost response.<br />

A smaller turbocharger or smaller turbine housing would be<br />

most suitable for this application. While this will sacrifice<br />

ultimate power due to increased exhaust backpressure at<br />

higher engine speeds, boost response of the small turbo will<br />

be excellent.<br />

Alternatively, on a car dedicated to track days, peak<br />

horsepower is a higher priority than low-end torque. Plus,<br />

engine speeds tend to be consistently higher. Here, a<br />

larger turbocharger or turbine housing will provide reduced<br />

backpressure but less immediate low-end response. This<br />

is a welcome trade-off given the intended operating<br />

conditions.<br />

Selecting the turbocharger for your application goes<br />

beyond “how much boost” you want to run. Defining your<br />

target power level and the primary use for the application<br />

are the first steps in selecting the best <strong>Garrett</strong> ® Turbo<br />

for your vehicle. This catalog includes the formulas and<br />

considerations needed to corectly match a turbo to either<br />

your gasoline or diesel engine!<br />

What is A/R?<br />

A/R describes a geometric characteristic of all compressor<br />

and turbine housings. It is defined as the inlet cross-sectional<br />

area divided by the radius from the turbo centerline to the<br />

centroid of that area.<br />

Compressor A/R - Compressor performance is largely<br />

insensitive to changes in A/R, but generally larger A/R housings<br />

are used to optimize the performance for low boost applications,<br />

and smaller housings<br />

are used for high boost<br />

applications. Usually there<br />

are not A/R options available<br />

for compressor housings.<br />

Turbine A/R – Turbine<br />

performance is greatly<br />

affected by changing the<br />

A/R of the housing. Turbine<br />

A/R is used to adjust the<br />

flow capacity of the turbine.<br />

Using a smaller A/R will increase the exhaust gas velocity<br />

into the turbine wheel, causing the wheel to spin faster at<br />

lower engine RPMs giving a quicker boost rise. This will<br />

also tend to increase exhaust backpressure and reduce the<br />

max power at high RPM. Conversely, using a larger A/R<br />

will lower exhaust gas velocity and delay boost rise, but the<br />

lower backpressure will give better high-RPM power. When<br />

deciding between A/R options, be realistic with the intended<br />

vehicle use and use the A/R to bias the performance toward<br />

the desired powerband.<br />

What is Wheel Trim?<br />

Trim is an area ratio used to describe both turbine and<br />

compressor wheels. Trim is calculated using the inducer and<br />

exducer diameters.<br />

Trim = (Inducer 2 /Exducer 2 ) x 100<br />

Example:<br />

Inducer diameter = 88mm<br />

Exducer diameter = 117.5mm<br />

Trim = (88 2 /117.5 2 ) x 100= 56 Trim<br />

As trim is increased, the wheel can support more air/gas flow.<br />

Compressor Wheel Trim = (Inducer 2 /Exducer 2 ) x 100<br />

Turbine Wheel Trim = (Exducer 2 /Inducer 2 ) x 100<br />

Honeywell<br />

www.TurboBy<strong>Garrett</strong>.com

Turbo Basics<br />

<strong>Garrett</strong> ®<br />

by Honeywell<br />

Other Components<br />

Blow-Off (Bypass) Valves<br />

The blow-off valve (BOV) is a<br />

pressure relief device on the intake<br />

tract to prevent the turbo’s compressor<br />

from going into surge. The BOV should<br />

be installed between the compressor<br />

discharge and the throttle body,<br />

preferably downstream of the charge<br />

air cooler (if equipped).<br />

When the throttle is closed rapidly, the<br />

this energy (e.g. exhaust flow) reduces<br />

the power driving the turbine wheel<br />

to match the power required for a<br />

given boost level. Similar to the BOV,<br />

the wastegate uses boost pressure<br />

and spring force to regulate the flow<br />

bypassing the turbine.<br />

<strong>Garrett</strong> ® ball bearing turbochargers<br />

require less oil than journal bearing<br />

turbos. Therefore an oil inlet restrictor<br />

is recommended if you have oil<br />

pressure over approximately 40 psig.<br />

The oil outlet should be plumbed to the<br />

oil pan above the oil level (for wet sump<br />

systems). Since the oil drain is gravity<br />

fed, it is important that the oil outlet<br />

points downward, and that the drain<br />

tube does not become horizontal or go<br />

“uphill” at any point.<br />

airflow is quickly reduced, causing flow<br />

instability and pressure fluctuations.<br />

These rapidly cycling pressure<br />

fluctuations are the audible evidence<br />

of surge. Surge can eventually lead to<br />

bearing failure due to the high loads<br />

associated with it.<br />

Blow-off valves use a combination<br />

of manifold pressure signal and spring<br />

force to detect when the throttle is<br />

closed. When the throttle is closed<br />

rapidly, the BOV vents boost from<br />

the intake tract to atmosphere or<br />

recirculates it to relieve the pressure<br />

from the turbo, eliminating surge.<br />

Wastegates<br />

On the exhaust side, a wastegate<br />

provides a means to control the boost<br />

pressure generated by the turbocharger<br />

by controlling the turbocharger shaft<br />

speed. Some commercial diesel<br />

applications do not use a wastegate at<br />

all. This type of system is called a free<br />

floating turbocharger.<br />

However, the vast majority of gasoline<br />

performance applications require a<br />

wastegate. There are two configurations<br />

of wastegates: internal and external.<br />

Both internal and external wastegates<br />

provide a means for exhaust gas to<br />

bypass the turbine wheel. Bypassing<br />

Internal wastegates are built into<br />

the turbine housing and consist of a<br />

“flapper” valve, crank arm, rod end,<br />

and pneumatic actuator. It is important<br />

to connect this actuator only to boost<br />

pressure since it is not designed to<br />

handle vacuum and as such should<br />

not be referenced to an intake<br />

manifold.<br />

External wastegates are added<br />

to the exhaust plumbing on the<br />

exhaust manifold or header. The<br />

advantage of external wastegates<br />

is that the bypassed flow can<br />

be reintroduced into the exhaust<br />

stream further downstream of the<br />

turbine. This improves the turbine’s<br />

performance. On racing applications,<br />

this wastegated exhaust flow can be<br />

vented directly to atmosphere.<br />

Oil & Water Plumbing<br />

The intake and exhaust plumbing<br />

often receives the focus, leaving the<br />

oil and water plumbing neglected.<br />

Following a hot shutdown of a<br />

turbocharger, heat soak begins. This<br />

means that the heat in the head, exhaust<br />

manifold, and turbine housing raises<br />

the temperature of the turbo’s center<br />

housing. These extreme temperatures<br />

can result in oil coking.<br />

Water-cooled center housings<br />

were introduced to minimize the<br />

effects of heat soak-back. These<br />

use unpressurized coolant from the<br />

engine to act as a heat sink after<br />

engine shutdown, preventing the oil<br />

from coking. The water lines utilize<br />

a thermal siphon effect to reduce the<br />

peak heat soak-back temperature after<br />

key-off. The layout of the pipes should<br />

eliminate peaks and troughs with the<br />

(cool) water inlet on the low side. To<br />

help this along, it is advantageous to<br />

tilt the turbocharger approximately 25°<br />

about the axis of shaft rotation.<br />

<strong>Garrett</strong> ® offers many turbos that are<br />

water-cooled for enhanced durability.<br />

Want to learn more?<br />

Visit http://www.TurboBy<strong>Garrett</strong>.com<br />

and check out the Turbo Tech section<br />

for more great articles!<br />

<br />

www.TurboBy<strong>Garrett</strong>.com<br />

Honeywell

<strong>Garrett</strong> ®<br />

by Honeywell<br />

Turbo Selection - Gas<br />

This article is more involved and will describe parts of the<br />

compressor map, how to estimate pressure ratio and mass flow<br />

rate for your engine as well as how to plot the points on the maps to<br />

help choose the right turbocharger. Have your calculator handy!<br />

Parts of the Compressor Map<br />

The compressor map is a graph that describes a particular compressor’s<br />

performance characteristics, including efficiency, mass<br />

flow range, boost pressure capability, and turbo speed. Shown below<br />

is a figure that identifies aspects of a typical compressor map:<br />

Pressure Ratio<br />

Pressure Ratio ( ) is defined as the Absolute outlet pressure<br />

divided by the Absolute Inlet Pressure.<br />

Where:<br />

= Pressure Ratio<br />

P1c = Compressor Inlet<br />

Pressure<br />

P2c = Compressor Discharge<br />

Pressure<br />

It is important to use<br />

units of Absolute Pressure<br />

for both P1c and<br />

P2c. Remember that<br />

Absolute Pressure at<br />

sea level is 14.7 psia (in<br />

units of psia, the “a” refers<br />

to “absolute”). This<br />

is referred to as standard<br />

atmospheric pressure at<br />

standard conditions.<br />

Gauge Pressure (in<br />

units of psig, the g refers<br />

to “gauge”) measures the pressure above atmospheric, so a<br />

Gauge Pressure reading at atmospheric conditions will read zero.<br />

Boost gauges measure the manifold pressure relative to atmospheric<br />

pressure, and thus are measuring Gauge Pressure. This<br />

is important when determining P2c. For example, a reading of 12<br />

psig on a boost gauge means that the air pressure in the manifold<br />

is 12 psi above atmospheric pressure.<br />

For a day at standard atmospheric conditions:<br />

12 psig + 14.7 psia = 26.7 psi Absolute Pressure in the manifold,<br />

the Pressure Ratio at this condition can now be calculated:<br />

26.7 psia / 14.7 psia = 1.82<br />

However, this assumes there is no adverse impact of the air filter<br />

assembly at the compressor inlet.<br />

In determining Pressure Ratio, the Absolute Pressure at the<br />

compressor inlet (P2c) is often LESS than the Ambient Pressure,<br />

especially at high load. Why is this? Any restriction (caused by<br />

the air filter or restrictive ducting) will result in a “depression,”<br />

or pressure loss, upstream of the compressor that needs to be<br />

accounted for when determining pressure ratio. This depression<br />

can be 1 psig or more on some intake systems. In this<br />

case P1c on a standard day is:<br />

14.7psia – 1 psig = 13.7 psia at compressor inlet<br />

Taking into account the 1 psig intake depression, the pressure<br />

ratio is now.<br />

(12 psig + 14.7 psia) / 13.7 psia = 1.95.<br />

That’s great, but what if you’re not at sea level? In this case,<br />

simply substitute the actual atmospheric pressure in place of the<br />

14.7 psi in the equations above to give a more accurate calculation.<br />

At higher elevations, this can have a significant effect on pressure<br />

ratio.<br />

For example, at Denver’s 5000 feet elevation, the atmospheric<br />

pressure is typically around 12.4 psia. In this case, the pressure<br />

ratio calculation, taking into account the intake depression, is:<br />

(12 psig + 12.4 psia) / (12.4 psia – 1 psig) = 2.14<br />

Compared to the 1.82 pressure ratio calculated originally, this<br />

is a big difference.<br />

As you can see in these examples, pressure ratio depends on a<br />

lot more than just boost.<br />

Mass Flow Rate<br />

Mass Flow Rate is the mass of air flowing through a compressor<br />

(and engine!) over a given period of time and is commonly<br />

expressed as lb/min (pounds per minute). Mass flow can be<br />

physically measured, but in many cases it is sufficient to estimate<br />

the mass flow for choosing the proper turbo.<br />

Many people use Volumetric Flow Rate (expressed in cubic feet<br />

per minute, CFM or ft 3 /min) instead of mass flow rate. Volumetric<br />

flow rate can be converted to mass flow by multiplying by the air<br />

density. Air density at sea level is 0.076lb/ft 3 .<br />

What is my mass flow rate? As a very general rule, turbocharged<br />

gasoline engines will generate 9.5-10.5 horsepower (as measured<br />

at the flywheel) for each lb/min of airflow. So, an engine with a target<br />

peak horsepower of 400 HP will require 36-44 lb/min of airflow to<br />

achieve that target. This is just a rough first approximation to help<br />

narrow the turbo selection options.<br />

Surge Line<br />

Surge is the left hand boundary of the compressor map.<br />

Operation to the left of this line represents a region of flow<br />

instability. This region is characterized by mild flutter to wildly<br />

fluctuating boost and “barking” from the compressor. Continued<br />

operation within this region can lead to premature turbo failure<br />

due to heavy thrust loading.<br />

Surge is most commonly experienced when one of two<br />

situations exist. The first and most damaging is surge under load.<br />

It can be an indication that your compressor is too large. Surge<br />

is also commonly experienced when the throttle is quickly closed<br />

after boosting. This occurs because mass flow is drastically<br />

reduced as the throttle is closed, but the turbo is still spinning<br />

and generating boost. This immediately drives the operating<br />

point to the far left of the compressor map, right into surge. Surge<br />

will decay once the turbo speed finally slows enough to reduce<br />

the boost and move the operating point back into the stable<br />

region. This situation is commonly addressed by using a Blow-<br />

Off Valve (BOV) or bypass valve. A BOV functions to vent intake<br />

pressure to atmosphere so that the mass flow ramps down<br />

smoothly, keeping the compressor out of surge. In the case of a<br />

recirculating bypass valve, the airflow is recirculated back to the<br />

compressor inlet.<br />

Honeywell<br />

www.TurboBy<strong>Garrett</strong>.com

Turbo Selection - Gas<br />

<strong>Garrett</strong> ®<br />

by Honeywell<br />

A Ported Shroud Compressor (see Fig. 2) is a feature that is<br />

incorporated into the compressor housing. It functions to move<br />

the surge line further to the left (see Fig. 3) by allowing some<br />

airflow to exit the wheel through the port to keep surge from<br />

occurring. This provides additional useable range and allows<br />

a larger compressor to be used for higher flow requirements<br />

without risking running the compressor into a dangerous surge<br />

condition. The presence of<br />

the ported shroud usually<br />

has a minor negative impact<br />

on compressor efficiency.<br />

The Choke Line is the<br />

right hand boundary of<br />

the compressor map. For<br />

<strong>Garrett</strong> ® maps, the choke<br />

line is typically defined by the<br />

point where the efficiency<br />

drops below 58%. In<br />

addition to the rapid drop of<br />

compressor efficiency past<br />

this point, the turbo speed<br />

Fig 2<br />

will also be approaching or<br />

exceeding the allowable limit.<br />

If your actual or predicted<br />

operation is beyond this<br />

limit, a larger compressor is<br />

necessary.<br />

Turbo Speed Lines are<br />

lines of constant turbo speed.<br />

Turbo speed for points<br />

between these lines can be<br />

estimated by interpolation. As<br />

turbo speed increases, the<br />

pressure ratio increases and/<br />

or mass flow increases. As<br />

indicated above in the choke<br />

line description, the turbo<br />

Fig 3<br />

speed lines are very close together at the far right edge of the<br />

map. Once a compressor is operating past the choke limit, turbo<br />

speed increases very quickly and a turbo over-speed condition is<br />

very likely.<br />

Efficiency Islands are concentric regions on the maps that<br />

represent the compressor efficiency at any point on the map. The<br />

smallest island near the center of the map is the highest or peak<br />

efficiency island. As the rings move out from there, the efficiency<br />

drops by the indicated amount until the surge and choke limits are<br />

reached.<br />

Plotting Your Data on the Compressor Map<br />

In this section, methods to calculate mass flow rate and boost<br />

pressure required to meet a horsepower target are presented.<br />

This data will then be used to choose the appropriate compressor<br />

and turbocharger. Having a Horsepower Target in mind is a vital<br />

part of the process. In addition to being necessary for calculating<br />

mass flow and boost pressure, a Horsepower Target is required<br />

for choosing the right fuel injectors, fuel pump and regulator, and<br />

other engine components.<br />

Estimating Required Air Mass Flow and Boost Pressures to<br />

reach a Horsepower Target.<br />

Things you need to know:<br />

-Horsepower Target<br />

-Engine Displacement<br />

-Maximum RPM<br />

-Ambient conditions (temperature and barometric<br />

pressure. Barometric pressure is usually given as inches of mercury<br />

and can be converted to psi by dividing by 2)<br />

Things you need to estimate:<br />

· Engine Volumetric Efficiency. Typical numbers for peak Volumetric<br />

Efficiency (VE) range in the 95%-99% for modern 4-valve heads, to<br />

88%-95% for 2-valve designs. If you have a torque curve for your<br />

engine, you can use this to estimate VE at various engine speeds.<br />

On a well-tuned engine, the VE will peak at the torque peak, and<br />

this number can be used to scale the VE at other engine speeds.<br />

A 4-valve engine will typically have higher VE over more of its rev<br />

range than a 2-valve engine.<br />

· Intake Manifold Temperature. Compressors with higher efficiency<br />

give lower manifold temperatures. Manifold temperatures of<br />

intercooled setups are typically 100 - 130 degrees F, while nonintercooled<br />

values can reach from 175-300 degrees F.<br />

· Brake Specific Fuel Consumption (BSFC). BSFC describes the<br />

fuel flow rate required to generate each horsepower. General<br />

values of BSFC for turbocharged gasoline engines range from 0.50<br />

to 0.60 and higher.<br />

The units of BSFC are<br />

Lower BSFC means that the engine requires less fuel to generate<br />

a given horsepower. Race fuels and aggressive tuning are required<br />

to reach the low end of the BSFC range described above.<br />

For the equations below, we will divide BSFC by 60 to convert<br />

from hours to minutes.<br />

To plot the compressor operating point, first calculate airflow:<br />

Where:<br />

Wa= Airflow actual (lb/min)<br />

HP = Horsepower Target (flywheel)<br />

= Air/Fuel Ratio<br />

= Brake Specific Fuel Consumption = ( ) ÷ 60 (to<br />

convert from hours to minutes)<br />

EXAMPLE:<br />

I have an engine that I would like to make 400HP, I want to<br />

choose an air/fuel ratio of 12 and use a BSFC of 0.55. Plugging<br />

these numbers into the formula from above:<br />

of air.<br />

Thus, a compressor map that has the capability of at least 44<br />

pounds per minute of airflow capacity is a good starting point.<br />

Note that nowhere in this calculation did we enter any engine<br />

displacement or RPM numbers. This means that for any engine,<br />

in order to make 400 HP, it needs to flow about 44 lb/min (this<br />

assumes that BSFC remains constant across all engine types).<br />

Naturally, a smaller displacement engine will require more boost or<br />

higher engine speed to meet this target than a larger engine will. So<br />

how much boost pressure would be required?<br />

10 www.TurboBy<strong>Garrett</strong>.com<br />

Honeywell

<strong>Garrett</strong> ®<br />

by Honeywell<br />

Turbo Selection - Gas<br />

Calculate manifold pressure required to meet the Horsepower, or<br />

flow target:<br />

Where:<br />

· MAPreq = Manifold Absolute Pressure (psia) required to meet the<br />

horsepower target<br />

· Wa = Airflow actual(lb/min)<br />

· R = Gas Constant = 639.6<br />

· Tm = Intake Manifold Temperature (degrees F)<br />

· VE = Volumetric Efficiency<br />

· N = Engine speed (RPM)<br />

· Vd = engine displacement (Cubic Inches, convert from liters to CI<br />

by multiplying by 61.02, ex. 2.0 liters * 61.02 = 122 CI)<br />

EXAMPLE:<br />

To continue the example above, let’s consider a 2.0 liter engine<br />

with the following description:<br />

· Wa = 44 lb/min as previously calculated<br />

· Tm = 130 degrees F<br />

· VE = 92% at peak power<br />

· N = 7200 RPM<br />

· Vd = 2.0 liters * 61.02 = 122 CI<br />

= 41.1 psia (remember, this is<br />

Absolute Pressure. Subtract Atmospheric Pressure to get Gauge<br />

Pressure (aka boost):<br />

41.1 psia – 14.7 psia (at sea level) = 26.4 psig boost<br />

As a comparison let’s repeat the calculation for a larger<br />

displacement 5.0L (4942 cc/302 CI) engine.<br />

Where:<br />

· Wa = 44 lb/min as previously calculated<br />

· Tm = 130 degrees F<br />

· VE = 85% at peak power (it is a pushrod V-8)<br />

· N = 6000 RPM<br />

· Vd = 4.942*61.02= 302 CI<br />

= 21.6 psia (or 6.9 psig boost)<br />

This example illustrates that in order to reach the horsepower<br />

target of 400 hp, a larger engine requires lower manifold pressure<br />

but still needs 44lb/min of airflow. This can have a very significant<br />

effect on choosing the correct compressor.<br />

With Mass Flow and Manifold Pressure, we are nearly ready to<br />

plot the data on the compressor map. The next step is to determine<br />

how much pressure loss exists between the compressor and the<br />

manifold. The best way to do this is to measure the pressure<br />

drop with a data acquisition system, but many times that is not<br />

practical.<br />

Depending upon flow rate, charge air cooler characteristics,<br />

piping size, number/quality of the bends, throttle body restriction,<br />

etc., the plumbing pressure drop can be estimated. This can be 1<br />

psi or less for a very well designed system. On certain restrictive<br />

OEM setups, especially those that have now higher-than-stock<br />

airflow levels, the pressure drop can be 4 psi or greater.<br />

For our examples we will assume that there is a 2 psi loss. So to<br />

determine the Compressor Discharge Pressure (P2c), 2 psi will be<br />

added to the manifold pressure calculated above.<br />

Where:<br />

· P2c = Compressor Discharge Pressure (psia)<br />

· MAP = Manifold Absolute Pressure (psia)<br />

· ΔPloss = Pressure Loss Between the Compressor and the<br />

Manifold (psi)<br />

For the 2.0 L engine:<br />

For the 5.0 L engine:<br />

= 43.1 psia<br />

= 23.6 psia<br />

Remember our discussion on inlet depression in the Pressure<br />

Ratio discussion earlier, we said that a typical value might be 1 psi,<br />

so that is what will be used in this calculation. For this example,<br />

assume that we are at sea level, so Ambient Pressure is 14.7<br />

psia.<br />

We will need to subtract the 1 psi pressure loss from the ambient<br />

pressure to determine the Compressor Inlet Pressure (P1).<br />

Where:<br />

· P1c = Compressor Inlet Pressure (psia)<br />

· Pamb = Ambient Air Pressure (psia)<br />

· ΔPloss = Pressure Loss due to Air Filter/Piping (psi)<br />

P1c = 14.7 - 1 = 13.7 psia<br />

With this, we can calculate Pressure Ratio ( ) using the<br />

equation.<br />

For the 2.0 L engine: = 3.14<br />

For the 5.0 L engine: = 1.72<br />

We now have enough information to plot these operating points<br />

on the compressor map. First we will try a GT2860RS. This turbo<br />

has a 60mm, 60 trim compressor wheel.<br />

Clearly this<br />

c o m p r e s s o r<br />

is too small,<br />

as both points<br />

are positioned<br />

far to the right<br />

and beyond the<br />

c o m p r e s s o r ’s<br />

choke line.<br />

Honeywell<br />

www.TurboBy<strong>Garrett</strong>.com<br />

11

Turbo Selection - Gas<br />

<strong>Garrett</strong> ®<br />

by Honeywell<br />

Another potential<br />

candidate might<br />

be the <strong>Garrett</strong> ®<br />

GT3076R. This<br />

turbo has a 76mm,<br />

56 trim compressor<br />

wheel.<br />

This is much<br />

better; at least both<br />

points are on the<br />

map! Let’s look at<br />

each point in more<br />

detail.<br />

For the 2.0L<br />

engine this point is<br />

in a very efficient<br />

area of the map,<br />

but since it is in the<br />

center of the map,<br />

there would be a<br />

concern that at lower<br />

engine speeds that it would be near or over the surge line. This<br />

might be ok for a high-rpm-biased powerband that might be used<br />

on a racing application, but a street application would be better<br />

served by a different compressor.<br />

For the 5.0L engine, this looks like a very good street-biased<br />

powerband, with the lower engine speeds passing through the<br />

highest efficiency zone on the map, and plenty of margin to stay<br />

clear of surge. One area of concern would be turbo overspeed when<br />

revving the engine past peak power. A larger compressor would<br />

place the operating<br />

point nearer to the<br />

center of the map<br />

and would give some<br />

additional benefit to<br />

a high-rpm-biased<br />

powerband. We’ll<br />

look at a larger<br />

compressor for the<br />

5.0L after we figure<br />

out a good street<br />

match for the 2.0L<br />

engine.<br />

So now lets look at<br />

a <strong>Garrett</strong> ® GT3071R,<br />

which uses a 71mm,<br />

56 trim compressor<br />

wheel.<br />

For the 2.0L<br />

engine, this is a better<br />

mid-range-oriented<br />

compressor. The operating point is shifted a bit towards the choke<br />

side of the map and this provides additional surge margin. The<br />

lower engine speeds will now pass through the higher efficiency<br />

zones and give excellent performance and response.<br />

For the 5.0L engine, the compressor is clearly too small and<br />

would not be considered.<br />

Now that we have arrived at an acceptable compressor for the<br />

2.0L engine, lets calculate a lower rpm point to plot on the map to<br />

better get a feel for what the engine operating line will look like. We<br />

can calculate this using the following formula:<br />

We’ll choose the engine speed at which we would expect to see<br />

peak torque, based on experience or an educated guess. In this<br />

case we’ll choose 5000rpm.<br />

Where:<br />

· Wa = Airflow actual (lb/min)<br />

· MAP = Manifold Absolute Pressure (psia) =41.1 psia<br />

· R = Gas Constant = 639.6<br />

· Tm = Intake Manifold Temperature (degrees F) =130<br />

· VE = Volumetric Efficiency = 0.92<br />

· N = Engine speed (RPM) = 5000rpm<br />

· Vd = engine displacement (Cubic Inches, convert from liters to CI<br />

by multiplying by 61, ex. 2.0 liters * 61 = 122 CI)<br />

= 34.1 lb/min<br />

Plotting this on the GT3071R compressor map demonstrates the<br />

following operating points.<br />

This provides a good<br />

representation of the<br />

operating line at that<br />

boost level, which is<br />

well suited to this map.<br />

At engine speeds lower<br />

than 5000 rpm the boost<br />

pressure will be lower,<br />

and the pressure ratio<br />

would be lower, to keep<br />

the compressor out of<br />

surge.<br />

Back to the 5.0L<br />

engine. Let’s look at<br />

a larger compressor’s<br />

map. This time we<br />

will try a GT3582R<br />

with an 82mm, 56 trim<br />

compressor.<br />

Here, compared to<br />

the GT3076R, we can<br />

see that this point is not<br />

quite so deep into choke<br />

and will give better highrpm<br />

performance than<br />

the 76mm wheel. A<br />

further increase in wheel<br />

size would provide<br />

even better high-rpm<br />

performance, but at the<br />

cost of low- and midrange<br />

response and<br />

drivability.<br />

Hopefully this<br />

provided a basic idea of<br />

what a compressor map<br />

displays and how to<br />

choose a compressor. If<br />

real data is available to<br />

be substituted in place of estimation, more accurate results can<br />

be generated.<br />

12 www.TurboBy<strong>Garrett</strong>.com<br />

Honeywell

<strong>Garrett</strong> ®<br />

by Honeywell<br />

Turbo Selection -Diesel<br />

Today’s diesel engines represent the state of the art in technology<br />

with high power density, excellent drivability, and good fuel<br />

economy. Fortunately for the diesel enthusiast, they are easier<br />

to upgrade for additional performance and the aftermarket is<br />

responding with more options for your high performance needs.<br />

As the major air system component, the turbocharger is a vital part<br />

of the performance equation and choosing the right turbo is critical<br />

to meeting your performance targets.<br />

So why would I want to upgrade my Turbo Diesel engine?<br />

Better towing performance -- Maybe you bought your truck to tow<br />

that gooseneck for work, to get your 5th wheel to the next resort or<br />

your boat to the lake. It sure would be nice to get up to freeway<br />

speeds quickly and maintain highway speeds in hilly terrain. With<br />

the right upgrades, that can be done safely and efficiently.<br />

power target. Since turbochargers are sized by how much air they<br />

can deliver and airflow is proportional to engine power, a realistic<br />

horsepower goal is critical to make the right choice.<br />

The concept of a realistic goal needs to be stressed in order to<br />

ensure maximum performance and satisfaction. Sure, everyone<br />

would like to have a mega-horsepower vehicle but past a reasonable<br />

limit, as the power goes up, the reliability, drivability and day-to-day<br />

utility is diminished. Things are more likely to go wrong, wear out<br />

and break down as the power output climbs.<br />

Most project vehicles fall into one of the following general<br />

categories:<br />

Great, So what turbo do I choose?<br />

Competition Use -- More and more enthusiasts are interested in<br />

heavily modifying their vehicles for competition use. Some are<br />

weekend warriors that use their vehicles during the week for routine<br />

duty then go to the track on the weekends while others are building<br />

strictly race vehicles that give up streetability for the demands of<br />

the track.<br />

More fun -- For many, making modifications for increased<br />

performance is a way of personalizing the vehicle and to have a<br />

bit more fun with the daily drive. There is a satisfaction that comes<br />

from modifications that put you back into your seat a little harder<br />

when the light turns green. And, there are always the grudge<br />

matches at the local drag strip.<br />

What do I need to know to choose the right diesel upgrade<br />

turbocharger?<br />

The amount of power that a diesel engine makes is directly<br />

proportional to the amount of fuel injected into the cylinder and that<br />

fuel needs sufficient air for complete combustion. For smoke-free<br />

performance, the engine needs about 18 times more air (by mass)<br />

than fuel. So clearly, as more fuel is added, additional air needs<br />

to be added also. In most applications, the stock turbo has some<br />

additional capacity for increased power, but as the compressor<br />

reaches the choke limit (maximum flow), the turbo speed increases<br />

rapidly, the efficiency drops dramatically, and the compressor<br />

discharge temperature ramps up very quickly. This creates a<br />

“snowball” effect in that the higher discharge temps mean higher<br />

intake manifold temps and higher exhaust gas temps. The lower<br />

efficiency means that more turbine power is required to reach the<br />

same boost causing higher back pressure in the exhaust manifold.<br />

This can usually be seen on an engine with a performance chip<br />

(at the highest power setting) and maybe an intake or exhaust<br />

upgrade. Under heavy acceleration, smoke is pouring from the<br />

tailpipe as the EGT’s and turbo speeds are climbing into the danger<br />

zone requiring a prudent driver to back off the accelerator pedal<br />

early to keep from damaging the engine. Under these conditions,<br />

the stock turbo is running on borrowed time. With an upgrade<br />

turbocharger selected to compliment the extra fuel, smoke is<br />

drastically reduced, EGT’s are under control and, since the turbo<br />

is operating in a more efficient range, horsepower and drivability<br />

are enhanced. When the modifications get more serious, a bigger<br />

turbo is a must-have to compliment even more fuel.<br />

In order to decide on the appropriate turbocharger for your diesel<br />

engine, the very first thing that needs to be established is the<br />

Let’s take each case and calculate a turbo choice based on the<br />

intended power increase. The first step is to read the catalog<br />

section “Turbo Selection - Gasoline” (pages 8-11). This article<br />

explains the reading of a compressor map and the equations<br />

needed to properly match a turbo. The examples given, however,<br />

are for gasoline engines, so the additional examples here will be<br />

using those same equations but with a diesel engine. Matches<br />

will be calculated with an Air Fuel Ratio (AFR) of 22:1 for low or<br />

no smoke performance. Likewise a typical Brake Specific Fuel<br />

Consumption (BSFC) is in the range of 0.38. Let’s get started!<br />

The first example will be for the Daily Driver/Work Truck/Tow<br />

Vehicle category. This includes vehicles up to 150HP over stock.<br />

But wait, this power level can be accomplished with just a chip or<br />

tuning module. So why bother with a new upgrade turbo? An upgrade<br />

turbo will enhance the gains made by installing the chip and<br />

other upgrades. The extra air and lower backpressure provided<br />

by the upgrade turbo will lower EGTs, allow more power with less<br />

smoke and address durability issues with the stock turbo at higher<br />

boost pressures and power levels. Because this will be a mild<br />

upgrade, boost response and drivability will be improved across<br />

the board.<br />

EXAMPLE:<br />

I have a 6.6L diesel engine that makes a claimed 325 flywheel<br />

horsepower (about 275 wheel Horsepower as measured on a<br />

chassis dyno). I would like to make 425 wheel HP; an increase of<br />

150 wheel horsepower. Plugging these numbers into the formula<br />

and using the AFR and BSFC data from above:<br />

Honeywell<br />

www.TurboBy<strong>Garrett</strong>.com<br />

13

Turbo Selection - Diesel<br />

<strong>Garrett</strong> ®<br />

by Honeywell<br />

Recall from Turbo Selection - Gasoline:<br />

Where:<br />

Wa = Airflowactual (lb/min)<br />

HP = Horsepower Target<br />

= Air/Fuel Ratio<br />

= Brake Specific Fuel Consumption ( ) ÷ 60<br />

(to convert from hours to minutes)<br />

of air.<br />

So we will need to choose a compressor map that has a capability<br />

of at least 59.2 pounds per minute of airflow capacity. Next,<br />

how much boost pressure will be needed?<br />

Calculate the manifold pressure required to meet the horsepower<br />

target.<br />

Where:<br />

MAPreq = Manifold Absolute Pressure (psia) required to<br />

meet the horsepower target<br />

Wa = Airflowactual (lb/min)<br />

R = Gas Constant = 639.6<br />

Tm = Intake Manifold Temperature (degrees F)<br />

VE = Volumetric Efficiency<br />

N = Engine speed (RPM)<br />

Vd = engine displacement (Cubic Inches, convert from li<br />

ters to CI by multiplying by 61, ex. 2.0 liters*61 = 122 CI)<br />

For our project engine:<br />

Wa = 59.2 lb/min as previously calculated<br />

Tm = 130 degrees F<br />

VE = 98%<br />

N = 3300 RPM<br />

Vd = 6.6 liters * 61 = 400 CI<br />

To get the correct inlet condition, it is now necessary to estimate<br />

the air filter or other restrictions. In the Pressure Ratio discussion<br />

earlier we said that a typical value might be 1 psi, so that is what<br />

will be used in this calculation. Also, we are going to assume that<br />

we are at sea level, so we are going to use an ambient pressure<br />

of 14.7 psia. We will need to subtract the 1 psi pressure loss from<br />

the Ambient Pressure to determine the Compressor Inlet Pressure<br />

(P1).<br />

Where:<br />

P1c = Compressor Inlet Pressure (psia)<br />

Pamb = Ambient Air pressure (psia)<br />

Ploss = Pressure loss due to Air Filter/Piping (psi)<br />

= 13.7 psia<br />

With this, we can calculate Pressure Ratio (<br />

equation.<br />

For the 2.0L engine:<br />

) using the<br />

= 2.7<br />

We now have enough information to plot these operating points<br />

on the compressor map. First we will try a GT3788R. This turbo<br />

has an 88mm tip diameter 52 trim compressor wheel with a<br />

64.45mm inducer.<br />

As you can see, this point falls nicely on the map with some additional<br />

room for increased boost and mass flow if the horsepower<br />

target climbs. For this<br />

reason, the GT37R turbo<br />

family is applied on<br />

many of the <strong>Garrett</strong> ®<br />

PowerMax TM turbo kits<br />

that are sized for this<br />

horsepower range.<br />

= 34.5 psia (remember, this is Absolute Pressure; subtract Atmospheric<br />

Pressure to get Gauge Pressure, 34.5 psia – 14.7 psia (at<br />

sea level) = 19.8 psig).<br />

So now we have a Mass Flow and Manifold Pressure. We are<br />

almost ready to plot the data on the compressor map. Next step<br />

is to determine how much pressure loss exists between the compressor<br />

and the manifold. The best way to do this is to measure<br />

the pressure drop with a data acquisition system, but many times<br />

that is not practical. Depending upon flow rate and charge air cooler<br />

size, piping size and number/quality of the bends, throttle body<br />

restriction, etc., you can estimate from 1 psi (or less) up to 4 psi<br />

(or higher). For our examples we will estimate that there is a 2 psi<br />

loss. Therefore we will need to add 2 psi to the manifold pressure<br />

in order to determine the Compressor Discharge Pressure (P2c).<br />

Where:<br />

P2c = Compressor Discharge Pressure (psia)<br />

MAP = Manifold Absolute Pressure (psia)<br />

Ploss = Pressure loss between the Compressor and<br />

the Manifold (psi)<br />

= 36.5 psia<br />

For the next example,<br />

let’s look at the Weekend<br />

Warrior. This category<br />

is for daily driven<br />

vehicles that have up<br />

to 250 horsepower<br />

over stock or 525 wheel<br />

horsepower.<br />

Plugging that power<br />

target into our formula<br />

yields an airflow requirement of:<br />

And a pressure ratio of:<br />

of air flow.<br />

= 43.5 psia<br />

= 45.5 psia<br />

= 3.3<br />

14 www.TurboBy<strong>Garrett</strong>.com<br />

Honeywell

<strong>Garrett</strong> ®<br />

by Honeywell<br />

Turbo Selection - Diesel<br />

Looking at the previous map, the compressor does not flow<br />

enough to support this requirement, so we must look at the next<br />

larger size compressor. (Technically, the engine could probably<br />

easily make this power with the previous compressor, but it would<br />

be at risk of more smoke, higher EGT’s and backpressure; kind of<br />

like pushing a stock compressor too far…) The next larger turbo is<br />

a <strong>Garrett</strong> ® GT4094R. Another option that could also be considered<br />

is the GT4294R which has<br />

a slightly larger inducer<br />

compressor and the next<br />

larger frame size turbine<br />

wheel. The larger wheel’s<br />

inertia will slow down the<br />

response a bit, but provide<br />

better performance at the<br />

top end of the rpm range.<br />

For the next example,<br />

let’s look at the Extreme<br />

P e r f o r m a n c e . T h i s<br />

category is for real hot rod<br />

vehicles that have up to<br />

350 horsepower over stock<br />

and owners that are willing<br />

to give up some of the daily utility in order to achieve higher power<br />

gains.<br />

Plugging that power target into our formula yields an airflow<br />

requirement of:<br />

of air<br />

And a pressure ratio of :<br />

= 50.8 psia<br />

= 52.8 psia<br />

= 3.8<br />

For this flow and pressure ratio, the GT4202R is appropriate and<br />

is shown below. Since this is approaching a pressure ratio of 4-<br />

to-1, we are about at the limit of a single turbo on an engine of this<br />

size.<br />

Additional power gains can be had with more boost or a larger<br />

single turbo, but it is<br />

getting close to the edge<br />

of the envelope in terms of<br />

efficiency and turbo speed.<br />

The final case is the<br />

Competition category.<br />

Since this is a special case<br />

and there are so many ways<br />

to go about an ultimate<br />

power diesel application,<br />

it is not possible to cover it<br />

adequately in this article.<br />

There are, however, some<br />

general guidelines. At<br />

this power level, as stated<br />

above, it is a good idea<br />

to consider a series turbo<br />

application. This is a situation where one turbo feeds another turbo,<br />

sharing the work of compressing the air across both compressors.<br />

A larger turbo is designated as the “low-pressure” turbo and the<br />

smaller secondary stage as the “high pressure” turbo. The lowpressure<br />

compressor feeds the high-pressure compressor which<br />

then feeds the intake. On the turbine-side the exhaust first passes<br />

through the high-pressure turbine and then on to the low-pressure<br />

turbine before being routed out through the tailpipe. We can still<br />

calculate the required mass flow, but the pressure ratio is more<br />

involved and questions should be discussed with your local <strong>Garrett</strong> ®<br />

PowerMax TM distributor. To calculate the required mass flow, we<br />

use the normal equation. This time the power target will be 500<br />

wheel horsepower over stock, for a total of 775 wheel horsepower.<br />

of air flow.<br />

This air flow rate will apply only to the low-pressure compressor<br />

as the high-pressure compressor will be smaller because it is further<br />

pressurizing already compressed air. In most cases, the highpressure<br />

turbo tends to be about two frame sizes smaller than the<br />

low pressure stage. So in this case, after selecting the appropriate<br />

low-pressure turbo (hint: look at the GT4718R compressor map), a<br />

GT4088R or GT4094R would be the likely candidates.<br />

One more comment on<br />

choosing a properly sized<br />

turbine housing A/R. A<br />

smaller A/R will help the<br />

turbo come up on boost<br />

sooner and provide a better<br />

responding turbo application,<br />

but at the expense<br />

of higher back pressure in<br />

the higher rpm zones and,<br />

in some cases, a risk of<br />

pushing the compressor<br />

into surge if the boost rises<br />

too rapidly. On the other<br />

hand, a larger A/R will respond<br />

slower, but with better<br />

top end performance<br />

and reduced risk of running<br />

the compressor into<br />

surge. Generally speaking,<br />

the proper turbine housing<br />

is the largest one that<br />

will give acceptable boost<br />

response on the low end<br />

while allowing for more optimal<br />

top end performance.<br />

This information should<br />

be used as a starting point<br />

for making decisions on<br />

proper turbo sizing.<br />

For more specific<br />

information on your<br />

engine, consult a <strong>Garrett</strong> ®<br />

PowerMax TM Distributor.<br />

Find your <strong>Garrett</strong> ®<br />

PowerMax TM Distributor<br />

at<br />

www.TurboBy<strong>Garrett</strong>.com.<br />

Honeywell<br />

www.TurboBy<strong>Garrett</strong>.com<br />

15

Turbo System Optimization<br />

<strong>Garrett</strong> ®<br />

by Honeywell<br />

This section is intended to cover many of the auxiliary systems in a<br />

more complete and in-depth manner. With this additional section, you<br />

will better understand how to optimize your turbo system.<br />

Turbo System Optimization will cover:<br />

1. Application Information<br />

2. Turbo Match<br />

3. System Components<br />

- Air Filter<br />

- Oil Supply & Drain<br />

- Water Lines<br />

- Charge Tubing & Charge-Air-Cooler<br />

- BOV<br />

- Wastegate<br />

4. Common Causes of Oil Leakage<br />

5. System Testing/Monitoring<br />

6. 11-Point Checklist<br />

1. Application Information<br />

The most important thing to understand before designing a system<br />

is the application. Is it going to be used for road racing, drag racing or<br />

drifting or maybe it will be primarily a street driven car. The intended use<br />

greatly affects the turbo selection as well as the system components. A<br />

turbo system that works well for a 9 second drag car is most likely not<br />

going to work well for a drift car or road race car.<br />

You need to have a target flywheel horsepower in mind. It will be used<br />

to help design the entire system.<br />

2. Turbo Match<br />

• Visit the Turbo Tech Section of www.TurboBy<strong>Garrett</strong>.com.<br />

• Or use the Turbo Selection sections of this catalog.<br />

• Using formulas in Turbo Selection, calculate mass flow and<br />

pressure ratio (PR) at redline for your specific application.<br />

• Plot mass flow and PR on several compressor maps to<br />

determine the best fit.<br />

• For the example in this presentation, the “application” will<br />

be a 400 flywheel hp street car using pump gas, therefore<br />

the estimated mass flow ~ 40 lbs/min<br />

3. System Components<br />

Air Filter<br />

It is important to appropriately size the air filter for the maximum flow<br />

rate of the application. For our specific example, we are looking for target<br />

face velocity of ≤130 ft/min at redline to minimize restriction so as to<br />

provide the turbo with all the air necessary for it to function optimally.<br />

If the turbo does not have access to the proper amount of air, excessive<br />

restriction can occur and cause:<br />

• Oil leakage from the compressor side piston ring, which<br />

results in oil loss, a fouled CAC and potentially smoke out<br />

of the tailpipe.<br />

• Increased pressure ratio, which can lead to turbo overspeed.<br />

• Overspeed will reduce turbo durability and could result in<br />

an early turbo failure.<br />

Determining the correct air filter size<br />

Example:<br />

Face Velocity = 130 ft/min<br />

Mass Flow = 40 lbs/min<br />

Air density = 0.076 lbs/ft 3<br />

Mass Flow (lbs/min)=Volumetric Flow Rate (CFM) x Air Density (lbs/ft 3 )<br />

Volumetric Flow Rate (CFM) = Mass Flow (lbs/min)<br />

Air Density (lbs/ft 3 )<br />

Volumetric Flow Rate = 526 CFM<br />

**For twin turbo setups, simply divide the flow rate by two.<br />

Face Velocity (ft/min) = Volumetric Flow rate (CFM) / Area (ft 2 )<br />

Area (ft 2 ) = Volumetric Flow rate (CFM) / Face Velocity (ft/min)<br />

Area (ft 2 ) = 526 / 130 = 4.05<br />

Area (in 2 ) = 4.05 x 144<br />

Area = 582 in 2<br />

Now that we know the required surface area that our air filter must have,<br />

we need to determine the correct air filter size using information provided by<br />

the filter manufacturer. We will need to know the following information about<br />

the filters we are considering:<br />

• Pleat height<br />

• Pleat depth<br />

• Number of pleats<br />

Example:<br />

Pleat Height = 9.00 in.<br />

Pleat Depth = 0.55 in.<br />

# of Pleats = 60<br />

Area (in 2 ) = pleat height x pleat depth x # of pleats x 2<br />

Area (in 2 ) = 9.00 x 0.55 x 60 x 2<br />

Area = 594 in 2<br />

Actual Filter Area (594 in 2 ) > Calculated Area (582 in 2 )<br />

Since the actual filter area (594 in 2 ) is greater than the required area, this<br />

air filter will work for our application.<br />

Oil Supply & Drainage<br />

Journal Bearing Turbo<br />

Journal-bearings function similarly to rod or crank bearings in an engine:<br />

oil pressure is required to keep components separated. An oil restrictor is<br />

generally not needed except for oil pressure-induced leakage.<br />

The recommended oil feed for journal bearing turbochargers is -4AN or<br />

hose/tubing with an ID of approximately 0.25”.<br />

Be sure to use an oil filter that meets or exceeds the OEM specifications.<br />

Ball Bearing Turbo<br />

An oil restrictor is recommended for optimal performance with ball bearing<br />

turbochargers. Oil pressure of 40 – 45 psi at maximum engine speed is<br />

recommended to prevent damage to the turbocharger’s internals. In order to<br />

achieve this pressure, a restrictor with a 0.040” orifice will normally suffice,<br />

but you should always verify the oil pressure entering the turbo after the restrictor<br />

in insure that the components are functioning properly.<br />

Recommended oil feed is -3AN or -4AN line or hose/tubing with a similar ID.<br />

As always, use an oil filter that meets or exceeds the OEM specifications.<br />

OIL LEAKAGE SHOULD NOT OCCUR ON A PROPERLY FUNCTION-<br />

ING SYSTEM IF RESTRICTOR IS NOT USED UNLESS THE SYSTEM<br />

PRESSURE IS EXCESSIVELY HIGH.<br />

Oil Drain<br />

In general, the larger the oil drain, the better. However, a -10AN is typically<br />

sufficient for proper oil drainage, but try not to have an inner diameter smaller<br />

than the drain hole in the housing as this will likely cause the oil to back up<br />

in the center housing. Speaking of oil backing up in the center housing, a<br />

gravity feed needs to be just that! The oil outlet should follow the direction of<br />

gravity +/-35° when installed in the vehicle on level ground. If a gravity feed<br />

is not possible, a scavenge pump should be used to insure that oil flows freely<br />

away from the center housing.<br />

Avoid:<br />

• Undulations in the line or extended lengths parallel to the ground<br />

• Draining into oil pan below oil level<br />

• Dead heading into a component behind the oil pan<br />

• Area behind the oil pan (windage tray window) where oil sling<br />

occurs from crankshaft<br />

When installing your turbocharger, insure that the turbocharger axis of rotation<br />

is parallel to the level ground within +/- 15°. This means that the oil<br />

inlet/outlet should be within 15° of being perpendicular to level ground.<br />

Water Lines<br />

Water cooling is a key design feature for improved durability and we recommend<br />

that if your turbo has an allowance for water-cooling, hook up the<br />

water lines. Water cooling eliminates the destructive occurrence of oil coking<br />

by utilizing the Thermal Siphon Effect to reduce the Peak Heat Soak Back<br />

Temperature on the turbine side after shut-down.<br />

In order to get the greatest benefit from your water-cooling system, avoid<br />

undulations in the water lines to maximize the Thermal Siphon Effect.<br />

16 www.TurboBy<strong>Garrett</strong>.com<br />

Honeywell

<strong>Garrett</strong> ®<br />

by Honeywell<br />

Turbo System Optimization<br />

• Available packaging space in the vehicle usually dictates<br />

certain designs<br />

Selecting a Charge Air Cooler (aka intercooler) has been made simple<br />

with www.TurboBy<strong>Garrett</strong>.com ‘s intercooler core page. Each core is rated<br />

for horsepower, making it as easy as matching your desired power target<br />

to the core. In general, use the largest core that will fit within the packaging<br />

constraints of the application.<br />

Negative degrees: water outlet of center housing is lower than water inlet<br />

Positive degrees: water outlet of center housing is higher than water inlet<br />

For our example:<br />

Another important factor in selecting the correct intercooler is the end tank<br />

design. Proper manifold shape is critical in both minimizing charge air pressure<br />

drop and providing uniform flow distribution. Good manifold shapes minimize<br />

losses and provide fairly even flow distribution. The over-the-top design<br />

can starve the top tubes however. The side entry is ideal for both pressure<br />

drop and flow distribution, but it is usually not possible due to vehicle space<br />

limitations.<br />

For best results, set the orientation of the center housing to 20°.<br />

Significant damage to the turbo can occur from improper water line<br />

setups.<br />

Charge Tubing<br />

The duct diameter should be sized with the capability to flow approximately<br />

200 - 300 ft/sec. Selecting a flow diameter less than the calculated<br />

value results in the flow pressure dropping due to the restricted<br />

flow area. If the diameter is instead increased above the calculated<br />

value, the cooling flow expands to fill the larger diameter, which slows<br />

the transient response.<br />

For bends in the tubing, a good design standard is to size the bend<br />

radius such that it is 1.5 times greater than the tubing diameter.<br />

The flow area must be free of restrictive elements such as sharp transitions<br />

in size or configuration.<br />

For our example:<br />

• Tubing Diameter: velocity of 200 – 300 ft/sec is desirable.<br />

Too small a diameter will increase pressure drop.<br />

Too large can slow transient response.<br />

• Velocity (ft/min) = Volumetric Flow rate (CFM) / Area (ft 2 )<br />

Again, for twin turbo setups, divide the flow rate by (2).<br />

Charge tubing design affects the overall performance, so there are<br />

a few points to keep in mind to get the best performance from your<br />

system.<br />

• Duct bend radius:<br />

-Radius/diameter > 1.5<br />

• Flow area:<br />

-Avoid area changes, sharp transitions, shape changes<br />

Proper mounting of the intercooler increases the durability of the system.<br />

Air to air charge air coolers are typically “soft-mounted”, meaning they use<br />

rubber isolation grommets. This type of mounting is also used for the entire<br />

cooling module. The design guards against vibration failure by providing<br />

dampening of vibration loads. It also reduces thermal loads by providing for<br />

thermal expansion.<br />

Benefits of Isolation:<br />

• Guards against vibration by damping loads<br />

• Reduces thermal loading by providing for thermal expansion<br />

Blow Off Valves (BOV)<br />

Using the proper blow off valve (BOV) affects the system performance.<br />

There are two main types to consider.<br />

MAP (Manifold Absolute Pressure) sensor uses either a<br />

vent-to-atmosphere valve or a recirculation valve.<br />

- Connect signal line to manifold source<br />

- Surge can occur if spring rate is too stiff<br />

Honeywell<br />

www.TurboBy<strong>Garrett</strong>.com<br />

17

Turbo System Optimization<br />

<strong>Garrett</strong> ®<br />

by Honeywell<br />

MAF (Mass Air Flow) sensor uses a recirculation (bypass) valve for<br />

best drivability.<br />

- Connect signal line to manifold source<br />

- Position valve close to the turbo outlet for<br />

best performance (if valve can handle<br />

high temp).<br />

- Surge can occur if valve and/or outlet plumbing are restrictive.<br />

Wastegates<br />

Internal wastegates are part of the turbo and integrated<br />

into the turbine housing. Two connection possibilities exist<br />

for signal line. The first is to connect line from compressor<br />

outlet (not manifold - vacuum) to the actuator. The second is<br />

to connect a line from compressor outlet to boost controller<br />

(PWM valve) and then to the actuator.<br />

Manifold pressure is limited by the spring rate of the<br />

actuator.<br />

Most OEM style actuators are not designed for vacuum,<br />

and thus, the diaphragm can be damaged resulting in excessive<br />

manifold pressure and engine damage.<br />

External wastegates are separate from the turbo and<br />

integrated into the exhaust manifold rather than the turbine<br />

housing.<br />

Connection to the manifold greatly affects flow capability,<br />

and correct orientation of the wastegate to the manifold<br />

is essential. For example, placing the wastegate at 90° to<br />

the manifold will reduce flow capacity by up to 50%! This<br />

greatly reduces the control that you have over the system<br />

and puts your entire drivetrain at risk. Instead, the ideal<br />

connection is at 45° with a smooth transition.<br />

There are two connection possibilities for signal line:<br />

• Connect a line from the compressor outlet<br />

(not manifold - vacuum) to the actuator<br />

• Connect a line from the compressor outlet to a boost<br />

controller (PWM valve) and then to the actuator<br />

Again, manifold pressure is limited by spring rate of actuator.<br />

4. Common Causes of Oil Leakage<br />

A properly installed turbo should NOT leak oil.<br />