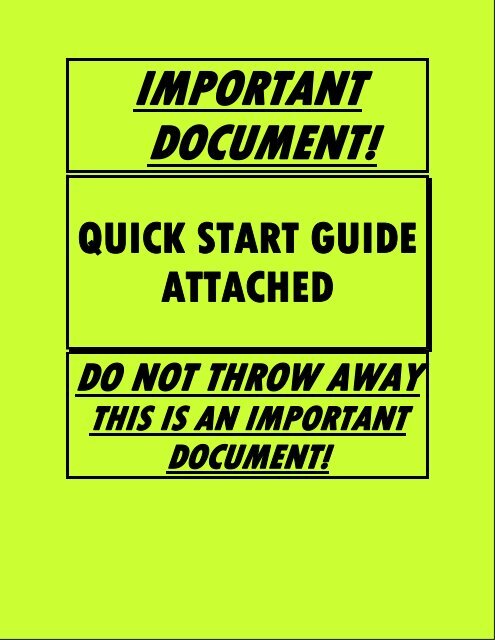

IMPORTANT DOCUMENT!

IMPORTANT DOCUMENT!

IMPORTANT DOCUMENT!

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>IMPORTANT</strong><strong>DOCUMENT</strong>!QUICK START GUIDEATTACHEDDO NOT THROW AWAYTHIS IS AN <strong>IMPORTANT</strong><strong>DOCUMENT</strong>!

COSENG C322 WHEEL BALANCERQUICKSTART GUIDEDo not use anextension cordTABLE OF CONTENTS

PAGE 2:PAGE 3-5:PAGE 6-8:PAGE 9:PAGE 10:BUTTON DIAGRAM/WHEEL DIMENSION GUIDE/FIGURESSETTING UP AUTOMATIC DATA ENTRY FEATURECALIBRATIONCONVERTING GRAMS OUNCESBUTTON REFERENCE

FIGURE 3

SETTING UP AUTOMATIC DATA ENTRYA. BEGIN BY CALIBRATING THE “A” MEASUREMENT (DISTANCE OF RIM FROMTHE MACHINE)1. PRESS AND HOLD THE “STOP” AND “FINE” KEYS AT THE SAME TIME. HOLDUNTIL THE LED’S ON THE DISPLAY READ CAL P.0.2. MOVE THE DISTANCE GAUGE (LOCATEDON THE FRONT RIGHT OF THE WHEELBALANCER) TO THE “0” POSITION.3. PRESS AND HOLD THE “ALU” KEY UNTIL THE LED’S READ CAL P.15.4. MOVE THE DISTANCE GAUGETO THE “15” MARK. HOLD

THE GAUGE IN THIS POSITION.5. PRESS AND HOLD THE “ALU” KEY UNTIL THE LED’S READ 000 000 000.6. RETURN THE DISTANCE GAUGE TO THE NORMAL, REST POSITION. THE “A”MEASUREMENT OF THE AUTOMATIC DATA ENTRY FEATURE IS NOWCALIBRATED.B. NOW CALIBRATE THE “D” MEASUREMENT (DIAMETER OF THE RIM)1. PRESS AND HOLD THE “STOP” AND “OPT” KEYS UNTIL THE LED’S READCAL 14.0.2. MOUNT A BARE 14 OR 15 INCH STEEL WHEEL ON THE BALANCERBEGIN BY SELECTING A CONE WHICH WILL FIT THE CENTER HOLE OFTHE RIM. PLACE THE CONE ON THE SHAFT AND THEN THE WHEEL ON

THE SHAFT SO THAT THE WHEEL IS FIRMLY MOUNTED ON THE SHAFT.(SEE FIGURE 1) FINISH BY ATTACHING THE QUICK NUT TO THE SHAFT.OVERTIGHTING THE QUICK NUT WILL CAUSE DAMAGE3. MANUALLY ENTER THE “D” MEASUREMENT OF THE WHEEL USING THE“D↑” OR “D↓” KEYS.4. MOVE THE DISTANCE GAUGE SO THAT THE TIP TOUCHES THE RIM JUSTUNDER THE EDGE.5. PRESS AND HOLD THE “ALU” KEY UNTIL THE LED’S READ 000 000 0006. RETURN THE DISTANCE GAUGE TO THE NORMAL, REST POSITION. THE “D”MEASUREMENT OF THE AUTOMATIC DATA ENTRY FEATURE IS NOWCALIBRATED.CALIBRATIONA. MOUNT A 14 OR 15 INCH STEEL WHEEL ON THE BALANCERBEGIN BY SELECTING A CONE WHICH WILL FIT THE CENTER HOLE OFTHE RIM. PLACE THE CONE ON THE SHAFT AND THEN THE WHEEL ONTHE SHAFT SO THAT THE WHEEL IS FIRMLY MOUNTED ON THE SHAFT(SEE FIGURE 1). FINISH BY ATTACHING THE QUICK NUT TO THE SHAFT.OVERTIGHTING THE QUICK NUT WILL CAUSE DAMAGE

B. USE THE AUTOMATIC DATA ENTRY FEATURE OR MANUALLY ENTER THEFOLLOWING (REFER TO FIGURE 2):“A” (DISTANCE OF RIM FROM THE MACHINE)“B” (WIDTH OF THE RIM) (THIS MEASUREMENT MUST BE ENTEREDMANUALLY)“D” (DIAMETER OF RIM)ENTER SELF CALIBRATION MODE USING THE FOLLOWING STEPS1. PRESS AND HOLD THE D & C KEYS AT THE SAME TIME. THE LED’S ON THEDISPLAY WILL READ CAL CAL CAL AND WHEN THE LED’S STOP FLASHING,RELEASE THE D & C KEYS.2. CLOSE THE HOOD AND PRESS THE START KEY. (THE MACHINE WILL SPINTHROUGH A COMPLETE CYCLE FOR AROUND 20 SECONDS AND THEN COMETO A COMPLETE STOP.)THE DISPLAY WILL READ ADD 100 OR ADD 350 (100G = 3.5OZ)

3. NEXT, RAISE THE HOOD AND ATTACH THE CALIBRATION WEIGHT, 100GRAM/3.5 OZ., WHICH COMES WITH THE MACHINE TO THE OUTSIDE OF THERIM IN ANY POSITION.4. CLOSE THE HOOD AND PRESS THE START KEY. (THE MACHINE WILL SPINTHROUGH ANOTHER COMPLETE CYCLE FOR AROUND 20 SECONDS AND THENCOME TO A COMPLETE STOP.)THE DISPLAY WILL READ End CALCHECKING THE CALIBRATION1. OPEN THE HOOD2. CLOSE THE HOOD3. PRESS “START”

THE BALANCER WILL SPIN THROUGH A NORMAL BALANCING CYCLE.WHEN THE BALANCER STOPS, IT SHOULD ASK FOR 100G/3.5OZ ATTHE 12 O’CLOCK POSITION ON THE WHEEL, WITH THE CALIBRATION WEIGHTAT THE 6 O’CLOCK POSITION.REMOVE THE CALIBRATION WEIGHT (100 GRAM/3.5 OZ.) AND WHEEL.THE BALANCER IS NOW CALIBRATED AND READY FOR USE.

CONVERTINGGRAMS - OUNCES1. TURN THE WHEEL BALANCER ON AND MOUNT A WHEEL ONTO THEMACHINE. USING THE AUTOMATIC DATA ENTRY FEATURE OR MANUALLYENTER THE FOLLOWING:“A” (DISTANCE OF RIM FROM THE MACHINE),“B” (WIDTH OF THE RIM) (THIS MEASUREMENT MUST BE ENTEREDMANUALLY)“D” (DIAMETER OF RIM)2. CLOSE THE HOOD AND THE MACHINE WILL SPIN THROUGH A CYCLE ANDCOME TO A COMPLETE STOP. OPEN THE HOOD AND THE DISPLAY WILL SHOWTHE WEIGHT REQUIRED IN THE LED SCREEN.3. THE FIRST TIME THIS IS DONE THE WEIGHT READING WILL BE IN GRAMS. TOCONVERT TO OUNCES:PUSH AND HOLD: THE “STOP” KEY AND BOTH THE “A” AND “A”MEASUREMENT KEY.THE KEYS MUST BE PUSHED SIMULTANEOUSLY.4. YOU WILL KNOW THE WEIGHT SCALE HAS BEEN CHANGED TO OUNCES BY ADECIMAL POINT APPEARING IN THE LEDUNTIL THE BALANCER IS UNPLUGGED, IT WILL REMAIN IN EITHER GRAMS OROUNCES, DEPENDING ON YOUR PREFERENCE.BUTTON REFERENCE

Allows the user to switch between Dynamic and Static balancingmodes.The balancer automatically rounds off the imbalance value tothe nearest quarter ounce. This button allows the user to seethe ACTUAL imbalance value of the wheel.The balancer is capable of isolating the heavy and light spots ofthe wheel/tire. Use this feature when the balancer is asking formore weight than you think the wheel should need. The balancerwill instruct you on where to mark the tire and then the rim. Youthen will remove the wheel/tire assembly from the balancer, letout the air, and loosen the bead.Match up the mark that you made on the tire with the markon the rim; now air up the tire and place the assembly back on themachine and run through a cycle. The amount of weight thebalancer asks for should be considerably less than before.Allows you to scroll through the different alloy balancingoptions. You can use the more commonly used clip-on weights, orif you would like the weight to be hidden, you can opt to useadhesive weights. Use the ALU key to scroll through thedifferent options and choose the one that best suits your needs.Pressing this key after a cycle has been completed will allowyou to change previously entered dimensions and the balancerwill re-calculate the weight reading without the need to runanother cycle.Pressing this key by itself will run a diagnostic on the displayled’s, lighting each one up individually to show they are working.Also used in conjunction with the “c” key to enter calibrationmode.This button changes the “b” (width of rim) and the “d” (diameter ofrim) measurements from inches to millimeters.