GENEVA ENERGY - Stuart B. Millner & Associates

GENEVA ENERGY - Stuart B. Millner & Associates

GENEVA ENERGY - Stuart B. Millner & Associates

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

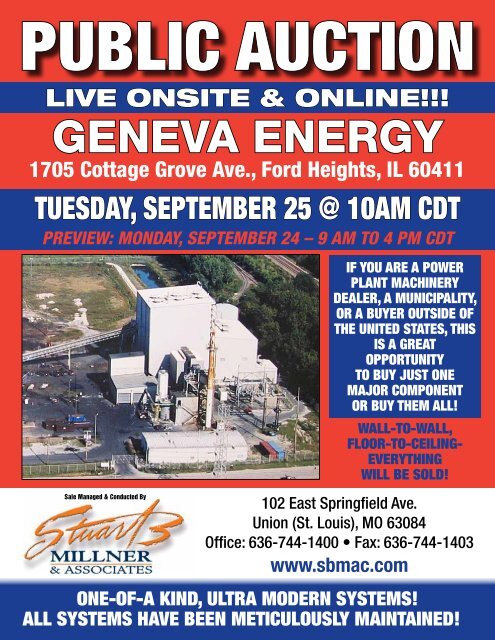

LIVE ONSITE & ONLINE!!!<br />

Geneva Energy<br />

1705 Cottage Grove Ave., Ford Heights, IL 60411<br />

TUESDAY, SEPTEMBER 25 @ 10AM CDT<br />

Preview: MONDAY, SEPTEMBER 24 – 9 am to 4 pm CDT<br />

Sale Managed & Conducted By<br />

IF YOU ARE A POWER<br />

PLANT MACHINERY<br />

DEALER, A MUNICIPALITY,<br />

OR A BUYER OUTSIDE OF<br />

THE UNITED STATES, THIS<br />

IS A GREAT<br />

OPPORTUNITY<br />

TO BUY JUST ONE<br />

MAJOR COMPONENT<br />

OR BUY THEM ALL!<br />

WALL-TO-WALL,<br />

FLOOR-TO-CEILING-<br />

EVERYTHING<br />

WILL BE SOLD!<br />

ONE-OF-A KIND, ULTRA MODERN SYSTEMS!<br />

ALL SYSTEMS HAVE BEEN METICULOUSLY MAINTAINED!

BUY ONE COMPONENT … OR BUY THEM ALL!!<br />

IMPORTANT INFORMATION FOR THE BUYER:<br />

• <strong>Stuart</strong> B. <strong>Millner</strong> & <strong>Associates</strong> (“SBMA”) has been<br />

chosen to conduct, manage and sell the assets at<br />

the <strong>GENEVA</strong> POWER PLANT in Ford Heights, IL.<br />

• The replacement cost of this plant when built in<br />

1996 was $110 million.<br />

• The auction will consist of the MAJOR<br />

COMPONENTS described on the following pages,<br />

PLUS all additional surplus equipment.<br />

• This 22 MW tire-fired power plant was<br />

commissioned in 1996 and shut down in late 2011.<br />

• The current steam turbine-generator system was<br />

installed in 2008.<br />

• The Zurn boiler was designed to burn shredded<br />

tires, but can also be fueled by natural gas or other<br />

solid fuels, including biomass.<br />

• This auction will allow you to buy only ONE<br />

component, or you can buy them ALL … whatever<br />

best suits your needs.<br />

• ALL major components described on the following<br />

pages can be removed and re-installed at your<br />

facility.<br />

TABLE OF CONTENTS<br />

• This plant is state-of-the-art and has been<br />

meticulously maintained.<br />

• All drawings, engineering specifications,<br />

foundation plans, spare parts, files, etc. are<br />

available for every component.<br />

• The equipment has been CERTIFIED not to contain<br />

any hazardous materials.<br />

• Due to the nature of the equipment being sold,<br />

SBMA is allowing for an extended time-frame for<br />

removal of the assets. SBMA has solicited quotes<br />

for the dismantling and loading of every major<br />

component being offered. You can take advantage<br />

of these quotes, or you can solicit your own.<br />

If you have any questions, please do not hesitate<br />

to contact Bob Findeiss at 866-842-5280, or via<br />

e-mail at bfindeiss@sbmac.com. You can also<br />

visit www.sbmac.com for complete information,<br />

photos, and detailed specifications.<br />

COMPONENT DESCRIPTION<br />

PAGE NUMBER<br />

Shin Nippon 22,000 KW Steam Turbine .............................3<br />

Electric Machinery Co. 13,800 Volt Generator ...................3<br />

Zurn Boiler...........................................................................4<br />

NOx Reduction System........................................................4<br />

Graham Condenser..............................................................4<br />

(4) Byron Jackson Condensate Pumps...............................5<br />

(2) Sulzer Feed Pumps.........................................................5<br />

Zurn Flue Gas Scrubber.......................................................6<br />

Foxboro DCS........................................................................7<br />

Switchgear/Circuit Breakers...............................................7<br />

COMPONENT DESCRIPTION<br />

PAGE NUMBER<br />

(4) Transformers..................................................................7<br />

PLC’s....................................................................................7<br />

CEM System.........................................................................8<br />

Struthers Ind. Feed Water Heater........................................8<br />

Deaerator & Storage Tank...................................................8<br />

Bag House............................................................................9<br />

Cooling Tower................................................................... 10<br />

Support/Miscellaneous Equipment............................10-11<br />

Cummins Back-Up Generators......................................... 11<br />

2<br />

ONE-OF-A-KIND, ULTRA MODERN SYSTEMS!

LOG ON TO WWW.SBMAC.COM FOR COMPLETE SPECIFICATIONS AND PHOTOS<br />

22,000 KW STEAM TURBINE<br />

Shin Nippon Mdl. C10-R13 22,000 KW Turbine: 13 Stages; (2) Extraction Points, (1)<br />

Controlled, (1) Uncontrolled; 17,000 lbs./hr. Steam Flow; 949.8 psig Main Steam Pressure;<br />

900 Deg. F Main Steam Temp.; 3600 RPM; Woodward 502 Speed Control System; Bently<br />

Nevada Vibration Monitoring System<br />

13,800 VOLT GENERATOR<br />

Electric Machinery Co.<br />

13,800 Volt Generator: S/N<br />

100102601; Water Cooled; (2)<br />

Poles; 60 Hz; 969 @ 23,158<br />

Kva Current; 3600 RPM<br />

Lube Oil System: (2) 100% Main Pumps; 100% DC<br />

Emergency Lube Oil Pump; Main and Spare Lube Oil<br />

Coolers; Main and Spare Lube Oil Filters; 1,450 Gal. Lube<br />

Oil Reservoir; Oil Purification Unit<br />

ALL COMPONENTS HAVE BEEN METICULOUSLY MAINTAINED<br />

3

WALL-TO-WALL, FLOOR-TO-CEILING …<br />

ZURN BOILER<br />

NOx Reduction System:<br />

Nalco/Fueltech Designed<br />

Injection System Comprised<br />

of: 6,000 Gal. Storage Tank<br />

and Circulating Module; Mixing<br />

and Metering Module; (3)<br />

Distribution Modules Sufficient<br />

to Supply (18) Injection Nozzles<br />

NOx REDUCTION SYSTEM<br />

Zurn/Standard Kessel/Lambion Boiler: 170,219 lb./hr. Main Steam<br />

Flow; 1450 psig Design Pressure; 1170 psig Main Steam Pressure;<br />

952 Deg. F Main Steam Temp.; Heating Surface Area: Boiler-13,832<br />

sq. ft.; Water Walls-14,025 sq. ft.; Primary Super Heater-11,154<br />

sq. ft.; Secondary Super Heater-5,280 sq. ft.; Screen-1,685 sq. ft.;<br />

Economizer-3,800 sq. ft.; Material: Boiler-SA-178 Gr. C; Water Walls-<br />

SA-178 Gr. C; Primary Super Heater: SA-213 Gr. T11; Secondary Super<br />

Heater: SA-213 Gr. T22; Screen-SA-178 Gr. C; Economizer-3,800 sq. ft.;<br />

Tube Dia./Wall Thickness: Boiler-2.50 x .150; Water Walls- 3.00 x .180;<br />

Primary Super Heater-1.75 x .22/.18; Secondary Super Heater-1.75 x<br />

.15; Screen-2.50 x .150; Economizer-2.00 x .150<br />

BUY 1 COMPONENT…. BUY 2 COMPONENTS… BUY THEM ALL! BUY AS MANY AS YOU NEED!<br />

GRAHAM CONDENSER<br />

Graham Mdl. 78104/24.00 Condenser: 129 MMBTU/hr.; 21.017 sq. ft.; (2)<br />

Cooling Water Passes; (1) Shell; Perpendicular; 90/10 Copper/Nickel Tube<br />

Material 1st and 2nd Pass; 20 BWG Gauge Tube Wall Thickness; ¾” Tube<br />

Dia.; 4,460 Copper Nickel Tubes; 24’ Tube Length; 20 Gauge<br />

4<br />

EVERYTHING WILL BE SOLD!

ALL COMPONENTS CAN BE REMOVED AND RE-INSTALLED AT YOUR FACILITY!<br />

(4) BYRON JACKSON CONDENSATE PUMPS<br />

(2) Byron Jackson Mdl. 700VLT Condensate<br />

Pumps: S/N’s 94WS0007 and 94WS0008; 100%<br />

Cap.; (4) Stages; 305 gpm Design Flow; 310’ Design<br />

Total Dynamic Head; 40-HP, 460 Volt Motor;<br />

3550 RPM Design Speed; One Installed, One<br />

Spare<br />

(2) Byron Jackson Mdl.<br />

1000VLT Condensate<br />

Pumps: S/N’s 901W0010 and<br />

901W0011; 100% Cap.; (9)<br />

Stages; 529 gpm Design Flow;<br />

410’ Design Total Dynamic<br />

Head; 75-HP, 460 Volt Motor;<br />

1770 RPM Design Speed; One<br />

Installed, One Spare<br />

BUY 1 COMPONENT…. BUY 2 COMPONENTS… BUY THEM ALL!<br />

BUY AS MANY AS YOU NEED!<br />

(2) SULZER FEED PUMPS<br />

(2) Sulzer Mdl. 3X6X9EMSD2 Feed Pumps: S/N’s 1E347 and 1E348; 100% Cap.; (1) 10-Stage; (1) 8-Stage;<br />

Siemens Pump Drive: 600-HP; 4,160 Volt; 3600 RPM; Design Flow: 357 gpm-10 Stage; 350 gpm-8 Stage;<br />

Design Total Dynamic Head: 4,100’ for 10 Stage; 2,900’ for 8 Stage; 240 Deg. F Design Temp; 3600 RPM;<br />

Siemens Mdl. CG11 600-HP Motors; S/N 183471A and 183471B; 4,160 Volt<br />

ALL COMPONENTS HAVE BEEN METICULOUSLY MAINTAINED<br />

5

BUY ONE COMPONENT … OR BUY THEM ALL!!<br />

ZURN FLUE GAS SCRUBBER<br />

Designed by Zurn Air Systems and Modified in 2009 by BACT Process Systems, Inc. The Scrubber is Designed for a Max. Gas Flow<br />

of 98,965 ACFM and an SO2 Removal Efficiency of Greater than 90%, Utilizing a Lime Slurry Recycle Rate of 5,000 gpm Through (42)<br />

Nozzles Spraying Countercurrent to Flue Gas Flow. The Absorbed SO2 is Converted to Calcium Sulfate (Gypsum) in (2) Reaction Tanks<br />

Included in the Recycle Loop. Product Gypsum is Removed Utilizing a Continuous Feed 1’ x 3’ Rotary Vacuum Filter. Other Equipment<br />

Included: 1) (3) Gallagher Recycle Pumps; 1,980 gpm Driven by 100-HP, 460 Volt, 1,775 RPM Motors; 2) (2) Wallinga 180 CFM Air<br />

Blowers w/15-HP, 460 Volt, 1760 RPM Motors; 3) Lightning Mixers on Each of the (2) Reaction Tanks; 4) Clarage ID Fan 356,500 lb./hr.<br />

Driven by 800-HP, 4,160 Volt, 1160 RPM Motor; 5) (2) 300 gpm @ 147’ Vertiflo Mdl. 1326 Water Pumps w/25-HP, 460 Volt, 1800 RPM<br />

Motors; 6) Allen-Bradley Panel View and PLC Control System<br />

6 ALL COMPONENTS CAN BE REMOVED AND RE-INSTALLED AT YOUR FACILITY!

ALL COMPONENTS HAVE BEEN CERTIFIED NOT TO CONTAIN<br />

ANY HAZARDOUS MATERIALS<br />

STATE-OF-THE-ART FOXBORO DCS<br />

Foxboro I/A Series Modules: IPMS Power Module (44) ea.; FBM2 Thermocouple Input (15) ea.; IO-ISO ½ Y Field Bus Isolator (20)<br />

ea.; FBM 3A RTD Input (3) ea.; FBM 4//39/44 O-20 mA Input/Output (18) ea.; FBM1/42 O-20 mA Input Interface (14) ea.; FBM9C, 14C<br />

Contract/DC Input/Output (5) ea.; FBM 7B/12B Contract/DC Input (26) ea.; FBM 10/15 120 Volt AC Input/Output (53) ea.<br />

SWITCHGEAR / CIRCUIT BREAKER<br />

Switchgear/Circuit Breaker: Series P-51000 Powl-Vac – 13,800 Volt Metal Clad Switchgear/Vacuum Breakers; Series P-51000 Powl-<br />

Vac – 4,160 Volt Metal Clad Switchgear/Vacuum Breakers; Sub Station Circuit Breaker GE/Hitachi – 145,000 Volt; S/N H145A2109-201<br />

BUY 1 COMPONENT…. BUY 2 COMPONENTS… BUY THEM ALL! BUY AS MANY AS YOU NEED!<br />

(4) TRANSFORMERS<br />

(12) Allen Bradley PLC’s: Scrubber – Allen Bradley Compact<br />

Logix L32E CPU w/(2) AC Output, (2) AC Input, (2) Analog Input,<br />

and (2) Analog Output Cards and Panel View Plus 700<br />

Interface; Allen Bradley SIC 5/01 CPU – (4) Input, (5) Output<br />

Isolated, (1) Output Relay, Bag House; SLC 5/03 CPU – Scanner,<br />

Output/Input Relay; Output/Input Analog; DCS Room<br />

(12) ALLEN-BRADLEY PLC’S<br />

#1 – Delta Star, Inc. Transformer: S/N<br />

E77450295; 138,000 – 13,800 Volts; 14<br />

KVA Rating; 3,825 Gal. Oil Cap.<br />

#2 – Square D Transformer: S/N 940748.A;<br />

13,800 – 4,160 Volts; 375/5,250 KVA Rating;<br />

740 Gal. Oil Cap.<br />

#3 & #4 – Square D Transformers: S/N’s<br />

940748.B and 940748.c; 4,160 – 480 Volts;<br />

1500 KVA Rating; 470 Gal. Oil Cap.<br />

LOG ON TO WWW.SBMAC.COM FOR COMPLETE SPECIFICATIONS AND PHOTOS<br />

7

ONE-OF-A-KIND, ULTRA MODERN SYSTEMS!<br />

COMPLETE CEM SYSTEM - UPGRADED<br />

BUY 1 COMPONENT…. BUY 2 COMPONENTS… BUY THEM ALL!<br />

BUY AS MANY AS YOU NEED!<br />

STRUTHERS IND. FEED<br />

WATER HEATER<br />

CEM System Components: Teledyne Ultraflow 150 Flow/<br />

Temp. Monitor – Measures Flue Gas Velocity & Temp.;<br />

Thermo Electron Mdl. 42C NO-NO2-Nox Monitor – Utilizes<br />

Chemiluminescence Technology to Measure Nox, No. 2;<br />

Thermo Mdl.42 ID Nox Monitor – Utilizes Chemiluminescence<br />

Technology to Measure Nox in the Sub ppb Levels up to 100<br />

ppm; Thermo Electron Mdl. 431 SO2 Monitor – Utilizes Pulsed<br />

Fluorescence Technology to Measure Low Concentrations of<br />

SO2; Sick Maihak Mdl. MCS100E – Continuous Measurement<br />

of NH3, CO, NO, SO2, NO2, CO2 & H2O; Environmental Systems<br />

Co. Data System Controller – Collects Data from Monitors<br />

and Provides it to the ESC Mdl. 8832; Heated 100’ Umbilical<br />

Cord – Used for Extracting Flue Gas Sample from Stack to<br />

Monitors; Air Conditioned CEM 8’ x 10” Monitor Shelter –<br />

Used to House Monitors in Required Temperature Conditions;<br />

Durag D-R290AW Opacity Monitor – Measures Opacity of Flue<br />

Gas as it Leaves the Bag House<br />

DEAERATOR &<br />

STORAGE TANK<br />

Struthers Ind. Feed Water Heater: Shell & Tube – U-Tube;<br />

Manual Condensate By-Pass; 5/8” Tube Dia.; 0.409” Tube<br />

Wall Thickness; WSSA688-304 Tube Material; 2000 psi<br />

Tube Design Pressure; 918 sq. ft.; Shell Dimensions 22” x<br />

365”; Shell Material A-106-B; 250 & Vac psi Shell Design<br />

Pressure<br />

Crane-Cochrane Environmental Systems Mdl.<br />

D-60 Counterflow Deaerator & Storage Tank:<br />

Spray Type w/Horiz. Storage Vessel; 170,540 lb. /<br />

hr. Cap.<br />

8<br />

ALL COMPONENTS HAVE BEEN METICULOUSLY MAINTAINED

WALL-TO-WALL, FLOOR-TO-CEILING …<br />

(8) COMPARTMENT BAG HOUSE<br />

50’ Long x 34’5” Wide x 39-1/2’ Tall; WMW<br />

Meyers & Sons Airlock w/Vibco Vibrators;<br />

Screw Type Conveyors, (2) 23’ and (2) 25’; Falk<br />

Gear Boxes; External Surfaces Isolated; (165)<br />

Bags per Compartment; Bags are 318” Long;<br />

(3) Ash Tech Drag Chain Conveyors<br />

EVERYTHING WILL BE SOLD!<br />

9

ONE-OF-A-KIND, ULTRA MODERN SYSTEMS!<br />

COOLING TOWER<br />

Cooling Tower: (2) Cell; 2-Speed Reversing<br />

Fan Motors: 200/50-HP, 460 Volt, 1783/893<br />

RPM; (2) Gould Mdl. 3196 Make Up Pumps:<br />

450 gpm w/15-HP, 460 Volt, 1750 RPM Motors;<br />

(3) Ingersoll Rand/Dresser Mdl. 21RSM 50%<br />

Circulating Pumps: 1-Stage 91.5” Column,<br />

9,500 gpm w/200-HP, 460 Volt, 1190 RPM<br />

Vertical Motors<br />

BUY 1 COMPONENT…. BUY 2 COMPONENTS… BUY THEM ALL! BUY AS MANY AS YOU NEED!<br />

MAN LIFT<br />

-JLG 35 Electric Man Lift (2000)<br />

HEAT EXCHANGERS<br />

-(2) Alfa Laval Heat Exchangers: S/N’s 3010-<br />

1-9660 and 3010-1-96601 (New 1995); Max.<br />

Allowable Working Pressure 125 PSI @ -5-150<br />

Deg. F; Cap. 93.66 US Gal.; (2) Gould Mdl. 3196D<br />

950 GPM Closed Cooling Pumps; 1800 rpm<br />

AIR COMPRESSORS<br />

-Atlas Copco Mdl. GA55 Air Compressor: S/N<br />

ALL-473356 (2001); Max Final Pressure 132<br />

psi; Free Air 313 cfm; 75-HP Cap.; 3600 rpm<br />

Siemens Motor; 460 Volt, 3 Phase<br />

-Atlas Mdl. GA55W Air Compressor: New in<br />

1994; 220 psi<br />

WASTE WATER TREATMENT SYSTEM<br />

-Kisco Water Treatment System: Clarifier<br />

Tank; Fluctuator Tank; (2) Other Tanks w/Agitators;<br />

Hoffland Filer Press; Approx. 6’ Long; (28)<br />

Filters<br />

FILTER PRESSES<br />

-Hoesch Filter Press: 59” x 59” Filters; Overall<br />

Machine Approx. 73.5” x 27’; (78) Filters<br />

10 LOG ON TO WWW.SBMAC.COM FOR COMPLETE SPECIFICATIONS AND PHOTOS

ALL COMPONENTS HAVE BEEN METICULOUSLY MAINTAINED<br />

CUMMINS BACK-UP GENERATORS<br />

Technical Data<br />

Example Data Gen #2 Gen #1 - (Same as #2 exc as listed)<br />

Genset Model 1000GF 1000 DFJD<br />

Prime power 1000kw 900 kw<br />

Standby power<br />

1000 kw<br />

Rated Voltage 400/230V 4,160 v<br />

Frequency 60HZ 60HZ<br />

Power Factor 0.8(lagging) don’t have<br />

Dimension(L×W×H)(mm) 4500×1900×2450 90”X74.56”X98.73”h<br />

Genset weight (kg) 9350 19,760 lb wet<br />

Diesel Engine<br />

Brand Cummins Cummins<br />

Model KTA38-G9A KTA 38-G4 KTA 38-G5<br />

Date of Mfg<br />

Dec-94 Dec-00<br />

Number of Cylinders 12 12<br />

Rotating Speed 1500RPM 1800 RPM<br />

Cylinder Arrangement 60°Vee form 60°Vee<br />

Cylinder Block<br />

Cast iron w/ replaceable wet liners<br />

Cycle Four stroke Four stroke<br />

Aspiration Turbocharged after Turbocharged after<br />

water-cooled<br />

water-cooled<br />

Bore×Stroke(mm) 159×159 6.25” X 6.25”<br />

Displacement(L) 37.8 2,300 cu in<br />

Compression Ratio 13.9:1 13.9:2<br />

Speed Governor Electrical Electronic<br />

Cooling System Water-cooled Water-cooled<br />

Speed Stability(%) ≤5% ≤5%<br />

Total Lubrication System<br />

capacity(L) 135 139 US quarts<br />

Fuel Consumption at<br />

100% load 201.8g/kw.h 70.1 gph @ 1,000kW output<br />

Starting Method<br />

DC24V Electrical starting DC24V Electrical starting<br />

Alternator<br />

Brand Engga Onan<br />

Model EG400L-900N MV734WEI<br />

Number of phase 3 3<br />

Connecting Type 3 phase and 4 wires 4 phase and 4 wires<br />

Number of Bearing 1 1<br />

Protection Grade IP23 don’t have<br />

Altitude ≤1000m ≤5,700 ft @ 104 deg ambient temp<br />

Exciter Type Brushless,Self-excting, Brushless,Self-excting,<br />

AVR automatic voltage AVR automatic voltage<br />

regulating<br />

regulating<br />

Insulation Class H H<br />

Telephone Influence Factor(TIF) ≤50<br />

don’t have<br />

THF ≤2% don’t have<br />

Voltage Regulation,Steady State ≤±1%<br />

don’t have<br />

Transient State Voltage ≤-15%~+20% don’t have<br />

The components of the genset<br />

(1) Cummins Diesel (1) Cummins Diesel Engine<br />

Engine (2)Engga (2) Onan Alternator<br />

Alternator<br />

(3) Engine Control Panel<br />

(3)Control Panel<br />

(4) Generator Control Panel<br />

Engine Control Panel<br />

The control panel is AMF<br />

The engine control panel<br />

control panel,with the<br />

provides readouts for engine<br />

display of voltage, current,<br />

temperature, oil pressure, DC voltage<br />

frequency, water temperature, and engine run hours. Included<br />

oil pressure, The genset with is a 12-light monitor that monitors<br />

low oil pressure, high water engine conditions and alarms<br />

temperature, over speed, over non-normal conditions.<br />

load protection function.<br />

Generator Control Panel<br />

The control panel consists of one free-standing, three section enclosure for the control of two<br />

1000 kW diesel driven generators. The system includes Woodward governors and synchronizers<br />

and a GE Fanuc PLC. The generators can be manually started and paralleled to the 4,160v bus, or<br />

automatically started from a remote contact closure. The generator control panels contain all the<br />

required metering, governoring and voltage regulation necessary for automatic synchronizing and<br />

paralleling, and for standby<br />

emergency operation.<br />

BUY 1 COMPONENT…. BUY 2 COMPONENTS… BUY THEM ALL! BUY AS MANY AS YOU NEED!<br />

TANKS<br />

-(3) Stainless Steel Storage Tanks<br />

-GPI Fiberglass Tank: S/N 00-6535; 96” x 155”<br />

Sidewall; Wind Load 80 MPH; Veil Type C/Glass;<br />

Seismic Zone 1; Water Only<br />

-400 Gal. Air Receiver Tank: Rated 150 psig<br />

@ 600 Deg. F<br />

-Steel Demineralized Water Tank<br />

-(2) 4,500 Gal. Poly Tanks<br />

-750 Gal. Fiberglass Tank<br />

-(2) Pyro 600 Gal. Diesel Tanks<br />

-12’ Tall Plastic Tank<br />

SOOT BLOWER SYSTEM<br />

-Furnace Soot Blower System: (4) Types of<br />

Soot Blowers in the system: Rotary (D5-E),<br />

Wall Deslaggers (RW-7E), Combustion Retractable<br />

(T-30MKIE); Retractable/Wall blower<br />

(T-20E); (21) Wall Deslaggers; (28) Retractable<br />

(Combustion and Wall Blower Combined); (15)<br />

Rotary<br />

FIRE SUPPRESSION SYSTEM<br />

-Fire Suppression System<br />

CONVEYOR<br />

-Large Qty. Misc. Conveyor<br />

ELECTRICAL<br />

-MCC Switch Gear<br />

-(3) Section Nema Control Panel<br />

-Manes 50 KVA Power Unit<br />

PUMPS<br />

-Franklin 2-HP Pump<br />

-(2) Marathon 1/3-HP Pumps<br />

MISCELLANEOUS<br />

-600-HP Motors *Various Pumps w/Motors<br />

* Lockers * Laboratory Equipment * Scales<br />

* PVC Piping * Fire Jockey Pumps * PLUS<br />

MUCH, MUCH MORE!<br />

ALL COMPONENTS CAN BE REMOVED AND RE-INSTALLED AT YOUR FACILITY!11

102 East Springfield Ave.<br />

Union (St. Louis), MO 63084<br />

Office: 636-744-1400 • Fax: 636-744-1403<br />

www.sbmac.com<br />

Questions? Call 866-842-5280<br />

<strong>Stuart</strong> B. <strong>Millner</strong> IL License #: 41.0000336<br />

Watson Road Holding Corp. IL License #:<br />

444.000272<br />

VISIT OUR WEBSITE FOR MORE<br />

DETAILED SPECIFICATIONS, AND TO<br />

VIEW ALL OUR UPCOMING EVENTS!<br />

www.sbmac.com<br />

AUCTION TERMS AND CONDITIONS:<br />

1. PAYMENT TERMS:<br />

a. REGISTRATION DEPOSIT REQUIRED: ***Prior to Auction, each Bidder<br />

must provide a Registration Deposit equivalent to 25% of estimated<br />

bid total or a minimum of $500, whichever is greater. *** Registration<br />

Deposits may be delivered via cash, wire transfer, pay pal,<br />

(Reference auction name, date and buyer#), cashier’s check, or<br />

company check accompanied by a Bank Letter of Guarantee valid<br />

for 30 days. ***<br />

b. No Person shall be permitted to bid without providing the required<br />

$500 minimum Registration Deposit.<br />

(Qualified Platinum Elite Members are excluded from this requirement).<br />

c. Balance of Bidder’s invoice may be paid by cash, cashier’s check,<br />

wire transfer, or company check. All checks must be accompanied<br />

by a letter from the payer’s bank guaranteeing unqualified payment<br />

to STUART B. MILLNER & ASSOCIATES (hereinafter “SBMA”).<br />

(A $25.00 fee shall be assessed to Buyer for all returned checks).<br />

d. Payment is due in full upon receipt of invoice. If payment is not received<br />

within 24 hours of the conclusion of the auction, Buyer’s invoice<br />

will be voided, and all items will be forfeited with NO REFUND<br />

of deposit or payment. All legal fees, collection fees and any other<br />

charges arising from nonpayment will be paid by the Buyer.<br />

e. All methods of payment shall be made payable to STUART B. MILLNER<br />

& ASSOCIATES.<br />

f. Wire-transfer instructions are available at the registration desk or by<br />

calling the SBMA office at 636-744-1400.<br />

g. No purchases may be removed until complete settlement is made<br />

with cleared funds. Buyer is responsible for the complete removal<br />

of Buyer’s purchase(s).<br />

h. Each buyer shall be responsible for payment of any city, county and/<br />

or state sales tax that may apply.<br />

i. Buyer is entirely responsible for any customs or duty issues and/or<br />

payments<br />

j. A 15% Buyer Premium applies to all sales. An 18% Buyers Premium<br />

applies to all online sales.<br />

2. CONDITIONS OF SALE:<br />

a. All items up for auction will be sold to the highest bidder in accordance<br />

with the Auctioneer’s Customary Terms of Sale.<br />

b. If an item shall become non-deliverable for any reason, SBMA shall<br />

not, in any event, be liable for non-delivery, or for any other matter<br />

or thing, to any Buyer of any lot, other than for the return to the<br />

Buyer of monies actually paid to SBMA for said lot, should the Buyer<br />

be entitled thereto.<br />

c. SBMA expressly reserves the right to determine the manner of conducting<br />

the auction and to sell items by individual or group lots, as<br />

it may deem appropriate.<br />

d. The Auctioneer and Seller disclaim all warranties, expressed or implied,<br />

about the merchantability of the items and their fitness for a<br />

particular purpose.<br />

e. SBMA assumes no liability for error, omissions, accurate weights or<br />

measures, additions and/or deletions in this brochure or auction/lot<br />

book and all assets are Sold “As Is, Where Is.” Items offered may or<br />

may not be sold as described and/or photographed in this brochure.<br />

f. Buyer/rigger is responsible for all waste/oil/substance in the removal<br />

of assets, along with all spills that may occur during the removal<br />

process.<br />

g. All sales are made “As Is, Where Is” and Buyer acknowledges having<br />

inspected the property and to be satisfied with same prior to<br />

bidding.<br />

h. All sales are FINAL.<br />

i. The Certificate of Insurance is required to use motorized equipment or<br />

torching equipment on premises for lot removal.<br />

j. Buyer/rigger MUST bring a copy of its liability insurance to the premises<br />

(onsite) and fax a copy to the offices of SBMA. The insurance<br />

certificate must list SBMA and Seller as additional insureds.<br />

k. All items MUST be paid and picked-up by the last checkout date or<br />

they will be forfeited with no refund of deposit or payment, unless<br />

special arrangements have been made.<br />

l. <strong>Stuart</strong> B. <strong>Millner</strong> & <strong>Associates</strong> shall not be responsible for any property<br />

or bodily damages, howsoever caused, arising from the pickup<br />

or transport of the property, and all risks relating thereto are fully<br />

assumed by Buyer to the complete exoneration of SBMA. Buyer/rigger<br />

waives any and all claim it may have for any damages, including<br />

actual and punitive, whether caused by negligence, willful misconduct<br />

or otherwise, and assumes all risk related to the removal of<br />

its purchases.<br />

m. Buyer will comply with all United States of America Export Administration<br />

Regulations, the Export Administration Act or any order, license,<br />

License Exception, or other authorization issued there under.<br />

n. For all lots sold as scrap, weight will be estimated until actual weight<br />

is determined during checkout. Once actual weight is confirmed,<br />

Buyer will pay the balance due, if any, or Buyer will be issued a<br />

refund, if due.<br />

DRIVING DIRECTIONS:<br />

From: Chicago, O’Hare International Airport:<br />

To: 1705 Cottage Grove Ave., Ford Heights, IL 60411<br />

Start out going south on Bessie Coleman Dr. Merge onto<br />

I-190 E toward I-90/I-294/Chicago. Merge onto I-294<br />

S via Exit 1D toward Indiana (portions toll). Take I-294<br />

S (portions toll). Merge onto IL-394 S/Bishop Ford Fwy<br />

toward Danville. Merge onto US-30W/E 14th St/E Lincoln<br />

Hwy. Turn left onto Cottage Grove Ave. 1705 Cottage Grove<br />

Ave. will be on your left. Enter through second gate.<br />

From: Chicago Midway Airport:<br />

Start out going south on S Cicero Ave/IL-50 S toward W<br />

59th St. Continue to follow IL-50 S. Turn left onto W 127th<br />

St./IL-83. Continue to follow W 127th St. Merge onto I-294<br />

S toward Indiana (portions toll). Merge onto IL-394 S/<br />

Bishop Ford Fwy toward Danville. Merge onto US-30 W/E<br />

14th St./E Lincoln Hwy. Turn left onto Cottage Grove Ave.<br />

1705 Cottage Grove Ave. will be on your left. Enter through<br />

second gate.<br />

acCoMmodations:<br />

Red Roof Inn Chicago-Lansing<br />

866-264-5744<br />

Comfort Suites of Lansing<br />

866-272-4856<br />

Sale Managed & Conducted By<br />

Can’t attend the auction? Bid online at www.sbmac.com<br />

Questions? Call 866-842-5280<br />

12<br />

ALL COMPONENTS HAVE BEEN METICULOUSLY MAINTAINED