Robert Bosch (France) S.A.S – Rodez plant - EFQM

Robert Bosch (France) S.A.S – Rodez plant - EFQM

Robert Bosch (France) S.A.S – Rodez plant - EFQM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Robert</strong> <strong>Bosch</strong> (<strong>France</strong>) S.A.S <strong>–</strong> <strong>Rodez</strong> <strong>plant</strong><br />

PRIZE WINNER IN CONTINUOUS LEARNING, INNOVATION & IMPROVEMENT<br />

ORGANISATION PROFILE<br />

� Country: <strong>France</strong><br />

� Number of employees: 2000<br />

� Turnover: 260 000 000 Euro<br />

� Sector: Automotive supplier <strong>–</strong> Fabricated metal products<br />

� Track record in Awards:<br />

� Recognised for Excellence 2007 +500 points<br />

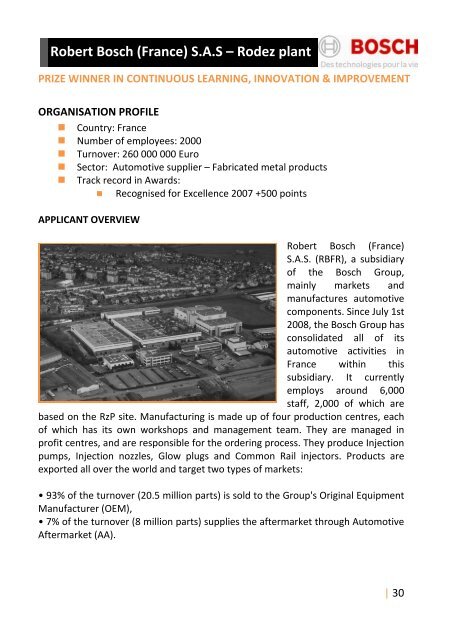

APPLICANT OVERVIEW<br />

<strong>Robert</strong> <strong>Bosch</strong> (<strong>France</strong>)<br />

S.A.S. (RBFR), a subsidiary<br />

of the <strong>Bosch</strong> Group,<br />

mainly markets and<br />

manufactures automotive<br />

components. Since July 1st<br />

2008, the <strong>Bosch</strong> Group has<br />

consolidated all of its<br />

automotive activities in<br />

<strong>France</strong> within this<br />

subsidiary. It currently<br />

employs around 6,000<br />

staff, 2,000 of which are<br />

based on the RzP site. Manufacturing is made up of four production centres, each<br />

of which has its own workshops and management team. They are managed in<br />

profit centres, and are responsible for the ordering process. They produce Injection<br />

pumps, Injection nozzles, Glow plugs and Common Rail injectors. Products are<br />

exported all over the world and target two types of markets:<br />

• 93% of the turnover (20.5 million parts) is sold to the Group's Original Equipment<br />

Manufacturer (OEM),<br />

• 7% of the turnover (8 million parts) supplies the aftermarket through Automotive<br />

Aftermarket (AA).<br />

| 30

ROLE MODEL AREAS<br />

Role Model Area <strong>–</strong> Continuous learning, innovation and improvement<br />

Approach<br />

The applicant has implemented a comprehensive management system <strong>–</strong> so called<br />

“<strong>Bosch</strong> Production System (BPS)” <strong>–</strong> with a huge set of toolboxes like, CIP<br />

(Continuous Improvement Process), cockpits‐charts, Ishikawa, six sigma, 5S, IT‐<br />

systems and databases and so on to continuously improving the product quality<br />

and process performance.<br />

The best practice approach is to combine (a) the methodologies of learning,<br />

innovation and improvement with (b) the people working in the business processes<br />

and (c) with adequate technologies and instruments.<br />

Deployment<br />

BPS is deployed throughout the whole company, for all products and processes;<br />

from the top management to shop floor level. All leaders and almost all employees<br />

are trained in a specific internal BPS training centre.<br />

BPS is for the applicant not just a methodology but rather a part of its culture. Not<br />

only the manufacturing processes but also BPS is a kind of core competence of the<br />

applicant. It was really a pleasure to participate in a CIP group session with six<br />

employees and to see how they solved a technical problem within only one hour.<br />

31 |

Assessment and Review<br />

Indicators and cockpits‐charts for<br />

measuring the effectiveness and<br />

efficient are in place; partnership<br />

contracts with universities and<br />

3rd parties are implemented to<br />

learn from each other.<br />

Knowledge is also shared with<br />

Group partners. Many examples<br />

are given how the applicant is<br />

improving its approach (e.g. a<br />

STeP‐up program has started for<br />

the shopfloor team‐leaders to<br />

facilitate teams as moderators).<br />

Impact on performance<br />

� Reducing failure rate (less than 5 parts per million)<br />

� Increasing productivity<br />

� Increasing quality and customer satisfaction<br />

� Lead <strong>plant</strong> for some technologies and products<br />

� Contact person � Mrs Claire Champel‐Peter<br />

� Project Leader "Business Excellence"<br />

� Address � ZI de Cantaranne ‐ BP 3212 Onet le Château<br />

RODEZ <strong>–</strong> 12032<br />

<strong>France</strong><br />

� Telephone � +33 565 67 94 95<br />

� E‐mail � claire.champel@fr.bosch.com<br />

� Website � http://www.bosch.fr<br />

| 32