A52 - Alpha Materials Laboratory - Research Sites Restoration Ltd

A52 - Alpha Materials Laboratory - Research Sites Restoration Ltd

A52 - Alpha Materials Laboratory - Research Sites Restoration Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

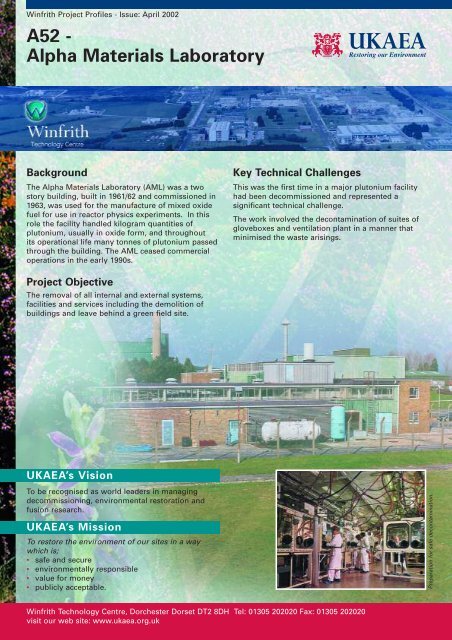

Winfrith Project Profiles - Issue: April 2002<br />

<strong>A52</strong> -<br />

<strong>Alpha</strong> <strong>Materials</strong> <strong>Laboratory</strong><br />

Background<br />

The <strong>Alpha</strong> <strong>Materials</strong> <strong>Laboratory</strong> (AML) was a two<br />

story building, built in 1961/62 and commissioned in<br />

1963, was used for the manufacture of mixed oxide<br />

fuel for use in reactor physics experiments. In this<br />

role the facility handled kilogram quantities of<br />

plutonium, usually in oxide form, and throughout<br />

its operational life many tonnes of plutonium passed<br />

through the building. The AML ceased commercial<br />

operations in the early 1990s.<br />

Key Technical Challenges<br />

This was the first time in a major plutonium facility<br />

had been decommissioned and represented a<br />

significant technical challenge.<br />

The work involved the decontamination of suites of<br />

gloveboxes and ventilation plant in a manner that<br />

minimised the waste arisings.<br />

Project Objective<br />

The removal of all internal and external systems,<br />

facilities and services including the demolition of<br />

buildings and leave behind a green field site.<br />

UKAEA’s Vision<br />

To be recognised as world leaders in managing<br />

decommissioning, environmental restoration and<br />

fusion research.<br />

UKAEA’s Mission<br />

To restore the environment of our sites in a way<br />

which is;<br />

• safe and secure<br />

• environmentally responsible<br />

• value for money<br />

• publicly acceptable.<br />

Preparation for safe decontamination.<br />

Winfrith Technology Centre, Dorchester Dorset DT2 8DH Tel: 01305 202020 Fax: 01305 202020<br />

visit our web site: www.ukaea.org.uk

UKAEA Solutions<br />

UKAEA recognised that the principal financial risk<br />

to the project was the potential to generate large<br />

volumes of plutonium contaminated material<br />

(PCM) waste.<br />

UKAEA let a competitive contract in which waste<br />

optimisation was incentivised.<br />

The bidding contractors were encouraged to bring<br />

innovation to the project.<br />

The contractor was required to work to UKAEA’s<br />

safety management system and UKAEA provided<br />

close supervision of the work.<br />

Once the decontamination work was completed<br />

to UKAEA’s standards, conventional demolition<br />

techniques were used to remove the shell of<br />

the building.<br />

Contractors<br />

UKAEA appointed AEA Technology as<br />

decommissioning contractors for all the AML,<br />

who mobilised in May 1996.<br />

Outcome<br />

The contract delivered a green field site with<br />

no significant safety or environmental incidents.<br />

The waste arisings were optimised.<br />

Project Manager<br />

Dave Smith<br />

Dave Smith<br />

Key Dates<br />

The AML judged economically viable Early 1990s<br />

Funding approved for<br />

glovebox decommissioning<br />

1990s<br />

75 gloveboxes decommissioned 1990-1994<br />

AEA Technology appointed as<br />

decommissioning contractors 1996<br />

Green field status achieved 1999<br />

Decommissioning gloveboxes.