HAPTER - Cemont

HAPTER - Cemont

HAPTER - Cemont

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

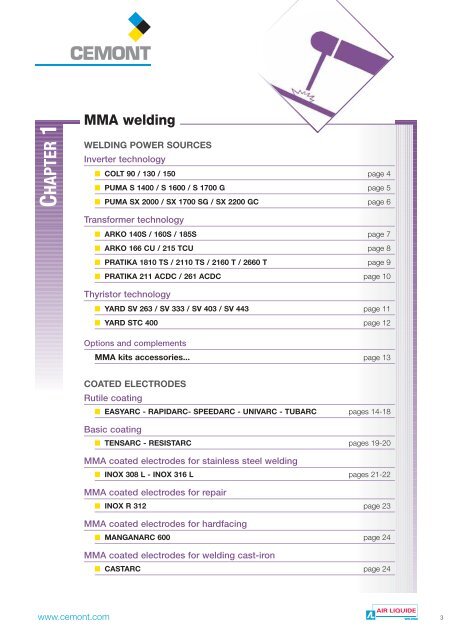

C<strong>HAPTER</strong> 1<br />

MMA welding<br />

WELDING POWER SOURCES<br />

Inverter technology<br />

■ COLT 90 / 130 / 150 page 4<br />

■ PUMA S 1400 / S 1600 / S 1700 G page 5<br />

■ PUMA SX 2000 / SX 1700 SG / SX 2200 GC page 6<br />

Transformer technology<br />

■ ARKO 140S / 160S / 185S page 7<br />

■ ARKO 166 CU / 215 TCU page 8<br />

■ PRATIKA 1810 TS / 2110 TS / 2160 T / 2660 T page 9<br />

■ PRATIKA 211 ACDC / 261 ACDC page 10<br />

Thyristor technology<br />

■ YARD SV 263 / SV 333 / SV 403 / SV 443 page 11<br />

■ YARD STC 400 page 12<br />

Options and complements<br />

MMA kits accessories... page 13<br />

COATED ELECTRODES<br />

Rutile coating<br />

■ EASYARC - RAPIDARC- SPEEDARC - UNIVARC - TUBARC pages 14-18<br />

Basic coating<br />

■ TENSARC - RESISTARC pages 19-20<br />

MMA coated electrodes for stainless steel welding<br />

■ INOX 308 L - INOX 316 L pages 21-22<br />

MMA coated electrodes for repair<br />

■ INOX R 312 page 23<br />

MMA coated electrodes for hardfacing<br />

■ MANGANARC 600 page 24<br />

MMA coated electrodes for welding cast-iron<br />

■ CASTARC page 24<br />

www.cemont.com<br />

3

Power source for MMA welding<br />

with coated electrodes. Inverter technology.<br />

Single-phase input voltage.<br />

COLT 90 / 130 / 150<br />

MMA POWER<br />

SOURCES<br />

The range of COLT power sources, known all around<br />

the world for its exceptional ratio “weight / power”,<br />

shows a new handle more ergonomic.<br />

The Advantages:<br />

■ Input voltage: 230 V single-phase with 16 A plug.<br />

■ Light weight: less than 4 kg.<br />

■ Simple: only 1 regulation potentiometer.<br />

■ Versatile: able to weld all types of coated<br />

electrodes (steel / stainless steel / special etc…).<br />

■ Comfortable: over-intensity when starting /<br />

anti-stick device.<br />

■ Complete: delivered complete for<br />

an immediate use.<br />

ULTRA-MOBILE<br />

Classification<br />

EN 60974-1<br />

EN 60974-10<br />

COLT 90<br />

Cat. nr : W 000 260 935<br />

COLT 130<br />

Cat. nr : W 000 260 938<br />

COLT 150<br />

Cat. nr : W 000 260 937<br />

TECHNICAL DATA:<br />

Single-phase input voltage<br />

COLT 90 COLT 130 COLT 150<br />

230 V (50-60 Hz)<br />

Primary consumption* - 13 A 26 A 26 A<br />

Power* 2.1 kVA 3.8 kVA 3.8 kVA<br />

Effective consumption 7 A 10 A 14 A<br />

No-load voltage 82 V 82 V 82 V<br />

Welding current 5 - 80 A 5 - 125 A 5 - 130 A<br />

Duty cycle at 30 % 80 A 125 A (15 %) 130 A (25 %)<br />

at 60 % 60 A 80 A 85 A<br />

at 100 % 50 A 60 A 70 A<br />

Protection class IP 23<br />

Dimensions<br />

220 x 120 x 320 mm<br />

Weight 2.9 kg 3.8 kg 4 kg<br />

• Accessories<br />

see page 13<br />

Delivered equipped with:<br />

■ primary cable,<br />

■ welding cable with electrode holder,<br />

■ welding cable equipped with earth clamp,<br />

■ hammer / brush / helmet,<br />

■ pack of rutile electrodes,<br />

■ safety instructions<br />

and maintenance manual,<br />

■ PVC case for transportation.<br />

* at maximum welding intensity<br />

4<br />

www.cemont.com

Power source for MMA welding<br />

with coated electrodes and TIG DC “scratching”.<br />

Inverter technology. Single-phase input voltage.<br />

PUMA S 1400 / 1600 / 1700 G<br />

MMA POWER<br />

SOURCES<br />

The PUMA are power sources for MMA coated<br />

electrodes welding for an industrial and daily use.<br />

A special version compatible with generators is<br />

available (1700 G). The PUMA have been designed<br />

for on site utilisation.<br />

The Advantages:<br />

■ Input voltage: 230 V single-phase.<br />

■<br />

■<br />

■<br />

Light weight: less than 7 kg.<br />

Simple: only 1 regulation potentiometer.<br />

Versatile: able to weld all type of coated<br />

electrodes (steel / stainless steel etc…).<br />

■ Comfortable: over-intensity when starting /<br />

anti-stick device.<br />

■ Powerful: duty cycle at 40°C.<br />

■<br />

Transportable: with its shoulder strap.<br />

3<br />

1<br />

2<br />

PUMA S 1400<br />

Cat. nr : W 000 263 627<br />

PUMA S 1600<br />

Cat. nr : W 000 263 636<br />

MOBILE<br />

Classification<br />

EN 60974-1<br />

EN 60974-10<br />

POWER SOURCES FOR COATED ELECTRODES WELDING<br />

PUMA S 1700 G<br />

4<br />

1<br />

2<br />

3<br />

4<br />

Power potentiometer.<br />

Switch on/off.<br />

Error indicator.<br />

Power borders.<br />

Cat. nr : W 000 263 650<br />

COMPATIBLE<br />

WITH<br />

GENERATOR<br />

TECHNICAL DATA:<br />

PUMA S 1400 PUMA S 1600 PUMA S 1700 G<br />

Single-phase input voltage<br />

230 V (50 - 60 Hz)<br />

Primary consumption* - 25 A 31 A 31 A<br />

Power* 3.8 kVA 4.5 kVA 4.5 kVA<br />

Effective consumption 15 A 16 A 19 A<br />

No-load voltage<br />

85 V<br />

Welding current 5 - 130 A 5 - 150 A 5 - 150 A<br />

Duty cycle at 35 % 130 A 150 A (25%) 150 A<br />

at 60 % 100 A 120 A 120 A<br />

at 100 % 80 A 100 A 100 A<br />

Protection class IP 23<br />

Dimensions<br />

145 x 230 x 365 mm<br />

Weight<br />

7 kg<br />

• Accessories<br />

see page 13<br />

Delivered equipped with:<br />

■ electric cable,<br />

■ safety instructions<br />

and maintenance manual.<br />

* at maximum welding intensity<br />

www.cemont.com<br />

5

Power source for MMA welding with coated<br />

electrodes and TIG DC (TIG lift). Inverter technology.<br />

Single-phase or three-phase input voltage.<br />

PUMA SX 2000<br />

PUMA SX 1700 GC / SX 2200 GC<br />

MMA POWER<br />

SOURCES<br />

The PUMA SX family is specially remarkable showing<br />

greater duty cycles and new functions such as digital<br />

display, “TIG LIFT” mode and Arc dynamism.<br />

Moreover the PUMA G are compatible with generators.<br />

The Advantages:<br />

■ Digital display: better adjustment and reading of the<br />

parameters (Amp/ % / sec) on PUMA SX 2200 G.<br />

■ Versatile: able to weld all types of coated electrodes<br />

(rutile, basic, etc…) including cellulosics (for GC<br />

versions).<br />

■<br />

■<br />

■<br />

4<br />

Light and compact:<br />

for quick interventions.<br />

Safety: IP 23 protection class<br />

for outdoor interventions.<br />

Comfortable: over-intensity when starting<br />

and anti-stick device (pre-programmed on versions<br />

1700/ 2000, and adjustable on 2200).<br />

3<br />

2<br />

1<br />

1<br />

2<br />

3<br />

4<br />

Switch on/off.<br />

Power potentiometer.<br />

Thermics safety indicator.<br />

Selection MMA / TIG DC.<br />

Classification<br />

EN 60974.1<br />

EN 60974.10<br />

PUMA SX 2000<br />

Cat. nr : W 000 263 686<br />

PUMA SX 1700 GC<br />

Cat. nr : W 000 263 662<br />

PUMA SX 2200 GC<br />

Cat. nr : W 000 263 688<br />

3<br />

4<br />

2<br />

1<br />

1<br />

2<br />

3<br />

4<br />

TIG DC mode selection.<br />

Digital display Amp/Sec/ %.<br />

Remote control socket.<br />

Welding intensity adjustment.<br />

COMPATIBLE<br />

WITH<br />

GENERATOR<br />

TECHNICAL DATA:<br />

PUMA SX 1700 GC PUMA SX 2000 PUMA SX 2200 GC<br />

Input voltage 50/60 Hz 230 V single-phase 400 V three-phase<br />

Primary consumption* - 25 A 34 A 14 A<br />

Power* 4.5 kVA 6 kVA 7.2 kVA<br />

Effective consumption 19 A 19 A 9 A<br />

No-load voltage 108 V 82 V 105 V<br />

Welding current 5 - 160 A 5 - 180 A 5 - 220 A<br />

Duty cycle at 30 % 160 A 180 A 220 A (40%)<br />

at 60 % 130 A 140 A 190 A<br />

at 100 % 100 A 110 A 150 A<br />

Protection class IP 23<br />

Dimensions 180 x 250 x 400 mm 185 x 310 x 440 mm 250 x 470 x 450 mm<br />

Weight 8 kg 10 kg 18 kg<br />

* at maximum welding intensity<br />

• Accessories<br />

see page 13<br />

Delivered equipped with:<br />

■ electric cable,<br />

■ safety instructions<br />

and maintenance manual.<br />

6 www.cemont.com

Traditional power source for MMA welding<br />

with coated electrodes. Transformer technology.<br />

Single-phase input voltage.<br />

ARKO 140S / 160S / 185S<br />

MMA POWER<br />

SOURCES<br />

The ARKO family includes transformer power<br />

sources regulated by shunt and delivering AC current.<br />

They are compact, robust and easy to use.<br />

The Advantages:<br />

■ Input voltage: 230 V single-phase or 230 V –<br />

400 V single-phase (185S).<br />

■<br />

■<br />

■<br />

■<br />

Simple: adjustment by shunt with visualisation<br />

of the current.<br />

Successful: ideal for craft applications.<br />

Quick: delivered ready-to-use.<br />

Safety: with the integrated thermics security.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

Switch on/off.<br />

Adjustment wheel.<br />

Electrode holder cable. ARKO 160S<br />

Clamp cable.<br />

Welding intensity display.<br />

Primary alimentation cable.<br />

5<br />

Cat. nr : W 000 263 668<br />

ARKO 140S<br />

MOBILE<br />

ECONOMIC<br />

Cat. nr : W 000 263 667<br />

POWER SOURCES FOR COATED ELECTRODES WELDING<br />

1<br />

2<br />

3<br />

ARKO 185S<br />

Cat. nr : W 000 263 669<br />

6<br />

TECHNICAL DATA:<br />

4<br />

Classification<br />

EN 60974.1<br />

EN 60974.10<br />

ARKO 140S ARKO 160S ARKO 185S<br />

Single-phase input voltage 230 V - (50 Hz) 230 - 400 V - (50 Hz)<br />

Primary consumption* -<br />

18 A / 3 kVA 26 A / 4.2 kVA 34 - 21 A / 5.4 kVA<br />

Power*<br />

Effective consumption 6 A 13 A 14 - 5 A<br />

No-load voltage 46 V 48 V 48 V<br />

Welding current 30 - 110 A 40 - 140 A 55 - 160 A<br />

Electrodes/ hour 10 in diam. 2.5 mm 20 in diam. 2.5 mm 10 in diam. 3.2 mm<br />

Suitable electrodes<br />

diameter<br />

2.0 to 2.5 mm 2.0 to 3.2 mm 2.0 to 4.0 mm<br />

Protection class IP 21<br />

Dimensions<br />

220 x 330 x 280 mm<br />

Weight 11.3 kg 12.5 kg 14 kg<br />

* at maximum welding intensity<br />

• Accessories<br />

see page 13<br />

Delivered equipped with:<br />

■ electric cable,<br />

■ welding cables equipped<br />

with earth clamp and<br />

electrode holder,<br />

■ safety instructions<br />

and maintenance manual.<br />

www.cemont.com<br />

7

Traditional power source for MMA welding<br />

with coated electrodes. Transformer technology.<br />

Single-phase input voltage.<br />

ARKO 166 CU / 215 TCU<br />

MMA POWER<br />

SOURCES<br />

The ARKO family includes transformer power sources<br />

regulated by shunt and delivering AC current.<br />

They are compact, robust and easy to use.<br />

The Advantages:<br />

■ Input voltage: 230 V – 400 V single-phase.<br />

■<br />

■<br />

■<br />

■<br />

■<br />

Simple: adjustment by shunt with visualisation<br />

of the current.<br />

Successful: ideal for craft applications.<br />

Quick: delivered ready-to-use.<br />

Professional: ventilated copper transformer (T).<br />

Safety: with the integrated thermics security.<br />

MOBILE<br />

ECONOMIC<br />

Classification<br />

EN 60974.1<br />

EN 60974.10<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

Switch on/off and primary<br />

tension selection.<br />

Adjustment wheel.<br />

Plug for electrode holder cable.<br />

Plug for clamp cable.<br />

Welding intensity display.<br />

Primary alimentation cable.<br />

ARKO 166 CU<br />

Cat. nr : W 000 263 670<br />

5<br />

1<br />

2<br />

3<br />

4<br />

ARKO 215 TCU<br />

Cat. nr : W 000 263 671<br />

6<br />

TECHNICAL DATA:<br />

Single-phase input voltage<br />

Primary consumption* -<br />

Power*<br />

ARKO 166 CU<br />

230 - 400 V - (50 Hz)<br />

ARKO 215 TCU<br />

27 - 15 A / 5.4 kVA 39 - 23 A / 6 kVA<br />

Effective consumption 10.5 A (400 V) 18.5 A (400 V)<br />

No-load voltage 48 V 48 V<br />

Welding current 55 - 155 A 55 - 185 A<br />

Electrodes/ hour 15 in diam. 3.2 mm 15 in diam. 4.0 mm<br />

Suitable electrodes<br />

diameter<br />

2.0 to 4.0 mm 2.0 to 4.0 mm<br />

Protection class IP 21<br />

Dimensions<br />

240 x 400 x 320 mm<br />

Weight 15 kg 16 kg<br />

* at maximum welding intensity<br />

• Accessories<br />

see page 13<br />

Delivered equipped with:<br />

■ electric cable,<br />

■ safety instructions<br />

and maintenance manual.<br />

8<br />

www.cemont.com

Traditional power source for MMA welding<br />

with coated electrodes. Transformer technology.<br />

Single-phase input voltage.<br />

PRATIKA 1810 TS / 2110 TS<br />

PRATIKA 2160 T / 2660 T<br />

The PRATIKA are transformer technology power<br />

sources air cooled. The welding intensity can be<br />

adjusted by shunt. They provide an AC current<br />

(T and TS ranges) for easy welding with rutile electrodes.<br />

PRATIKA is your daily welding tool.<br />

The Advantages:<br />

■ Input voltage: 230 V single-phase or<br />

230 V – 400 V single-phase.<br />

■<br />

■<br />

■<br />

■<br />

Simple : adjustment by shunt with visualisation<br />

of the current.<br />

Ready-to-use: delivered with welding accessories.<br />

Professional: robust transformer air cooled.<br />

Safety: with the integrated thermics security.<br />

2<br />

1<br />

PRATIKA 1810 TS<br />

Cat. nr : W 000 264 088<br />

PRATIKA 2110 TS<br />

Cat. nr : W 000 264 091<br />

TRANSFORMER<br />

PRATIKA 2160 T<br />

Cat. nr : W 000 264 094<br />

MMA POWER<br />

SOURCES<br />

Classification<br />

EN 60974.1<br />

EN 60974.10<br />

POWER SOURCES FOR COATED ELECTRODES WELDING<br />

PRATIKA 2660 T<br />

4<br />

3<br />

1<br />

2<br />

3<br />

4<br />

Welding intensity display.<br />

Switch on/off.<br />

Adjustment wheel.<br />

Primary cable.<br />

Cat. nr : W 000 263 672<br />

TECHNICAL DATA:<br />

PRATIKA 1810 TS 2110 TS 2160 T 2660 T<br />

Single-phase input voltage 230 V (50 Hz) 230 V - 400 V (50 Hz)<br />

Primary consumption* - 26 A 26 A 36 A - 20 A 39 A - 23 A<br />

Power* 4.2 kVA 5.4 kVA 5.4 kVA 6.2 kVA<br />

Effective consumption 12 A 13 A 15 A (230 V) 19 A - 12 A<br />

No-load voltage 48 V 48 V 48 V 48 V<br />

Welding current 40 - 140 A 55 - 160 A 55 - 160 A 40 - 195 A<br />

Electrodes diameter 1.6 to 3.2 mm 1.6 to 4.0 mm 1.6 to 4.0 mm 1.6 to 5.0 mm<br />

Protection class IP 21<br />

Dimensions (mm) 220 x 400 x 320 240 x 550 x 410 240 x 560 x 445 240 x 640 x 445<br />

Weight 13.4 kg 17 kg 16.5 kg 20 kg<br />

* at maximum welding intensity<br />

• Accessories<br />

see page 13<br />

Delivered equipped with:<br />

■ electric cable,<br />

■ welding cables equipped<br />

with earth clamp and<br />

electrode holder (TS<br />

models),<br />

■ safety instructions<br />

and maintenance manual.<br />

www.cemont.com<br />

9

Traditional power source for MMA welding<br />

with coated electrodes. Transformer technology.<br />

Single-phase input voltage.<br />

PRATIKA 211 AC/DC/ 261 AC/DC<br />

MMA POWER<br />

SOURCES<br />

The PRATIKA AC/DC are transformer technology<br />

power sources air cooled. The welding intensity<br />

can be adjusted by shunt. They provide an AC<br />

or DC current allowing welding with all types<br />

of coated electrodes.<br />

PRATIKA is your power source<br />

for all applications.<br />

The Advantages:<br />

TRANSFORMER FOR ALL<br />

TYPES OF ELECTRODES<br />

Classification<br />

EN 60974.1<br />

EN 60974.10<br />

■<br />

Input voltage: 230 V – 400 V single-phase.<br />

■ Simple : adjustment by shunt with visualisation<br />

of the current.<br />

■ Versatility: AC/DC for all types<br />

of coated electrodes.<br />

■ Powerful: welding current up to 215 A.<br />

■<br />

■<br />

Professional: robust transformer air cooled.<br />

Safety: with the integrated thermics security.<br />

1<br />

2<br />

PRATIKA 211 AC/DC<br />

3<br />

4<br />

1<br />

2<br />

3<br />

Welding intensity display.<br />

Thermics safety light.<br />

Switch on/off.<br />

Cat. nr : W 000 263 673<br />

PRATIKA 261 AC/DC<br />

6<br />

5<br />

4<br />

5<br />

6<br />

Welding cables plug.<br />

Adjustment wheel.<br />

Primary cable<br />

Cat. nr : W 000 264 096<br />

TECHNICAL DATA:<br />

PRATIKA 211 AC/DC<br />

PRATIKA 261 AC/DC<br />

Single-phase input voltage<br />

230 V - 400 V (50 Hz)<br />

Primary consumption* - 45 A - 26 A 49 A - 26 A<br />

Power* 4.5 kVA 7 kVA<br />

Effective consumption 13 A - 7.5 A 20 A - 12 A<br />

No-load voltage 92 V 95 V<br />

Welding current AC 30 A - 160 A 50 A - 215 A<br />

DC 20 A - 115 A 25 A - 160 A<br />

Electrodes diameter 1.6 to 4 mm 2 to 5 mm<br />

Duty cycle at 40 °C at 10 % 160 A (8%) 205 A<br />

at 60 % 60 A 80 A<br />

Protection class IP 21<br />

Dimensions (mm) 360 x 300 x 460 360 X 300 x 460<br />

Weight 27 kg 33.5 kg<br />

* at maximum welding intensity<br />

• Accessories<br />

see page 13<br />

Delivered equipped with:<br />

■ electric cable,<br />

■ handle and wheels,<br />

■ safety instructions<br />

and maintenance manual.<br />

10<br />

www.cemont.com

Power source for MMA welding<br />

with coated electrodes. Transformer technology.<br />

Three-phase input voltage.<br />

YARD SV 263 / SV 333<br />

SV 403 / SV 443<br />

The YARD power sources are rectifiers for MMA coated<br />

electrodes welding. They are perfectly adapted to workshop<br />

and outdoor working conditions. Easy use with adjustment<br />

by shunt, they are aimed to professional and intensive<br />

applications.<br />

The Advantages:<br />

■ Input voltage: bi-tension 230 V – 400 V three-phase.<br />

■<br />

■<br />

■<br />

■<br />

■<br />

Simple : power adjustment by shunt.<br />

Successful: parameterized for<br />

intensive applications.<br />

Technology: ventilated transformer.<br />

Practice: due to its large<br />

diameter wheels and its handle.<br />

Versatile: able to weld all types<br />

of electrodes (including cellulosics).<br />

1<br />

2<br />

4<br />

3<br />

1<br />

2<br />

3<br />

4<br />

YARD SV 263<br />

Switch on/off and primary<br />

tension selection.<br />

Power adjustment.<br />

Welding intensity indicator.<br />

Power borders.<br />

Cat. nr : W 000 263 691<br />

YARD SV 333<br />

Cat. nr : W 000 263 693<br />

POWERFUL<br />

ROBUST<br />

YARD SV 403<br />

Cat. nr : W 000 263 695<br />

YARD SV 443<br />

Cat. nr : W 000 263 696<br />

Classification<br />

EN 60974.1<br />

EN 60974.10<br />

MMA POWER<br />

SOURCES<br />

POWER SOURCES FOR COATED ELECTRODES WELDING<br />

TECHNICAL DATA:<br />

Input voltage<br />

YARD SV 263 YARD SV 333 YARD SV 403 YARD SV 443<br />

230 V - 400 V three-phase (50 Hz)<br />

Primary consumption* - 36 A - 21 A 42 A - 24 A 57 A - 33 A 78 A - 45 A<br />

Power* 7.6 kVA 10.5 kVA 16 kVA 27.7 kVA<br />

Effective consumption 21 A - 12 A 25 A - 15 A 34 A - 19,5 A 52 A - 30 A<br />

No-load voltage 62 V / 66 V 61 V / 66 V 63 V / 70 V 71 V / 79 V<br />

Welding current 45 - 220 A 55 - 260 A 50 - 325 A 60 - 400 A<br />

Duty cycle at 35 % 220 A 260 A 325 A 400 A<br />

at 60 % 170 A 200 A 250 A 345 A<br />

at 100 % 130 A 155 A 190 A 265 A<br />

Protection class IP 21<br />

Dimensions (mm) 450 x 620 x 890 560 x 730 x 1080<br />

Weight 57 kg 83 kg 107 kg 123 kg<br />

* at maximum welding intensity<br />

• Accessories<br />

see page 13<br />

Delivered equipped with:<br />

■ electric cable,<br />

■ safety instructions<br />

and maintenance manual.<br />

www.cemont.com<br />

11

Power source for MMA welding<br />

with coated electrodes. Thyristor technology.<br />

Three-phase input voltage.<br />

YARD STC 400<br />

The YARD STC 400 power source is built<br />

with thyristor technology, known as robust,<br />

successful and reliable all over the world.<br />

The YARD STC 400 had already been<br />

approved in all types of environment<br />

as transport equipments manufacturing,<br />

shipyards, repair, etc…<br />

The YARD STC 400 is the solution for intensive<br />

welding with coated electrodes (including<br />

cellulosic) and for gouging.<br />

The Advantages:<br />

■ Input voltage: bi-tension 230 V –<br />

400 V three-phase.<br />

■ Intensity adjustment: electronic.<br />

■ Display: digital A / V.<br />

■ Versatility: coated electrodes / TIG DC lift /<br />

gouging.<br />

■ Flexible: possibility to adjust Hot Start and arc<br />

dynamism.<br />

■ Professional: steel structure equipped with<br />

wheels, retractable crutch and slinging eyes.<br />

■ Remote control: remote adjustment flexibility.<br />

EXTENSIVE – VERSATILE<br />

(coated electrode / gouging / TIG DC)<br />

YARD STC 400<br />

Cat. nr : W 000 263 712<br />

MMA POWER<br />

SOURCES<br />

Classification<br />

EN 60974-1<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

Switch on/off and primary tension<br />

selection.<br />

Regulation potentiometer.<br />

Digital display A/V.<br />

Selection coated electrode / TIG.<br />

Hot Start / ARC FORCE adjustment.<br />

Remote control connection.<br />

TECHNICAL DATA:<br />

YARD STC 400<br />

Three-phase input voltage<br />

230 - 400 V (50 - 60 Hz)<br />

Primary consumption* - Power*<br />

60 - 32 A / 33 kVA<br />

No-load voltage<br />

80 V<br />

Welding current<br />

10 - 400 A<br />

Duty cycle at 35 % 400 A<br />

at 60 %<br />

300 A<br />

at 100 %<br />

230 A<br />

Electrodes diameter<br />

1.6 to 6.3 mm<br />

Protection class IP 23<br />

Dimensions<br />

970 x 670 x 730 mm<br />

Weight<br />

140 kg<br />

* at maximum welding intensity<br />

• Accessories<br />

see page 13<br />

Delivered equipped with:<br />

■ electric cable,<br />

■ safety instructions<br />

and maintenance manual.<br />

Remote control box<br />

Cat. nr : W 000 219 557<br />

12<br />

www.cemont.com

Options and commplements<br />

for MMA power sources.<br />

MMA<br />

OPTIONS<br />

MMA KIT ACCESSORIES:<br />

COMPLETE ACCESSORIES KIT FOR CHANGE OR FIRST ASSEMBLY<br />

16C25 25C25+ 50C50 50C50+<br />

COLT W 000 360 680 - - -<br />

PUMA 140/160 - W 000 260 683 - -<br />

PUMA 190/220 - W 000 260 684 - -<br />

ARKO W 000 360 680 - - -<br />

PRATIKA - W 000 360 683 - -<br />

YARD SV - - W 000 260 681 -<br />

YARD STC - - - W 000 260 682<br />

MMA OPTIONS:<br />

COLT PUMA PUMA SX YARD STC<br />

Remote control - - W 000 242 069 W 000 215 557<br />

TIG torch with valve W 000 266 936 W 000 266 936 W 000 266 936 -<br />

COATED ELECTRODES (SELECTION) :<br />

Complete range<br />

on pages 14 to 24<br />

OPTIONS AND COMPLEMENTS FOR MMA POWER SOURCES<br />

Rutile Basic Stainless steel Cast iron<br />

RAPIDARC TENSARC INOXARC CASTARC<br />

Diameter 2.0 mm W 000 262 696 W 000 262 850 W 000 264 730 W 000 264 737<br />

Diameter 2.5 mm W 000 262 697 W 000 262 851 W 000 264 731 W 000 264 738<br />

Diameter 3.2 mm W 000 262 698 W 000 262 853 W 000 264 732 W 000 264 739<br />

Diameter 4.0 mm W 000 262 699 W 000 262 854 - -<br />

www.cemont.com 13

EASYARC<br />

General characteristics:<br />

General purpose electrode for application<br />

in all positions. Highly versatile electrode<br />

due to the smooth fusion.<br />

Main applications:<br />

■ Shet-iron works<br />

■ Metal fitting steelworks.<br />

■ Metal frame works<br />

MMA electrodes - Rutile coating.<br />

Classification<br />

EN 499 : E 420 RC 14<br />

AWS A 5.1 : E 6013<br />

COATED<br />

ELECTRODES<br />

STEELS TYPES TO BE WELDED:<br />

AFNOR DIN ASTM<br />

A 33 - A 34 - A 37 A 42 St 33 A 283 – A 442<br />

A 48 - E 24 - E 26 Ust 37.2 - St 37.3<br />

E 28 - E 30<br />

St 44 - HI - HII<br />

Welding<br />

positions:<br />

MECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1579-1):<br />

Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)<br />

(MPa) (MPa) (%) 0 °C<br />

510 - 610 > 420 > 22 > 47<br />

ORDERING INFORMATION:<br />

Ø<br />

(mm)<br />

l<br />

(mm)<br />

kg<br />

/1000<br />

Quant.<br />

Cat. nr<br />

2.0 300 12,7 330 990 W 000 262 847<br />

2.5 350 19.7 205 615 W 000 262 848<br />

3.2 350 31 115 345 W 000 262 849<br />

Current conditions:<br />

Type of coating:<br />

■<br />

DC<br />

–<br />

AC<br />

Uo ><br />

45 V<br />

Semi-thick<br />

rutilo-cellulosic.<br />

14<br />

www.cemont.com

RAPIDARC<br />

General characteristics:<br />

General purpose and very versatile electrode.<br />

It can be used for all positions welding.<br />

Excellent arc-striking even on slightly rusted,<br />

calaminated or poorly prepared parts.<br />

Main applications:<br />

■ Current works.<br />

■ Mainteance general works.<br />

■ Small running repair.<br />

MMA electrodes - Rutile coating.<br />

Classification<br />

EN 499 : E 380 RC 11<br />

AWS A 5.1 : E 6013<br />

COATED<br />

ELECTRODES<br />

MMA ELECTRODES - RUTILE COATING<br />

STEELS TYPES TO BE WELDED:<br />

AFNOR DIN ASTM<br />

A 33 - A 34 - E 24 - E 28 St 33.1 - Ust 37.2 A 283 - A 442<br />

E 30 - A 37 (CP) - A 42 (CP) St 37.3 - St 44 - HI - HII<br />

A 48 (CP) - A 50 (CP) - X 52<br />

Welding<br />

positions:<br />

MECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1579-1):<br />

Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)<br />

(MPa) (MPa) (%) 0 °C<br />

480 - 550 > 380 > 22 > 47<br />

ORDERING INFORMATION:<br />

Ø<br />

(mm)<br />

l<br />

(mm)<br />

kg<br />

/1000<br />

Quant.<br />

Cat. nr<br />

2.0 350 11.4 355 1065 W 000 262 696<br />

2.5 350 17.25 250 750 W 000 262 697<br />

3.2 350 27.5 155 465 W 000 262 698<br />

4.0 350 42.8 100 300 W 000 262 699<br />

Current conditions:<br />

Type of coating:<br />

■<br />

DC<br />

–<br />

AC<br />

Uo ><br />

45 V<br />

Semi-thick<br />

rutilo-cellulosic.<br />

www.cemont.com<br />

15

SPEEDARC<br />

General characteristics:<br />

General purpose and very versatile electrode.<br />

It can be used for all positions welding except vertical-down.<br />

Excellent arc-striking even on slightly rusted,<br />

calaminated or poorly prepared parts.<br />

Main applications:<br />

■ Current works.<br />

■ Mainteance general works.<br />

■ Small running repair.<br />

MMA electrodes - Rutile coating.<br />

Classification<br />

EN 499 : E 380 R 12<br />

AWS A 5.1 : E 6013<br />

COATED<br />

ELECTRODES<br />

STEELS TYPES TO BE WELDED:<br />

AFNOR DIN ASTM<br />

A 33 - A 34 - E 24 - E 28 St 33.1 - Ust 37.2 A 283 - A 442<br />

E 30 - A 37 (CP) - A 42 (CP) St 37.3 - St 44 - HI - HII<br />

A 48 (CP) - A 50 (CP) - X 52<br />

MECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1579-1):<br />

Welding<br />

positions:<br />

Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)<br />

(MPa) (MPa) (%) 0 °C<br />

490 - 600 > 430 > 24 > 47<br />

ORDERING INFORMATION:<br />

Ø<br />

(mm)<br />

l<br />

(mm)<br />

Quant.<br />

kg<br />

Cat. nr<br />

/1000<br />

2.0 350 11.8 323 969 W 000 263 639<br />

2.5 350 19.5 230 690 W 000 263 638<br />

3.2 350 31.9 141 423 W 000 263 637<br />

3.2 450 41.8 139 417 W 000 263 635<br />

4.0 350 48.1 93 279 W 000 263 634<br />

4.0 450 64.5 90 270 W 000 263 633<br />

5.0 450 97.2 62 186 W 000 263 632<br />

Current conditions:<br />

Type of coating:<br />

■<br />

DC<br />

–<br />

AC<br />

Uo ><br />

50 V<br />

Semi-thick rutile.<br />

16<br />

www.cemont.com

UNIVARC<br />

General characteristics:<br />

General purpose electrode designed<br />

for less spatters during welding.<br />

Excellent electrode for works requiring<br />

smooth fusion.<br />

Main applications:<br />

■ Shet-iron works.<br />

■ Metal fitting steelworks.<br />

■ Metal frame works.<br />

MMA electrodes - Rutile coating.<br />

Classification<br />

EN 499 : E 380 RC 11<br />

AWS A 5.1 : E 6013<br />

COATED<br />

ELECTRODES<br />

MMA ELECTRODES - RUTILE COATING<br />

STEELS TYPES TO BE WELDED:<br />

AFNOR DIN ASTM<br />

A 33 - A 34 - E 24 (1.2.3) ST 331 - Ust 37.2 A 283 - A 442<br />

E 28 (2.3) - A 37 (CP)<br />

St 44 (2.3) - HI - HII<br />

A 42 (CP) Ast 35 - Ast 41<br />

Welding<br />

positions:<br />

MECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1579-1):<br />

Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)<br />

(MPa) (MPa) (%) -20 °C 0 °C<br />

480 - 550 > 380 > 24 > 30 > 80<br />

Current conditions:<br />

DC<br />

–<br />

AC<br />

Uo ><br />

50 V<br />

ORDERING INFORMATION:<br />

l<br />

Ø<br />

kg /1000<br />

(mm) (mm)<br />

Quant.<br />

Cat. nr<br />

2.5 350 18.5 230 690 W 000 262 842<br />

3.2 350 27.6 165 495 W 000 262 843<br />

Type of coating:<br />

■<br />

Semi-thick<br />

rutilo-cellulosic.<br />

www.cemont.com<br />

17

TUBARC<br />

General characteristics:<br />

General purpose electrode designed<br />

for the pipe welding applications.<br />

This electrode gives a very good bead aspect.<br />

The TUBARC is approved by GDF ( French gas).<br />

Low level of fume emission.<br />

Main applications:<br />

■ Industrial pipe works.<br />

■ Heat exchangers.<br />

■ Pressure vessels construction.<br />

MMA electrodes - Rutile coating.<br />

Classification<br />

EN 499 : E 380 RC 11<br />

AWS A 5.1 : E 6013<br />

COATED<br />

ELECTRODES<br />

STEELS TYPES TO BE WELDED:<br />

AFNOR DIN ASTM<br />

A 34 - A 342 E 24 (2.3.4) ST 331 - Ust 37.2 A 283 gr C ou D - A 284 gr C<br />

E 28 (2.3.4) - A 37 (CP.AP.FP) St 44 - HI - HII A 284 gr D - A 414 gr C<br />

A 42 (CP.AP.FP) AST 35 - AST 41<br />

Welding<br />

positions:<br />

MECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1579-1):<br />

Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)<br />

(MPa) (MPa) (%) -20 °C<br />

500 450 28 > 60<br />

ORDERING INFORMATION:<br />

Ø<br />

(mm)<br />

l<br />

(mm)<br />

kg<br />

/1000<br />

Quant.<br />

Cat. nr<br />

2.5 350 17.9 230 690 W 000 262 844<br />

3.2 350 30.7 150 450 W 000 262 845<br />

4.0 350 45.5 100 300 W 000 262 846<br />

Current conditions:<br />

Type of coating:<br />

■<br />

DC<br />

–<br />

AC<br />

Uo ><br />

45 V<br />

Semi-thick<br />

rutilo-cellulosic.<br />

18<br />

www.cemont.com

TENSARC<br />

General characteristics:<br />

Electrodes for application requiring important<br />

mechanical properties. High efficiency basic<br />

coated electrodes for applications at low temperature.<br />

Smooth fusion for a good bead aspect.<br />

Excellent arc-striking properties for a basic<br />

coated electrode.<br />

Main applications:<br />

■ Metal fitting steelworks.<br />

■ Heavy boiler making.<br />

■ Shipbuilding.<br />

■ Transport equipment<br />

construction.<br />

STEELS TYPES TO BE WELDED:<br />

MMA electrodes - Basic coating.<br />

Classification<br />

EN 499 : E 42 5 B 32 H 5<br />

AWS A 5.1 : E 7018-1<br />

COATED<br />

ELECTRODES<br />

MMA ELECTRODES - RUTILE COATING<br />

AFNOR DIN ASTM<br />

A 33 - A 34 - E 24 - E 28 - E 30 ST 33 - 37 - 44 - 52 A 283 - A 284 - A 440 - A 441 - A 570<br />

E 36 - A 50 all qualities. all qualities. A 572 Gr 50 - A 573 - A 588<br />

A 37 (CP.AP.FP) ST 50.2 A 709 Gr 50 - A 285 - A 299 - A 414<br />

A 42 (CP.AP.FP) ST E 36 A 442 - A 515 - A 516.<br />

A 48 (CP.AP) HI - HII - HIV UNI : Fe 33 - 34 B - 37 - 44 - 52<br />

A 52 (CP.AP) 17 Mn 4 all qualities.<br />

E 355 R - A 510 (CP.AP) AST 35 - 41 - 45 - 52 Fe 50 - Fe E - 355 - Fe 360 - 410<br />

A 530 (CP.AP) - A 550 (CP AP). TT ST 41. 460 - 510 all qualities.<br />

MECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1579-1):<br />

Welding<br />

positions:<br />

Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)<br />

(MPa) (MPa) (%) -30 °C -50 °C<br />

530 - 640 > 420 > 22 140 > 47<br />

Current conditions:<br />

ORDERING INFORMATION:<br />

DC<br />

+<br />

AC<br />

Uo ><br />

70 V<br />

l<br />

Ø<br />

kg /1000<br />

(mm) (mm)<br />

Quant.<br />

Cat. nr<br />

2.5 350 21 185 555 W 000 262 850<br />

3.2 350 35 115 345 W 000 262 851<br />

3.2 450 46.1 115 345 W 000 262 852<br />

4.0 450 69 80 240 W 000 262 853<br />

5.0 450 104.2 55 165 W 000 262 854<br />

Type of coating:<br />

■<br />

Thick basic<br />

with iron powder<br />

www.cemont.com<br />

19

RESISTARC<br />

General characteristics:<br />

Electrodes for application requiring important<br />

mechanical properties. High efficiency basic<br />

coated electrodes for applications at low temperature.<br />

Smooth fusion for a good bead aspect.<br />

Excellent arc-striking properties for a basic<br />

coated electrode.<br />

Main applications:<br />

■ Metal fitting steelworks.<br />

■ Heavy boiler making.<br />

■ Shipbuilding.<br />

■ Transport equipment construction.<br />

MMA electrodes - Basic coating.<br />

Classification<br />

EN 499 : E 42 4 B 42 H 10<br />

AWS A 5.1 : E 7018-1<br />

COATED<br />

ELECTRODES<br />

STEELS TYPES TO BE WELDED:<br />

APPROVAL: TÜV<br />

AFNOR DIN ASTM<br />

A 33 - A 34 - E 24 - E 28 - E 30 ST 33 - 37 - 44 - 52 A 283 - A 284 - A 440 - A 441 - A 570<br />

E 36 - A 50 all qualities. all qualities. A 572 Gr 50 - A 573 - A 588<br />

A 37 (CP.AP.FP) ST 50.2 A 709 Gr 50 - A 285 - A 299 - A 414<br />

A 42 (CP.AP.FP) ST E 36 A 442 - A 515 - A 516.<br />

A 48 (CP.AP) HI - HII - HIV UNI : Fe 33 - 34 B - 37 - 44 - 52<br />

A 52 (CP.AP) 17 Mn 4 all qualities.<br />

E 355 R - A 510 (CP.AP) AST 35 - 41 - 45 - 52 Fe 50 - Fe E - 355 - Fe 360 - 410<br />

A 530 (CP.AP) - A 550 (CP AP). TT ST 41. 460 - 510 all qualities.<br />

MECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1579-1):<br />

Welding<br />

positions:<br />

Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)<br />

(MPa) (MPa) (%) -20 °C -40 °C<br />

510 - 640 > 430 > 24 > 80 > 47<br />

Current conditions:<br />

ORDERING INFORMATION:<br />

DC<br />

+<br />

AC<br />

Uo ><br />

70 V<br />

l<br />

Ø<br />

kg /1000<br />

(mm) (mm)<br />

Quant.<br />

Cat. nr<br />

2.5 350 22.3 180 540 W 000 263 631<br />

3.2 350 35.7 112 336 W 000 263 630<br />

3.2 450 46.7 117 351 W 000 263 629<br />

4.0 450 67.8 81 243 W 000 263 628<br />

5.0 450 100.9 55 165 W 000 263 626<br />

Type of coating:<br />

■<br />

Thick basic<br />

with iron powder.<br />

20<br />

www.cemont.com

INOXARC 308 L<br />

General characteristics:<br />

MMA coated electrode for welding stainless<br />

steel (type 18.8 and 20.10). Highly versatile<br />

electrode due to great easiness of use.<br />

Excellent for low carbon steels.<br />

Main applications:<br />

■ Stainless steel boiler making.<br />

■ Stainless steel application.<br />

■ Equipment processing<br />

(excepting food industry).<br />

STEEL TYPES TO BE WELDED:<br />

MMA coated electrodes<br />

for stainless steel welding.<br />

Classification<br />

EN 1600 : E 19 9 L R 12<br />

AWS A 5.4 : E 308 L - 17<br />

COATED<br />

ELECTRODES<br />

MMA COATED ELECTRODES FOR STAINLESS STEEL WELDING<br />

AFNOR DIN ASTM<br />

Z 2 CN 18.10 à Z 12 CN 18.10 X 2 Cr Ni 18.9 301 - 302 - 304 L - 305 - 308<br />

Welding<br />

positions:<br />

MECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1579-1):<br />

Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)<br />

(MPa) (MPa) (%) +20 °C<br />

> 560 > 320 > 30 80<br />

ORDERING INFORMATION:<br />

Ø<br />

(mm)<br />

l<br />

(mm)<br />

kg<br />

/1000<br />

Quant.<br />

Cat. nr<br />

2.0 300 11.3 310 930 W 000 264 730<br />

2.5 300 17.4 195 595 W 000 264 731<br />

3.2 350 35.8 110 330 W 000 264 732<br />

Current conditions:<br />

DC<br />

+<br />

Type of coating:<br />

■<br />

AC<br />

Uo ><br />

50 V<br />

Semi thick rutile with<br />

Cr & Ni compensation<br />

www.cemont.com<br />

21

INOXARC 316 L<br />

General characteristics:<br />

MMA coated electrode for welding stainless steels<br />

type 316L. Excellent for applications requiring<br />

good bead aspect. Very easy slag removal.<br />

Main applications:<br />

■ Application for food processing.<br />

■ Construction of milk industry equipment.<br />

■ Construction of pharmaceutical installation.<br />

MMA coated electrodes<br />

for stainless steel welding.<br />

Classification<br />

EN 1600 : E 19 12 3 L R 12<br />

AWS A 5.4 : E 316 L - 17<br />

COATED<br />

ELECTRODES<br />

STEELS TYPES TO BE WELDED:<br />

AFNOR DIN ASTM<br />

Z 2 CND 17.12 X 2 Cr Ni Mo 18.10 316 - 316 L<br />

Z 2 CND 17.13 X 2 Cr Ni Mo 18.12<br />

Z 2 CND 18.11 à Z 12 CND 20.10<br />

Welding<br />

positions:<br />

MECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1579-1):<br />

Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)<br />

(MPa) (MPa) (%) +20 °C<br />

> 500 > 300 > 25 > 47<br />

ORDERING INFORMATION:<br />

Ø<br />

(mm)<br />

l<br />

(mm)<br />

kg<br />

/1000<br />

Quant.<br />

Cat. nr<br />

2.0 300 11.5 320 960 W 000 264 733<br />

2.5 300 17.6 180 540 W 000 264 734<br />

3.2 350 35.8 115 345 W 000 264 735<br />

Current conditions:<br />

DC<br />

+<br />

Type of coating:<br />

■<br />

AC<br />

Uo ><br />

50 V<br />

Semi-thick<br />

rutilo-basic<br />

22<br />

www.cemont.com

INOXARC R 312<br />

General characteristics:<br />

MMA rutile coated electrode for repairing applications.<br />

Excellent for difficult-to-weld steels. It allows dissimilar<br />

steels joining (non or low alloyed steels with<br />

stainless steels). Smooth fusion with good bead aspect.<br />

Main applications:<br />

■ Various repairing works requiring an underlayer.<br />

■ Non alimentary stainless steels works.<br />

STEEL TYPES TO BE WELDED:<br />

- Non or low alloyed steels.<br />

- High tensile strength steels.<br />

- Stainless steels.<br />

- 13% Mn steels.<br />

MMA coated electrodes<br />

for stainless steel welding.<br />

Classification<br />

EN 1600 : E 29 9 R 12<br />

AWS A 5.4 : E 312 - 17<br />

Welding<br />

positions:<br />

COATED<br />

ELECTRODES<br />

MMA COATED ELECTRODES FOR STAINLESS STEEL WELDING<br />

MECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1579-1):<br />

Tensile Strength Yield Strength Elongation A 5<br />

(MPa) (MPa) (%)<br />

> 720 > 600 > 30<br />

Current conditions:<br />

DC<br />

+<br />

AC<br />

Uo ><br />

50 V<br />

ORDERING INFORMATION:<br />

Ø<br />

(mm)<br />

l<br />

kg /1000<br />

(mm)<br />

Quant.<br />

Cat. nr<br />

2.5 300 7 190 570 W 000 264 066<br />

3.2 350 37 115 690 W 000 264 067<br />

Type of coating:<br />

■<br />

Semi thick rutile with<br />

Cr & Ni compensation<br />

www.cemont.com<br />

23

MMA coated electrodes for hardfacing.<br />

MANGANARC 600<br />

General characteristics:<br />

For pieces submitted to abrasion<br />

(example: excavator's buckets).<br />

Excellent resistance to wear and impacts.<br />

COATED<br />

ELECTRODES<br />

Main applications:<br />

■<br />

■<br />

■<br />

■<br />

Agricultural works.<br />

Civil works and mining equipment.<br />

Crawler shoes.<br />

Hardness : 550 - 650 HV.<br />

OREDERING INFORMATION:<br />

Ø<br />

(mm)<br />

l<br />

kg /1000<br />

(mm)<br />

Quant.<br />

Cat. nr<br />

3.2 450 40.6 135 405 W 000 264 740<br />

4.0 450 61 90 270 W 000 264 741<br />

5.0 450 97.5 60 180 W 000 264 742<br />

Current conditions:<br />

Type of coating:<br />

■<br />

DC<br />

–<br />

AC<br />

Uo ><br />

60 V<br />

Semi-thick rutile<br />

MMA coated electrodes for welding cast-iron<br />

CASTARC<br />

General characteristics:<br />

Joining steel and cast-iron.<br />

Repairing casting defects.<br />

Hardfacing of cast-iron.<br />

Excellent for welding high-strength<br />

and nodular cast-irons.<br />

Main applications:<br />

■ Casting ■ Pipe<br />

Classification<br />

AWS A 5.15 : E Ni Fe Ci<br />

ORDERING INFORMATION:<br />

l<br />

Ø<br />

kg /1000<br />

(mm) (mm)<br />

Quant.<br />

Cat. nr<br />

2.5 350 19.1 110 660 W 000 264 737<br />

3.2 350 29.8 70 420 W 000 264 738<br />

4.0 350 46.8 45 270 W 000 264 739<br />

Current conditions:<br />

Type of coating:<br />

■<br />

DC<br />

+/-<br />

AC<br />

Uo ><br />

45 V<br />

Graphitic-basic<br />

24<br />

www.cemont.com