Catalog - SP series - Allied Automation, Inc.

Catalog - SP series - Allied Automation, Inc.

Catalog - SP series - Allied Automation, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

AC Drives<br />

Pre-packaged Solutions<br />

for Unidrive <strong>SP</strong><br />

“Solutions” for the Unidrive <strong>SP</strong> enable quick startup on<br />

some of the most common industrial applications.<br />

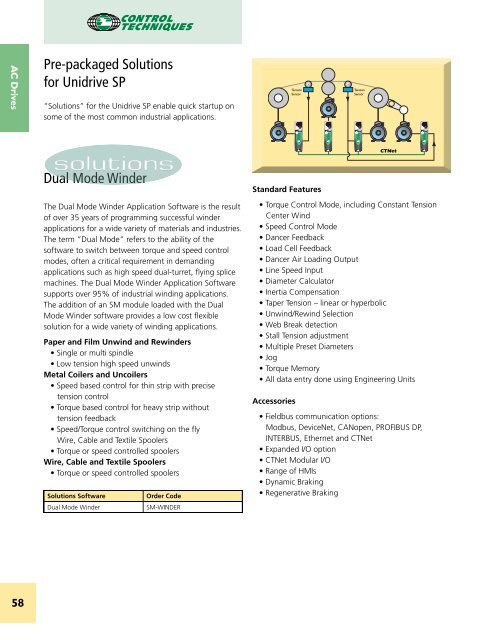

Tension<br />

Sensor<br />

Tension<br />

Sensor<br />

CTNet<br />

Dual Mode Winder<br />

The Dual Mode Winder Application Software is the result<br />

of over 35 years of programming successful winder<br />

applications for a wide variety of materials and industries.<br />

The term “Dual Mode” refers to the ability of the<br />

software to switch between torque and speed control<br />

modes, often a critical requirement in demanding<br />

applications such as high speed dual-turret, flying splice<br />

machines. The Dual Mode Winder Application Software<br />

supports over 95% of industrial winding applications.<br />

The addition of an SM module loaded with the Dual<br />

Mode Winder software provides a low cost flexible<br />

solution for a wide variety of winding applications.<br />

Paper and Film Unwind and Rewinders<br />

• Single or multi spindle<br />

• Low tension high speed unwinds<br />

Metal Coilers and Uncoilers<br />

• Speed based control for thin strip with precise<br />

tension control<br />

• Torque based control for heavy strip without<br />

tension feedback<br />

• Speed/Torque control switching on the fly<br />

Wire, Cable and Textile Spoolers<br />

• Torque or speed controlled spoolers<br />

Wire, Cable and Textile Spoolers<br />

• Torque or speed controlled spoolers<br />

Solutions Software<br />

Dual Mode Winder<br />

Order Code<br />

SM-WINDER<br />

Standard Features<br />

• Torque Control Mode, including Constant Tension<br />

Center Wind<br />

• Speed Control Mode<br />

• Dancer Feedback<br />

• Load Cell Feedback<br />

• Dancer Air Loading Output<br />

• Line Speed Input<br />

• Diameter Calculator<br />

• Inertia Compensation<br />

• Taper Tension – linear or hyperbolic<br />

• Unwind/Rewind Selection<br />

• Web Break detection<br />

• Stall Tension adjustment<br />

• Multiple Preset Diameters<br />

• Jog<br />

• Torque Memory<br />

• All data entry done using Engineering Units<br />

Accessories<br />

• Fieldbus communication options:<br />

Modbus, DeviceNet, CANopen, PROFIBUS DP,<br />

INTERBUS, Ethernet and CTNet<br />

• Expanded I/O option<br />

• CTNet Modular I/O<br />

• Range of HMIs<br />

• Dynamic Braking<br />

• Regenerative Braking<br />

58