Catalog - SP series - Allied Automation, Inc.

Catalog - SP series - Allied Automation, Inc.

Catalog - SP series - Allied Automation, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1OZ 2ABC 3DEF<br />

F1 F2 F3<br />

4GHI 5JKL 6MNO<br />

F4 F5 F6<br />

7PRS 8TUV 9WXY<br />

F7 F8 F9<br />

0 Space<br />

Del F10 +/-<br />

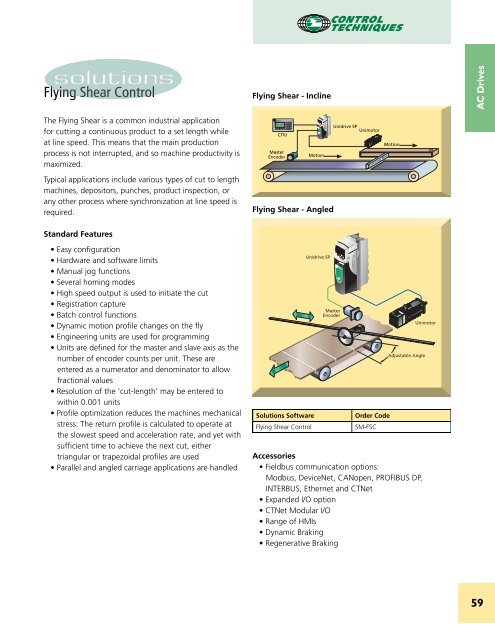

Flying Shear Control<br />

Flying Shear - <strong>Inc</strong>line<br />

AC Drives<br />

The Flying Shear is a common industrial application<br />

for cutting a continuous product to a set length while<br />

at line speed. This means that the main production<br />

process is not interrupted, and so machine productivity is<br />

maximized.<br />

Operator<br />

Interface<br />

CTIU<br />

Master<br />

Encoder<br />

Motion<br />

Unidrive <strong>SP</strong><br />

Unimotor<br />

Cutting Bar<br />

Motion<br />

Typical applications include various types of cut to length<br />

machines, depositors, punches, product inspection, or<br />

any other process where synchronization at line speed is<br />

required.<br />

Flying Shear - Angled<br />

Standard Features<br />

• Easy configuration<br />

• Hardware and software limits<br />

• Manual jog functions<br />

• Several homing modes<br />

• High speed output is used to initiate the cut<br />

• Registration capture<br />

• Batch control functions<br />

• Dynamic motion profile changes on the fly<br />

• Engineering units are used for programming<br />

• Units are defined for the master and slave axis as the<br />

number of encoder counts per unit. These are<br />

entered as a numerator and denominator to allow<br />

fractional values<br />

• Resolution of the ‘cut-length’ may be entered to<br />

within 0.001 units<br />

• Profile optimization reduces the machines mechanical<br />

stress: The return profile is calculated to operate at<br />

the slowest speed and acceleration rate, and yet with<br />

sufficient time to achieve the next cut, either<br />

triangular or trapezoidal profiles are used<br />

• Parallel and angled carriage applications are handled<br />

Solutions Software<br />

Flying Shear Control<br />

Unidrive <strong>SP</strong><br />

Master<br />

Encoder<br />

Order Code<br />

SM-FSC<br />

Adjustable Angle<br />

Accessories<br />

• Fieldbus communication options:<br />

Modbus, DeviceNet, CANopen, PROFIBUS DP,<br />

INTERBUS, Ethernet and CTNet<br />

• Expanded I/O option<br />

• CTNet Modular I/O<br />

• Range of HMIs<br />

• Dynamic Braking<br />

• Regenerative Braking<br />

Unimotor<br />

59