BIOQUELL Clarus L2 (609K) - APEX Laboratory Equipment Company

BIOQUELL Clarus L2 (609K) - APEX Laboratory Equipment Company

BIOQUELL Clarus L2 (609K) - APEX Laboratory Equipment Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

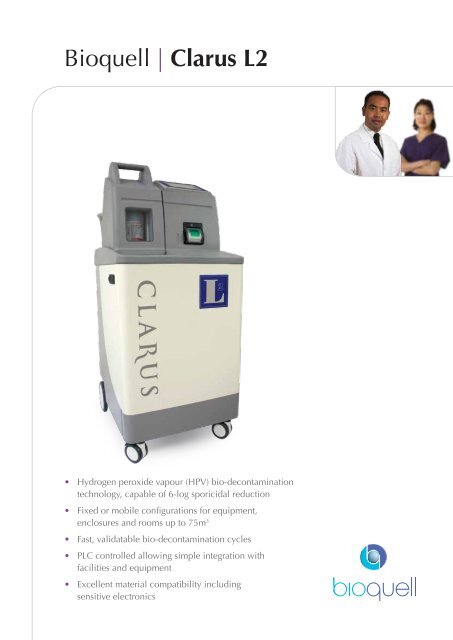

Bioquell | <strong>Clarus</strong> <strong>L2</strong><br />

• Hydrogen peroxide vapour (HPV) bio-decontamination<br />

technology, capable of 6-log sporicidal reduction<br />

• Fixed or mobile configurations for equipment,<br />

enclosures and rooms up to 75m 3<br />

• Fast, validatable bio-decontamination cycles<br />

• PLC controlled allowing simple integration with<br />

facilities and equipment<br />

• Excellent material compatibility including<br />

sensitive electronics

Bioquell <strong>Clarus</strong> <strong>L2</strong> multi-function HPV generator<br />

The Bioquell <strong>Clarus</strong> <strong>L2</strong> is a second generation hydrogen peroxide vapour<br />

(HPV) generator, replacing Bioquell’s widely used <strong>Clarus</strong> L HPV generator.<br />

The <strong>Clarus</strong> <strong>L2</strong> offers enhanced functionality and is able to bio-decontaminate<br />

both enclosures and rooms/laboratories up to 75m 3 . The <strong>Clarus</strong> <strong>L2</strong> has<br />

enhanced HPV delivery and control, as well as an improved user interface<br />

using touch screen controls.<br />

• Accurate measurement of the amount of hydrogen peroxide vaporised<br />

• Simple menu-driven user interface to set cycle parameters and access<br />

to bio-decontamination parameters<br />

• Graphical display of bio-decontamination cycle progress tracking critical<br />

parameters in real time<br />

• Communications port allows integration to building management system<br />

(BMS) or related systems and equipment<br />

• Data logging option allowing data export into Excel ® format<br />

• Multiple language options<br />

• Bioquell dual circuit technology for fast and efficient<br />

bio-decontamination cycles<br />

• No requirement for room dehumidification prior to cycles<br />

Operation<br />

Easy to clean and safe bottle loading mechanism with built-in drip<br />

tray and wipe clean mechanism. Housing accepts Bioquell 0.5 ltr<br />

and 1 ltr hydrogen peroxide solution allowing multiple cycles<br />

without intervention.<br />

A thermal printer allows for hard copy data recording. Each stage of the<br />

cycle is recorded and printed.

Bioquell hydrogen peroxide solution<br />

• Bioquell hydrogen peroxide is specified and<br />

approved for use with Bioquell HPV generators<br />

• Approved for use as a biocide by regulatory<br />

bodies (BPD, EPA)<br />

• Selected for optimal biocidal effectiveness<br />

Optional accessories include:<br />

• Remote control with room gassing distribution facility<br />

• Sensor pack - integrated hydrogen peroxide<br />

vapour sensor<br />

• Data logging and archive with USB interface<br />

• Hand-held HPV detector<br />

• External aeration/catalyst unit to reduce cycle<br />

times further<br />

Validation and service<br />

Fully validatable to comply with requirements of<br />

GMP using GAMP compliant software. Bioquell<br />

provides complete service including:<br />

• Installation and integration<br />

• Preventative maintenance plans<br />

• Extensive field-based service<br />

engineer network<br />

• IQ/OQ/PQ documentation<br />

and execution<br />

• Bio-decontamination cycle<br />

development services<br />

• Ongoing MQ and RQ support*<br />

*Provided as part of a preventative maintenance plan

Materials of external construction<br />

Temperature<br />

Operating 15°C to 35°C<br />

Storage -15°C to 50°C<br />

Relative humidity<br />

Operating<br />

Storage<br />

Top moulding – polypropylene<br />

Side panels – polyurethane coated aluminium<br />

75% RH maximum<br />

95% RH (non-condensing)<br />

Power requirement AC 220 – 240V 50 Hz (Euro) 6 amps<br />

AC 110 – 120V 60 Hz (USA) 12 amps<br />

AC 90 – 110V 50/60 Hz (Japan) 12 amps<br />

Power consumption<br />

Power supply<br />

Operating position<br />

Pollution degree environment 2<br />

Dimensions (WxHxD)<br />

Weight<br />

Maximum H 2<br />

O 2<br />

liquid volume<br />

H 2<br />

O 2<br />

liquid concentration<br />

Hose pipes<br />

Gas hose connections<br />

Control system<br />

Airflow rate<br />

Gassing<br />

Conditioning/aeration<br />

Temperature of supply gas at outlet<br />

H 2<br />

O 2<br />

liquid injection rate<br />

Refrigeration system off coil temperature<br />

Condensate removal<br />

1300W<br />

Installation category II<br />

Upright only<br />

515 x 1140 x 705mm<br />

80 kg<br />

1 litre<br />

30-35% w/w Bioquell hydrogen peroxide (stored at 2-8°C)<br />

1.5 inch nominal bore<br />

male/female<br />

Camlock fittings 1.5 inch<br />

Siemens ® S7 PLC<br />

(GAMP compliant software)<br />

Controlled at 25 m 3 /hr<br />

Controlled at 25 m 3 /hr at 750Pa external pressure<br />

75°C maximum<br />

Inlet air HEPA filter efficacy 99.997%<br />

Gassing & dehum circuit HEPA filter efficacy 99.997%<br />

Pressurisation system flow rate<br />

Pressurisation system range<br />

Noise<br />

1.5 to 6 g/min (gassing); 0 or 1.5 to 6 g/min (dwell)<br />

Approx 2°C (from 20°C return)<br />

Evaporation to atmosphere<br />

100 l/min (max)<br />

+200 to -200 Pa<br />

Less than 60 dBA at 1 metre (free field)<br />

Features in brief<br />

• Dual circuit technology for optimum cycle times<br />

• Closed circuit operation<br />

• Siemens ® colour touch screen<br />

• GAMP compliant software<br />

• Compact and highly portable design<br />

• Easily cleanable external surface<br />

• Volt-free contacts for external signals<br />

• Integral thermal paper printer<br />

• Remote start/stop<br />

• Simple connection, flexible supply/return hoses<br />

and pressure monitoring<br />

• Supply return hoses (2mtrs long)<br />

• Cycle edit and store facility for new applications<br />

• Effective against a wide range of micro-organisms<br />

• Hydrogen peroxide vapour gas sensor<br />

• Utilises 30-35% w/w Bioquell hydrogen peroxide<br />

solution in 0.5 ltr or 1 ltr<br />

• Maximum enclosure bio-decontamination 75m 3

Hydrogen peroxide vapour (HPV) technology<br />

HPV concentration<br />

1<br />

2<br />

3<br />

Inactivation of micro-organisms<br />

t=0*<br />

GASSING DWELL AERATION<br />

TIME<br />

* Conditioning phase not shown (vaporiser reaches temperature)<br />

Note: “features” on graph change e.g. depending on size of<br />

chamber (& related temperature effect)<br />

4<br />

5<br />

Schematic of Bioquell HPV concentration/time graph<br />

1. HPV introduced – initial rapid increase in HPV concentration<br />

2. HPV saturation/“dew point” achieved – onset of rapid bio-decontamination<br />

3. HPV gassing plateau – sustained micro-condensation effecting bio-deactivation<br />

4. Dwell period (contact time)<br />

5. Aeration – removal of HPV from the atmosphere typically by catalytic<br />

conversion to water vapour and oxygen, leaving no residues<br />

Schematic of dew point and Bioquell kill dynamics<br />

1. Injection of HPV into the enclosure starts (t=0)<br />

2. Only slight decline in biological indicator population prior to dew point<br />

3. Rapid micro-biological kill occurs immediately after saturation/“dew point” is achieved –<br />

process optimised to achieve reliable 6-log sporicidal reduction on all exposed surfaces<br />

4. Onset of micro-condensation correlates with rapid bio-deactivation<br />

5. Bio-deactivation achieved via micro-condensation (invisible layer) of hydrogen<br />

peroxide (2-6µm)<br />

* Typical BI: Tyvek ® pouched 6-log<br />

Geobacillus stearothermophilus spores<br />

Key benefits of HPV<br />

• Excellent material compatibility<br />

including sensitive electronics<br />

• Environmentally friendly -<br />

“residue-free” (breaks down to<br />

water vapour and oxygen)<br />

• Effective against a wide range<br />

of micro-organisms<br />

• High level disinfection achieved<br />

(6-log sporicidal reduction)<br />

HPV applications<br />

• GMP cleanrooms<br />

• Aseptic processing<br />

• Biologics<br />

• Biomedical<br />

• Biosafety/security<br />

• Material transfer chambers<br />

• Ambient decontamination of<br />

autoclaves/freeze driers<br />

• Robotic enclosures<br />

• Safety cabinets/isolators<br />

Key features and benefits of the <strong>Clarus</strong> <strong>L2</strong> HPV generator<br />

FEATURES<br />

Optimised cycle performance producing fast and effective<br />

bio-decontamination<br />

Flexible multi-use generator<br />

Critical condition monitoring with alarm set points for<br />

‘Alert’ or ‘Action’<br />

Advanced software and Siemens ® PLC controls for ease of<br />

use and operation<br />

BENEFITS<br />

Minimal process downtime – no need for preconditioning,<br />

process operates with ambient environment<br />

Can bio-decontaminate rooms and enclosures up to 75m 3 .<br />

Small footprint requiring minimal floor space<br />

Compatible with GMP and GLP requirements<br />

Simple integration into a building management system<br />

(BMS) or the <strong>Clarus</strong> PORT rapid decontamination<br />

transfer chamber

Other unique bio-decontamination<br />

solutions from Bioquell<br />

Bioquell RBDS rapid facility bio-decontamination service<br />

A unique bio-decontamination service from Bioquell<br />

for zones, rooms and buildings:<br />

• “Infinitely scalable” – no room or building too large<br />

• Emergency, scheduled, contract or new-build<br />

• Rapid deployment by highly trained Bioquell technicians<br />

Bioquell Material Transfer Solutions<br />

Bio-decontamination chambers:<br />

• Material transfer incorporating HPV bio-decontamination<br />

at ambient temperature<br />

• Rapid bio-decontamination leading to fast material transfer<br />

• Inflatable door seals for reliable, safe operation<br />

Bioquell Z HPV generator<br />

State-of-the-art bio-decontamination equipment offering:<br />

• Large scale room/zone bio-decontamination<br />

• Parametric cycle control<br />

• Simple to operate “plug and play”<br />

Disclaimer: Bioquell UK Ltd or its affiliates, distributors, agents or licensees<br />

(together “Bioquell”) reserves the right to change the specification of<br />

the Bioquell <strong>Clarus</strong> <strong>L2</strong> without notice. In addition, Bioquell makes no<br />

claims as to the guarantee of sterilisation using these products; however,<br />

Bioquell recommends that customers ensure that the requisite level of<br />

bio-decontamination is achieved using standard biological indicators such as<br />

6-log Geobacillus stearothermophilus spores; and the Bioquell <strong>Clarus</strong> <strong>L2</strong>, subject<br />

to appropriate cycle development, is designed to be able to provide such levels of<br />

bio-deactivation.<br />

Your local distributor:<br />

<strong>Clarus</strong> / Bioquell / RBDS are registered trade marks of Bioquell UK Ltd.<br />

© Bioquell UK Ltd (2010). All rights reserved.<br />

For further information on Bioquell’s technology:<br />

E: info@bioquell.com<br />

W: www.bioquell.com<br />

Bioquell UK Ltd<br />

T: +44 (0)1264 835 835<br />

Bioquell Ireland<br />

T: +353 (0)61 603 622<br />

Bioquell Inc<br />

T: +1 (215) 682 0225<br />

Bioquell SAS<br />

T: +33 (0)1 43 78 15 94<br />

Bioquell Asia Pacific Pte Ltd<br />

T: +65 6592 5145<br />

127/10