BIOQUELL Clarus L2 (609K) - APEX Laboratory Equipment Company

BIOQUELL Clarus L2 (609K) - APEX Laboratory Equipment Company

BIOQUELL Clarus L2 (609K) - APEX Laboratory Equipment Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

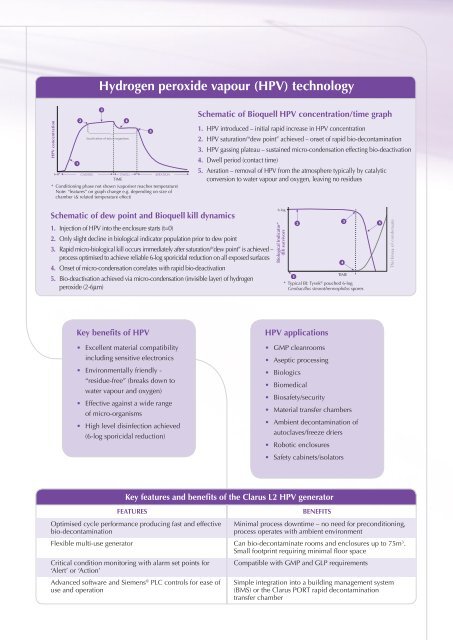

Hydrogen peroxide vapour (HPV) technology<br />

HPV concentration<br />

1<br />

2<br />

3<br />

Inactivation of micro-organisms<br />

t=0*<br />

GASSING DWELL AERATION<br />

TIME<br />

* Conditioning phase not shown (vaporiser reaches temperature)<br />

Note: “features” on graph change e.g. depending on size of<br />

chamber (& related temperature effect)<br />

4<br />

5<br />

Schematic of Bioquell HPV concentration/time graph<br />

1. HPV introduced – initial rapid increase in HPV concentration<br />

2. HPV saturation/“dew point” achieved – onset of rapid bio-decontamination<br />

3. HPV gassing plateau – sustained micro-condensation effecting bio-deactivation<br />

4. Dwell period (contact time)<br />

5. Aeration – removal of HPV from the atmosphere typically by catalytic<br />

conversion to water vapour and oxygen, leaving no residues<br />

Schematic of dew point and Bioquell kill dynamics<br />

1. Injection of HPV into the enclosure starts (t=0)<br />

2. Only slight decline in biological indicator population prior to dew point<br />

3. Rapid micro-biological kill occurs immediately after saturation/“dew point” is achieved –<br />

process optimised to achieve reliable 6-log sporicidal reduction on all exposed surfaces<br />

4. Onset of micro-condensation correlates with rapid bio-deactivation<br />

5. Bio-deactivation achieved via micro-condensation (invisible layer) of hydrogen<br />

peroxide (2-6µm)<br />

* Typical BI: Tyvek ® pouched 6-log<br />

Geobacillus stearothermophilus spores<br />

Key benefits of HPV<br />

• Excellent material compatibility<br />

including sensitive electronics<br />

• Environmentally friendly -<br />

“residue-free” (breaks down to<br />

water vapour and oxygen)<br />

• Effective against a wide range<br />

of micro-organisms<br />

• High level disinfection achieved<br />

(6-log sporicidal reduction)<br />

HPV applications<br />

• GMP cleanrooms<br />

• Aseptic processing<br />

• Biologics<br />

• Biomedical<br />

• Biosafety/security<br />

• Material transfer chambers<br />

• Ambient decontamination of<br />

autoclaves/freeze driers<br />

• Robotic enclosures<br />

• Safety cabinets/isolators<br />

Key features and benefits of the <strong>Clarus</strong> <strong>L2</strong> HPV generator<br />

FEATURES<br />

Optimised cycle performance producing fast and effective<br />

bio-decontamination<br />

Flexible multi-use generator<br />

Critical condition monitoring with alarm set points for<br />

‘Alert’ or ‘Action’<br />

Advanced software and Siemens ® PLC controls for ease of<br />

use and operation<br />

BENEFITS<br />

Minimal process downtime – no need for preconditioning,<br />

process operates with ambient environment<br />

Can bio-decontaminate rooms and enclosures up to 75m 3 .<br />

Small footprint requiring minimal floor space<br />

Compatible with GMP and GLP requirements<br />

Simple integration into a building management system<br />

(BMS) or the <strong>Clarus</strong> PORT rapid decontamination<br />

transfer chamber