Kein Folientitel

Kein Folientitel

Kein Folientitel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

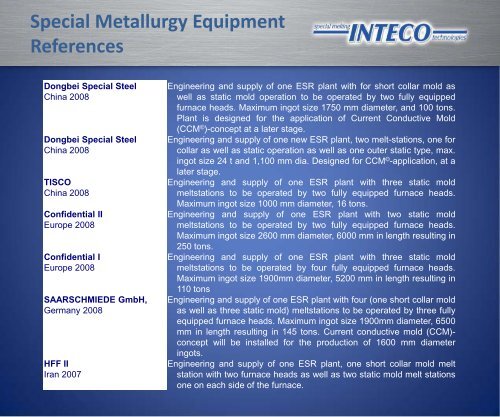

Special Metallurgy Equipment<br />

References<br />

Dongbei Special Steel<br />

China 2008<br />

Dongbei Special Steel<br />

China 2008<br />

TISCO<br />

China 2008<br />

Confidential II<br />

Europe 2008<br />

Confidential I<br />

Europe 2008<br />

SAARSCHMIEDE GmbH,<br />

Germany 2008<br />

HFF II<br />

Iran 2007<br />

Engineering and supply of one ESR plant with for short collar mold as<br />

well as static mold operation to be operated by two fully equipped<br />

furnace heads. Maximum ingot size 1750 mm diameter, and 100 tons.<br />

Plant is designed for the application of Current Conductive Mold<br />

(CCM © )-concept at a later stage.<br />

Engineering and supply of one new ESR plant, two melt-stations, one for<br />

collar as well as static operation as well as one outer static type, max.<br />

ingot size 24 t and 1,100 mm dia. Designed for CCM © -application, at a<br />

later stage.<br />

Engineering and supply of one ESR plant with three static mold<br />

meltstations to be operated by two fully equipped furnace heads.<br />

Maximum ingot size 1000 mm diameter, 16 tons.<br />

Engineering and supply of one ESR plant with two static mold<br />

meltstations to be operated by two fully equipped furnace heads.<br />

Maximum ingot size 2600 mm diameter, 6000 mm in length resulting in<br />

250 tons.<br />

Engineering and supply of one ESR plant with three static mold<br />

meltstations to be operated by four fully equipped furnace heads.<br />

Maximum ingot size 1900mm diameter, 5200 mm in length resulting in<br />

110 tons<br />

Engineering and supply of one ESR plant with four (one short collar mold<br />

as well as three static mold) meltstations to be operated by three fully<br />

equipped furnace heads. Maximum ingot size 1900mm diameter, 6500<br />

mm in length resulting in 145 tons. Current conductive mold (CCM)concept<br />

will be installed for the production of 1600 mm diameter<br />

ingots.<br />

Engineering and supply of one ESR plant, one short collar mold melt<br />

station with two furnace heads as well as two static mold melt stations<br />

one on each side of the furnace.