Kein Folientitel

Kein Folientitel

Kein Folientitel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

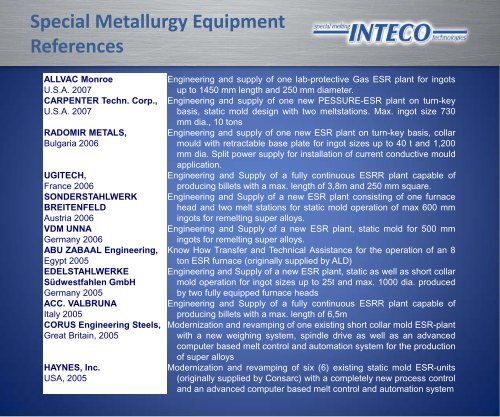

Special Metallurgy Equipment<br />

References<br />

ALLVAC Monroe<br />

U.S.A. 2007<br />

CARPENTER Techn. Corp.,<br />

U.S.A. 2007<br />

RADOMIR METALS,<br />

Bulgaria 2006<br />

UGITECH,<br />

France 2006<br />

SONDERSTAHLWERK<br />

BREITENFELD<br />

Austria 2006<br />

VDM UNNA<br />

Germany 2006<br />

ABU ZABAAL Engineering,<br />

Egypt 2005<br />

EDELSTAHLWERKE<br />

Südwestfahlen GmbH<br />

Germany 2005<br />

ACC. VALBRUNA<br />

Italy 2005<br />

CORUS Engineering Steels,<br />

Great Britain, 2005<br />

HAYNES, Inc.<br />

USA, 2005<br />

Engineering and supply of one lab-protective Gas ESR plant for ingots<br />

up to 1450 mm length and 250 mm diameter.<br />

Engineering and supply of one new PESSURE-ESR plant on turn-key<br />

basis, static mold design with two meltstations. Max. ingot size 730<br />

mm dia., 10 tons<br />

Engineering and supply of one new ESR plant on turn-key basis, collar<br />

mould with retractable base plate for ingot sizes up to 40 t and 1,200<br />

mm dia. Split power supply for installation of current conductive mould<br />

application.<br />

Engineering and Supply of a fully continuous ESRR plant capable of<br />

producing billets with a max. length of 3,8m and 250 mm square.<br />

Engineering and Supply of a new ESR plant consisting of one furnace<br />

head and two melt stations for static mold operation of max 600 mm<br />

ingots for remelting super alloys.<br />

Engineering and Supply of a new ESR plant, static mold for 500 mm<br />

ingots for remelting super alloys.<br />

Know How Transfer and Technical Assistance for the operation of an 8<br />

ton ESR furnace (originally supplied by ALD)<br />

Engineering and Supply of a new ESR plant, static as well as short collar<br />

mold operation for ingot sizes up to 25t and max. 1000 dia. produced<br />

by two fully equipped furnace heads<br />

Engineering and Supply of a fully continuous ESRR plant capable of<br />

producing billets with a max. length of 6,5m<br />

Modernization and revamping of one existing short collar mold ESR-plant<br />

with a new weighing system, spindle drive as well as an advanced<br />

computer based melt control and automation system for the production<br />

of super alloys<br />

Modernization and revamping of six (6) existing static mold ESR-units<br />

(originally supplied by Consarc) with a completely new process control<br />

and an advanced computer based melt control and automation system