Boot leg forming machine STF 1-2

Boot leg forming machine STF 1-2

Boot leg forming machine STF 1-2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

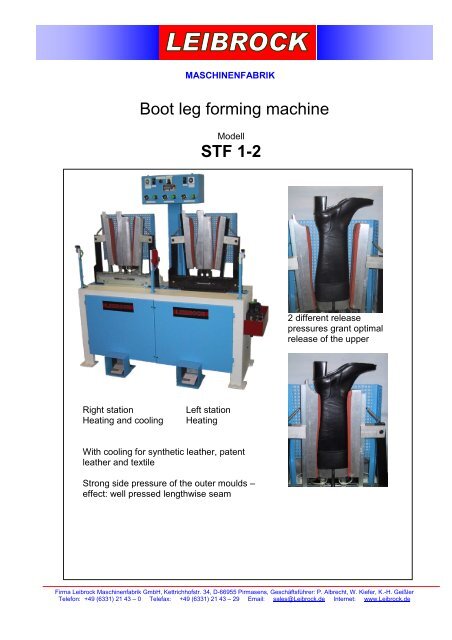

MASCHINENFABRIK<br />

<strong>Boot</strong> <strong>leg</strong> <strong>forming</strong> <strong>machine</strong><br />

Right station Left station<br />

Heating and cooling Heating<br />

Modell<br />

<strong>STF</strong> 1-2<br />

With cooling for synthetic leather, patent<br />

leather and textile<br />

Strong side pressure of the outer moulds –<br />

effect: well pressed lengthwise seam<br />

2 different release<br />

pressures grant optimal<br />

release of the upper<br />

Firma Leibrock Maschinenfabrik GmbH, Kettrichhofstr. 34, D-66955 Pirmasens, Geschäftsführer: P. Albrecht, W. Kiefer, K.-H. Geißler<br />

Telefon: +49 (6331) 21 43 – 0 Telefax: +49 (6331) 21 43 – 29 Email: sales@Leibrock.de Internet: www.Leibrock.de

<strong>Boot</strong> <strong>leg</strong> <strong>forming</strong> <strong>machine</strong> <strong>machine</strong> model <strong>STF</strong> 1<br />

The <strong>machine</strong> is used for the production of boots with high uppers.<br />

An improvement of quality is achieved, the upper of the boot is moulded free of wrinkles, the lining is<br />

ironed smoothly.<br />

If boots of the materials synthetic leather, lacquer or brush are processed we recommend to equip the<br />

<strong>machine</strong> with a cooling unit, so that the boot can be put again on cold moulds after having been on hot<br />

ones. In this case the boot keeps the desired shape.<br />

Serial equipment of the <strong>machine</strong>:<br />

• Electronic heating regulation for outer mould<br />

• Electronic heating regulation for the inner mould<br />

• Time adjustment for right working station<br />

• Time adjustment for left working station<br />

• Regulating valve with pressure gauge for extending pressure in the calf area<br />

• Regulating valve with pressure gauge for extending pressure in the heel area.<br />

• Regulating valve with pressure gauge for pressing pressure of the outer mould.<br />

The working method is described as follows:<br />

The boot is put on heated inner moulds that have been made according to the contour of the boot.<br />

A foot pedal is operated that causes the inner moulds to move and to extend the boot. Advantage: on<br />

one regulating valve with pressure gauge the extending pressure in the area of the calf can be adjusted,<br />

on a further regulating valve with pressure gauge the extending pressure in the area of the heel is<br />

adjustable.<br />

The movements of the inner mould have the result that the boot is now extended free of wrinkles and<br />

the lining is ironed smoothly.<br />

A two-hand release is operated, the silicone coated outer moulds move, press the seam, iron and mould<br />

the upper at the same time.<br />

Technical details:<br />

length, width, hight 1220x510x1440<br />

packing dimensions 1400x800x1650<br />

electrical supply 240V 50 Hz<br />

electrical contact 2,9 kW<br />

pneumatical contact 1/2"<br />

air consumption per pair 36 Ltr./ Paar<br />

weight gross (crate) 360 Kg ( Verschlag )<br />

weight net 220 Kg