SZH-9CD

SZH-9CD

SZH-9CD

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

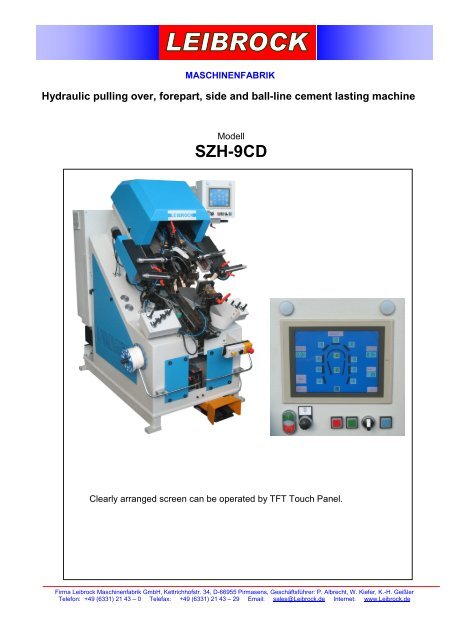

MASCHINENFABRIK<br />

Hydraulic pulling over, forepart, side and ball-line cement lasting machine<br />

Modell<br />

<strong>SZH</strong>-<strong>9CD</strong><br />

Clearly arranged screen can be operated by TFT Touch Panel.<br />

Firma Leibrock Maschinenfabrik GmbH, Kettrichhofstr. 34, D-66955 Pirmasens, Geschäftsführer: P. Albrecht, W. Kiefer, K.-H. Geißler<br />

Telefon: +49 (6331) 21 43 – 0 Telefax: +49 (6331) 21 43 – 29 Email: sales@Leibrock.de Internet: www.Leibrock.de

Hydraulic Pulling-Over-, Toe-, Side- and Ball-Lasting Machine<br />

With PLC-Control Model <strong>SZH</strong>-<strong>9CD</strong><br />

Advantages of Leibrock Lasting Machine:<br />

1st Advantage<br />

The shank wipers can be programmed differently – innen and outer ball-point – and automatically adapt itself during working process to the<br />

exact size of the shoe. Positioning is very accurate thanks to a motoric- not a hydraulic-movement.<br />

2nd Advantage<br />

Lasting cement (adhesive) will be attached on toe-area by a small extruder<br />

followed by programmable nozzles (tracers) in side and ball-area.<br />

The programming of the tracer-contour will be easily done for a shoe of medium size directly on the screen and all other shoe-sizes will be<br />

graded automatically. If a correction is necessary, this can also be done directly on the screen digitising-point by digitising-point.<br />

3rd Advantage<br />

Upper and lower position of the last support also can be adjusted directly on the screen.<br />

4th Advantage<br />

Pincer-pull can be adjusted each pincer-pair in mm-distance on the screen. By choice, each individual<br />

pincers can be re-adjusted manually via a lever nearby. It goes without saying, that all described adjustments can be stored per style and/or<br />

model of the shoe.<br />

5th Advantage<br />

Hydraulic machines can create problems, if oil-temperature is getting too hot or too cold. Movements of the machine will be more fast or slow<br />

and this can come to the result, that pincers when pulling the upper do not hold same position.<br />

Leibrock Lasting Machines will be protected by adding a heater and a cooler, so that always a steady temperature and perfect working<br />

conditions are guaranteed.<br />

One further advantage can be achieved by having steady temperatures of oil: Only very limited wear of all sealing-elements (gaskets).<br />

The Toe-Laster will be available in the following specifications:<br />

<strong>SZH</strong>-7C Hydraulic Toe-Lasting-Machine with PLC-Control, Rod-Cement-Supply and Extruder, with Ball-Lasting-Equipment,<br />

programmable, 7 pincers<br />

<strong>SZH</strong>-9C Hydraulic Toe-Lasting-Machine with PLC-Control, Rod-Cement-Supply and Extruder, with Ball-Lasting-Equipment,<br />

programmable, 9 pincers<br />

<strong>SZH</strong>-<strong>9CD</strong> Hydraulic Toe-Lasting-Machine with PLC-Control, Rod-Cement-Supply and small Extruder followed by a programmable nozzle<br />

(tracer)-system, with Ball-Lasting-Equipment, 9 pincers<br />

<strong>SZH</strong>-9CC Hydraulic Toe-Lasting-Machine with PLC-Control, Rod-Cement-Supply, full nozzle (tracer)-system = without any extruder, with<br />

Ball-Lasting-Equipment, 9 pincers<br />

Technical details:<br />

length, width, hight: 1700x1200x1750<br />

packing dimensions: 1800x1300x2000<br />

electrical supply: 230/400 V 50 Hz<br />

electrical contact: 4,0 KW<br />

pneumatical contact: 3/8“<br />

air consump.: 10 NL/Takt<br />

oilfilling: 60 Ltr.<br />

output pair/hour: 160 Paar/Std.<br />

weight net: 1200 Kg<br />

weight gross (crate): 1400 Kg