THE OFFICIAL PUBLICATION FOR BONANZA, BARON & TRAVEl ...

THE OFFICIAL PUBLICATION FOR BONANZA, BARON & TRAVEl ...

THE OFFICIAL PUBLICATION FOR BONANZA, BARON & TRAVEl ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>THE</strong> <strong>OFFICIAL</strong> <strong>PUBLICATION</strong> <strong>FOR</strong> <strong>BONANZA</strong>, <strong>BARON</strong> & <strong>TRAVEl</strong> AIR OPERATORS

Falcon Insurance is one of the largest mdepcndcntly owned<br />

IIlsurance specialists in the country. Our (lrofessional staff<br />

has decades of eX[lerience in aviation insurance, and we<br />

are uniquely qualified to provide com(llete insurance<br />

protection for AilS members.<br />

iThe ASS Program is one of the most cOlllprehensive<br />

insurance programs available in tlie industry today and<br />

features expanded coverages, access to a variety of underwriters<br />

and competitive rates. • • •<br />

is ileoicated to servmg ASS members with an msurance<br />

AmerIC~~<br />

Bonanza ~<br />

Soclet.!l~~<br />

~

ur 1e 013 Number 4<br />

Pubished by America"t Bonanza Society. OrganlZed.la'luary 1967<br />

A PR I L<br />

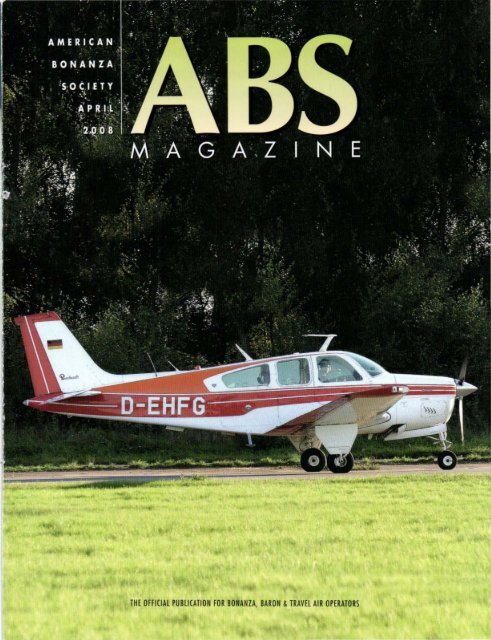

ON <strong>THE</strong> COVER<br />

10111 BEECHCRAFT<br />

OF <strong>THE</strong> MONTH<br />

Bernhard Rallderath's<br />

1977 F33A.<br />

FEATURES<br />

10113 WHY MY ENGINE FAILED<br />

By Ma, Groga/l<br />

10116 OSHKOSH AIRVENTURE:<br />

DISPlAY PlANE CONTEST<br />

CALL <strong>FOR</strong> TENT-TOPIC SPEAKERS<br />

10119 TRANSITIONING TO<br />

A NEWG58<br />

By Hal M. SUlllilojf<br />

10123 <strong>THE</strong> VALUE OF MY<br />

ABS MEMBERSHIP<br />

By Roben Hellley<br />

10124 CALL <strong>FOR</strong> SPEAKERS<br />

ABS CONVENTION<br />

LEXINGTON, KENTUCKY<br />

10129 FAA: MAINTENANCE<br />

ALERTS & SERVICE<br />

DIFFICULTY REPORTS<br />

TECH TALK:<br />

10132 CHANGING ENGINES<br />

PART V<br />

By Dick Pedersen<br />

10109 BPPP SCHEDULE<br />

10110 PRESIDENT'S COMMENTS<br />

by Art Brock<br />

10125<br />

10ngA<br />

10115 WHAT'S WRONG 10130<br />

hI' Adriall Eic/Jllom<br />

& ROil 7iilllllennallS 10136<br />

10111 AVIONICS<br />

by 101111 Co/liils 10139<br />

h.1' uw Gtlge<br />

TECH TIPS/NEIl'S NOTES 10141<br />

AD SECTION 10142<br />

<strong>FOR</strong>UM 10143<br />

SAVVY OWNER<br />

hy Alike Busch 10144<br />

MEMBERS IN <strong>THE</strong> NEWS 10144<br />

by Gerry Parker<br />

GA NEWS<br />

ABS AVIATORS<br />

AEROMEDICAL NEWS<br />

by Charles /)(lI'/(/SOIl, AID<br />

GENERATIONS<br />

10146 INSURANCE<br />

by 10/111 AI/ell<br />

Falcon 1,ISUI1J11ce<br />

10141 GROUND CONTROL<br />

by NOllc), Jolln.ron<br />

10141 ABS MEMBERSHIP<br />

APPLICATION<br />

EDITORIAL CALEN DAR 10148 EVENT CALENDAR<br />

Send articles/letters to:<br />

ABS Magozlne Publication Office<br />

PO. Box 12888. Wichita. KS 67277<br />

Tel : 316-945-17oo Fax: 316-945-1710<br />

E-mail: bonanzal@bonanza.org<br />

WebSite: http://www.bonanza.org<br />

~. lind photfllJ1ll'hs ~ub mi llfC/ rur pub/inlion hewmt 1M propffl)" or tbr Soddy<br />

Indshall not 1M! rtlurnnlArtn:ks submi ufC/ ..... Itb picllllri rtttl\~ publlCallOll prefemIiCC<br />

EDITOR-IN-CHIEF: Nancy Johnson. ABS Executive Director<br />

MANAGING EDITOR: BellY Rowley<br />

AIRCRAFT TECHNICAL EDITOR: Thomas P. Tumer<br />

ART DIRECTOR: Jim Simpson<br />

Display Advertising<br />

Director<br />

John Shoemoker<br />

2779 Aefo Pork Dnve.<br />

PO Box 968<br />

Tro.....arse C ty M149684<br />

1-800-327-7377. ext 3017<br />

F-Jx 231-946-9588<br />

E-mOII: johm NllOgepres. com<br />

ASS MAGAZINE (ISS!" 15)8·99601 IS pubh~ lIlOIIIhIy II) the Ammcan Bonmu.<br />

SoclCI,. [922 Midfield Ro.d., " r.elti ta, 1

ABS MEMBERSHIP SERVICES Monthly ABS Magazine · One-on-One Aircraft Advice<br />

• Beechcraft Pilot Proficiency Program · Aircraft Service Clinics · Air Safety Foundation Research &<br />

Development Projects · Regulofory & Industry Representation · Annual Convention & Trade Show<br />

• Affiliated Aircraft Insurance with Falcon Insurance · Members-only Website Section · Educational<br />

Books, Videos & Logo Merchandise · ABS Platinum Visa® (with RAPID Discounts) • Tool Rental<br />

Program · Professionally Staffed Headquarters<br />

1922 MIDFIELD ROAD, P.O. BOX 12888 , WICHITA, KS 67277 ASS exists to promote oviation safety and ftying enjoymentthraugh<br />

TEl: 316-945-1700 FAX 316-945-1710 E-MAIL:ABSmail@bononzo.org education and information-sharing among owners and operators of<br />

OFFICE HOURS: M-f 8:30 am - 5 pm (Central Time)<br />

Bonanzas, Borons, Debonairs and Travel Airs throughout the warld.<br />

ABS BOARD OF DIRECTORS<br />

TERM EXPIRES<br />

PRESIDENT<br />

ARTHUR W. BROCK (Area 6) ·2009<br />

Committee Choir: Events, Executive, Plonning.<br />

Technicol<br />

2631 Colt ReI" Rancho Palos Verdes, CA 90275<br />

phone: 310-548-8507. fox: 310-548-3767<br />

e-mail: brockorl@oot.com<br />

VICE PRESIDENT<br />

BILL STOVAll (Area 6) ·2009<br />

Committee Choir: AS~ Project Funding, Media<br />

32675 Woodside Or" Evergreen, CO 80439<br />

phone: J03..67(}'22.44, fox: 303-670-3385<br />

e-mail: billstovoll@evcohs.com<br />

SECRETARY<br />

RONALD LESSLEY (Area 5)<br />

Committee Cholr:'Bylows, Membership<br />

PO Box 1023. Claremore, OK 74018<br />

phone: 918-341-0741 ; fax 918-341-4464<br />

e-mail: ronlessley@sbcglobol.nel<br />

TREASURER<br />

STEPHEN P. BLY<strong>THE</strong> (At-large)<br />

Committee Choir: Finance. HR<br />

21065 Sorclay lane, lake Forest, CA 92630<br />

phone: 949-583-9500 ext. 131 , fax: 949-583-06d9<br />

e-mail: spb@blytheco.com<br />

2008<br />

2008<br />

ASST. TREASURER<br />

CHARLES S. DAVIDSON, M.D. (Area 3) ·2009<br />

Committee Choir: Aeromedical. Education<br />

1605 Wood Duck Ln .. Kill Devil Hills. NC 27948<br />

phone: 252441-5698, fox: 252-441-5853<br />

e-mail: chor1es_dovidson@chorter.net<br />

GREGORY KESHISHIAN (Area 1)<br />

401 East 74th Street. New'looc NY 10021<br />

phone 212-535-6617<br />

e-mail: gk(!i)gk-portners.com<br />

KEITH W. KOHOUT (Area 2)<br />

2128 East 2nd Streel. Covington, KY 41011<br />

phone: 513-479-2533<br />

e-mail: kk@flightresource.com<br />

ANDREW REARDON (Area 4)<br />

5S5 W. Westrelgh Rood, lake Forest, Il6004&'2717<br />

phone: 312-984-3816<br />

e-mail: ofreardon@ttx.com<br />

2010<br />

2010<br />

2010<br />

JON LUY (Area 7) '2008<br />

Committee Choir: Nominating, ReGional<br />

205 Amador Rood. Sutter Creek, CA 95685<br />

phone: 209-267-0167, fox: 209-267-0247<br />

e-mail: jdebonoir@hotmoil.com<br />

• Second and/or final term<br />

Executive Director, NANCY JOHNSON<br />

AB5-ASF Service Clinics provide a valuable 'second opinion' about the mointenance state 01 your<br />

Beechcraft. You 'll follow our highly experienced inspector as he checks your airplane in areas that<br />

often meril a closer look. Bring your mechanic so you can both learn more about your Beechcraft!<br />

On~ 5166 for Bonanza'iiDebonairs, 5233 for Baron..-rrovel Airs<br />

DATE LOCATION HOST/AIRPORT<br />

Apr 17-20 Tulsa, Oklahoma Roodhouse Aviation (RVS)<br />

May 8-11 Madero, California Sorber Aviation (MAE)<br />

Jun 5-8 Spokane, WaShington Spokane Airways (GEG)<br />

JuI IO-13 Greeley, Colorado Harris Aviation (GXY)<br />

Aug 21-24 Nashua, New Hampshire<br />

Oct 2-5 Rockford, Illinois Emery Air (RFD)<br />

Nov 6-9<br />

Edmonds Aircraft Service (ASH)<br />

Fernandina Beach, Florida Island Aviation (55J)<br />

Dec 4-7 Ramona, California Cruiseair Aviation (RNM)<br />

Register online ot www,bonanza.org or ASS headquarters 316-945-1700<br />

Apr 25-27<br />

Concord, California<br />

May 16-18 Colurnbus, Ohio (CMH)<br />

Sept 5-7 Manchester, NH (MHT)<br />

Sept 19-21 Waukesha, WI (UES)<br />

Oct 3-5 Santo Moria, CA (SMX)<br />

Oct 24-26 Richmond, VA (RIC)<br />

Nov 14-16 Tulsa, OK (RVS)<br />

Visit www.bppp.org for more info or to register. Bonanzas/Barons/Debonairs/Travel<br />

Airs at all locations. Cockpit Companion course available. Call the BPPP<br />

Registration Office to make arrangements: 97D-377-1877 or fax 97D-377-1512.<br />

Eligible for 70 ABS Aviator points.<br />

PAST PRESIDENTS<br />

BJ. McClonohon. MD 1967-1971<br />

Fronk G. Ross (dec.) 1971-1973<br />

Russell W. Rink (dec.) 1973--1975<br />

Hypolite 1. lOndry, Jr., MD 1975-1976<br />

Colvin B. Eorly, MD, PhD 1976-1977<br />

Copt. Jesse FAcloms USN(R) (dec.)1977-1978<br />

Dovid P Borton 1976-1979<br />

1979-1960<br />

Fred A. Driscoll. Jr. (dec.) 1980-1981<br />

E.M Ande

ABS-ASF spar web investigation<br />

It is difficult to project the facts in a dynamic situation when there is a sig·<br />

nificant delay between the time of reporting and publishing. I'm writing<br />

this in early March while you are reading it in mid·April. by which time I<br />

hope some importa nt and positive events will have taken place. Please<br />

bear with me as I bring you up to date on where we are right now.<br />

How we got to where we are<br />

As you know, a substantial part of the fleet is operating<br />

under two Airworthiness Directives (ADs)--{)ne for Bonanzas<br />

and Debonairs and another for Travel Airs and Barons-that<br />

require periodic inspections of the front wing spar carry-thru<br />

assembly for cracking, monitoring any cracks found and<br />

repairing them if they grow beyond specified limits.<br />

In 1996 the FAA adopted a policy that no longer allows<br />

continued operations wi th any cracks in primary structure, and<br />

in 2004 they notified ABS of their intention to revise the ADs<br />

to impose that "no cracks" policy on our airplanes. The only<br />

approved repair is installation of a doubler kit supplied by the<br />

Beech factory. This repair is very difficult to accomplish correctly<br />

and everyone agrees that improper installation poses a<br />

real threat to the integrity of the airframe.<br />

We have been operating under the inspection and monitoring<br />

program for 20 years and have a fleet-wide history of<br />

perhaps 60 mi//ioll flight hOllrs without a single mishap.<br />

Furthermore, in 2004 there was a growing body of qualified<br />

engineering opinion that the repair kit did not address the root<br />

cause of the cracki ng. In view of the fleet history, engineering<br />

opinions and the difficulties and risks associated with the<br />

repair, the ABS Technical Committee was concemed that<br />

eliminating the crack-monitoring program and requiring<br />

installation of the doubler kit in all cracked airplanes might not<br />

be in the best interests of our members.<br />

Although we asked, the factory was unwilling to share<br />

any engineering information. Consequently, the ABS Air<br />

Safety Foundation engaged two highly regarded consulting<br />

engineers to review the situation. Although suggesting a probable<br />

cause of the cracking, more importantl y, the reports recommended<br />

further study.<br />

ABS-ASF then sought bids and eventually contracted for<br />

an engineeri ng study to definitively determine the cause of the<br />

cracking and analyze the safety issues involved. Although we<br />

clearly hoped the study would provide the engineering basis<br />

for continuing the inspection and monitoring program. our primary<br />

goal was to understand the physics of the structure, the<br />

loads imposed on it, what was causing the craCking and to<br />

what extem small cracks posed a safety issue.<br />

Responding to our request, the FAA has held off on further<br />

action to allow us time to complete our investigation and<br />

has indicated they wi ll review and consider the results of that<br />

investigation in their final evaluation. Their forbearance in giv-<br />

ing us this window has been greatly<br />

appreciated.<br />

The study contract<br />

The investigation was conducted<br />

by J.B. Dwerlkotte Associates (JBDA)<br />

and consisted of developing a computer<br />

model (finite element model) of the<br />

airframe and the carry-thru structure, developing the loads to<br />

apply, instrumenting an aircraft (thanks to owner Robert<br />

Majoros), gathering stress data from actual flights, predicting<br />

crack propagation and analyzing and drawing conclusions.<br />

We received the contract fina l report from JBDA in<br />

ovember 2007. It is not an exaggeration to describe it as a<br />

very hefty document, both in terms of its physical size as well<br />

as its depth of content. It has been a real challenge for our<br />

Tech nical Committee to absorb its substance and put it in<br />

proper perspective. There was no way we could do that on our<br />

own and we relied heavily on our engineeri ng consultant,<br />

retired Boeing chief of structures engineering Peter Harradine.<br />

We have gone through about six rounds of detailed questions<br />

and answers, including several hours on the phone with JBDA.<br />

The bottom line is that the study is inconclusive in sever·<br />

al key areas. It just doesn't go far enough to get the answers<br />

that we need. That is not to say the study didn 't yield impor.<br />

tam insights and it does provides ABS-ASF with some really<br />

valuable anal ysis and data. But we are not able to answer some<br />

critical questions, at least not to the level of engineering certainty<br />

that we feel is necessary to go forward.<br />

JBDA worked diligently, accomplished a great deal and<br />

has been extremely cooperati ve during this review period and<br />

we have concluded their contract.<br />

Where we want to go<br />

JBDA and Peter Harradine are in total agreement that a<br />

fo llow-on phase of the investigation, expanding on the work<br />

already performed, should yield the definitive answers that we<br />

eek. There is no question that we have come a long way down<br />

the road of understanding, but we know we are not yet at our<br />

destination. Consequently, the Technical Committee has asked<br />

Peter to prepare a statement of work for a subsequent contract<br />

to take the investigation to the next level, and JBDA has agreed<br />

to perform the work in the near term.<br />

When we have an agreed-upon statement of work, price<br />

and schedule, we will determine whether to expand the investigation.<br />

If we decide to proceed, we'll then ask the FAA for<br />

their continued patience to allow us to complete it.<br />

By the time you read thi , we may have already<br />

announced the outcome on our website. If so, you already<br />

know how it comes out I hope you're smiling!<br />

Until next momh. -Art<br />

ABS April 2008 www.bonanza.org Page 10710

1977 F33A<br />

~[E[HCRAfl Of T~[ M~ T~<br />

made my own personal reasons and<br />

~<br />

experiences in flying a Bonanza a<br />

long time ago when I followed my<br />

heart and started working as an aircraft<br />

technician and engineer. While I<br />

was working in a general aviation maintenance<br />

station. I was selected to<br />

support my examiner during all the<br />

run-ups with the Bonanzas. I became<br />

addicted during the first run-up with this<br />

nice aircraft.<br />

I could feel immediately that there<br />

was something very special about the<br />

way it rolled, its size, the way it handled,<br />

coupled with the power during<br />

taxi, takeoff and flight-and I knew that<br />

someday I would be flying my own<br />

Beech Bonanza.<br />

It has been my experience that once<br />

you fly a Bonanza, you're hooked ! And<br />

now, today, [ own such a lovely<br />

Bonanza.<br />

When I new this 1977 F33A forthe<br />

first time, it was such a wonderful expeo<br />

rlFG<br />

Bernhard Randeralh<br />

Drochlersen. Germany<br />

rience and I was not aware that the aircraft<br />

was in the history books for having<br />

made a world record flight. An additional<br />

value- that [ initially underestimated-was<br />

the airplane's long duration<br />

of being parked in a hangar.<br />

The machine belonged to a manager<br />

of economics and [ shared D-EHFG<br />

with him kind of like a partner in a club<br />

membership. Although the arrangement<br />

was very fair and I enjoyed this time,<br />

the obligations became someti mes difficult<br />

and also the aircraft's condition was<br />

a problem.<br />

In December 1997, it finally<br />

became possible for me to purchase<br />

D-EHFG and begin a complete restoration<br />

. Some of the details involved<br />

replacement of avionics, autopilot, new<br />

paint and upholstery.<br />

My ski lls and experience as an aircraft<br />

technician and engineer certainly<br />

paid off. The deep troubleshooting in<br />

such an aircraft is a nice experience.<br />

That is what I love. Due to my former<br />

job in Lufthansa and now as an Airbus<br />

manager in maintenance engineering, I<br />

love specia lised troubleshooting cases.<br />

I learned that Bonanza problems<br />

can be solved in a more practical way:<br />

See what you think is the problem,<br />

study the manuals and then fi nd a way<br />

to fix it. Don't trust any computer in<br />

fault isolation when you have one on<br />

board. That's a big difference from what<br />

I'm investigating and developing on an<br />

Airbus where fault-isolation programmes<br />

are developed to find the right<br />

and fastest way to solve the problem.<br />

Nevertheless, I love my Bonanza<br />

with its great mechanical behaviour.<br />

After the restoration of D-EHFG, flights<br />

along the northern rOlltes to Sweden and<br />

Norway as we ll as the Southern<br />

European area became the greatest of<br />

pleasure. My father joined some of<br />

these trips and he became a pilot at the<br />

age of 63. lt was the Bonanza virus.<br />

During this period I was infornled<br />

that Dieter Schmitt, a former Beechcraft<br />

ferry pilot, had completed a "Lindbergh<br />

Memorial Flight" and set a world record

for a nonstop flight from JFK Airport,<br />

New York, to Munich , Germany in<br />

D-EHFG. That flight was made in the<br />

summer of 1977 in the record-setting<br />

time of 25 hours, 47 minutes. The flight<br />

entailed fl ying over the ocean without<br />

any GPS while dealing with weather<br />

and icing conditions.<br />

Now 83. Dieter holds a number of<br />

records with Bonanzas. To this day, I<br />

keep in touch with him, but nothing recognizable<br />

of hi s hi storical flight<br />

remains on this airplane. On ly logbook<br />

entries serve as a reminder of that great<br />

period in its history.<br />

Perhaps the possibility exists for me<br />

to accomplish the return fli ght from<br />

Munich to ew York, certainly not as an<br />

attempt to surpass Dieter's record time,<br />

but in honour of his accompl ishment.<br />

The first preparations for that fli ght are in<br />

place and perhaps within the next year or<br />

so, I will accomplish this adventure.<br />

In 2006, Bernhard Randeroth and<br />

eight other Bonanza owners and Beech<br />

enthusiasts founded the European<br />

Bonanza Society (EBS), which now has<br />

101 members.<br />

One of the biggest EBS events in<br />

2008 will be the 2nd European Bonanza<br />

Fly-In at Wilhelmshaven (EDWI) in<br />

Germany. September 4~7 .<br />

For more about EBS. contact<br />

Bernhard or go to www.beechbonanza.org<br />

or the EBS reservation desk<br />

www.ebs-services.de.<br />

EQU PMc~T LIST<br />

D-EHFG<br />

ADF Col ns RCR-650<br />

VHF Com 1/2 KY'97A<br />

JHF Nov Coil ns GLS-350E<br />

Damaged engine comportment ofter on inflight engine fa ilure.<br />

WHY MY ENGINE fAILED<br />

BY MAX GROGAN. KNOXVILLE. TENNESSEE<br />

lasl month my article on an emergency landing provided details of on inflight engine failure and<br />

a safe landing at an airport. This is a follow·up with the details of Ihat event. including the cause<br />

of the engine failure. my purchase of another engine and resumption of fiying.<br />

It was not immediately apparent why<br />

the engine failed. It was. however,<br />

visibly obvious through the hole in the<br />

engine case that the connecting rod of the<br />

#4 cylinder was broken, but not why.<br />

The rod had seized, welding itself to<br />

the crankshaft. As the crank rotated, the<br />

rod, unable to rotate around its bearings,<br />

broke in half. After breaking the rod, the<br />

crank was turned a bit more. The broken<br />

rod then impacted the engine case, making<br />

a four-inch hole. This resulted in broken<br />

pieces wedging into other pans of<br />

the engine. No longer able to tum, the<br />

engine was stopped. Elapsed time from<br />

the break to the stop was, for all practical<br />

purposes, immediate.<br />

After my emergency landing at<br />

Powell, Tennessee (9A2) with no further<br />

damage to the airplane, I had to fi g<br />

ure out how to get it to my home airport.<br />

For assistance I contacted Barry<br />

Sanders, the man who does its maintenance<br />

and inspections.<br />

I checked on the availability of a<br />

new engine and discovered it would be<br />

eight weeks before I could expect shipment.<br />

Fortunately, Barry had an engine<br />

he could install for temporary use. This<br />

would allow the plane to be flown back<br />

to Knoxville Downtown Island Airport<br />

(KDKX) and secured in my hangar. I<br />

would also be able to continue to fl y<br />

while waiting for the new engine.<br />

I removed all my personal gear and<br />

the avionics from the plane, installed the<br />

cover and contacted Teledyne Continental<br />

Motors (TCM) to arrange for a representative<br />

to inspect the damaged engine.<br />

Barry and T were there to observe<br />

when Joe Barton of TCM borescoped<br />

the engine, drained and captured the<br />

two quarts of remaining oil and took<br />

photos. Before he staned the examination,<br />

Joe prov ided a form that TCM<br />

would grant a core credit of $11,000 in<br />

exchange for the engine. He said TCM<br />

wo uld consider possible warranty coverage<br />

even though the engine was just<br />

beyond the warranty period.<br />

I then ordered a remanufactured<br />

engine for $27,8 11 including one-way<br />

shipping. Payment of this and Barry's bills<br />

seriously damaged my fl ying budget!<br />

A week later Barry, his mechanic<br />

Quentin Elkins and I removed the damaged<br />

engine and replaced it with Barry's<br />

loaned engine, which took about six<br />

Hole in engine case.<br />

hours. Barry flew the plane to his private<br />

airfield where he does his maintenance<br />

work and put the fini shing touches<br />

on the installation. He flew my<br />

Bonanza to KDKX the next day and it<br />

was home again!<br />

TeM shi pped me an empty engine<br />

crate with prepaid return shipping. The<br />

crate was marked "Warranty Department<br />

." We secured the damaged engine<br />

in the crate and shi pped it to TCM in<br />

Mobi le, Alabama.<br />

Prior to shipment, Barry diagnosed<br />

the cause of the failure. It was so simple<br />

and avoidable: Improper installation of<br />

a particular probe that provides oil temperature<br />

information to a JPI Model<br />

EDM-700 engine monitor.<br />

The oil temperature probe is a basic<br />

thermocouple sealed inside a metal tube<br />

brazed to a threaded shank. The length<br />

of the probe from the end to the beginning<br />

of the threads is one inch. Two<br />

wires exit the rear of the threaded shank<br />

for transmitting the temperature reading<br />

to an instrument on the paneL The probe<br />

is screwed into the engine at a place<br />

where it will be in contact wi th oiL The<br />

protruding wires are then attached to the<br />

wires going inside the cabin to the<br />

engine mon.itor.<br />

My plane's engine had run slightly<br />

more than 200 hours when J bought it.<br />

Whenever the engine probes were<br />

installed, the installer had a choice of<br />

locations for the oil temperature probe.<br />

He chose the location at the bottom of<br />

Page 10713<br />

www. bonanza.org<br />

ABS April 2008

Removing the damaged engine.<br />

the oi l cooler, even though the TCM<br />

literature specifies that it be installed on<br />

the top front of the engine.<br />

Oil coolers on this engine model<br />

are attached to the engine at the left rear.<br />

Thi s location is OK for installation of a<br />

probe IF IT IS DO E CORRECTLY. It<br />

was installed incorrectly on my engine.<br />

The male thread on the probe is 114"<br />

diameter. The fema le thread on the oil<br />

cooler is 3/8" diameter.<br />

For installation, a brass reducer<br />

bushing was used, an NPT 3/8" to NPT<br />

1/4". Barry discovered the bushing was<br />

not long enough. He measured the length<br />

of the probe while attached to the bushing<br />

and also the space available in the threaded<br />

hole. The space was not long enough<br />

when using this particular bushing.<br />

The engine is Shipped with a<br />

threaded stud at the bottom of the oil<br />

cooler, adjacent to the internal vernitherm<br />

valve. This valve works much<br />

the same as a coolant thermostat on a<br />

Installing the loaned engine.<br />

car engine. Engines perform best with<br />

warm oil. As the oil warms to optimum<br />

temperature, the valve opens, allowing<br />

oil to flow through the cooler. This cooler<br />

will maintain oi l at a temperature of<br />

about 180' to 200' F, optimally.<br />

When the vernitherm valve opens,<br />

it grows in size due to expansion of a<br />

spring as it heats up. In this particular<br />

installation, the spring was contacting<br />

the probe each time it expanded. This<br />

would have slightly flexed the probe<br />

each time the valve opened and closed,<br />

i.e. one cycle each flight.<br />

The probe broke after only 480<br />

hours of engine running time. When it<br />

broke it allowed the oil, which is under<br />

great pressure, to exit alongside the<br />

probe's wires. The diameter of the probe<br />

tube is about 1/16". In less than six minutes<br />

enough oil was ejected to allow heat<br />

to destroy the engine.<br />

There was not enough oil remaining<br />

in circulation to lubricate the connecting<br />

rod bearings-and probably other things<br />

as weU-by the time it seized. This oil<br />

wou ld have come out in a fine stream<br />

exiting the engine compartment above<br />

the left-side exhaust pipe.<br />

Simply put: The engine failed due<br />

10 heat. The high heat was caused by a<br />

lack of lubrication, resulting in friction.<br />

The loss of lubricating oil was due to a<br />

broken probe. The probe was improperly<br />

installed. The engine did not fail due<br />

to a manufacturing defect.<br />

The threaded stud 01 the bottom of the oil cooler is<br />

adjacent 10 the internal vernitherm valve. The<br />

original oil temperature probe was installed allhis<br />

locolian.<br />

When the original ail lemperature probe was ins lolled, the<br />

installer chose the looation at the boffam of the oil oooler adja·<br />

cent to the vemitherm valve, and installed it incorreclly. The mole<br />

probe thread is 1/4" dia. and the female thread on the oil cooter<br />

is 3/8" die. The brass reducer used was not long enough.<br />

The vemitherm valve works much like a coolant thermostat on a<br />

car engine. As the oil worms to optimum temperature, the valve<br />

opens, allowing oil to flow through the oooler. When the valve<br />

opens, it grows in size due to expansion of a spring as it heats<br />

up. The spring was contacting the oil temperature probe each<br />

time it expanded. stightly flexing the probe each flight. The probe<br />

broke after only 480 hours of engine running time, allowing oil to<br />

escope down the probe tUbe.<br />

ABS April 2008<br />

www.bononza.org Page 10714

As promi sed, in about eight weeks<br />

my new engine was received. Barry<br />

took out his engine and installed the<br />

new one. He did not use the hole on the<br />

oil cooler. He removed the 1/4" plug at<br />

the top front of the engine and installed<br />

the probe directly into it. This is the<br />

location TCM recommends.<br />

I hope that others fl ying with a<br />

probe installed at the oil cooler location<br />

will have it installed with the correct<br />

longer adapter bushing. Moving it to the<br />

recommended location is a better idea.<br />

If it is not, you may also experience an<br />

engine failure if the probe should break.<br />

TCM declined to give me warranty<br />

credit, but at least I got the core credit.<br />

They do not disclose their results on<br />

engine teardown and laboratory analysis<br />

(for liability reasons?). The total cost of<br />

my engi ne failure was about $33,000,<br />

including the two engine removals and<br />

two installations.<br />

Flying is not cheap! I learned that in<br />

1969, the year I became a pilot. However,<br />

I have found no other endeavor that is as<br />

thrilling, satisfying and enjoyable. I<br />

When the new eng ine was insta lled, they did not use the hole on the oil cooler. They removed the 1/4" plug<br />

at the lop front of the engine and installed the probe directly into it. This is the location that TeM recommends.<br />

believe life should be enjoyed as much as<br />

possible, while living up to one's responsibilities.<br />

Flying my Bonanza provides<br />

tremendous enjoyment.<br />

Yes, the engine failure was traumatic.<br />

BUll handled it successfull y and<br />

I continue to experience the joy of flying.<br />

I do admit, however, to having had<br />

some nervousness on my first few<br />

flights after the emergency.<br />

May this be the only engine failure<br />

ever experience. I hope to continue<br />

fly ing to exotic destinations and to have<br />

the speed, comfort and convenience of<br />

my Bonanza for many more years.<br />

N1512W is Max Grogan's second<br />

Bonanzo. He is a commercial pilot (1969)<br />

ASEL multi- and instrument-rated with<br />

2.000+ hours, a nd is president of the East<br />

Tennessee Genera l Aviation Association.<br />

- -- -- - - - - --<br />

. ADRIAN EICHHORN & RON TIMMERMANS<br />

These two photos are views up into nose wheel tunnels<br />

(wheel well immediately behind Ihe nose geor). Vou may<br />

seldom look up inside this area on your aircraft. but you and<br />

your mechanic will explore it when you attend on ABS<br />

Service Clinic or during a one-on-{)ne maintenance review at<br />

a BPPP clinic.<br />

As you compare these photos from two separate<br />

aircraft. you will discover a common flaw near<br />

the idler arm that should be a concern if it was<br />

found in your aircraft.<br />

See page 10742 for the answer<br />

Page 10715 www.bonanza.org ABS April 2008

S@OSH<br />

OSHKOSH TENT TOPICS<br />

Going to Oshkosh? Shore some of what you've<br />

learned with olher ASS members. We're looking for members<br />

to presenl Tent Topics in the ASS hospitality tenl during<br />

AirVenture 2008. Tenl Topics ore informal, 50-minule presenlalions<br />

on flying, mainlaining and owning Seech airplanes.<br />

Lei us know what you'd like to talk about, and which days<br />

you'll be at Oshkosh, by contacting Tom Turner at bonanza8@<br />

bonanza .org or 316-945-1700. See you at AirVenture!<br />

DISPLAY YOUR PRIDE & JOY AT OSHKOSH '08!<br />

Submil your airplane la be Ihe display plane al Ihe ASS Oshkosh<br />

lenl and grace Ihe cover of Ihe July 2008 ASS Magazine!<br />

If you are planning to be at Oshkosh for AirVenture 200B, July 2B-Aug. 3, here's how to make<br />

it extra special:The honor of displaying your airplane beside the ASS tent AND on the cover<br />

of the July ABS Magazine is up for grabs! In addition, the selected owner will receive two<br />

passes to AirVenture and to the ASS dinner!<br />

HURRY, <strong>THE</strong> DEADLINE <strong>FOR</strong> ENTRY IS APRIL 30.<br />

IF YOU HAVE ALREAOY SUBMIITED<br />

YOUR AIRPLANE <strong>FOR</strong> BEECHCRAFT OF<strong>THE</strong><br />

MONTH (MAGAZINE COVER) AND IT HAS NOT<br />

BEEN USED YET-FEEL FREE TO ENTER THIS<br />

CONTEST. JUST CONTACT US AND<br />

LET US KNOW.<br />

Here are the requ irements to be considered for the AirVenture ABS display airplane:<br />

1. Arrive July 27 10 place your airplane on display at the ABS tent the entire week of AirVenture (July 2B-Aug. 3).<br />

2. Check In 01 the ASS lent each morning to prepare your aircraft for display. (If you wont to open il up for people to see inside. that is up 10 you.)<br />

3. Check in each afternoon 10 secure your aircraft. (You, not Ihe ABS staff, will be responsible for your aircraft.)<br />

IF YOU CAN MEET <strong>THE</strong> OBLIGATIONS LISTED ABOVE, HERE'S HOW TO PUT YOUR PLANE IN NOMINATION:<br />

SUBMIT A PHOTO <strong>FOR</strong> COVER OF ASS MAGAZINE.<br />

Look at past covers for ideas. Prinl or digital pictures<br />

are occeploble, but high-res digital images<br />

are preferred. The most importanl points are Ihat<br />

Ihe pholo needs 10 be high resolution, clean.<br />

clear and show your airplane at its best.<br />

WRITE AN ARTICLE ABOUT YOUR AIRPLANE, and<br />

include an equipment lisl.You need nol be concerned<br />

about your writing skills. Just give us Ihe<br />

facts and your besl effort 01 putling your<br />

thoughls on paper. You will have an opportunity<br />

10 review the article after ediling 10 make sure<br />

you're pleased with the final result. Again,<br />

review pasl Beechcraft of Ihe Monlh articles,<br />

selecl a style that suits you and lell your story!<br />

SEND ADDITIONAL PHOTOS OF EXTERIOR AND<br />

PANEl. Other Ihan the cover shot and an equally<br />

sharp photo of the panel, we encourage you to<br />

provide a variety of pictures that Ihe magazine<br />

deSigner con choose from. "People pictures' are<br />

greal-wilh you, or you and your family ar<br />

friends, pased with your airplane. (Idenlify all<br />

people in photos.)<br />

Do not send your only copy of a pholo, as<br />

Iheyare nol relurned 10 you. Place a label on Ihe<br />

back of each phola with your name, tail number<br />

and model of your airplane. But do nol write<br />

directly on the bock of Ihe photo as thai con<br />

sometimes make it unusable.<br />

MAIL YOUR SUBMITIAL TO:<br />

Oshkosh BOM<br />

Americon Bonanza Society<br />

PO Box 12B8B<br />

Wichilo, KS 67277<br />

Q!l<br />

absmoil@bananza .arg<br />

E-mail subject line:<br />

OSH Display Plane<br />

REMEMBER, <strong>THE</strong> DEADLINE <strong>FOR</strong> ENTRIES<br />

IS APRIL 30.<br />

If your airplane is selected, you will be notified<br />

by early June.<br />

If your entry is nal chosen, the material you<br />

send will be filed for passible future use as a<br />

Beechcraft of the Month or as a teature story.<br />

DISPLAY PLANE &<br />

MAGAZINE COVER<br />

ABS April 2008<br />

www.bonanza.org<br />

Page 1

Putting it a ll together, Port II<br />

In my article in Ihe March issue we reviewed pilot actions when Hying<br />

on approach using a GNS480, a DAC GDC3l GPSS and a KFC200<br />

autopilot all working together. Now let's look at other differences in<br />

avionics and approach types.<br />

Difference between a DA and an MDA<br />

The DA is a decision altitl/de, Momentum may cause the<br />

aircraft to continue to descend below the DA for a brief time<br />

whi le you make your decision and start the aircraft back up for<br />

a mi ssed approach, (Note: An approach with a published DA<br />

is designed wi th obstacle clearance to permit this,) This is not<br />

true with a minimum descelll aitilllde (MDA). You have to<br />

level off at or above the MDA without descending below it<br />

until you have the runway in sight and are in a normal position<br />

to descend,<br />

If you descend below the MDA without the runway in<br />

sight, even briefl y, you have violated the regulations. More<br />

importantl y, you have put yourself and your passengers at risk,<br />

If you use the advisory vertical guidance and start a missed<br />

approach just before you reach the MDA, you will likely only<br />

complete approaches when the visibility and the cloud base are<br />

well above minimums. On the other hand, if you level off at the<br />

MDA and continue to the MAP, you will be able to safely complete<br />

approaches when the conditions are closer to minimums.<br />

ILS differences<br />

For an LLS, everything is similar except you must have<br />

tuned and identified the LLS frequency and selected the localizer<br />

as the navigation source for your HSI. The GNS480 and<br />

GNS530W can automatically switch the HSI navigation<br />

source to the localizer for an LLS approac h. There is an exception<br />

to the auto-switch capability when the autopilot is a<br />

KFC225 or a KAP 140 and the GPS is a 530W. In this<br />

instance, the GNS530W cannot be configured to auto-switch.<br />

GPSS differences and issues<br />

Certain installations of GPSS units can affect when roll<br />

steering is available to the autopilot. In an effort by the FAA to<br />

protect you from yourself on an ILS approach, they require<br />

that the GPSS be disabled when an lLS (localizer) frequency<br />

is chosen as the navigation source for the HSI. This means that<br />

if you try to get ahead of the situation when nearing your destination<br />

and select LLS as the source for the HSI, it will prevent<br />

the GPSS from providing steering to the autopilot.<br />

The switch will occur automatically when the navigation<br />

is auto-switched by the GPS . Supposedly this won't be a problem<br />

because, according to the Pilot Guide for the GNS480 and<br />

the GNS530W, the auto-switch does not occur until within 1.2<br />

nm of the final-approach course and aligned within 45 degrees.<br />

The problem is that I have seen my GNS530W auto-switch<br />

while going outbound,<br />

In my opinion this adds confusion at a critical time and is<br />

not a good idea. It is similar to the bogus idea that forced the<br />

prior generation of GPS annunciator control units (ACUs) to<br />

automatically switch the HSI to the nav radio anytime an [LS<br />

frequency was tuned in. I remember customers complaining<br />

that the ACU was broken, and that they could not select the<br />

GPS for navigation,<br />

Both the Icarus SAM I and the S-Tec 90 1 GPSS units can<br />

be disabled by the GPS, and installation manuals indicate that<br />

the disable is to be wired to the GPS. J have recommended that<br />

this interconnect not be done and several individuals have<br />

obtained a field approval for the change. The Century A K I 081<br />

and the DAC GDC-31 don 't have a disable capability, so it is<br />

not an issue for them.<br />

GPS differences<br />

The G S480 will provide roll-steering information<br />

throughout the entire procedure and automatically initiate the<br />

missed-approach guidance. This is true on an lLS final <br />

approach leg as well.<br />

Unfortunately, the GNS530W stops sending roll-steering<br />

commands to the GPSS at the FAF all the way to the MAP. For<br />

those with a legacy autopilot that has vertical guidance, this<br />

should not be an issue because GPSS and vertical gu idance are<br />

mutually exclusive. But if you are using an autopilot that does<br />

not have vertical guidance and prefer to use the GPSS for lateral<br />

guidance on an ILS approach, you are forced to switch the<br />

autopilot to the approach mode of tracking, which is not as<br />

precise or as smooth as roll steeri ng,<br />

Some will argue that it's not legal to fl y the final segment<br />

coupled through roll steering, In my opi nion, this is not strictly<br />

true. The requirement is that the HSl must use the localizer<br />

and GS as the source for displaying the ILS , The pilot must<br />

monitor the HSJ and is responsible for making any corrections<br />

to the flight path.<br />

The tools the pilot uses to accomplish this task are up to the<br />

pilot. Some pilots hand fly, some use a wing leveler, some use the<br />

heading bug with an autopilot, some use the localizer coupled to<br />

the autopilot, some use GPSS for the lateral autopilot control.<br />

Regardless, if the course or GS needs correction, as indicated on<br />

the HSI, the pilot is responsible for causing that correction.<br />

Autopilot differences<br />

Several of the S-Tec autopilots use the NAY key for<br />

approach mode instead of an APPR key, The Century Ul uses<br />

the LOC NORM key for the same purpose, The S-Tee 55X has<br />

GPSS roll steering built in and the pilot switches between nav

tracking and GPSS tracking by repeated pressing of the AV<br />

key. The 55X also has an APPR key to activate approach mode.<br />

The KFC 225 and KAP 140 autopi lots have roll steering<br />

built in. There are no autopilot keys for GPSS ; it is automatic<br />

if connected. Anytime the HSI nav source is GPS, the autopilot<br />

will follow roll steering.<br />

The autopilot does not support a GS when GPS is the nav<br />

source. So for the GNS530W, Garmin had to fake out the<br />

autopi lot to get it to capture a GS on GPS approaches. This is<br />

accomplished by a pseudo-signal that indicates to the autopilot<br />

that a localizer is the nav source when tracking a GPS<br />

approach with vertical guidance.<br />

Special software is used to prompt the pilot to activate the<br />

autopilot outputs and instruct the pilot to press the APPR button<br />

on the autopi lot. This same logic is not available on the<br />

GNS480, so the built-in KFC225 GPSS is not supported.<br />

To obtain GPSS with a KFC225, one approach is to add<br />

an Icarus SAM I connected through the heading-bug input.<br />

The DAC GDC31 GPSS unit would probably work, but the<br />

KFC225 is not included on the STC.<br />

John Collins, Charlotte, North Carolina. owns a 1968 V3SA. He is a<br />

commercial pilot with more than 4,(XX) hours. has a BS in electrical<br />

engineering and has YoIOrked as an engineer and software d~<br />

oper for IBM and for his own technical business. John owned on<br />

FBO with an avionics shop that he operated for six years.<br />

QUESTIONS FROM MEMBERS<br />

ROLL STEERING<br />

Bill and Pam Smead<br />

Greenvi lle. Tennessee<br />

Q: We read wilh interest your November<br />

2007 article and olher ABS articles on roll sleering.<br />

We fly a 1999 Baron with KfC225 AP/flighl<br />

direclor. 11 come from the factory wilh a KLN90B<br />

but we recently installed a Gormin 480.<br />

I have read several times Ihe flight manual<br />

supplemenl for the 225 and the aircraft pilot<br />

manual. We gel excellent course guidance and<br />

autopilot function in bolh NAV and APR modes for<br />

inbound and outbound GPS courses. but get no<br />

course guidance during the procedure turn or<br />

when ffying the holding poftern.<br />

The GNS480 does annunciate the correct<br />

turns. but this does not result in autopilot<br />

response unless we change to heading mode. If<br />

there's something we are missing on sefting up<br />

the units. we would appreciate your advice. If<br />

not. are there installation options that have not<br />

been hooked up that would odd these features?<br />

A: The KfC225 has a built-in roll steering<br />

via the ARiNC 429 intertoce that is capable of<br />

flyi ng holds. procedure turns. DME arcs and all<br />

of the flight plan turns. When the KfC225 internal<br />

ARINC 429 roll steering is connected to a<br />

GPS. it is automatically activated any time the<br />

GPS CDI buffon has GPS selected and outputs<br />

the GPS annunciator.<br />

The problem is that there is no support in<br />

the KfC225 for verticol guidance when ARINC<br />

429 roll steering is selected. So you can have<br />

GPS roll steering or GPS GS copture, but not<br />

both. The GNS480 intertoce to the KfC225 uses<br />

only the lofter.<br />

UPGRADING TO WAAS<br />

Steve Self. Dallas, Texas<br />

Q: I recently upgraded my Gormin 530 to<br />

WAAS and after reinstalling in my V35B, experienced<br />

a complete loss of sotellites after dialing<br />

in VOR frequencies upon returning to Dallas from<br />

Mississippi. We removed the box, placed it on the<br />

test bench and discovered the rodio portion hod<br />

foiled. It was returned to Gormin for repoirs.<br />

After the first WAAS upgrade, we experienced<br />

interior panel light failure on the boffom<br />

rheastats.After turning them on to light the circuit<br />

breaker ponel, electncol burning smells were<br />

present so they were turned off and we are now<br />

inspecting that system. Is anyone else experiencing<br />

similar problems offer Ihe WAAS upgrade?<br />

A: for the most port, the upgrades I am<br />

aware of went well. I know of two situations<br />

where there were problems. One was on a 430<br />

upgrade to a 430W. Shortly after it was reinstalled,<br />

within a few days, the screen backlight<br />

foiled. Even though the component involved<br />

was not covered by the WAAS upgrade warranty,<br />

Garmin accepted it bock as a warranty<br />

repair since it foiled so close to the upgrade.<br />

They confirmed the fault and replaced the<br />

power converter boord, but they also complete-<br />

Iy replaced the front bezel, screen cover and<br />

buffons with new for solely cosmetic reasons.<br />

The other situation I heard of indirectly, in<br />

a post on rec.aviation.ifr news server, occurred<br />

after installation of a WAAS version 3.0 software<br />

upgrade. I copied the report and am<br />

repeating it here:<br />

'I hod the upgrade installed a liffle while<br />

ago and it seems to have impacted my screen.<br />

After the rodio has been running a while, I<br />

notice that when I change pages, the previous<br />

page seems to have 'burned in' to the screen<br />

for a few seconds and gradually fades away. I<br />

also found that on startup, especially if the<br />

radio has been used in the previous hour or so,<br />

the screen was nearly impossible to read until I<br />

manually set the display seffings contrast.<br />

"I contacted Garmin tech support and<br />

they said they'd seen something like this with<br />

the upgrade. They hod me set the contrast as<br />

"auto" and set the contrast to a number around<br />

095. They said it's best to leove the contrast as<br />

auto, since apparently it needs to be constantly<br />

tweaked as the screen heats up, but that the<br />

new software sometimes fouls up the reference<br />

poinl, setting it too high.<br />

"I set the contrast to 095/auto, and now it<br />

works at startup. But I notice that after the unit<br />

has run a while, the "burn in' is still there,<br />

although it fades after a few seconds. I suspect<br />

that either the new software makes the unit run<br />

hofter, or it has a problem adjusting contrast as<br />

the radio heats up.'<br />

@

TRANSITIONING TO A NEW G58<br />

BY HAL M STANlcOFF. EAST SETAUKE': NEW YOR~<br />

N <strong>THE</strong> SUMMER OF 2007 [ realized<br />

I constantly found myself running into<br />

more "no-go" than "go" decisions with<br />

my A36.<br />

My wife and [ have a summer home<br />

on Martha's Vineyard and use the house<br />

quite a bit during the spring and summer.<br />

The TEC routing for single-engine<br />

aircraft from Long [sland MacArthur<br />

(KlSP) keeps us close to land for most<br />

of the way up until aboUl the last 10<br />

minutes of the flight where we are out<br />

of glide range. This small. but significant<br />

window of exposure always worried<br />

me.<br />

During the summer months in the<br />

Northeast. !MC becomes more of an<br />

issue. Although my Bonanza was<br />

recently upgraded with WAAS and the<br />

GDL69 Weather Link, I did not feel<br />

comfortable dodging weather, perhaps<br />

at night, over the water. in IMC-especially<br />

with my kids on board. Even<br />

though I consider myself a competent<br />

and safe instrument pilot, [ believed this<br />

to be too risky. Also, when departing the<br />

Vineyard, ATC tends to keep you on the<br />

straight-out after departing Rwy 24 -<br />

clear over the ocean. Another overwater<br />

exposure.<br />

In October 2003, we found ourselves<br />

in icing conditions on our way up<br />

to Burlington, Vermont. This was before<br />

the Weather Link upgrade. The fuel<br />

vents on the Bonanza are not heated. A<br />

vaporlock in icing conditions over the<br />

mountains would most likely have<br />

ended in disaster if we had gone down.<br />

Luckily, I worked my way out of it and<br />

we landed safely at Burlington.<br />

1 wanted to fly down south to visit<br />

family, but my Bonanza would never be<br />

able to accommodate our luggage ror<br />

seven days, even if we packed light.<br />

Taking off heavy, in warm temperatures,<br />

could have me experiencing longer<br />

takeoff distances and anemic climb performance.<br />

Sure, 1 could offioad fuel, but<br />

that would shorten my trip legs, thus<br />

extending the time for my trip.<br />

We have all heard the argument: "[s<br />

a twin aCllIally safer than a singleT' [<br />

wrestled with this debate many times<br />

with my long-time night instructor. aviation<br />

mentor and good friend, Master<br />

CFI and BPPP instructor Paul<br />

Gretschel. He told me. "With proper<br />

training and proficiency. you'll be fine.<br />

Proficiency is the key. You can do this,<br />

no problem."<br />

Although this was a strong statement<br />

coming from my flight instructor,<br />

1 began asking everyone who knows<br />

about me and my flying experience if<br />

Page 10719<br />

www.bonanza.org<br />

ABS April 2008

they thought I was about to become initiated<br />

into the "More Money Than<br />

Brains" club. Everyone of my aviation<br />

friends, along with my family, encouraged<br />

me and said, "You can do this!"<br />

My confidence swelled. So ...<br />

In April 2007, I contacted Byron<br />

Severson, the regional salesperson for<br />

Hawker Beechcraft (HB C) in the<br />

Northeast, and told him I wanted to buy<br />

a new G58. We came to terms and I put<br />

a deposit down that month. Now there<br />

was no turning back! And in October<br />

2007, I sold my beloved Bonanza. It<br />

was a sad day!<br />

Training lor Ihe Baron<br />

Immediately. I began renting my<br />

friend Mike Cain's 1976 B55 to start<br />

building multiengine time. In ovember<br />

2007, I completed the BPPP Baron Initial<br />

in that airplane. I also began reviewing<br />

the FAA's muitiengine resources as well<br />

as at-home study courses. I went back<br />

over King Schools' Cleared for Multi<br />

Eugiues that I completed when I earned<br />

my multiengine rating.<br />

Since the G58 is equipped with the<br />

Garmin G 1000, I also felt the need to<br />

start studying up on the avionics. I purchased<br />

King Schools' Cleared for<br />

Flyiug the G1000 and took copious<br />

notes. I also purchased the G I 000<br />

avionics simulator for my PC and<br />

installed a joystick so I could start<br />

working on the instrument scan.<br />

Then I contacted FlightSafety to<br />

request the G58 8arou Pilot Traiuing<br />

Manual so I could start studyi ng it prior<br />

to my arrival. This turned out to be<br />

worthwhile because when I got 10<br />

FlightSafety, I was in a position to ask<br />

better questions about the airplane and<br />

its systems.<br />

h was the beginning of January. My<br />

Baron was scheduled for delivery on<br />

February I . I found myself with really<br />

nothing more to prepare for other than<br />

the actual acquisition of the aircraft.<br />

Beechcraft originally wanted to do<br />

the customer acceptance night on<br />

Friday. Febmary I. the day before my<br />

flight horne to Long Island. This pre-<br />

sented a problem since FlightSafety<br />

training was to end with a course-completion<br />

flight on that Friday. That also<br />

would have left me with very little time<br />

to address any last-minute issues wi th<br />

the airplane as well as deal with any<br />

weather issues for the trip home.<br />

HBC accommodated me and I did<br />

my acceptance flight on Wednesday,<br />

January 30. The plane wasn' t detailed<br />

yet-a fact they kept reminding me<br />

of-but I didn't care. The goal was 10<br />

identify any glaring issues before<br />

accepti ng the airplane.<br />

I completed the acceptance and<br />

identified only some minor cosmetic<br />

squawks. The plane was perfect! After<br />

the flight, the Baron went immediately<br />

to detail and spent all day Thursday the<br />

31 st having the finishing touches done<br />

along with addressing my concerns.<br />

Taking dellverv<br />

On Friday morning, Febmary I, I<br />

met my new salesperson, Jenny<br />

Elsenrath, at the CuslOmer Delivery<br />

Center. Since Byron Severson had been<br />

transferred to Austria, Jenny handled<br />

the final aspects of my Baron's delivery.<br />

She was excellent.<br />

After the photo shoot that morning,<br />

I was schedu led to fl y my course-completion<br />

flight with Dylan Lamb of<br />

FlightSafety. During that flight, the<br />

MFD on the G 1000 reported a "stuck"<br />

joystick. So HBC replaced the MFD<br />

and also fixed a software configuration<br />

issue with the GWX-68.<br />

[ was sweating a little bit; concerned<br />

Nancy and Hal Staniloff absolutely love their beautiful new Boron.<br />

that they wouldn't get this done in time<br />

for my departure the next day. But HBC<br />

is running three shifts to meet the<br />

demand of the European market, which<br />

seems to be exploding due to the weak<br />

dollar. [n the end, they got it done and we<br />

were able to depart on Saturday to Long<br />

Island, MacArthur Airport (KJSP).<br />

The G1000 panel<br />

The G I 000 panel is a quantum leap<br />

forward in avionics design and implementation.<br />

Anyone thinking about transitioning<br />

10 a G 1000-equipped airplane<br />

shou ld know that extensive experience<br />

with the GNS530/430 will make the<br />

G I 000 seem like old hat.<br />

I had no problem dealing with the<br />

interface. !n fact, with a few exceptions,<br />

it's the same as the 530/430. But be<br />

warned: The instmment scan on the<br />

PFD is different. Gone are the days of<br />

the "music-beat" scan and the like. The<br />

G I 000 PFD compresses your scan and<br />

puts everything you need right in front<br />

of you. It's a brave new world.<br />

As for the Baron? Well. what else<br />

needs to be said? h's beautiful. It's<br />

totally awesome. Lots of power along<br />

with great styling and superb handling<br />

characteristics. I absolutely love my<br />

new G58!<br />

For more photos, visit http://<br />

gallery.mac.comihstaniloff# I 00 154.<br />

Hal Staniloff is a commercial. instrument,<br />

multiengine pilot and advanced/instrument<br />

ground instructor wtth more than<br />

1,200 hours of time. He con be reached<br />

at halagi@mac.com.<br />

ABS April 2008<br />

www.bonanza.org Page 10720

CELESTIAL HAPPENINGS<br />

I hod a column in August lost yeor about my good luck at getting in on<br />

the tail end 01 Ihe ancient art 01 celestial navigation, adapted lor use in<br />

aircraft. Members must be reading their ABS Magazine thoroughly<br />

because I received a number 01 phone calls and e-moils saying it's an<br />

interesting article, and they would like a more complete explanation 01<br />

how observing a celestial body (sun, moon, stors and planets) could tell<br />

anything about where we are on the surtoce-or in this case above the<br />

surtace-ol the earth. So if you are really interested. read on.<br />

Although the celestial navigator does in fact measure the<br />

altitude of any selected body above the horizon, the actual information<br />

needed to determine the observer's line of position<br />

(LOP) is the angle in degrees and minutes of degrees (60 minutes<br />

of angle in each degree) from the observer's zenith (directly<br />

overhead), Of course the best way to determine that angle is<br />

to use either the real horizon or a bubble horizon described in the<br />

August 2007 article on sextants used in aircraft.<br />

An example: If the measured angle were 40 degrees above<br />

the horizon, the angle from the observer's zenith would be 50<br />

degrees (50 + 40 = 90), Since there are 60 nm in each degree<br />

of arc of a sphere the size of the earth, the SP of the observed<br />

body is 3,000 om (50 times 60 = 3000) from the observer. Of<br />

course the observation is made in degrees and minutes of angle<br />

to provide accuracy to the closest mile, But to keep the math<br />

simple, mostly for my benefit, we will give the examples in<br />

whole degrees only.<br />

So, if we knew the exact position of the body's SP and the<br />

direction in which we were looking at the time of the observation,<br />

we could plot from the SP the reciprocal of that direction for<br />

the 3,000 miles (in this example), and that would be our position.<br />

Plotting a distance of that magnitude, however, would not<br />

only be very cumbersome and require a chart the size of a tennis<br />

court, but there would also be several errors in the plotting<br />

that would negate the accuracy needed. However, that is the general<br />

principal of using the stars, etc, for obtaining a position.<br />

So instead of doing that mega plotting, we used the navigator's<br />

volumes that were stored in the navigation locker<br />

above the nav table to substitute for the 3,000 nm line on a<br />

chart. Those books wou ld be the Air Almanac and the two volumes<br />

of the Sight Reduction Tables (all out of print now, so I<br />

have been told).<br />

Navigating by the stars<br />

Most people know that if one observes the star Polaris and<br />

its altitude in degrees above the horizon (polaris may only be<br />

observed north of the Equator), you will know the north latitude<br />

of your position. Actually, that is not an exactitude, for<br />

Polaris is not exactly above the true North Pole but rather<br />

orbits the pole describing, as best I can recall, a 36-nm circle.<br />

The subpoim (SP) describes this circle on the earth's surface,<br />

The SP of any body is that point on the surface ofthe earth that<br />

is on an imaginary line fro m the center of the body to the center<br />

of the earth.<br />

Polaris is the only body used in navigation that provides<br />

any useful information by knowing its altitude above the horizon<br />

and then only approximately, unless Greenwich Mean<br />

Time (GMT) is taken into account so we know where the SP<br />

is at that moment.

Golden Age of Exploration<br />

The navigators during the golden age of exploration, after<br />

accurate timepieces were developed, did the calculations with<br />

pen and paper, a process that required a great deal of computation<br />

time. But that was all OK since the vessel was moving<br />

very slowly. At 450-plus knots in the 707, the math was in tabular<br />

form in the above-mentioned publications. Good thing,<br />

too, since the first handheld calculators (Casio Personal M-l)<br />

did not appear until about a year after I started navigating. And<br />

although we all learned to use the sight reduction tables, there<br />

would have been few or none who would have been able to<br />

handle the manual method of the necessary computations.<br />

By knowing the approximate position of the aircraft, we<br />

would take an assumed position (AP) on the chart that was fairly<br />

close (maybe 100 miles maximum) to our estimated position.<br />

By using the sight reduction tables and air almanac, we<br />

would be able to determine that IF we were at the assumed<br />

position, we would see the selected body at a certain altitude<br />

at the exact desired time of the fix. Since<br />

we actually were not at the AP, we<br />

would see the body either higher or<br />

lower than the computed height.<br />

Let's assume we determined that<br />

we should see the body 40 degrees<br />

above the horizon if we were actually at<br />

the AP at the desired time of the fix.<br />

(Refer to my previous article in the<br />

August issue on page 10372 on how the<br />

Kollsman Periscopic Sextant functioned.) However, with the<br />

sextant we measure the altitude as 41 degrees. Now, the only<br />

way we can see it higher is to be closer to the SP of the body.<br />

Picture yourself in a room with a light fixture mounted on the<br />

ceiling. As you enter the room, the light fixture appears at<br />

some low angle of elevation. As you get closer, it gains altitude<br />

until you are directly under it, at which time it is at your zeni th<br />

or 90 degrees above the horizon.<br />

Since in our example we see the body one degree higher<br />

than we should have seen it at the AP, our actual position is 60<br />

nm toward the body. Since we know the direction we took the<br />

observation, we can plot a line out of the AP for 60 nm, draw<br />

a line at right angles to that plotted line and we now know our<br />

actual position is somewhere on that 90-degree line.<br />

By doing the same procedure for one or two other bodies<br />

and crossing the first line of position (LOP) with the second<br />

LOP, we can get an actual position for the time of the fix. If<br />

three stars or other bodies are used, and the three LOPs do not<br />

form a pinpoint on the chart but rather a triangle of hopefully<br />

small dimensions, the triangle is bisected so the center is located<br />

and that is the fix position.<br />

I have read accaunts of pilots<br />

going to the rear lavatory of a DC-4<br />

or other such airplane or window,<br />

taking a celestial observation from<br />

the porthole and claiming to get<br />

an accurate LOP from such a<br />

sighting location. I really doubt the<br />

result would have much accuracy.<br />

Techniques taught in navigation schools<br />

Of course, there were many techniques taught in the very<br />

fine Pan American World Airways (gone but not forgotten)<br />

Navigation School and many others developed by the individual<br />

navigators as they gained experience to make all the monkey<br />

motion described in this article take a relatively short time.<br />

There were also needed corrections to the observed altitude<br />

that might need to be used in these computations. These<br />

might include refraction caused by the bending of light as it<br />

passes through the earth's atmosphere (you can see about 3<br />

degrees over the horizon at low body elevations) when shooting<br />

bodies at very low elevations; the semi-diameter of the<br />

earth when shooting close Objects such as the sun, moon or<br />

planets (stars are considered to be an infinite distance away,<br />

and the fact we are not taking the observation from the center<br />

of the earth is negligible for stars and only comes into play<br />

with close-in bodies when they begin to get rather low in elevation);<br />

and many other such corrections as necessary to make<br />

the resultant computations as accurate as<br />

possible within the capability of the navigator's<br />

equipment to determine angles.<br />

I have read accounts of pilots going<br />

to the rear lavatory of a DC-4 or other<br />

such airplane or window (Beech 18s,<br />

Cessna 172s, etc.) and taking a celestial<br />

observation from the porthole and claiming<br />

to be able to get an accurate LOP<br />

from such a sighting location. I really<br />

doubt the result would have much accuracy. Although being able<br />

to accomplish reliable fixing using celestial observations does<br />

not take more than an average working brain, one needs proper<br />

training and a suitable place to take the observations and equipment.<br />

A three-star fix could be computed, shot and plotted in<br />

about 15 minutes and would provide a definite position for the<br />

navigator. Hopefully the position would be on the flightplanned<br />

track drawn on the navigation chart, proving that the<br />

heading slips being passed up to the pilots were good ones and<br />

that the pilots were able to fly those headings.<br />

That last concern was a real issue at times. I have had very<br />

senior captains fly off the posted heading as much as 20<br />

degrees for no other reason than that they misread the compass.<br />

Well, we had to make allowances for those really old<br />

guys. After all, some were pushing past 55 on their way to 60!<br />

ABS Life Member l ewis C. Gage has AlP multiengine land with<br />

Boeing 707/720/747 {Airbus-3tO rotings. Commerciol singleengine<br />

land: flight instructor MEl/SEl airplanes and instruments;<br />

ground instructor advanced and instrument: flight navigator:<br />

flight engineer; mechanic-airplane and engine: and FAA parts<br />

manufacturing authorization. Flight time: 15,QOO-plus hours. Lew<br />

may be contacted at 2255 Sunrise Dr., Reno, NV 89509.<br />

Phone/ Fax: 775-826-7184. E-mail: sunrisereno@gmail.com

1947 Bonanza. SIN 0·948, prior ta purchase.<br />

<strong>THE</strong> VALUE OF MY<br />

I<br />

acquired a 1947 Model 35, N3738<br />

(D-948), in March<br />

2007. I have owned several Beech airplanes-a V35B,<br />

F33A, A36 and D17S Staggerwing, but this is my fIrst<br />

early-model Bonanza and I soon discovered I still had a lot to<br />

learn. ABS has provided the way to do it.<br />

I first joined ABS in 1989 and my wife and I had the privilege<br />

of getting flight instruction from Lee Larson, Jack<br />

Hirsch, Ken Pearce and Bill Guinther. I attended BPPP, Phases<br />

I and II. I have also provided ground and flight instruction for<br />

the BPPP mountain flying course.<br />

38N has the Miller Truss, a Continental E-225 enoine and<br />

"<br />

all ADs had been complied with before [ took ownership. I<br />

now have a copy of Lew Gage's E-Series Bonan zas - Flying,<br />

Owning and Maintaining a Classic (available from ABS) to<br />

help me learn about my classic Bonanza.<br />

In the September 2007 ABS Magazine, fellow Arizonan<br />

Frank Wolfe's Diary of an Emergency Landing caught my eye.<br />

He chronicled his plight when his engi ne-driven fuel pump<br />

failed. He made an emergency landing and was lucky to find a<br />

good off-airpon landing spot. The postscript to the anicle<br />

indicated Frank was installing an electric auxiliary fuel pump.<br />

I had an auxiliary fuel pump with a 337 documenting its<br />

installation in 1953. The 337 showed it was a Pesco Model<br />

T-llOO electric fuel pump. However, by itself, it would not<br />

bring the pressure up into the green arc.<br />

The same issue of the magazine also had a note from ABS<br />

Technical Advisor Neil Pobanz providing Warren James as a<br />

contact for an STC'd electric fuel boost pump for early<br />

Bonanzas. [ called Mr. James to discuss my problem and find<br />

out the cost of his product in case I had to replace my unit.<br />

I sent my fue l pump off to Aircraft Accessories of<br />

Oklahoma in Tulsa for overhaul. Later when I spoke with a<br />

company representative, I was informed that, regardless of what<br />

was etched on the pump, it was not a Pesco product. What a<br />

surprise to learn I have a bogus pan that was installed back in<br />

1953! It was a very professional-looking installation, but it<br />

couldn't be overhauled. That put me in the position of becoming<br />

Warren James' next customer for his electric fuel pump.<br />

It took some time to get the Dukes-based pump from<br />

Warren and even more time to get it fitted and installed in the<br />

airplane. It works great and it can boost the pressure by itself<br />

beyond the max pressure redline. I now feel very comfonable<br />

that I have two backup solutions in case the engine-driven fuel<br />

pump fail s: the wobble pump at the fuel selector and Mr.<br />

James' auxiliary boost pump.<br />

I rejoined ABS in April 2007 and within a few months [<br />

have received more than I paid for my membership. Lew<br />

Gage's book* has also helped me understand how to properly<br />

operate my E-225 engine and provided some explanation on<br />

flying the early-model Bonanzas.<br />

Thank you, ABS!<br />

' Lew's E-series book is available for $30+S&H from the ABS<br />

Store (316-945-1700). All plVceeds go to the ABS Air Safety<br />

Foundation for educational development and research into<br />

Bonanza alld Baron technical issues.<br />

Bagus auxiliary electric boost pump installed in 1953, Warren James STC'd electric fuel boost pump installed in N3738N in 2007.<br />

Page 10723 www.bononzo.org ABS April 2008

A good idea that isn't shared is a small thing. If you share it-it con become a big ideal<br />

A mistake made is experience. If you share It With ABS members it becomes knowledgel

SWitching wing tip parts<br />

Steve Carter<br />

Fort Worth. Texas<br />

Q: lawn a 1979 F33A (SIN CE-<br />

860). Will the wing tips, strobes and nav<br />

lights work from a 200612007 G36 to<br />

replace my tips?<br />

A: The wing tips wi ll til fine but,<br />

before you purchase the G36 tips, you<br />

will need to talk to your local FSDO to<br />

see what type of approval paperwork<br />

they will require. Make sure you have<br />

all the paperwork issues covered before<br />

you buy or install. -BR<br />

A flap problem<br />

Barry Beaver<br />

Shelby. North Carolina<br />

Q: When the flaps are retracted or all<br />

the way down on my 1960 M35, they<br />

appear to be real tight. After they stop<br />

moving, it sounds as if the motor actually<br />

still moves some more. Is this normal?<br />

Is there a brake that is supposed to work?<br />

What would be the proper adjustment?<br />

A: The limit switches are on the left<br />

flap. Sometimes, the roller on the switch<br />

actuator freezes up and causes the actuator<br />

arm to get bent. The flap should not<br />

run out of travel in either direction.<br />

There are little rubber half-moon<br />

bumpers that glue into the end of the<br />

track, and normally you can feel a little<br />

play, rather than being hard against the<br />

end of the track. -NP<br />

Flap motor repair<br />

David Maodonald<br />

Cary, North Carolina<br />

Q: The flap motor on my 1990 A36<br />

is in need of repair or replacement. Can<br />

you advise on potential sources for<br />

exchange or overhaul.<br />

A: Try Kelly Aerospace (Aero<br />

Electric, 316-943-6100) or Aircraft<br />

Systems (8 15-399-0225) -NP<br />

Fin fairing<br />

Arthur Miller<br />

Ocala. Florida<br />

Q : I was recently asked about an<br />

aftermarket source for a vertical fin fairing<br />