Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TCM1s Factory Installations,built by the factory ... installed by the factory.A powerful combination; for your peace of mind.¥' Comprehensive factory installation.~ Complete price with no hidden cost.ilC Complete fuel system set up.lY' TopCare" Cylinder Warranty Program.il

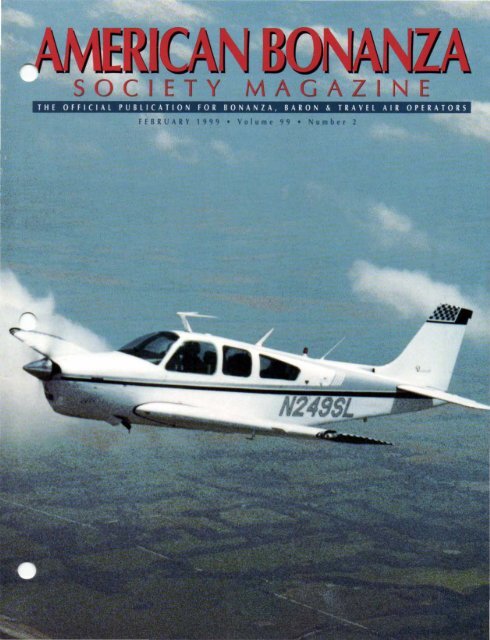

"/ traded l1Iy previously perfectly good aircraft (Cess1Ia 172-RG) for all F33C <strong>Bonanza</strong>, N249SL(more affectionately knowll as Two Four Niner Sweet LipS)."- WilliQIII R. Vcll1ce1978 F33Cor reasons unknown 10 me al Ihelime-and complele conslernalionand disbelief from my wife-inmid-1997 Ilraded my previously perfeciC-I72RG for an F33C <strong>Bonanza</strong>, N249SL(more affectionately known as Two FourNiner Sweel Lips).This aircraft has an interesling hislory.Afler il was born in 1978, il was purchasedby Ihe Royal DUlch Flying Academy(The Netherlands), which laler becameKLM Advanced Flighl School. IIwas used to Irain KLM pilols in unusualalliludes and lighl aerobatics. The aircraflregislralion was Ihen G-BTFN.In OClober 1991 , Ihe aircrafl was sold10 Ihe Siapieion Flying Club al SiapletonAerodrome in Essex, England, where ilremained until <strong>February</strong> 1997. II was reregisteredunder British regislration numberPH-BNF.The aircraft was flown to Houston,Texas, in March 1997 where it underwenta complete and extensive refurbishing thatincluded a new light grey glove leather interior,new paint. new linted 0' Shannon3/8-inch-thick windows and windshield, athree-blade McCauley prop, etc.I have some other additional goodieslike Stormscope, elc. in the planningstage for <strong>1999</strong>. The paint scheme is whilewi lh lighl grey and black slripes andblack melallic checkerboard on Ihewinglips and lip of Ihevertical stabilizer.The aircrafl is Iheaerobatic model wilha Continental 10-520engine. This machineis really a delighl 10fly and solid duringaerobatic maneuvers.Siandard recoveryfrom rolls, spins andloops is easy and effonless.copilot,The transition from the C-I72RG 10Ihe <strong>Bonanza</strong> was nOI difficult at all as Iheaircrafl is very docile and very slable,making for an excellent instrument platfonn.Basically, the only surprise so farwas the first set of logbooks-all handwrillenin Dutch. It nearly drove me andmy mechanic nuts trying to translate thestuff. Finally, the Dutch consulate came10 Ihe rescue and the logs were Iran slatedinto English (sort 01) and, as expected,no major surprises were found.This aircraft is used primarily for funand cross-country flight s wilh the familyin the order of 400-500 nm. Sometimethis fall , we are planning a trip tothe Cayman Islands. I'll let you knowhow it goes.The aircraft is hangared at all timesand il is based al West Houston Airport(TWS).-William R. Vallce, HOIIS/Oll, Texas

BONANZA OF THE MONTHCover: Wi ll iam R. Vance of Houston, Texas, in his 1978 F33C <strong>Bonanza</strong>, anaerobatic model w ith a Continental 10-520 engine. . ... .. ...... .. . 5559(lSSN 0161 -3545)Published byAMERICAN BONANZA SOCIETYOrganized January 1967ABS EXECUTIVE DIRECTOREDITOR IN CHIEFNancy JohnsonPUBLI CATION OFFICE1922 Midfield RoadP.O. Box 12888Wi chita, KS 672773 16-945-1700Fax 316-945-1710ASS web site: hltp://www.bonanza.orgASS e-mail : bonanza2@bonanza.orgSend articles/letters to theabove address/fax/e-mail.EDITORBetty RowleyASSOCIATE EDITORTom HutchinsonDESIGN EDITORJim SimpsonDISPLAY ADVERTISING DIRECTORJohn Shoemaker2779 Aero Park Drive. P.O. Box 968Traverse City, MI 496841-800-773-7798, ext. 3317FEATURESGUEST EDITORIALBy Bryall Lewis, Teledyne Conlillelltal MOlOrs ... . .......•.. . _ . _ .... 5561HURRICANE MITCH IN HONDURASBy George De Tray ......... . .......... . . • . . . . _ . . . . . • . _ . . . . .... 5562TIPS ON AN AVIONICS UPGRADEBy George Wilhelmsen ... . ........... . ......... .. ....... . 5570COST OF CONVERTING FROM AN 10-470-C TO AN 10-520-BABy Sleven Oxman . ........................ . ................... 5572REG ARDING THE USE OF GAMljECTORSBy Kennelh E. SUllon ..... . ........... . .... . .•.....• __ • . • .• .... 5574<strong>1999</strong> CD-ROM NOW AVAILABLEBy Ron Vickrey. . . .. . ....... .. .. _ . . . . . . •. _ . . . . . _ ... .• .... 5576FLIGHT TO ARGENTINABy Madeleine DUpOlI1 de Bock ............ .. .... •. •. • .•...... . .. 5589NOMINATIONG COMMITIEE REPORT . . _ . _ . __ . _ . _ . . _ . _ .... _ . . 5592DEPARTMENTSCOLVIN'S CORNER . .. .. . . . 5564by Neil Pobanz and Arky FoulkFORUM . ................ 55 77INSURANCE . . . . . . .. . .... 5580Preveming aircraft theftby John Allen. Falcon InsuranceAVIONICS ......... . .... . 5S81Archangelby Jim HughesSHOP TALK ........ . •.... 5583by Lynn JenkinsCUR REN TS .............. 5585.. Reconditioned crankcasesby Lew GageREGIO NAL NEWS ..CALENDAR . . .... .BPPP SCHEDULE •... _ 5579 SERVICE CLINIC SCHEDULE . _ .. 5579Support the <strong>American</strong> <strong>Bonanza</strong> <strong>Society</strong>with a Life Membership for $1,000559 15593PRINTERVillage Press, Traverse City, MichiganAMERICA,~ BO~NZA SOCIETY MAGAZINE is publishedmonthly by !he Americdn <strong>Bonanza</strong> <strong>Society</strong> at tileWichita Mid,Continent A.ifpo r ~ 1922 Midfield R()

THE "MARRIAGE" BETWEEN BEECH AND CONTI ENTAL has been long and, with the exception of a fewdalliances li ke Duke and 56TC, quite loya l. I believe after meeting Bryan Lewis at Oshkosh and li stening to hisquestion and answer period during the SI. Loui s Convention, our members will continue to enjoy the support of thi scombination.Brya n handled questions that informed us about future engines and Continental's opin ion concerning the"lean of peak" issue. Brya n and AI Beech have been contri butors to the ABS Magazine and we look forward to theircontinued straight-forward information from the manufacture r.I especia lly thank Bryan for his enthusiastic wi ll ingness to support our Service Cl inics with technical resourcesthat provide information and promote safety. - Bill Carter, presidentGuestEditorialBY BRYAN LEWIS, PresidentTeledyne Continental MotorsGreetings again to ABS membersfrom Teledyne Continental Motors. Onbehalf of the employees of TCM, let mebegin by wishing you a successful andsafe New Year. I would like to take thisopponunity to share with you some ofthe things TCM plans to bring to youduring the New Year.ABS MAINTENANCE CLINICS1 will begin with our plans for thepopular ABS maintenance clinics. Overthe past two years, TCM has participatedin the ABS maintenance clinics by performingHealth Check'M inspections on<strong>Bonanza</strong> and Baron aircraft based on theTCM TopCare'" Program.The Health Check inspection includesa cylinder leak check, engine timing rc-ABS <strong>February</strong> <strong>1999</strong>view, cylinder borescope and enginecompartment assessment. From thesevarious inspec tions, AI Beech, who hasheaded the TCM clinic teams, has identifiedcertain items that are freque ntl ynoted as discrepancies in these inspectionsand should be checked on a regularbasis to help keep your engine installationin the best condition.The top fou r discrepancies AI hasnoted during these inspections are: I)engine baffles and seals in need of repair,2) improper alternate ai r door riggingthat allows the engi ne to breath unfilteredair, thereby creating the potentialfor the introduction of abrasive contaminants,3) improper timing of themagnetos, and 4) throttle linkages that areimproperly torqued, opening the possibilityof control link age wear. These fouritems should be included in your checklistas you roll out your airplane for thefirst time in the new year.The overall response to TCM 's participationin these clin ics by the ABSmembership has been excellent. We arepleased to announce that TCM will continuethis program for <strong>1999</strong>. We also hopeto again host one of these clinics at ourCustomer Support Center in Fairhope,Alabama, during the comi ng year.HEALTH CHECKS AT CSCAdditionally. TCM will introduce thisHealth Check inspection program on aregular basis at our Customer SupportCenter beginning in the second quanerof the year. If you are in our neighborhood,stop by and see us.The Southeastern and SouthwesternABS regions are scheduled to have a fl yin to the factory for lunch and a plant touron April 30. A Health Check inspectioncunic will also be conducted during thiseven t. We hope you will join us.GET YOUR HEALTH CHECKSON THE WAY TO SUN ' N FUNIf you're headed to the EAA Sun 'nFun this year, you may wa nt to scheduleyour trip so that you can spend some timeat the Fairhope Customer Suppon Centeron your way to or from Lakeland,Florida. TCM will conduct engine HealthCheck inspections at Fairhope beginningthree days before the show opens (April8) until two days after it closes (April 19).The details of our Cu stomer SupportCenter Health Check inspect ion clinicand the events planned around Sun ' 0 Funwill be available on our web site beginningMarch I, <strong>1999</strong>. Participation wi ll beby registration only and we hope to seemany of you at Fairhope. TCM will alsohost a barbecue at our facility oneevening prior to the EAA show, the exactdate of which will be posted on theweb site www.tcmlink.com.REDESIGN OF TCM WEB SITEIn a previous anicle the TCM web sitewas briefly mentioned and I would liketo bring you up to speed on what we believewill be some very exciting developmentsat www.tcm link.com in <strong>1999</strong>.To date, our site has been used primarilyfor the dissemination of service, maintenanceand safety related data. The basicsite is now undergoing a lotal redesignthat will allow us to bring even morevalue to you as an owner of a Continentalpowered aircraft through the technologyof the Internet.As a result of the redesign. the AviatorServices and FBO Services programsdiscussed in the August 1997 issue of theABS Magazille will soon become avail able directly from our web site.The Internet will allow these programsto become truly global and will allow uscomilllled all page 5590Page 5561

<strong>Bonanza</strong> provides wayfor medical relief team to give assistance to victims ofI1UITITICllI1E I1ITCI1 1I1110I1DUMSBY GEORGE E. DeTRAY, Lake Tapawingo, MissouriOn November 13, a team of four departed from Grain Val $50 for landing at the first airport in Mexico and about $2 perley airport just outside Kansas City in my V35B <strong>Bonanza</strong> gallon for fuel and handling fees.headed for San Pedro Sula, Honduras, and then on to San Pedro Sula was not yet open for commercial flights.Tegucigalpa. The group consisted of Jim Christenson, The airport had been under 4 to 6 feet of water and the mud waspresident of La Buena Fe Foundation, Aracely Sierra still being cleared off some of the taxiways and roads. The areaChristenson, a Honduran doctor wbo11'1-----------returned to help her people, which had been the old terntinal was being used for the militaryher daughter Erica and me. We were the advance part of a medi- and civilian relief effort and we were directed there. We hadcal team of doctors and nurses 200 pounds of medical suppliesof La Buena Fe Foundation, awbich was fortunate becausenot-for-profit organizationtbe other medical supplies,wbich has run a clinic and teachingfacility in Honduras sincearrived a day late. Our 200flown in by commercial carrier1955.pounds of supplies, which hadFlying to New Orleans International,we spent the night andprime importance, kept thebeen carefully selected forstarted off early the next morningLFR to Cozumel. HoustonThe activity at the relief end .--..team operational.Center informed us that withoutof the field was fantastic. Austra-UHF we would have to climb to jim Christenson, Aracely Sierra Christenson, her daughter Erica lia had diverted a ship of rice to18,000 feet for the mid-part of and pilot Edd DeTray with his <strong>Bonanza</strong>. San Pedro Sula tower inour crossing. Our choice was to the background.go VFR. I had oxygen aboard and 3047W is turbonorrnalized,but we chose to stay at 1I ,500 feet for the crossing. We had afive-man life raft, life jackets, emergency kits and flares aboard.The crossing took 3.48 bours to Cozumel and another 1.5 hourson to San Pedro Sula.We were not required to clear customs in Cozumel becausewe did not enter the country. The expenses there were aboutthe harbor, and this cargo, alongwith dried milk and other supplies,was being hauled to the airport by tractor-trailer to beloaded on C130s, Hercules and helicopters, for delivery to villagesinaccessible by roads.The government workers, military and civilians all workedtogether to get the job done. Just like us, everyone was ready todo what was needed.Fuel was available there and at Tegucigalpa, but they pre-Relief supplies came pretty much a5 people sent them. Someplastic water banles broke with altitude, but 90 percent were ingood shape, were handled with care and reached people withreal need.~~~~;;:"Th.~ Housesriver in"-'"normally 8-10 feet lower than shown.everything ;n the picture.Page 5562ABS <strong>February</strong> 1 999

ferred we fuel there, so we did. Fuel was about $3.80 per galIon. When we left New Orleans, we were told that the large-----. planes were encountering landing fees of $6,000 to $10,000.What we found was that there were no charges for landing orparking if we were pan of the humanitarian relief effon.Monday afternoon we flew on to Tegucigalpa, about a 50-minute flight, at 10,000 feet, !FR. Tegucigalpa is at an altitudeof 3,294 feet with a 6,132 runway. It is almost always cloudy,and visibility is sometimes down to 400 feet with seven or eightmountain peaks ranging from I, I 00 feet to 4,219 feet above theairpon and within 10 miles.The airpon was busy with 727s, an airbus, (which was shootingapproaches with Honduran authorities, who approve all commercialpilots making their approaches), Hercules, C 130s, DC3s,etc. Planes were landing about every 10 minutes all day long atthe airpon which normally has about six flights a day._The FBO there is run byCeCessna, and they probablyhave IS small planes stationedthere. They were handling panof the relief effort to the outlyingareas, although the major effonwas across the airport at themilitary base where the helicopters,C 130s. Hercules and oth-ers flew in and out with supplieson a regular basis.The nations of the world werethere and were appreciated bythe Honduran s. The Mexicangovernment, even though hard-pressed with disaster in theirown country, sent a gro up of what we would think of as Seabeeswith caterpillar tractors, large back hoes, dump trucks and otherequipment, and they really made a difference in the infrastructureof that city. Planes came from Japan. The hotel where Istayed two nights was full of Japanese military personnel helpingin the effort. Planes came fro m all over the world with sup-Tips on how to be part of the solutionwithoutadding to the problem.I . Work with a qualified disaster relief team. People who havedone it before will help you avoid mistakes.2. Check in with and work through the government of the countryof the people you intend to help.3. Make sure you have enough gas to get back and that yourplane is in good shape. Your last leg into the disaster areashould be a short one.4. You and your team need to be qualified, have a service you knowis needed and that you can perfonn and have enough people whoknow the local language to make your mission a success.plies and sometimes people to help with the relief effon.Missionary Flights International was there with one of theirDC3s. Kenny Gumpel, an A&P mechanic and a pilo~ flew loadsof supplies out every day I was there.Another pilot from Wichita flying an Air Force version of aTwin Beech said he was in Honduras seven or eight years beforeon a relief team doing inoculations-a three-shot seriesbeing given awhile apart. They gave 600 the first day and onthe second day discovered they didn't have the serum for thesecond shot. "If I had a plane, I could solve this problem," hethought. So when Mitch struck, he had a plane and headed southto help. He went to the Catholic Monsignor who was in chargeof pan of the relief effon, and was able to transpon 20,000pounds of supplies to La Ceiba, an airpon otherwise inaccessiblebecause of washed out roads and bridges.I had been losing manifold pressure at altitude since departing Cozumel and decided that Ineeded to get it fixed before Ileft Tegucigalpa. I ordered anew turbine, which took twodays shipping time and after installingit, found a long crack inthe intercooler. The mechanicknew what needed to be done andHarry Maderra, a pilot atCeCessna, who speaks Englishwell, was a big help. The intercoolerwas patched and the planeperformed to specification.1 fl ew back to San PedroSula, picked up my crew and flew back to Kansas City, by wayof Cozumel, New Orleans and Little Rock, Arkansas. I had toswitch to lFR going into New Orleans and left Little Rock thenext morning IFR, arriving back at Grain Valley before noonon Monday.I feel this trip was one of the more rewarding things that I haveever done and I am grateful that I was privileged to participate.~There were only two usable bridges across Rio La Puera (riverat Tegucigalpa). This is the ro"d that led to the bridge. No carswere allowed over the bridge. Foot traffic was like this from 7a.m. untitl0 at night. There was a curfew from 11 p.m. untitSa.m. and no one was allowed on the street.ABS <strong>February</strong> <strong>1999</strong>Some buildings had six inches of mud on the third andfloors. It was thrown in the middle of the street and later hauledaway.Page 5563

<strong>Bonanza</strong> pre-purchaseinspectionDavid BeauchaineVancouver, WashingtonQ : I am very much interested in learn·ing how to buy a used F33 or V35. I justordered the ABS CD-ROM and expectto get a lot of information from that. Oneof my main questions is when an aircraftis on the other side of the country, whatis the best procedure to have the aircraftinspected? Should I send my local mechanic,who I know and trust and whowill maintain the plane. or perhaps callone of the mechanics who advertises inthe ABS Mllga~ille to do a pre-purchaseinspection? I'd appreciate any comments),ou could make, especially on which ofthe CD-ROM articles are the best on buyinga used F33 or V35.One more question: The plane I amlooking at has a Bendix FS-810 autopilot.Do you have any information on thereliability of this unit? I can't find anyinformation about it.A : If you call us with the location ofproposed aircraft, we'll try to provide thenames of any nearest mechanics we feelare capable. Certainly, sending your ownmechanic is a good way to go if he knows<strong>Bonanza</strong>s. Even if he doesn't, you maystill walll him to participate in the inspectionwith someone who is experienced.The Bendix autopilot is an old unitand not noted for reliability or ease ofrepair. Not all shops have the experienceor test equipment to repair them. 1 suggestyou talk with your local avionicsshop to determine their capabilities andPage 5564to get their opinions.The search engine on the A BS CDROM is great so you shouldn't have anyproblems finding everything written onany topic over the past 30 years. We recurrently working on a CD-ROM updateto include the 1997-98 magazine issuesplus AD, STC, AIM and FAR databases.This new edition should be avai lable bythe time this is publi shed. Those whobought the original version will be ableto exchange it for a reduced price.-NPG33 alternator vibrationproblemHal HuntScottsdale, Arizonan: I am having an alternator mountp~lem. It began when I had the 60 ampereFord alternator rebuilt with a newmounting half because of excessive wearin the mounting base where the boltpasses through. New mounting hardwarewas installed. Since then, on two occasions.the main output lead and the fieldlead have both broken at the alternatorterminals. After installing beefier connectorrings, this has stopped. On recentinspection, however, I found the mainmounting bolt was broken! The belt wasrightened to 13 ft/pounds. What is theproblem and what do 1 do about it?A: When the parts become worn. youdefinitely will tend to have more problems.Usually the washer stack is not thesame as recommended and the bolt isn' ttight enough. TCM offers a shock mountkit for rhe original generator installationand this is also approved for the altern a-tor as it uses the same mount.I consider a belt is tight enough if Icannot spin rhe pulley, but am still ableto see some flex in the belt. Out-of-balancecrankshafts also rransmit a lor ofvibration to the drive pulley. If this is thecase, the belt will really jump aroundwhen running. When dynamicall y balancingan engine/prop, it's advisable toput a pickup on the back of rhe engine aswell as up front.-NPF33A manualsGerald CoxVirsinia Beach, Virginian: I am the new owner of a 1986F:rlA and would like to obtain as manymanuals (maintenance, parts, etc) as Ican. Where is the best place to obtainthem?A: Congratulations on your new aircraft'I suggest you contact one of theapproved Beech service centers to cnsurethat you receive the most current versionsof the manuals you want. Piedmont atNorfolk, Virginia, 757-857-3413, shouldbe able to help you. Eventually, you maywanr to try ATP's system, which has allrelevant material but currently is expensivefor an individual's personal use.-NPK35 Pathfinder autopilot repairWard CombsOmaha, NebraskaQ: I'd like to know if you can recommendsomeone who could repair a PathfinderPT2 autopi lot in a K35 <strong>Bonanza</strong>.The plane is located in the Omaha-Lin-ABS <strong>February</strong> <strong>1999</strong>

coin . Nebraska, area. Any suggestionswould be greatly appreciated.A: u.s. Avionics (3 10-375-9898) andAstronautics (414-447-6204) are currentlyour best contacts forthis repair. Ifany members have had success withother shops, please let us know.- NPF33A overhaulvs. factory remanBob FinleyGoldsby, OklahomaQ: My newly acquired F33A has justover 1,500 hours SMOH. Oil consumplionIS about eight hours/quart and compressionsare in the mid to high '70s. Thecyltnders have not been off the aircraftsince the overhaul in the late ·80s. Obviously,the job was done right and theprevIous operators of the aircraft had allthe ducks in a row. The crankshaft is nonVAR so it must be replaced at overhaul.The existing engine was a factory remanto about 1979 and field overhauled in1988.Even though the oil consumption andc~mpress ion s are very acceptable, I realtzethat realistically an overhaul iswithin a year or so. I will fly the aircraftapproximately 125 hours per year. I planto do some homework before the timeoccurs in order to have my strategyplanned.I hear that a factory reman wi ll increasethe sell ing price of the aircraft bylip to 10 percent. I also know that a localeng ine shop can overhaul the enoine forsomewhere in the $10,000 to S I2,OOOarea, which is about $6,000 less than thefactory reman. I expect to own the aircraftfor 10 years or so. What is the truestory concerning factory reman vs. fieldoverhau l.Additionally, I have been told that myheavy case BA 520 can be line bored toconvert it to a BB model. Since I have tobuy the new VAR cran k anyway, whatwou ld I gain by converting from BA toBB model engine?The temps on my engine are very acceptable,however, the baffling is showIng lots of wear and lear. T have seen thenew style baffling that is needed for the300 HP 550 models. Is there any realadvantage to converting to it with the 285HP 520 engine? There seems to be a sionificanlcost difference in repairing theexisting baffling compared to convertingto the new style.ABS Fe bruary <strong>1999</strong>A: Since you must purchase a newcrankshaft, I doubt that the local overhaulwill be much less than a factoryreman. The factory includes the newcrank plus you also get new cylinders andpistons. The seventh stud requires abaffle conversion on the F33A. The twobaffle pieces, tight forward and left aftare about $1,000. [ would consider repairingthe baffles, go with a factoryreman exchange, realize a possible increasein resale value and suffer the leastamount of downtime during the enginechange.-NPF33 conversion to F33ADan HurleyKilty Hawk, North Carolinan: I am shopping for an earl y '70s33:'1 ran across an F33 that had been convertedto an F33A. When I inquired aboutIt, I was told that the useful load was only928 pounds. This seemed unusually lowcompared to other 33s I have seen. Hehas the usual panel toys, but nothing specIal.Can you offer an explanation?A: The original 3,050 pound grossweIght of an F33 is significantly less thanthe 3,400 pounds of an F33A. Even withthe engine change from the 10-470, 225HP to the 10-520. 285 HP, the ai rcraftgross weight remain s at the orioi nal3,050 pounds unless the STC includes agross weight increase. In addition, nowyou have a heavier engine with a correspondinglyhigher empty weight.-NPBaron heater shutdownJames HooperWebster, MinnesotaQ: We have been in a discussion aboutthe proper way to shut down a heater ina Baron. It is my contention that. althoughit probably doesn't make muchdifference in flight. the proper way is topush the temp control all the way in tothe coolest temp then wait until you feelcool alf before shutting off the heaterswitch.Another Baron owner says turn it offand on with the switch and leave the tempcontrol alone untt! you need a differenttemp. When on the ground. turning offWIth the switch only, you would stop thealf flow WIth a hIgh temperature remaintOgwithin the heater. In other wordsbetter to use the blower to cool the heater:We can't find anything in the book.Would you have any information on thissubject?A: Check Section VII, Systems Descriptionin the POH. Although it maynot state specifically, if you turn theheater switch to "off" in flight a few minutesprior to landing, the heater wi ll cooldown without moving the temperaturecontrol. The blower will not run in the"heat" or "blower" position with thelanding gear in the up position.On the ground, I recommend switchingbriefly to the "blower" position tocool the heater down and avoid blowingthe overheat fuse. You can just switchfrom "heater" to "blower" withoutchanging the temp control or you canreduce the temperature control and cooldown first in the "heater" position.-NPBaron auxiliary fuelScoN SeiboldLas Vegas, NevadaQ : Do you know of anybody offeringaux fuel capacIty such as tip tanks forthe Baron D55 or 56TC?A: Other than the factory installed optionalfuel tanks, Colemill is the onlyother source for Baron aux tanks. lostallationsvary by model and depend on thecapacIty of the existing tank installations.The B55 Baron is STC'd for wi ngletswith an additional 15 gallons per side.Colemlll (615-226-4256) is located inNashvi lle, Tennessee.-NPIO-470-C fuel pumpD eon SchroederVancouver, WashingtonQ: Where can I find information onthe fuel pump for an 10 470-C? CoLvin'sClinic talks about the problems but doesnot have enough detail. I have the engineparts catalog, but it shows the pumpas one part. I would like to find an overhaultype of publication if one is available.A : \' m not sure which type pump youhave but Aircraft Systems (815-399-0225) and Aircraft Accessories (800-255-9924) overhaul most of the commonpumps. They have been helpful with informationto members. Essco (30-644-7724) has service manuals for most commoncomponents.- PPage 5565

835 electric boost pumpjoe SalernoPrescott, ArizonaQ: I would like to obtain an STC andelectric fue l pump. I want to install thepump on my B35. I have an E-225 engineand I need a pump that produces 9to II psi. Can you advise me where topurchase the pump and STC?A: Rich Aviation (805-486-6760) hasWeldon pumps and Warren James (9 I 8-786-4506) has an STC for the Dukespumps for early model airplanes.- PA36 electric fuel pumpquestionsCary WeeksWinmalee, NSW AustraliaQ: We have an A36 <strong>Bonanza</strong> thatseems to have low output from the electricfuel pump during engine primingprior to engine start. What sort of fuelflow should I expect to see during priming?At the moment I am only seeing 11to 12 gph on the fuel flow guage.While there is never a problem withengine starting, 18 months ago I wouldsee 14 gph during prime. The fuel flowfrom the engine driven pump duringtakeoff and all other phases is normal.A: The output of the Dukes pump priorto installation of the updated vanes wasusually 14 to 15 on the panel gauge.Upon installation of the new vanes, manywere showing only 8 to 12. However.when tested on the !low bench (only wayto be sure), they met minimum !lowspecs. If you've seen a decrease withoutmaintenance. I would have it overhauledand updated.Q: Where on the airframe is the electricfuel pump mounted?A: The pump is under the left side wallby the pilot's feel.Q: Is there an expected timed life onthese fuel pumps? I can't find an y recordin the logs to say it has previously beenoverhauled although it could appear ona 100 hourly worksheet somewhere priorto our purchase a few years back. Myonly concern with this is that if the enginedriven pump was to fail, then theelectric pump may not supply enoughfuel to the engine under higher poweroperations.Page 55&&A : These pumps are listed as "on condition"to change or repair. One point toremember jf you acrually have an enginedrivenpump failure in flight and have tooperate on the aux pump: You can tryadjusting power (throllie selling) towhatever fue l flow you have to sustainflight, whereas at full throttle, it may notrun. Conversely, if it puts out too muchand the engine runs too rich. manualleaning may give you more power. Itpays to discuss this with a mechanic ifyour fli ght instructor isn't intimate withthe TCM fuel injection system .-NPSingle yoke instrumentflight testMike ParkinsonPinckneyville, IllinoisQ: I am completing fFR training inmy 1960 Debonair. I have not been ableto locate a local exami ner who will givethe IFR !light test in the Debonair becauseit has a throwover yoke. Do youknow of an examiner anywhere closewho will give the exam in the Deb? Obviously,I could travel to take the exam.The most conveniemlocations are Tulsa.Oklahoma. or SI. Louis, Missouri . If needbe, I could travel to Wichita. Kansas.Thanks for yo ur help.A: The si ngle yoke is legal for theexam at the prerogative of the examiner.However. I would not be surpri sed if youhave trouble finding an examiner willingto give the exam with the throwoveryoke. You can rent or purchase a dualyoke from Performance Aero (800-200-3 141), <strong>American</strong> Aero (800-359-6673)or Air Mech (888-282-90 I 0). A newPMA design is also available from CygnetAerospace (650 321-6880).-NP855 8aron auxiliary fuelSherman Olsen, Jr.Hilton Head Island, South Carolina() : I have a question about additionalf;;J tankage for my 1979 B55 Baron SIN TC-2263. I have the I 42-gallon capacitywith, I believe, two bladders in eachwing. My desire is for about 20 to 30additional gallons in the wings. I knowthe E model and 58s have more capacitywith, I think, thc same wing. Is it possibleto add these bladders with a kit toincrease my capacity, and if so. who mayknow about this?A: The wing structure is different insome of the different models of theBaron. Other than the factory-installedoptional fuel tanks, Colemill is the onlyother source for Baron aux tanks. Theyhave a B55 Baron STC for fiberglasswinglets/aux tanks containing an additional15 gallons per side with an electrictransfer to the main tanks. The wingspanis increased from 37 feet 10 inchesto approximately 40 feet. Cole mill (6 15-226-4256) is located in Nashville, Tennessee.-NPE33 CG queryjeff KoonceDeBary, Florida(): I have a 1968 E33 (N6256V) withS~ CD-1I20. A question has come upregarding the CG ARM for the rear seatpassengers. My POH says that it is 117inches and <strong>American</strong> Aeronautics (makersof a handy CG calculation system)says that Beech revised the POH in 1982and it is now 124 inches. That's seveninches further aft CG on an already aftCG critical airplane! Is this correct? DidBeech error in the original POHs byseven inches, and if so, where can I obtaina current and valid POH for my 1968Deb?A: The E33A shows rear seats (3 and4) as 121to 124 inches. I would obtain anew POH for your serial number throughRaytheon to ensure the latest information.Sources would be Ed at Ellioll Aviation(309-799-3183) or, in Florida,Raytheon at KFLL (954-359- 11 00) or atKTPA (8 I 3-878-4500).-NPS35 & Plumley fuel computerDavid IveyOxford, North CarolinaQ: 1 have seen George Braly's commentsin the last three issues of the ABSMagazine regarding leaning of the engineand running either rich or lean ofpeak. My question COncerns the Plumleycalculators for the 285 HP.What is the BPPP posi tion on usingthe Plumleys for mixture control? Aren'tthese calculators designed to run the enginesat peak ? Arc these devices accurateand are they useful in conjunctionwith EGT gauges and the leaning process?Many pilots have these and I wouldlike to see a discussion andlor some opinionsfrom you on the reliability, or shouldABS <strong>February</strong> <strong>1999</strong>

I say compatibility, with today's leaningprocedures.A: I have used the Plumley calculatorsto set power for years. Their datawas from TCM operators manual formX30041, which is approved data. However,there are many additional commentsin these instructions. Included isthe use of an EGT gauge to determine25 degrees F rich of peak at 64 to 75 percentpower; peak EGT could be used at65 percent power or less. Whether usin othe Pl umley or any other method, foraggressive leaning it is best to have agood, properly installed, responsive, sixcylinderEGT system.-NPThicker windshieldsDon KlingerEureka Springs, ArkansasQ : In the near future, I wi II be replacmgthe windshield. I hear a lot about installinga thicker windshield than thefactory 's one-fourth-i nch model. Thebiggest reason given is noise reduction.As I always use headsets, this does notmake sense to me. If thicker is betterwhy did Beech use the one-fourth inch?A: The thicker windshields do offersome sound reduction as well as betterbird strike protection. However, they arealso heavier, more expensive and can bemore difficult to install- factors nodoubt considered by the factory. You cango to three-eighth inch or one-half inchas well as the origi nal one-fourth inch.Price varies with thickness. There havebeen occasional reported distortion problemswith some hal f- inch installations.}35 paint schemeMel KlemmickSan Rafael, Californ ia-NPQ: I am starting to research paintschemes and paint shops for a sprinopaint job. Can you steer me to re so urce~to help me identify/select a paint schemeand a paint shop in California?Also, can you tell me what to look forin a paint shop, what stripping technologyshould be used, and what paints arerecommended and why? In other words,I want information that will help memake an informed decision, if not an intelligentone.A: Always use specific paint systemsconsisting of brands of primer and fin ish coats that are compatible and that thepaint shop is experienced in using. Severalbrands are about equal, but they differin how they are applied.Be careful if usi ng the various blastingmethods as the aircraft skin can bedamaged by too vigorous application ofthe medium, be it soda, shells or beads.Whether using blast or chemical strippingtechniques, the personnel should befamiliar with <strong>Bonanza</strong>s, both for themagnesium prep work and the controlsurface balancing.Shops usually have design schemesavailable. Computer programs include:One Mile Up (703-642- 11 77) and AircraftPaint Schemes (800-599-5499). Iwould ask Woodland (9 16-662-963 1)and Dick Kuch (760-789-8020) for localpaint shop recommendations.-NPA35 gear box leakEd MillerMontevideo, MinnesotaQ: I have a question concerning aflUId leak from the manual landing gearretractIOn crank handle on an A35 <strong>Bonanza</strong>.Is the problem most likely causedby a faulty seal or is the gearbox flui dlevel too high?A: It's not unusual for the fluid levelto be high enough to let it leak past theO-ring on the manual gear extensioncrankshaft. It doesn' t need to be thathigh. The fluid onl y needs to be whereit's picked up by the worm drive as itrotates. This can be checked by viewingthrough the fi ller hole.- PIntermittent fuel boostpumpTom RoperPoulsbo, WashingtonQ: My electric fuel pump occasionallywill not start on low boost. To startthe engine I mu st then momentarilysw itch to high boost to get the pump tostart. I then switch back to low and thepWllP continues to run on low quite satisfactorily.I think it is talking to me. Wherewould you recommend I take it for testinp:ervice?I live in the Seattle area.A . It appears to need the added power(amperage) of the high-speed position toget it started. Since UPS delivers everywhere.I suggest you consider AircraftSystems (815-399-0225), Aircraft Accessoriesof Oklahoma (800-255-9924),B&S (316-264-2397) or Aero Electric(3 I 6-943-6 lOO).-NPA36 trim problemsRichard GraysonAtlanta, GeorgiaQ: I have a question regarding the trimcharacteristics of the 1982 A36 r justpurchased and flew back from Californiato Atlanta. Throughout the day-anda-halfflight, when trimmed out for levelcrui se speed, I constantly had to applylight left pressure to the control wheel.Absent the pressure, the plane wouldbegin a slow turn to the right.A visual check out the side windowrevealed a slight downward deflection ofthe right aileron (as one would expectfrom slight left turn pressure). So it doesseem that when the ailerons are absolutelylevel wi th the trailing edge\wingtIp, the plane wants to turn to the right. Iwas constantly having to turn the ailerontrim wheel to the left, and it kept revertingback to center. There was occasionallynot enough travel in the trimwheel to completely offset the right turntendency.This condition seemed to persist regardlessof altitude, prop speed, fuel loadIII each tank, etc. The plane was recentlyrepamted, but the ailerons appear to beproperl y re-installed and align with thetrailing edge of the wing (if they wereremoved during painting, which I do notknow). Any thoughts as to the source ofthe problem and how to correct it?A: I would suspect the elevator adjustment.If the push-pull rods are not adjustedso the elevators are symmetrical,It can cause a rolling movement. Youshould have the rigging checked, but Iwould look there first. The control surfacesshould have been removed forpainting and the ailerons and elevatorsproperly balanced.-NPDebonair replacementinteriorJay JasonChestnut Ridge, New Yorkn : I am looking for a manufacturer ofr~acement interiors for a Beech Debonair.I remember seeing an ad in a pastedition of theABS Magazine. Any suggestions?ABS <strong>February</strong> <strong>1999</strong>Page 5567

A: AirTex at 215-295-4115 has legalprefabricated upholstery, side walls, carpetsand seat covers. Kinzie at 580-327-1565 makes replacement interior plasticwindow trim parts.- PA36 Mastin engine monitorRobert A. AndersonBeavercreek, OhioQ: I have an A36 SIN 583 with aMastin engine monitor. Mastin has goneout of business and I am looking for acompany that can service the device. Canyou recommend someone?A: I sugggest you call Dorr at 3 I 3-428-1008. He should be able to service yourunit..- NPF33A shoulder harness kitBart BrainerdLeesburg, FloridaQ: I fly a 1975 F33A. I don't own itbut I might in the near future. I heard arumor that the ABS had helped to put togethera front seat shoulder harness kitthat didn' t hold one hostage the way theBeech kit does. If this is true, how muchdoes a kit run and who markets it?A: We've been encouraging BAS todevelop an inertial reel kit for Beechproducts, but it doesn't exist yet. TheSafety Limited kit requires a field approvaland has the problem of limitingmovement. However, it is less expensivethan the inertial reel kits. Contact themat 630-584-9366.-NPF33A fuel pressure andalternator problemsJoe AlbrechtSt. Louis, MissouriQ: At full power on takeoff during thetest flight after my last annual inspection, the fuel flow needle went far pastthe last gph graduation and into the 7o'clock position ofthe manifold pressureside of the gauge. I cannot remember thishappening before. Is this normal? Whatcould cause it?Also my alternator light comes on atlow engine power (less than 1800 rpm).I have to reset with the alternator onloffswitch. Even in cruise flight, the needlewavers just barely on the charge side ofzero on the amp gauge. Is this a voltageregulator or alternator problem? The alternatoronly has 300 hours since installed.Page 5568A: The alternator light indicates thatthe alternator is either inoperative or itsoutput is low compared to the referencevoltage which should be the battery voltage.You need to monitor your bus voltageto troubleshoot the system. Use agood voltmeter to see what's happening.The ammeter doesn't tell us much otherthan whether the battery is giving or receivingpower tolfrom the bus. You couldpossibl y have reduced output from youralternator as a result of diode failure.The fuel flow gauge reading suggestssomeone adjusted the fuel pump pressureor the controls which is allowing an increasedfuel flow. Fuel flow (pressure)should be adjusted frequently with amaster gauge used in accordance withTSM SLD 97-3.-NPF33A battery chargerRick RengelTustin, CaliforniaQ: My 1976 F33A has a small dooron the cowling for a plug to a batterycharger. I thought it would be smart toinstall the plug, but Raytheon quoted me$ I ,600. I can buy a lot of batteries for$ I ,600. Are there any other suppliersbesides Raytheon?A: I believe you may be referring tothe auxiliary power supply door and thekit supplied by Raytheon, which wouldinclude a drawing, cables, relay and receptacleas well as the approved data tomake it legal. If all of the parts and thesystem are already installed and you onlyneed the receptacle, it is available fromChief Aircraft (800-447-3408) asAN2552-3A for $61.95.This plug is typically used as an externalpower source for engine starting, gearchecks, avionics work, elC. To avoid sys·tern damage, it is very important that youconsult Section VIIl of your POH instructionson the plug's use for thosepurposes, or for charging the batteries.NPC35 Cleveland brakesSteve ZellerAtlanta, Georgian: My G35 has the PIN 199-50 (6.50-8~ l eve l and brake conversion with steellinings. We are trying to figure out whatthe minimum allowable wear thicknessis for the PIN 164-02706 disk.A: The minimum thickness for yourparticular part number disk is .330 inch.However, members need 10 be aware thatthis specification may vary for disks havingdifferent part numbers. The manufacturer,Parker Hannifin, may be contactedat 440-937-6211.-NP535 window replacementJohn OrnellasAvon, MassachusettsQ: 1n replacing the emergency windowside glass as well as the cabin doorglass on my S35, is it better to leave theprotective paper on until after the job isdone and then remove it after the riveting,priming and painting?A: Absolutely. Peel the protective paperback from the edge of the glass justenough so that it doesn ' t interfere withthe installation.-NPK35 IO-470N conversionAntonio RodriguesAlamo, CaliforniaQ: Can a K35 <strong>Bonanza</strong> be convertedto use the IO-470N engine? Are there anyshops that specialize in this conversion?Any adverse effects on the airplane's flyingcharacteristics?A: This engine conversion makes anice flying aircraft. The IO-470N is avery reliable engine. I suggest you contactBeryl D'Shannon at 800-328 4629.They have the STC for this conversionand many other <strong>Bonanza</strong> modifications.-NP836TC hot startsFrank WelkerAgoura, CaliforniaQ: I have three versions for hot starts:one in the POH, one from FlightSafetyand this completely different one:l. Mixture full lean cut off2. Thronle fuJI open3. Fuel pump on HIGH for20 seconds4. Fuel pump off, then normal start procedures.Could you give me the correct procedurefor the 836TC?A: Although everyone has their favoritemethod, I still like a purposely floodedhot start to clear any fuel vapor in thesystem.I. Mixture rich throttle fu ll in2, Pump on untillhe fuel pressure needleis steady, then offABS <strong>February</strong> <strong>1999</strong>

3. Throttle still full open, mixture cut offand crank4.When it fires, throttle back andmixture inThe POH method clears the vapor asfar as the throttle unit, but you still havevaporized fuel downstream and youaren't sure if you are rich or lean, Thisway, you know your status and can workback toward a lean mi xture.-NPB33 fuel ventsBob DavidsonHamilton, GeorgiaQ : When I first bought my Debonair,the fuel vents under the wing had a smalltube about three inches long extendi ngdown and slightly canted forward intothe air stream, I just noticed that both ofthem are missing. I don 't know if theycame off in flight or were removed bysomeone. I think they are important andam told the angle into the air stream mustbe just right. What kind of tubing do Iuse? How long should it be? How do Iattach it? And what angle does it need tobe? Also, is the tubing end cut straight?Seems like the ends of the originals werecut on a bias.A: These vents consist of aluminumtubing, canted 10 degrees forward andwith a 45-degree bias cut also facing forward.The lengths vary from 1.75 inchesto 3 inches. The shop manual contains atemplate drawing showing the angle,length, and cut of the tube for your aircraft.The factory part is a very long tuberunning outboard in the wing. You canrepair by using a splice with a union andflare nuts in the wheel wel l. Be sure tofo llow the template. Occasionally thesevents will corrode and break off at thewing skin. They are also susceptible tobeing bent or broken when washing orperforming maintenance under the aircraft.-NPNeil Pobanz, ABS technical consultant, is aretired US. Army civilian pilot and maintenancemanager. Neil has been an A&P andJA for 40 years.Glen "'ArkyH Foulk, whose business is DeltaStrut, is an ABS assistant technical consultantwho has served as a part-time ABS ServiceClinic inspector since 1988.Please send your questionsand/ or tips and techniques to:<strong>American</strong> <strong>Bonanza</strong> <strong>Society</strong>Attn: Neil Pob.1nzP.O. Box 12888Wichita, KS 67277Fax 316-945-1 7 10 ore-mail at bonanza2@bonanza.orgPalm Pilot aviation softwareMembers interested in using their PalmPilot computer inthe cockpit may want to check out the Am::alc software. This559.95 package includes a comprehensive list of flight planningfunctions including W &B calculations. More information is availableat http://www.lNFOequipt.comorlNFOequipt,POBox299,Rowe, MA 01367, Tel 413-339-0120 or Fax 413-339-4902.B&C gains approval for A36and B36rc standby alternatorBill Bainbridge of B&C Specialty Products has recently obtainedan STC for his standby 20-amp alternator on A36 andB36TC airplanes. The basic alternator is a well-proven, qualityproduct. B&C Specialty Products may be reached at 316-283-8000.We hope that B&C is successful in obtai ning approval for awider range of <strong>Bonanza</strong> applications in the near future as thisis a much improved product from the earlier standby alternators.The effort to obtain an STC for the various aircraft models is significant,mainly due to differences in the electrical circuitry designsand the manner of alternator failure detection.rCM continues ABS Service Clinicparticipation in <strong>1999</strong>!Teledyne Continental Motors has confirmed their continuedparticipation in ABS Service Clinics throughout <strong>1999</strong>. Forthe past few years, TCM representati ves have provided freecylinder compression checks and borescope examinations tomembers attending the ABS clinics.This is a valuable optional "free" service not included in thenormal Service Clinic fee structure and, on very rare occasions,might not be available at a particular clinic due to a last minuteschedule connict.NEil'S NOTESEmergency ADsSome members fee l the emergency FAA AD issuancesshould be used on a more limited basis than the current trendwould suggest is necessary.We have researched the FAA's requirements for issuance ofADs via the emergency method (which bypasses the normalrequirement for a comment period) and I hope to have morediscussion on this soon. However, it is apparent that the FAAfocuses on the probabi lity of additional occurrences addressedby the AD as well as the seriousness of the potential effects ofthe fai lure being addressed.These factors are weighed by the FAA and the manufacturersprior to any regulatory action being taken. NTSB recommendationsare also considered as well as possible input fromother sources. It is possible that only one occurrence of a particularproblem could lead to an AD note issuance.Clarification of single yoke issuefor flight instructionIn reference to the December 1998 Colvin's Clinic article.this is a clarification of the single-yoke issue for flight instruction.The waivers referred to are actually exemptions issued bythe policy office at FAA headquarters. The March 1998 issuehas a complete review of the subject by Itzhak Jacoby. Theseexemptions are very limited to a rew BPPP instructors and havecertain conditions imposed.As a CFI. you still fall under your supervising FSDO. It is ourunderstanding that the FAA may violate instructors using singlecontrol yokes who act as pilot-in-conunand giving primary instruction,high performance or complex sign off and/or a flightreview.ABS <strong>February</strong> <strong>1999</strong>Page 5569

ITSDEAD,JIM'--../---.-.Tips on anAVIONICSUPGRADEBY GEORGE WILHELMSENThe day has finally arrived. Your favorite Nav/Comm,which has been part of your plane since the day youbought it, has left the monal coil and joined the electroniccrowd invisible. Your avionics technician, looking likethe venerable Dr. McCoy from Star Trek, surveys the piece ofgear and says, "It's dead, Jim."After a radio has been deemed too costly to repair, or it isunable to be repaired and still meet regulations, it's time to lookat your options. The departure of a single radio from the planedoes not mean the end of the world. Still, it is cenainly time totake stock of your current avionics situation to see if changesare either warranted by the age of your equipment, or by thecost savings that might be realized by making more changes atthe same time you replace your failed radio.As an example, if you happen to be a <strong>Bonanza</strong> owner that isstill trucking around with a couple of Nav/Comms that wereput in at the same time over 15 years ago, then chances are thatPage 5570the second radio's fai lure won't be long behind the first. In theelectronics industry, this principal is described as "the bathtubcurve," and is used to explain the situation when the componentsin a piece of electronics hit the age wall , and begin to failat a very hi gh rate.If this is the case with your aircraft, this would probably bea good time to approach your shop about replacing both Nav/Comm units at the same time. What many aircraft owners seemto forget is that a good quantity of the cost of an avionics upgradeis in the labor of installation. To that end, it is frequentlycheaper in the long run to change out both Nav/Comms whenthe fi rst one fai ls.Consider this: Your avionics shop will have to open up yourplane, remove remote equipment, pull wires, route power, purchasecircuit breakers, and then put the plane back together andtest it. This process can take anywhere from five to 20 hours fornon- pressurized ai rcraft, to up to 40 or more hours for pressurizedplanes like the Duke and 58P Baron. Taking the average ofthe non-pressurized numbers, an aircraft owner can save between$625 and $1,000 dollars by installing both radios at thesame time!More than radiosWhat about the rest of the radio system? Most pilots forgetthat their antennas are an imponant pan of the radio equation.This leaves them in the situation where the shop has to pointout that their 30-year-old Comm antenna isn't compatible withtheir state-of-the-art Garmin GPS-430 unit. The point here issimple: If your radio has died and it is fairly old, in most casesit is not only a good idea but necessary to change your antennaout along with the radio.The avionics shop would like to change out the antenna forone good reason. They want your newly installed radio to work!Old antennas and old, cracked antenna wires can cause problemswith newly installed radios. While some customers arewise enough to understand this, others tend to take their radioproblems and the frustration caused by not installing new antennasand cables on the avionics shop when the work done bythe shop really isn't the problem.The rest of the stackBut what about the rest of the stack? Should you take thisopportunity to replace all the radios or just stop with the secondNav/Comm? The fact of the matter is that the same economy ofscale applies in this case too, and if all the radios are 20 to 25years old, it may be a good idea to change them out.Still, it is important to get some feedback fmm the shop aboutthe radios you have in your airplane. As an example, if you have aplane flying with a KX-170B and a KX-170A, working in concertwith a scratchy, old audio panel, a T-12B ADF and a LORAN, youcan get into some nice equipment these days at a reasonable price.As an example, you could replace the entire stack with alIMorrow stack, which would include two GX60 GPS/Communits, while replacing the audio panel with the llMorrow's SLI 0-ASS <strong>February</strong> <strong>1999</strong>

MS un il. The total cost would be around $15,000, installed withantennas.In this process, you have lost your old audio panel, two heavyradios, one of which was out of frequency tolerance, your ADFreceiver, and your old LORAN. You have gained two movingmap GPS systems, and two Comm radios in about half the stackspace, for around a third of the electrical consumption.You could wa it a few months and do even better. Garminhas recently released information on their GNS-430 model,which has GPS and Comm built in, along with YOR, Localizerand Glideslope receivers. This all-in-one unit also comes witha large. color moving map di splay for a price significan tly lessthan the price of installing a Nav/Comm, GPS and Argus colormoving map.The Garmin GNS-430, which is expected to start shippingin early <strong>1999</strong>, is already causing a stir in the avionics shopsacross the country. Many shops placed fairly large orders at theOshkosh and NBAA shows, and most report that those preordershave been either mostly or completely sold as of November1998. That's a pretty big impact for a radio that 99.9 percentof the pilots in the country have never flown behind, and probably90 percent of the pilots in the country haven 't seen.Dispose of extra weightStill, with this aside you ha ve to consider what you can gain,and what you can therefore potentially drop from yo ur avionicsstack purchase. NBD transmitters across the country are alreadystarting to shut down in response to the Airspace CommunicationPlan.A recent check of Jeppesen OTAMs showed well over 30NDB stations have gone off the air, and more joining them everyday. Any panel-mount GPS receiver on the market (and mosthandhelds as well) will perform incredibly better than the best NDBreceiver on the market today. With this in mind, it makes tittlesense to keep the heavy (in most cases) NDB receiver on board.There are some who might argue wi th this position, notingthey can use commercial AM radio stations for navigation.It is hard to argue with a hard core fan of theNDB. But if one is interested in fFR operations, oneneed look only to their approach plates to find there isno WLS-890 approach approvedfor any airport, and AM stationsare not recogni zed as airwaymarkers or waypoints on anychartS. Thus, the use of such stations,while fine for the averageVFR day, has no value or placein the IFR environment.Get rid of INOPsWhat about other radios?REPLA CINGBOTH UNITSSEEMS 10 BEWE LOGICALCOURSE OFACTION, CAPTAIN.There are many pilots out therewho are ashamed to admit it, but they have stuff in theirradio stack that just doesn't work. For some reason or an-other, the equipment was either too broken to repair, or too costlyto fi x and so has been allowed to languish in the panel with anlNOP label over the display.Whether it is an old LORAN or DME or NDB or anythingelse, the time to get rid of it is when you replace your deadradio(s). Again, this comes down to simple cost savings in termsof the installation, but also comes back to your useful load. Oldradios weigh quite a bit, and it isn't unusual to pick up severalpounds of useful load by removing defunct equipment.The cost of re moval usually isn't that high, as the shop alreadyhas to pull out side panels and !loor covers to route variouspower and antenna cables for your new radios anyway. Thus,you can gain useful load and stop lugging around this extraweight everywhere you fly by getting rid of the broken equipmenton your plane.Leave old wires in or pull them?One question that comes up during radio installations iswhether to leave or pull the old wires out of the airframe. Inmost cases, the best thing to do is have the shop spend the timeto pull the old cables oul. This comes back to weight again, asthe soon-to-be-abandoned wires and equipment can come outto quite a bit of weight, which means more useful load in thelong run.Financing optionsIn the end, many decisions may come down to one simpleproblem: a lack of money. If you have the income but not thesavings, perhaps it is time to check out one of the various aviationfinance organizations.Most aviation finance companies, including Greentree, IowaTrust, Red River State Bank, Dorr and others, finance the purchaseof avionics by taking a lien against your airframe. This isdone because avionics are small and are not considered"real property" as is the airplaneitself. By taking such a loan, you may beable to get the avionics you want now,and save a bundle by doing the workall at one time.In the end, your decision regardingwhether to replace all or some of yourav ionics will be based on what you canafford. Take a moment to consider thecost savings that can come from doing, j more now. The reward of your foresight~ in such matters will be the money you, save in installation, fuel and time.ASS member George Wilhelmsenis a Senior System Engineer withan SRO license with CornEd. Heha s more than 700 hours, is acommercial instrument rated pilot,and is a contributing editor forPlane & Pilot magazine and AvionicsNews.ABS <strong>February</strong> <strong>1999</strong>Page 5571

A CASE STUDYThe cost of converti ng froman IO-470-C to an IO-S20-BABY STEVEN W OXMAN, Annapolis, MarylandOnVening a 1959 <strong>Bonanza</strong> K35 from ils original Continental10-470-C 10 a larger Continental [0-520-BA(powerplant is a larger lask than mighl meel Ihe eye atfirsl blush. In Ihis Iwo-pan series, I will provide a 101 of Ihedelails of my experiences.[n Ihi s firsl anicle, [will provide background fOrlhis projecI10 assisl Ihe reader wilh underslanding Ihe reasons and mOlivalionsfor whal was done. The second article will provide Ihefinancial delails of the projecI, information Ihat will undoubledlysurprise many readers.Background for this project[purchased my K35 approximalely Ihree years ago. The planehad approximately 2900 hours IOlal lime on Ihe airframe andapproximalely 1,000 hours since the lasl major overhaul on theoriginal engine. No work had been done on Ihe propeller in Ihelasl 10 years, which equaled 10 aboul 1,000 hours. The airframewas and is in good condilion. The engine seemed OK when Ipurchased Ihe airplane. It should be nOled Ihal Ihis was the firslairplane [ had ever purchased (and will mOSI likely be Ihe onlyplane I buy- I hope il will oUlli ve me). AI Ihe lime of Ihis purchase,I did nOI know whal 10 look for and I did nOl reali ze Ihisplane was going 10 require a 101 of work shortly afler ils purchase.My pre-purchase mechanic said nOlhing 10 me aboul Iheengine and propeller needing work in Ihe near fUlure.[ flew Ihe plane for a while and il seemed 10 fly fine. Thenthe engine started to give me some minor, but consistent, problems.Wilh each problem. I had my mechanic fix Ibe engine.Wilh each incident, I did more and more research on enginework and/or replacement. One day, while flying wilh my familyfrom Lee Airport, a 2,500-foot paved slrip in Annapoli s,Maryland, Ihe engine went from 26 inches 10 23 inches justafter rolalion and from 2,675 rpm 10 2,100 rpm wilhout melOuching anYlhing! My venical rale decreased quickly. I flew alight pallern and returned 10 Ihe field. ThaI day I declared IhalIhe engine was 10 be replaced.My mechanic found Ihree fouled injeclors. Wilh Ihese cleanedOUI, Ihe engine again ran fine. I continued 10 fly it. Bul I put myengine change projecl in mOlion.Decisions. Decisions.Whal 10 do? Local engine overhaul or an overhaul by oneof Ihe big guys (my mechanic likes Matlaluck)? Overhaul byone of Ihe advenisers in this magazine or overhaul by the manufacrurer?Faclory reman by the manufacturer? All of these seemedPage 557210 be valid ahemalives. However, [found little interest by the vendorsin working wilh my 1959 10-470-C engine. All the vendorsseemed 10 be imeresled in 10-470-Ns, [0-520s and [0-550s.The faclory did nOl even offer a faclory reman 0Plion for myengine. They did offer a faclory rebuild 0Plion. Wilh Ihe age ofmy engine, I decided Ihal Ihe overhaul 0Plion was nOI a COSIeffecliveoption. For one Ihing, many of the bids were openended(e.g., if Ihe crankshaft does not meel specs, Ihe cost willgo up by X dollars).OK, now thaI I had decided Ihal I was nOl going 10 overhaulmy engine, whal oplions were left Ihat [ knew aboul? A newengine or a faclOry reman engine from the factory was nOl anoption (Ihe 10-470-C was nOl available and the faclory had noSTCs for Ihe larger engi nes). To gel a faclOry reman or a newengine, I needed an STC. For cost reasons. 1 quickly removednew engines from consideralion. Therefore, I made Ihe decisionto purchase a larger, newer factory reman engine with alegal STC Ihrough a Ihird pany.Slill relatively new 10 Ihe <strong>Bonanza</strong> world, Ihe only option Jcame up wilh was a Continental (TCM) faclory reman with IheSTC from Beryl D'Shannon.Beryl offered me a small STC price break if [ ordered Iheengine through Ihem, which [did. 1 looked al Ihe 10-470-N, Ihe10-520-BA. the 10-520-BB and Ihe 10-550. [quickly removedIhe [0-470-N from consideration because il did nOI providemuch of a difference in horsepower.[ also quickly deleled Ihe 10-550 from my Iisl of choicesbecause I did nOl wish 10 modify Ihe front of my plane for Ihecanl requirement nor I did nOI want 10 li ve wilh Ihe power setlinglimilalion al lakeoff. Therefore, I was 10 purchase an [0-520. BUI which one, Ihe BA or Ihe BB? I was told Ihal the BBhad many posilive fealures like a heavy case and a VAR crank.and thaI I should spend Ihe difference in money 10 gel Ihesefearures. However, when I spoke wilh TCM people al Ihe ABSConvention, Ihey IOld me Ihal Ihe fealures [ was interesled inwould be on a BA engine, and Iherefore, save the money on Ihemodel. So that's whal I did.The add-ons and accessoriesTo gel Ihe STC from Beryl, [ also had to purchase a bafflekit. Allhough not a requirement of Ihe STC, I also needed 10purchase Ihe electrical upgrade kil and a hose kit. And since myold engine made a mess of Ihe underside, I purchased a Berylairfoil separalor. I also had to purchase a few new accessoriesIhal do nOI come wilh Ihe new engine, like the propeller gover-ABS <strong>February</strong> <strong>1999</strong>

nor and a new vacuum pump (why use old accessories?).I was told that I would not have to purchase a new air box,that myoid one could be modified to work with the new engine.Then after my old engine was removed and my new enginewas on its way from TCM , I was told that I had to purchasea new air box, which I did.The Beryl baffle kit includes new pieces added to the cowling.After installation of the cowling-mounted pieces of the newbaffling, I sent the cowling out to have its inside repainted toremove the multi-colored, add-on look.When the Continental engine arrived, the "gold"TCM valvecovers looked terrible, so I sent them out to ARS for powdercoating (black with silver lettering). After all, a new enginedeserves to look nice, doesn't it?I also purchased a lot of miscellaneous items: new lord mounts;a new crankcase pre-heater (to keep the engine from having tostan real cold); cleaning solvent to clean the engine compartment;primer and paint to paint the engine compartment; and newscrews, washers and nuts to make everything new.What about my propel/er?Options included a new two- or three-blade. My Beech 278would not be usable with the STC'd IO-520-BA. I searched fornew propeller deals like the Propeller Man. I looked for goodused propellers. I looked to try to sell my prop to defray someof the cost of a new propeller. The best combination deal I couldfind was a new Hartzell three-blade from the Hartzell servicecenter in Ohio, which included a trade-in of myoid Beech 278two-blade propeller.Thank goodness for the ABS ConventionGoing to the ABS Convention was the best thing I ever didin getting ready for this project. I listened and learned from the<strong>Society</strong>'S finest and the vendors, including TCM. DaveBlanchard from TCM was especially helpful. Dave providedme with great help. information and assistance. Dave convincedme that to put a new factory reman into an airplane with oldengine instrumentation was not a good idea. If my engine diedearly in its life and TCM determined that the engine instrumentationwas faulty, he cautioned me that the TCM warra nty couldbe adversely affected. Say no more, let us add a GEM 602, aShadin fuel flow Microflo computer, a new Horizon electronictach and a new vacuum gauge.The project work also includes labor costs, and for an STCengi ne project, this is a significant cost item (plus the downtimecosts related to using commercial carriers to my clientsfor an extended period of time). I did what I could, like cleaningthe engine compartment, and the priming and painting insidethe engine compartment. I assisted where I could do so withoutgetting in the way. But most of the labor came from my maintenanceshop and some from Beryl when my shop asked me to seeif I could get some Beryl assistance on the air box installation.Dave Blanchard also had me have my fuel cells checked.ABS <strong>February</strong> <strong>1999</strong>Side views of Steve Oxman's new IO-520-BA reM engine.We did not wish to get old fuel cell fragments clogging up theinjectors on the new engine. The inspection took time andmoney, but all was well here.The project took a lot more time than anyone estimatedthreemonths. Actual plane downtime (i.e., airplane in the hangarin pieces) was 10 weeks. The project length was influencedby many factors, including TCM's inability to deliver as promised,poor STC paperwork (difficult to understand), and havingto fly in a Beryl expert to assist with the air box job, which laterturned out to be a very good decision; this expert helped theproject a lot.SummaryThis project provided my K35 with a factory reman, zerotime,IO-520-BA TCM engine with the large case and the VARcrank, all new engine instrumentation, all new engine accessories,all new baffling, a larger air box with which to breathebener, an air/oil separator to keep the airplane's belly cleaner, anew crankcase pre-heater, all new wiring and plumbing, a totallycleaned up engine compartment and a new propeller.The results are fantastic! The K35's performance with thiscombination up front is superb. Many en route controllers havecome back on the radio with "Baron 12711, ..."Looking to do something with your high-time <strong>Bonanza</strong> witha smaller engine? This is definitely one way to go! But at whatcost? Stay tuned. That is for the next article. --@-Page 5573

Regarding the use of GAMljectorscant reduction in enginevibration, and in cruise,a modest reduction infuel flow. In discussingthe operation of the enginewith the folks atGAMI, they proposedthat I operate the engineon the lean side of peakEGT. However, flyingin the face of convention,especially with anew engine, did notseem like the prudentBY KENNETH 5. SUTTON, Barrington Hills, IllinoisFrom the first day I flew my newly acquired airplane, Inoticed on my JPI digital six-probe engi ne analyzer thatcylinder head temperatures on cylinders two and six (theback and front cylinders on the left side, respectively) ran hotterthan the other four cylinders. The airplane, a 1966 V35 <strong>Bonanza</strong>,had a new 1O-520-BB engine installed just before l purchasedit and I was concerned that perhaps there was somethingabnormal with these two cylinders.I spoke with everyone I could think of regarding thisanomaly: my mechanic, ABS, TCM, but nobody had a definitiveanswer. l was repeatedly told, however, that as long as Ikept the hottest cylinder below 400 F, I had nothing to worryabout. About a year ago, in an effort to reduce engine vibrationand fuel flow, I had GAMljectors installed.The GAMls have proven to be the best va lue of any of thealterations I have made to the airplane. From the first instantthat I staned the engine after the installation. I noticed a signifiengine,they also had CHTs two and six hotter than the othercylinders. For the first time, I had evidence that this CHTanomaly is a common problem and not specific to my engine. lwas determined to pursue a solution to this anomaly and furtherreduce my CHTs.The first step was to duplicate the test procedure used inBraly's anicle. This is a relatively simple test, provided youhave a digital six-probe engine analyzer (preferably to a singledegree) and a digital fuel flow meter. Staning at a fuel flow thatyou know is well rich of peak EGT, the procedure is to lean theengine in 0.3 gph increments, stopping to let the engine stabilize,then recording the CHTs and EGTs for all six cylinders.The desired outcome is to have all six cylinders operate on thelean side of peak, with the leanest cylinder approximately 50 Fdegrees lean of peak. without any engine vibration.After printing out several copies ofthe Test Form (availablefrom GAM!'s website www.ganti.com). it was time to performthe test on my engine.The test takes at least15 minutes, most ofwhich is spent withyour eyes focused insidethe cockpit. In theinterest of safety, lhighly recommend an"My 1966 V35 <strong>Bonanza</strong>, N7923M, that is now up to the standards Ihave grown accustomed to in flying for the airlines." -Kenneth Suttoncourse.So it was with great interest that I read George Braly's recentseries, "Back to the Future," in the ABS Magazil1e. In thisseries, Braly pointed out the importance of balancing the airlfuel ratios and how, if it were possible to get all cylinders tooperate on the lean side of peak EGT without engine vibration,there would be significant obvious advantage with the associateddrop in cylinder head temperatures.After reading Braly's ABS Magazille series. I decided theidea of operating on the lean side of peak was worth revisiting.Further, I heard of Mr. Braly's lecture at the ABS Conventionon the significant positive results GAMI had compiled in morethan two years of testing. After studying the test forms in Braly'sseries, it was clear that I could significantly funher reduce mycylinder head temperatures if I were able to operate on the leanside of peak.Interestingly, the test forms also showed that in GAM!,s testobserverlpi lot ridealong. As you can seeon Test Form I, all sixof my cylinders peakedwithin 0.6 gph.Unfonunately, however,the outcome was not satisfactory. The problem was thatwhen I continued to lean the engi ne to get the first cylindersthat peaked to 50 F degrees lean of peak, I began to sense aslight irregular vibration in the engine (as noted by asterisksnext to the fuel flow).After landing, I faxed GAM] the test form and a few minuteslater GAM! President Tim Roehl called me back. Afterdiscussing the results of the test, Tim suggested I rerun the testat a higher power setting. Rather than squaring the power, hesuggested a routine power setting at altitude of full throttle and2,500 rpm.A few weeks later I had a great opponunity to perform thetest again on a long flight from my home base near Chicago toaples, Florida. At 11 ,000 feet (with a 50 knot tailwind), I setup for the second test at full throttle, 19.2 inches MP and 2,500rpm. This time, all six cylinders peaked within 0.3 gph, butonce again, at 50 F degrees lean of peak I experienced occa-Page 5574ABS <strong>February</strong> <strong>1999</strong>

FLJGHT TEST DATA FORM #1IDATERP:.oo IPRESS ALT 65()( IDAT911 lQ4( I~; 7SF I~~:~' EDM700I Fuel F"" CHT 1 EGT I CHI EGT 2 CHT 3 EGT3 CHT4 EGT 4 CHT5 EGT5 CHT6 EGT6 TIT liAS1404 359 142, 1410 366 1423 369 145, 336 1386 383 1371 14114. 35l; 144· 143: 366 1431 369 1461 337 1393 385 1392if14113. 36C 1464 401 1446 36E 1456 369 148, 338 1411 393 141 141l13.5 35S 1470 400 1464 368 149' 338 1435 38B 1426146914113. 357 1486 399 1481 147149B 338 1441 391 1447 14012.B 334 1500 396 1485 1465 ~ 1505 336 145, 391 1453 14012. 33, 1486 388 1466 342 1441 351 1482 327 1443 386 1461 13912.2 335 1433 380 144, 330 1415 34, 1461 316 1411 381 1452 13911 .9 327 1411 369 1411 31 1393 329 1433 296 136B 367 1426 134- 11 .6 320 1400 366 1391 299 1361 316 1405 282 134S 354 1396 131NAME Kenneth S Sutton Ale TYPE : B-35 ENG MODEL" 10-520-88FLIGHT TEST DATA FORM #2f\DATE ENGINE START ITEST START ' ''''1~:.Fuel FlOw CHT1 EGT1 CHT2 EGT2 I CHT EGTI~~~'RP~ PRESS ALT 4500 IDAT5BFEGT4 I CHT5 EGT5 CHT 6 EGT6 TiT lASCH~17.4 337 1452 379~ 14 15101 lli ~37' 1446 18417. 331 1468 380 14 1529 3: 375 1459 18416.8 33B 1480 _ 381 147S 346 1491 352 1538 324 1455 376 147· 18316.5 338 1490 382 1491 346 1503 350 1546 325 1463 37: 1480 18316.2 338 1500 381 1491 345 1509 349 1548 325 1474 374 149C 18315.9 337 1510 381 ~ 343 151· 346 1549 324 1480 373 1495 18115.6 335 1516 379339 1504 341 15381 32: 1. 369 1491 181~15.3 330 1509 374 331 148715.0 324 1495 367 1500 323 147014.7 319 1471 361 1479 311 145214.4 314 1456 354 1462 309 1436- 14.1 307 1445 348 1445 303 14241333 1521 317 1477 365 1484 180325 1503 311 1459 356 1465 177317 1485 304 1435 350 1446 174310 1469 295 1416 341 1426 173304 1455 286 1390 333 1413 i 73NAME Kenneth S Suttoo AJC TYPE B-35sional engine vibralion.After discussing the results of the second test with Tim, he suggestedwe change injectors two and six in an effort to get thosecylinders to peak at the same fuel flow as the other cylinders.Then came the tricky part . Since the fuel manifo ld is commonto all cylinders, changing anyone injector changes the air/fuel ratios of all cylinders. So the exercise at thi s point becamea bit like a cat chasing its own tail. In working with Tim and thefolks at GAMI, we changed injectors, two at a time until weachieved the optimum result.I now have a perfectly balanced set of injectors that allowmy engine to run smoothly at 50 F on the lean side of peakwhere all cylinders are reaching peak EGT within 0.3 gph . I amthri lled with how incredibly smooth my engine is now runningat significa ntly reduced cylinder head temperatures, and at amuch lower fuel flow. As you can see on Test Form 2, I sti llhaven't been able to get cylinders two and six to run as cool asthe others. However, I can now safely run the engine on thelean side of peak where the overall CHTs are much cooler. andI am certain that much cooler CHTs will translate into prolongedengine life.In my lengthy discussions with Tim, he confided that GAMIENG MODEL. 10.520-88had recognized for some time the problem of unequal cylinderhead temperatures specific to cyli nders two and six. Yes, indeed,it is a common problem and it is related to the bafflingsystem on the <strong>Bonanza</strong>. Tim described testing GAMl has performedwhere thermocouples were installed every 30 degreesaround each of the six cy linders to determine specific hot spots.He told me to be patient because GAMl soon will be offering awholly new baffle system for the <strong>Bonanza</strong> that will solve thisanomaly and greatly improve overall cy linder cooli ng.Worki ng with the folks at GAMI has been an enjoyable experience.They are the definitive source of information when itcomes to balanci ng air/fuel ratios and cy li nder head cooling.Their expertise in this area is unmatched and their willingnessto work with their customers is extraordinary.Having been disturbed by the anomaly of uneven cylinderhead cooling for some time, you can be sure I'll be installingthe GAMI baffle system as soon as it becomes available.ABS member Kenneth Sutton is a B737-3oo pilot for US Airwayswith more than 11 ,000 hours. He is also founder and president ofSutton Capital Resources, Ltd, a private money-management firm.He regularly uses his <strong>Bonanza</strong> to fly between their offices inBarrington, Illinois, and Naples, Florida.ABS <strong>February</strong> <strong>1999</strong>Page 5575