View as PDF - Rail Professional

View as PDF - Rail Professional

View as PDF - Rail Professional

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

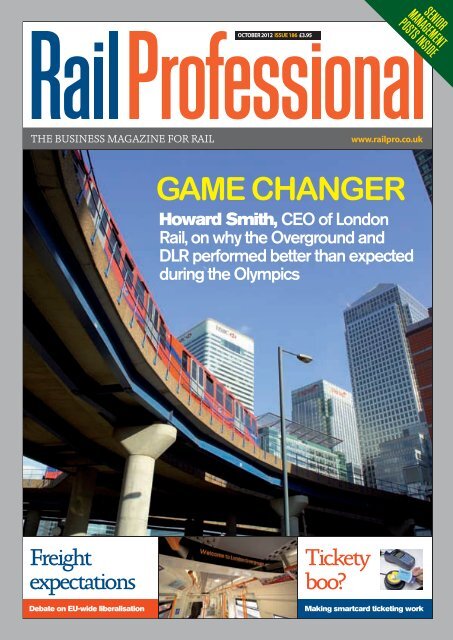

OCTOBER 2012 IssuE 186 £3.95<br />

THE BUSINESS MAGAZINE FOR RAIL<br />

www.railpro.co.uk<br />

GAME CHANGER<br />

Howard Smith, CEO of London<br />

<strong>Rail</strong>, on why the Overground and<br />

DLR performed better than expected<br />

during the Olympics<br />

Freight<br />

expectations<br />

Debate on EU-wide liberalisation<br />

Tickety<br />

boo?<br />

Making smartcard ticketing work

OCTOBER 2012 IssuE 186 £3.95<br />

THE BUSINESS MAGAZINE FOR RAIL<br />

www.railpro.co.uk<br />

GAME CHANGER<br />

Howard Smith, CEO of London<br />

<strong>Rail</strong>, on why the Overground and<br />

DLR performed better than expected<br />

during the Olympics<br />

Freight<br />

expectations<br />

Debate on EU-wide liberalisation<br />

Tickety<br />

boo?<br />

Making smartcard ticketing work

Debate on EU-wide liberalisation<br />

OCTOBER 2012 ISSUE 186 £3.95<br />

Making smartcard ticketing work<br />

Welcome<br />

www.RAILpRO.cO.Uk ISSUE 186 • OcTOBER 2012<br />

THE BUSINESS MAGAZINE FOR RAIL<br />

www.railpro.co.uk<br />

GAME CHANGER<br />

Howard Smith, CEO of London<br />

<strong>Rail</strong>, on why the Overground and<br />

DLR performed better than expected<br />

during the Games<br />

Freight<br />

expectations<br />

PUBLISHER<br />

RAIL PROFESSIONAL LTD<br />

Hallmark House, Downham Road,<br />

Ramsden Heath, Essex CM11 1PU.<br />

Tel : 02031 501 691<br />

EDITOR<br />

KATIE SILVESTER<br />

Tel: 01223 477426 (direct line)<br />

editor@railpro.co.uk<br />

ADVERTISING SALES<br />

CHRISTIAN WILES<br />

chris@railpro.co.uk<br />

DOUGLAS LEWIS<br />

doug@railpro.co.uk<br />

DESIGN & PRODUCTION<br />

MILES JOHNSTONE<br />

production@railpro.co.uk<br />

SUBSCRIPTIONS<br />

Tickety<br />

boo?<br />

AMY HAMMOND<br />

subscriptions@railpro.co.uk<br />

Cover image: <strong>Rail</strong> Images<br />

Thanks also to <strong>Rail</strong> Images for<br />

photographic <strong>as</strong>sistance in this<br />

issue.<br />

<strong>Rail</strong> <strong>Professional</strong> welcomes<br />

contributions in the form of articles,<br />

photographs or letters, preferably<br />

by email. Original photographs<br />

may be submitted, but, while every<br />

care will be exercised, neither<br />

the editor nor the publisher take<br />

responsibility for loss of, or damage<br />

to, material sent. Submission of<br />

material to <strong>Rail</strong> <strong>Professional</strong> will<br />

be taken <strong>as</strong> permission for it to<br />

be published in the magazine.<br />

Published monthly<br />

ISSN 1476-2196<br />

©All rights reserved. No part of this<br />

magazine may be reproduced or<br />

transmitted in any form or by any<br />

means, electronic or mechanical,<br />

including photocopying, recording<br />

or by any information storage<br />

and retrieval system, without prior<br />

permission in writing from the<br />

copyright owners.<br />

The views and opinions expressed<br />

in this publication are not<br />

necessarily those of the publisher,<br />

nor does he accept liability for any<br />

printing errors or otherwise which<br />

may occur.<br />

Comment & news<br />

4<br />

Samaritans launch new rail initiative; First Capital<br />

Connect begins apprenticeship scheme with a<br />

difference; West Co<strong>as</strong>t handover suspended;<br />

Southampton to get improved link to WCML<br />

Train of thought<br />

9<br />

Readers’ letters: have your say about the rail industry<br />

and <strong>Rail</strong> <strong>Professional</strong><br />

<strong>Rail</strong> <strong>Professional</strong> interview<br />

10<br />

London <strong>Rail</strong> CEO Howard Smith breathes a sigh of<br />

relief <strong>as</strong> London Overground and DLR get through the<br />

Olympics without incident. He tells Katie Silvester about<br />

the planning behind the Games<br />

In the p<strong>as</strong>senger seat<br />

16<br />

Is the move towards smartcard ticketing being driven<br />

by the industry or p<strong>as</strong>sengers’ needs? P<strong>as</strong>senger<br />

Focus’s Anthony Smith looks at what p<strong>as</strong>sengers<br />

want from more sophisticated tickets<br />

Cross-border co-operation<br />

17<br />

Ron Smith meets the head of a Swiss freight operator,<br />

which is part private and part public owned, to find out<br />

why rail liberation is important for freight operators in all<br />

business models<br />

Delivering the goods<br />

19<br />

An incre<strong>as</strong>e of Channel Tunnel traffic between the UK<br />

and Poland is good news, says Chris McRae, but the<br />

tunnel is still under used<br />

Proactive about pl<strong>as</strong>tic<br />

21<br />

David Naylor discusses the advantages of using<br />

pl<strong>as</strong>tic pipework systems for bulk refuelling<br />

Taking on the recession<br />

25<br />

Freightliner’s Peter Maybury tells Tim Gillett how<br />

the company h<strong>as</strong> improved business practices to<br />

survive difficult economic times – and ensure a more<br />

prosperous future<br />

Follow us on Twitter <strong>Rail</strong>ProMag@twitter<br />

IMAGINE<br />

Real-Time P<strong>as</strong>senger Information System<br />

built for the future and built to l<strong>as</strong>t<br />

Infr<strong>as</strong>tructure focus<br />

29<br />

Catch up on Crossrail, while Wessex gets longer platforms<br />

and Network <strong>Rail</strong> buys a new ultr<strong>as</strong>onic test train<br />

A duty of care<br />

32<br />

Whether staff are confronted with an incident on the<br />

railway – from a major accident to an attack on staff –<br />

the majority of those involved will experience a negative<br />

reaction. Gerry Jackson explains how staff can be<br />

supported through difficult times<br />

Institution of <strong>Rail</strong>way Operators<br />

34<br />

Find out what other IRO are<strong>as</strong> have been up to.<br />

Plus: dates for diary<br />

Safety in the pipeline<br />

37<br />

Ian Morris, of the British Fluid Power Association, explains<br />

why it is so important to chose the right hydraulic hoses<br />

Transport finishes first<br />

39<br />

Twelve million spectators travelled to and from venues<br />

on public transport to watch events during the Games.<br />

The ODA’s David Emmerson and William Barter<br />

explain how it w<strong>as</strong> done<br />

Off the rails?<br />

42<br />

Daniel Ball argues that FirstGroup taking over the West<br />

Co<strong>as</strong>t from Virgin may lead to a duff contract<br />

Business profiles<br />

45<br />

People<br />

55<br />

Introducing Klüber, Stannah, Socomec and the Severn<br />

Partnership. Plus details of the Transport Security Expo<br />

& Conference<br />

Patrick McLoughlin; Theresa Villiers; Norman Baker;<br />

Simon Burns; Stephen Hammond; Tom Clift; Maggie<br />

Simpson; Iain Mobbs; Ana Santos; Andy Lewis; Mark<br />

Bullock; Mike Fleming; John Coates; Richard Algeo; José<br />

Viegal; Emmanuel Moulin<br />

Recruitment<br />

57<br />

Find your next job here and online at<br />

www.railpro.co.uk/recruitment<br />

Your solution with our knowledge

<strong>Rail</strong> <strong>Professional</strong> opinion<br />

Katie Silvester, editor<br />

McLoughlin takes centre stage<br />

In just over six years there have been eight transport<br />

secretaries. How many people could name all of them?<br />

For the record, they were Al<strong>as</strong>tair Darling, Dougl<strong>as</strong><br />

Alexander, Ruth Kelly, Geoff Hoon, Lord Andrew<br />

Adonis, Philip Hammond, Justine Greening and now Patrick<br />

McLoughlin (see page 55).<br />

If a private company had had eight CEOs in seven years, would anyone have<br />

any confidence in it? Probably not. The only changeover that w<strong>as</strong> unavoidable<br />

w<strong>as</strong> between Andrew Adonis and Philip Hammond when Labour lost the<br />

election and perhaps between Ruth Kelly and Geoff Hoon when Kelly wanted to<br />

reduce her workload to concentrate on her family.<br />

Some of the changes seem, to the c<strong>as</strong>ual observer, to be without rhyme or<br />

re<strong>as</strong>on. If Theresa Villiers w<strong>as</strong> to be promoted to secretary of state, why not<br />

keep her in the Department of Transport? Instead, she h<strong>as</strong> moved across to the<br />

Northern Irish office. She will be missed, <strong>as</strong> Villiers w<strong>as</strong> the only consistent<br />

figure in the department, having shadowed the secretary of state role in<br />

opposition and been a transport minister proper since the coalition came to<br />

power. For most of that time she concentrated on rail.<br />

She w<strong>as</strong> largely responsible for High Speed 2 getting the go-ahead, the<br />

Conservatives having proposed it in opposition, with Andrew Adonis adopting,<br />

then progressing the idea into firm policy during his brief tenure <strong>as</strong> head of<br />

the department. Who knows why Villiers w<strong>as</strong> shuffled off to Belf<strong>as</strong>t instead of<br />

moving up within the DfT? We might find out when she does her memoirs in 20<br />

years time.<br />

There h<strong>as</strong> been talk of Greening’s removal being linked to her opposition to<br />

a third runway at Heathrow, with the suggestion that this Conservative policy is<br />

about to be reviewed. It w<strong>as</strong> Villiers who ushered in the ‘no third runway’ policy,<br />

but Simon Burns, who replaces her, h<strong>as</strong> also opposed a new runway. Newcomer<br />

McLoughlin is said to be more open to Heathrow’s expansion, while Stephen<br />

Hammond h<strong>as</strong> moved from being against a third runway to writing in the<br />

Evening Standard earlier this year that the c<strong>as</strong>e for an additional runway should<br />

be re-examined.<br />

It seems that the position of transport secretary is often viewed <strong>as</strong> a transitional<br />

one – a weighty role, but also a stepping stone to the lofty heights of defence<br />

or Tre<strong>as</strong>ury. This is in sharp contr<strong>as</strong>t to posts such <strong>as</strong> that of chancellor of the<br />

exchequer, which Gordon Brown held for 10 years and George Osborne looks<br />

set to hang onto for a while. Or foreign secretary, which Robin Cook did for four<br />

years, followed by Jack Straw for five years.<br />

We would like to see McLoughlin given time to see the job through – there<br />

is plenty for him to get stuck into. The coalition h<strong>as</strong> had a good record on rail<br />

so far – we hope that this will continue. The railways had a lucky escape in the<br />

coalition’s cuts, following the l<strong>as</strong>t election, which shows a broad commitment<br />

to rail. Crossrail and High Speed 2 are still on schedule, when some feared they<br />

would be delayed. And the Northern Hub h<strong>as</strong> got the funding it deserves. But<br />

McLoughlin will need to keep up the pressure for cost cutting<br />

in the industry.<br />

He h<strong>as</strong> walked straight into the West Co<strong>as</strong>t franchising<br />

row, of course. Whether he will consider that Virgin’s<br />

objections to the current franchising process have any merit<br />

remains to be seen.<br />

News in brief<br />

Cable thieves jailed<br />

Four men have been sentenced<br />

for conspiracy to commit<br />

railway cable theft, thanks to<br />

the use of SmartWater forensic<br />

markers. The four have been<br />

jailed for a total of 11 years<br />

due to tools found in their<br />

possession being marked by a<br />

forensic solution traceable to<br />

multiple Network <strong>Rail</strong> sites.<br />

Go-Ahead sees profits dip<br />

The Go-Ahead Group h<strong>as</strong><br />

reported its highest ever<br />

p<strong>as</strong>senger levels across both<br />

rail and bus in 2011-12. The<br />

group’s revenue grew from<br />

£2.3bn in 2011 to £2.4bn, but<br />

operating profits fell slightly<br />

from £115m to £110m. Gains in<br />

the bus division were eaten up<br />

by rising premium payments<br />

for Southern.<br />

Government subsidy<br />

decre<strong>as</strong>es<br />

The rail industry h<strong>as</strong> received<br />

£3.9bn in public subsidy from<br />

the government in the l<strong>as</strong>t<br />

financial year, data published<br />

by the ORR h<strong>as</strong> revealed. This<br />

is the fifth year in a row that<br />

government subsidy h<strong>as</strong><br />

decre<strong>as</strong>ed since it reached<br />

its height in 2006-7 when the<br />

rail industry received almost<br />

£6.31bn.<br />

GBRF expands Lafarge<br />

contract<br />

GB <strong>Rail</strong>freight h<strong>as</strong> incre<strong>as</strong>ed<br />

the amount of aggregate<br />

transported to Wellingborough<br />

from Mountsorrel for Lafarge,<br />

running up to five extra trains<br />

a week from the granite plant<br />

to a depot in Wellingborough.<br />

The move is part of a longterm<br />

deal that will see an<br />

incre<strong>as</strong>e in the amount of<br />

aggregate transported to<br />

Northamptonshire over the<br />

next few years.<br />

Signalling Solutions works<br />

on prototype<br />

Signalling Solutions, a joint<br />

venture between Alstom<br />

Transport and Balfour Beatty<br />

<strong>Rail</strong>, h<strong>as</strong> been awarded a<br />

contract worth around £7m<br />

from Network <strong>Rail</strong> to deliver a<br />

prototype for the introduction<br />

of a new National <strong>Rail</strong> Traffic<br />

Management System. The<br />

delivery is scheduled for 2013.<br />

Page 4 OCTOBER 2012

News<br />

West Co<strong>as</strong>t handover suspended<br />

after Virgin demands review<br />

by Alexandra Warren<br />

The start of the next West Co<strong>as</strong>t<br />

franchise is to be delayed by the<br />

legal challenge Virgin Trains h<strong>as</strong> launched<br />

against the Department of Transport,<br />

following its decision to award the West<br />

Co<strong>as</strong>t Main Line franchise to FirstGroup.<br />

The government h<strong>as</strong> admitted that<br />

the deal with FirstGroup to take over the<br />

West Co<strong>as</strong>t line, which runs from London<br />

to Gl<strong>as</strong>gow via Manchester, is unlikely to<br />

begin on 9 December due to the judicial<br />

review launched by Virgin. The start<br />

of the new franchise h<strong>as</strong> been delayed<br />

indefinitely.<br />

Sir Richard Branson, owner of Virgin,<br />

h<strong>as</strong> questioned the DfT’s decision to<br />

hand the franchise from Virgin Trains<br />

to FirstGroup, claiming that the rail<br />

franchise system is flawed.<br />

The Transport Select Committee h<strong>as</strong><br />

been examining the decision to award the<br />

contract to FirstGroup.<br />

Committee chair Louise Ellman MP<br />

said: ‘The government decision to award<br />

the West Co<strong>as</strong>t rail franchise to First<br />

West Co<strong>as</strong>t Ltd h<strong>as</strong> raised a number<br />

of concerns. I want the Transport<br />

Committee to have the opportunity to<br />

explore these issues.’<br />

While giving evidence to the Select<br />

Committee, Branson said that the<br />

government should not be opting for a<br />

franchise that w<strong>as</strong> risky over one that had<br />

the p<strong>as</strong>sengers’ interests at heart.<br />

Branson also claimed that the DfT<br />

is wrong in claiming that Virgin’s bid is<br />

‘less deliverable’ than FirstGroup’s, saying<br />

that in order for FirstGroup to cover the<br />

franchise it will have to fill every seat<br />

or put up fares. ‘The Virgin bid is more<br />

deliverable and much more financially<br />

robust,’ he said.<br />

FirstGroup chief executive, Tim<br />

O’Toole, told the Select Committee<br />

hearing: ‘We do not have a c<strong>as</strong>h flow<br />

problem.’ He also added that his bid<br />

<strong>as</strong>sumes fares will incre<strong>as</strong>e only with the<br />

rate of inflation and there would be no<br />

job losses, at le<strong>as</strong>t in the first five years.<br />

Branson’s fears for FirstGroup’s<br />

failure are not unfounded – two previous<br />

operators on the E<strong>as</strong>t Co<strong>as</strong>t line have<br />

gone bust – however O’Toole is confident<br />

in FirstGroup’s success. ‘I don’t think<br />

there is any chance of us handing back<br />

the keys,’ he said.<br />

An e-petition started by p<strong>as</strong>senger<br />

Ross McKillop <strong>as</strong>king the government to<br />

reconsider the decision h<strong>as</strong> collected over<br />

172,000 signatures, and celebrities such<br />

<strong>as</strong> Stephen Fry, Dermot O’Leary, Eddie<br />

Izzard and Joey Barton h<strong>as</strong> pledged their<br />

support via Twitter.<br />

Branson h<strong>as</strong> offered to run the service<br />

<strong>as</strong> a not-for-profit operation should the<br />

decision not have been reached by the<br />

handover date.<br />

It is more likely, however, that the<br />

government will temporarily nationalise<br />

the line through the state owned<br />

company Directly Operated <strong>Rail</strong>ways<br />

(DOR). DOR already operates the E<strong>as</strong>t<br />

Co<strong>as</strong>t line.<br />

Southampton to get improved link to WCML<br />

by Alexandra Warren<br />

The EU h<strong>as</strong> pledged £4m to improve freight access at the Port of Southampton,<br />

<strong>as</strong> part of a project to boost the European economy. The money will be used to<br />

upgrade links between the port and the West Co<strong>as</strong>t Main Line to improve hinterland<br />

connections. The European Commission h<strong>as</strong> pledged €200m overall to infr<strong>as</strong>tructure<br />

projects throughout the European Union for 74 projects in 27 countries. More than<br />

€15m h<strong>as</strong> been made available<br />

to projects in the UK with<br />

€4m to go to the Felixstowe<br />

to Nuneaton Freight Line and<br />

€1.3m to improve hinterland<br />

connections at Belf<strong>as</strong>t Port.<br />

EU Commission vicepresident,<br />

Siim Kall<strong>as</strong> said:<br />

‘The European Commission<br />

continues to support the<br />

construction and upgrade<br />

of European transport<br />

infr<strong>as</strong>tructure to ensure its<br />

citizens can reap the benefits<br />

of a complete, safe and<br />

modern network.’<br />

Sign of the<br />

times?<br />

Cheerful staff can make all the<br />

difference to p<strong>as</strong>sengers’ journeys<br />

on a grey day – even better if they have<br />

a sense of humour.<br />

Public announcements on trains<br />

and buses are designed to keep people<br />

informed on what’s happening on the<br />

transport networks, but according<br />

to a recent survey, not everyone is<br />

happy with them. In fact, some find<br />

announcements downright irritating.<br />

The survey, carried out by The Writer,<br />

a language consultancy, found that 57<br />

per cent of people disliked announcers<br />

who do not exhibit sincerity or<br />

even the mildest empathy in their<br />

announcements.<br />

The responses to Boris Johnson’s<br />

‘Get ahead of the Games’ recordings,<br />

aired during the Olympics, ranged from<br />

amusement to mild hatred.<br />

The consultancy polled nearly 300<br />

people on the best and worst ways<br />

to communicate with a transport<br />

audience. Creative director Nick Parker<br />

says the survey w<strong>as</strong> carried out to prove<br />

a link between reputation, profits and<br />

communication.<br />

‘We did the survey to prove our<br />

hunch that it’s not just irritating to<br />

customers – it’s costing train companies<br />

money,’ says Parker. ‘Which train<br />

company is finally going to change the<br />

language of its announcements to make<br />

its p<strong>as</strong>sengers happier?’<br />

But respondents also picked out<br />

people who brightened up their<br />

days with funny and informative<br />

announcements. Recently, a whiteboard<br />

sign at Farringdon station, London,<br />

advised p<strong>as</strong>sengers to watch out for<br />

mice attacks.<br />

A spokeswoman for Transport for<br />

London said that the notice, which<br />

advised travellers to tuck their socks<br />

into their trousers to avoid being bitten,<br />

w<strong>as</strong> not an ‘official TfL message’ and<br />

station staff had not been responsible<br />

for the board, which w<strong>as</strong> wiped clean <strong>as</strong><br />

soon <strong>as</strong> it came to attention.<br />

Other announcements that have<br />

brightened up people’s commute,<br />

according to the Evening Standard,<br />

include a spoof sign at South<br />

Kensington tube station, with<br />

the sarc<strong>as</strong>tic message: ‘Aren’t you<br />

wonderful, taking little Hugo to the<br />

museums? WALK ON THE LEFT.’<br />

Finally, one sign on a Gatwick Express<br />

train read: ‘For a more efficient service,<br />

ple<strong>as</strong>e alight at the next stop where a<br />

team of heavily drugged sloths will drag<br />

you to your destination.’<br />

OCTOBER 2012 Page 5

News<br />

Four apprentices with Keith Jipps, customer<br />

service director, Norman Baker MP and<br />

managing director Neal Lawson<br />

FCC launches new apprentice scheme<br />

by Peter Brown<br />

First capital connect chose speakers<br />

<strong>as</strong> diverse <strong>as</strong> transport minister<br />

Norman Baker Mp and former champion<br />

boxer Billy Schwer to talk to an invited<br />

audience at the launch of its first customer<br />

service apprenticeship scheme.<br />

Five apprentices had won their places<br />

on the scheme that had 266 applicants<br />

and w<strong>as</strong> launched in meeting rooms at<br />

Moorgate, city of London, in August.<br />

The 12-month course will lead to an<br />

NVQ Level Two in customer service and<br />

business administration.<br />

Fcc managing director Neal Lawson<br />

explained his company had engaged with<br />

schools, colleges and job centres in are<strong>as</strong><br />

on its network.<br />

He told the audience: ‘we pride<br />

ourselves in working with communities<br />

across our network. This is a new scheme<br />

in the training of customer services. It<br />

also includes participating in the Duke of<br />

Edinburgh Awards Scheme throughout<br />

the 12 months.<br />

‘There will be monitoring of the<br />

apprentices every three months. I believe<br />

in this scheme and that it will develop the<br />

hopes of these people.’<br />

Transport minister Norman Baker<br />

Mp applauded the introduction of the<br />

apprenticeship scheme, saying that it<br />

w<strong>as</strong> vitally needed in the modern railway<br />

industry.<br />

He said: ‘customer service is the key to<br />

growth of the railways. It is not just about<br />

putting money into tracks but a scheme<br />

which encourages people onto trains. And<br />

we want people on our trains! There are<br />

more people using the trains now than at<br />

any time since 1929.<br />

‘<strong>Rail</strong> traffic continues to grow year on<br />

year. people are choosing the train <strong>as</strong> a<br />

preference and not <strong>as</strong> a l<strong>as</strong>t resort. This is<br />

a growth industry and these apprentices<br />

are coming in at the right time. I think it’s<br />

going to be a great experience. Some 266<br />

people applied, so I hope that Fcc will<br />

expand the scheme.’<br />

Now an international speaker and<br />

performance coach, Billy Schwer w<strong>as</strong><br />

former National Schoolboy boxing<br />

champion in 1982 and 1983 before<br />

turning professional in 1990. Between<br />

then and 2001 he became IBO Light<br />

welterweight champion; European Light<br />

Heavyweight champion, commonwealth<br />

Light Heavyweight champion and British<br />

Lightweight champion.<br />

The title of his talk, aimed principally<br />

at the apprentices, w<strong>as</strong> Box clever. He<br />

spoke of his many disappointments at<br />

losing vital fights but told of his strengths<br />

to get to the top of his profession. He<br />

illustrated this in seven parts. The first w<strong>as</strong><br />

‘win or lose, you choose’ which dealt with<br />

choosing a new way of life, number two<br />

w<strong>as</strong> ‘knock out fear, then ‘Fight for what<br />

you want’.<br />

Number four w<strong>as</strong> ‘You are only <strong>as</strong><br />

good <strong>as</strong> your next fight’, five w<strong>as</strong> all about<br />

looking for a new approach and titled ‘Jab<br />

and move’, six w<strong>as</strong> ‘Take it on the chin’ and<br />

seven w<strong>as</strong> ‘Box clever’.<br />

Another former boxer – Mickey<br />

cantwell – w<strong>as</strong> at the presentation,<br />

sitting with the apprentices. The winning<br />

candidates are craig Evans-Bird, from<br />

Enfield, north London; Stacey Hawes,<br />

from Stevenage, Hertfordshire; Daniel<br />

Salemo, from Letchworth, Hertfordshire;<br />

Terrell kilpatrick, from Huntingdon,<br />

cambridgeshire; and Shaun Lennon from<br />

Bedford.<br />

Second ph<strong>as</strong>e of Samaritans rail suicides campaign begins<br />

The second ph<strong>as</strong>e of a campaign to reduce suicides on the<br />

GB rail network by 20 per cent over five years h<strong>as</strong> just been<br />

launched by a Samaritans/Network <strong>Rail</strong> partnership.<br />

key to the partnership strategy is a nationwide public<br />

awareness campaign: we’re In Your corner is designed to help<br />

people working in suicide prevention to understand more about<br />

working cl<strong>as</strong>s men in their 30s, 40s and 50s deemed at greatest<br />

risk, and to reach out to them.<br />

when the first ph<strong>as</strong>e of the we’re in Your corner national<br />

advertising campaign launched two years ago, the boxer image<br />

w<strong>as</strong> displayed at railway locations countrywide to incre<strong>as</strong>e<br />

public awareness of Samaritans’ support services for people<br />

struggling to cope.<br />

The challenge with this year’s campaign w<strong>as</strong> to find an image<br />

or images similarly recognisable to – and respected among – the<br />

target male audience. For the campaign to work, it w<strong>as</strong> vital for<br />

this target group to identify with the images.<br />

Feedback from the railway industry influenced a decision to<br />

produce three male images of differing ages, to reach a variety of<br />

male audiences.<br />

In-depth research by the Samaritans also sought to<br />

understand the target group of men and discern the challenges<br />

in developing a campaign to reach them.<br />

It identified that most men think talking about their<br />

problems feels like admitting defeat – that they can’t solve them<br />

on their own – and that <strong>as</strong> men get older, they can get ground<br />

down and their ‘fire’ goes out, replacing their internal rage with<br />

a depressive belief that life won’t improve.<br />

Typical comments from the research included: ‘Talking’s good<br />

if you know how to do it and if you don’t know how to do it, it’s<br />

hard’, and: ‘we’ve never<br />

been a talking family…<br />

talking’s not a big thing.<br />

I don’t think we’ve ever<br />

done it… there’s a block<br />

there somewhere… you<br />

just hold it in the back<br />

of your mind somewhere<br />

and it sort of goes way.<br />

I didn’t talk about the<br />

divorce – it’s always seen<br />

<strong>as</strong> a sign of weakness isn’t<br />

it?’<br />

To help shape the<br />

campaign, a series of<br />

one-to-one in-depth<br />

interviews, conducted<br />

with men from the target<br />

A registered charity * Ple<strong>as</strong>e see our website for latest call charges<br />

In partnership with<br />

audience to test a series<br />

of new close-up images,<br />

strongly identified that being able to see into the eyes of the<br />

images w<strong>as</strong> a way of connecting with them.<br />

The findings highlighted the need to portray the ‘ordinary<br />

man’ who seemed to be tough but ‘holding it together’ and<br />

getting on with life – most importantly they must not appear<br />

beaten, or <strong>as</strong> an object of pity.<br />

Three different images that tested positively – a boxing<br />

trainer, a soldier and a workman – will be appearing on<br />

campaign posters at Network <strong>Rail</strong> locations and across the<br />

country.<br />

Whatever you’ve done.<br />

Whatever life’s done to you.<br />

Call Samaritans.<br />

No pressure.<br />

No judgement.<br />

We’re here for you.<br />

<br />

PagE 6 OCTOBER 2012

Influencing your energy strategies<br />

with integrated solutions<br />

UK Power Networks Services is a leading provider of electrical infr<strong>as</strong>tructure with significant<br />

experience of working on high profile transport projects such <strong>as</strong> High Speed 1, High Speed 2<br />

and Crossrail.<br />

UK Power Networks Services:<br />

• Consistently delivers results on the most challenging projects<br />

• Can undertake the total requirements of any strategic infr<strong>as</strong>tructure project<br />

• H<strong>as</strong> access to a wealth of international experience in providing finance solutions<br />

Contact us by visiting: www.ukpowernetworksservices.co.uk<br />

Consulting | Technologies | Engineering | Construction | Operation & Maintenance | Finance<br />

OCTOBER 2012 Page 7

14086 1/4 Page Training Ad_AW_Layout 1 28/08/2012 14:17 Page 1<br />

Hydraulic Hose<br />

Safety & Skills Courses<br />

Building<br />

Flexible Solutions<br />

Healthcare Connections can tailor a combination<br />

of medicals to meet your specific industry<br />

requirement<br />

BOOK YOUR<br />

PLACE NOW BY<br />

CALLING 01608 647900<br />

OR EMAIL<br />

enquiries@bfpa.co.uk<br />

Creating bespoke medical <strong>as</strong>sessments can remove<br />

the need for separate medicals, reduce downtime<br />

and save you money<br />

Are your staff safe around hydraulics?<br />

Benefits<br />

Understand the risks<br />

Clarification of safe<br />

working practices<br />

Courses written by<br />

industry experts<br />

1 or 2 day options<br />

Course content<br />

Video presentations<br />

64 page personalised<br />

work book<br />

Delivered by experienced<br />

industry experts<br />

Locations nationwide<br />

<strong>Rail</strong>ways<br />

Construction<br />

• Medical Screening<br />

• Drug & Alcohol Testing<br />

• Health Surveillance<br />

• Medication Checking<br />

• Absence Management<br />

• Employee Medication<br />

www.hydraulichosesafety.co.uk/training<br />

or ple<strong>as</strong>e call 01608 647900<br />

Contact us to discuss the right solution for you<br />

B R I T I S H F L U I D P O W E R A S S O C I A T I O N<br />

www.healthcare-connections.com<br />

t: 08456 773002 e: sales@healthcare-connections.com<br />

i<br />

<br />

ONE DESTINATION...<br />

Stormcheck Polystorm Ridgiduct Lighting Ridgidrain Rainstream-XL Silt Trap Ridgisewer Ridgidrain<br />

Catchpits<br />

Ridgiduct Power<br />

...ONE SOURCE<br />

Cable Protection: Flexible ducting systems that<br />

protect cables and helps to minimise vandalism<br />

and theft.<br />

: Robust, durable, light in<br />

weight and supplied in long lengths, enabling quick<br />

installation and therefore minimising track closures.<br />

: Modular systems<br />

designed to fit any underground space to manage<br />

water within the development.<br />

: Modular construction allowing<br />

tanks to be sized for any application capturing rainwater<br />

for w<strong>as</strong>hrooms, irrigation and rolling stock w<strong>as</strong>h.<br />

01509 217671 to order your Product Selector or visit<br />

<br />

PCL-12-144 RP 130 x 183 <strong>Rail</strong> Ad.indd 1 17/09/2012 15:12<br />

Page 8 OCTOBER 2012

Letters<br />

Readers air their views about the railway industry and <strong>Rail</strong> <strong>Professional</strong><br />

Trainofthought<br />

Ple<strong>as</strong>e email your letters to: letters@railpro.co.uk or fax to: 01223 327356. Or post to The Editor,<br />

<strong>Rail</strong> <strong>Professional</strong>, 275 Newmarket Road, Cambridge CB5 8JE. Letters may be edited for length.<br />

David Fowler / Shutterstock.com<br />

Labour to re-nationalise?<br />

Heard it all before!<br />

Further to your editorial<br />

(August 2012 issue),<br />

I well remember the<br />

Labour manifesto when<br />

Tony Blair promised that if<br />

Labour got into power, they<br />

would reverse the Tories’<br />

privatisation of the railways<br />

– but of course they didn’t,<br />

they just made it worse, so I<br />

will have no confidence that<br />

they would do so this time<br />

round!<br />

I am sure that they are just<br />

picking on this <strong>as</strong> something<br />

to put forward to win some<br />

votes <strong>as</strong> the present system<br />

is patently not working to<br />

the customer’s advantage, on<br />

p<strong>as</strong>senger or freight.<br />

Ron Smith,<br />

Keith, Scotland<br />

McNulty ignored some of the<br />

main costs<br />

Your editorial<br />

about McNulty not<br />

having a similar<br />

European system to compare<br />

with is very true (August<br />

2012 issue). His report is all<br />

about the reduction of costs,<br />

but he makes no mention of<br />

reducing/doing away with<br />

all the lawyers/accountants/<br />

consultants that our system<br />

is dogged with – only because<br />

of the way it h<strong>as</strong> been set up.<br />

What would the effect<br />

be if Tocs and Network <strong>Rail</strong><br />

took all these ‘in-house’?<br />

They would become salaried<br />

staff and, while it would<br />

probably incre<strong>as</strong>e their<br />

numbers, it would v<strong>as</strong>tly<br />

reduce all the fees that they<br />

extract now.<br />

When I worked for<br />

BR, we had our own legal<br />

department/accountants<br />

and the operational research<br />

acted <strong>as</strong> the consulting arm.<br />

BR also set up Transmark,<br />

which did consulting<br />

both nationally and<br />

internationally.<br />

The other comments<br />

concern the ORR idea to raise<br />

freight prices in certain are<strong>as</strong>.<br />

As the FTA says – it’s totally<br />

unacceptable when freight<br />

traffic is steadily incre<strong>as</strong>ing.<br />

Regarding Anand Medepalli’s<br />

article (August 2012 issue),<br />

while the actions he proposes<br />

are perfectly valid, I think<br />

that if every company went<br />

to Network <strong>Rail</strong> and <strong>as</strong>ked<br />

for paths ‘that they think<br />

they will need’ they would be<br />

<strong>as</strong>ked to produce the contract<br />

before the pathway w<strong>as</strong><br />

granted.<br />

Anand’s proposition is all<br />

very well in a perfect world,<br />

but I see obstacles in the<br />

system we have today.<br />

John Edser FCILT<br />

Alsager<br />

Cheshire<br />

Government policy is what<br />

drives fares<br />

Your l<strong>as</strong>t editorial w<strong>as</strong><br />

categorically wrong<br />

to claim that ‘Britain<br />

now h<strong>as</strong> the most expensive<br />

rail fares in Europe... because<br />

private companies hive off<br />

the profits for shareholders’<br />

(August 2012 issue).<br />

The two key drivers of<br />

fare levels are the cost of<br />

running the railway and the<br />

government’s fares policy, not<br />

train company profits.<br />

Sir Roy McNulty’s Value<br />

for Money study said that GB<br />

rail w<strong>as</strong> more expensive to<br />

run than European railways<br />

and challenged the sector to<br />

be up to 30 per cent more<br />

efficient by 2019.<br />

While it is important to<br />

recognise that unit costs have<br />

steadily declined since their<br />

peak a decade ago, and that<br />

McNulty showed that GB<br />

train companies’ unit costs<br />

compare favourably with<br />

their European counterparts,<br />

we are committed to<br />

working with Network <strong>Rail</strong><br />

in continuing to improve<br />

efficiency delivering savings<br />

of at le<strong>as</strong>t £2.5bn by 2019.<br />

Efficiency gains on this<br />

scale allow the government<br />

to achieve its ambition of<br />

ending the era of aboveinflation<br />

fare incre<strong>as</strong>es, a<br />

decision only it can take.<br />

Train companies operate<br />

within a fares policy whereby<br />

successive governments<br />

have sought to reduce the<br />

contribution from taxpayers<br />

towards rail costs and<br />

incre<strong>as</strong>e the share paid for<br />

by p<strong>as</strong>sengers, with the<br />

aim of shifting the ratio of<br />

government subsidy to fares<br />

revenue from around 50:50<br />

to 25:75.<br />

The annual, above<br />

inflation average incre<strong>as</strong>e<br />

for regulated fares is the<br />

most explicit example of this<br />

policy but it is also a key part<br />

of the framework within<br />

which all fares are set.<br />

Train companies make<br />

profits of around three per<br />

cent of turnover on average,<br />

which is low by any standards<br />

and far outweighed by the<br />

benefits p<strong>as</strong>sengers and<br />

taxpayers gain from the<br />

private sector running rail<br />

services, including growing<br />

revenue that helps to pay for<br />

an incre<strong>as</strong>ingly large share<br />

of a public service when the<br />

government is seeking to cut<br />

its spending.<br />

Train companies recognise<br />

there is still much to do, in<br />

particular delivering more for<br />

p<strong>as</strong>sengers more efficiently.<br />

However, inaccurately<br />

claiming that fares are<br />

uniquely high because of<br />

industry profits prevents a<br />

mature debate which helps<br />

neither p<strong>as</strong>sengers, taxpayers<br />

nor the country.<br />

Michael Roberts<br />

Chief executive<br />

Association of Train Operating<br />

Companies<br />

OCTOBER 2012 Page 9

<strong>Rail</strong> <strong>Professional</strong> interview: Howard Smith

When I signed up at<br />

Waterloo general offices in<br />

1986, I thought I’d see life, but<br />

not quite <strong>as</strong> I have!<br />

London <strong>Rail</strong> CEO Howard Smith breathes a sigh of<br />

relief <strong>as</strong> London Overground and DLR get through<br />

the Olympics without incident. He tells Katie Silvester<br />

about the planning behind the Games<br />

Faced with a choice between teaching<br />

geography and economics or joining the<br />

railway after university, a young Howard<br />

Smith chose the latter. ‘After a year’s<br />

training, you were then left in charge of about<br />

100 people,’ he says. ‘In the south of England, you<br />

generally became a station manager, being left in<br />

charge of eight stations. That w<strong>as</strong> back in the days<br />

when you went out on the track, wound points and<br />

dealt with people who had put an end to themselves.<br />

It w<strong>as</strong> quite a lot of responsibility. It w<strong>as</strong> a bit<br />

amateurish and almost scary in retrospect!’<br />

These days, Smith’s portfolio includes London<br />

Overground, DLR and Croydon’s trams. He h<strong>as</strong> an<br />

office in London Underground’s iconic headquarters<br />

at 55 Broadway, London over St James’ Park<br />

Tube station. His father, a schedule compiler for<br />

London Buses, had an office in the same building<br />

– constructed in the 1920s to house the London<br />

Electric <strong>Rail</strong>ways Company of London – just after<br />

the war.<br />

I met Smith junior there between the Olympics<br />

and the Paralympics. The Olympics went better than<br />

expected he says, sounding genuinely chuffed.<br />

‘We all hoped that it would go well, but I think<br />

we expected to have to spend more time than we did<br />

having to intervene, rectifying in order for things<br />

to run smoothly, and mitigating issues that arose. It<br />

h<strong>as</strong>n’t been a completely smooth ride, but perhaps<br />

the surprise h<strong>as</strong> been that we’ve achieved what we<br />

have largely by avoiding incidents happening in the<br />

first place.’<br />

DLR moved twice <strong>as</strong> many people in the<br />

Olympics <strong>as</strong> it did in the same period l<strong>as</strong>t year<br />

– around 500,000 each business day. London<br />

Overground carried about half <strong>as</strong> many people again<br />

<strong>as</strong> it does normally. In spite of the dr<strong>as</strong>tic incre<strong>as</strong>e<br />

in numbers, DLR incre<strong>as</strong>ed its punctuality from<br />

the usual 98 per cent to 99 per cent PPM and the<br />

Overground went from around 96 to 98 per cent.<br />

‘Looking at what went so well, p<strong>as</strong>senger delays<br />

went down. That’s not <strong>as</strong> daft <strong>as</strong> it sounds, because<br />

there w<strong>as</strong> a lot of crowd control and there were extra<br />

trains. We saw much smoother flows than we do<br />

normally because people had really thought about<br />

how they would do their journey. We did stick to<br />

the timetable – the train plan matched very closely<br />

what we were able to do. There w<strong>as</strong> good execution<br />

and then the remaining factor w<strong>as</strong> luck. If it had<br />

been exceptionally hot or exceptionally rainy, that<br />

wouldn’t have helped, or if a bus had driven into a<br />

sub-station, or something. It w<strong>as</strong> a bit like people of<br />

my parents’ generation saying about how everyone<br />

pulled together in the war. The bigger the problem,<br />

the more people stop focusing on every day niggles<br />

and just get on with it.’<br />

Another factor w<strong>as</strong> that all works were halted<br />

during the Olympics, a state of play, which, Smith<br />

admits, could hardly be maintained in the long term.<br />

He likes the mantra ‘great railways do everything<br />

right’, which w<strong>as</strong> coined by a benchmarking group at<br />

Imperial College.<br />

‘I’m not making us out to be a great railway, but<br />

great railways do do everything right. The weakest<br />

OCTOBER 2012 Page 11

Integrated P<strong>as</strong>senger Information<br />

and Infotainment Solutions<br />

IMAGINE<br />

a PIS/CIS system<br />

built for the future<br />

and built to l<strong>as</strong>t<br />

Do you want a system that builds on<br />

proven standard blocks?<br />

Which builds exactly to your needs?<br />

With balanced advanced features,<br />

optimum life time, cost advantages<br />

and e<strong>as</strong>y upgradeability?<br />

If you can answer YES<br />

to our questions...<br />

You need to look into FOCON’s latest PIS / CIS<br />

platform. A platform we built on “customer’s<br />

voice” and smart thinking. With the help from<br />

key industry people, p<strong>as</strong>sengers, train builders,<br />

operators and consultancy companies we have<br />

acquired an in-depth insight into current and<br />

future needs within rolling stock and built our<br />

newest PIS / CIS generation around it. With our<br />

smart thinking we built it in a standardised way<br />

<strong>as</strong> proven building blocks that may be built into<br />

exactly your requirements.<br />

Not only is it proven, it’s also e<strong>as</strong>ily upgradeable<br />

over time. You may start with a b<strong>as</strong>ic PIS<br />

system and in an e<strong>as</strong>y approach later upgrade<br />

with our<br />

advanced, yet cost-effective infotainment<br />

system, route-follow system or other special<br />

features from our standard option packages.<br />

Our IMAGINE platform is not just a standalone<br />

PIS solution where you may add multiple<br />

options of your choice, it is effectively supported<br />

by a strong, customizable, aftersales concept<br />

InMotion ensuring optimum up-time and life time<br />

cost, by maximizing availability of spares and<br />

service with proven products of high reliability.<br />

FOCON stands today <strong>as</strong> a market leading<br />

solution provider whose core capabilities are<br />

integrated solutions consisting of total project<br />

management, software programming and<br />

software-friendly hardware. Our new platforms<br />

are IP-b<strong>as</strong>ed and include options such <strong>as</strong><br />

infotainment, CCTV, and disruption messaging.<br />

As a member of Luminator Technology<br />

Group, and IRIS and ISO certified we offer<br />

proven<br />

processes and global presence for the rolling<br />

stock market. We cover solutions from LRV<br />

(Light <strong>Rail</strong> Vehicles) over Commuter and<br />

Regional trains, Metros and Undergrounds to<br />

High-speed trains. We offer an excellent<br />

choice for those seeking solutions for the<br />

future, solutions that may be scaled up going<br />

forward and which may be run with a highly<br />

competitive level of life time cost. Our choice<br />

is well-liked by our extensive reference list of<br />

both leading train operators and train builders.<br />

Let us challenge you with our smart solution –<br />

you can’t IMAGINE all the possibilities that<br />

open to you.<br />

www.focon.com<br />

FOCON Electronic Systems ApS Damvang 2, DK-6400 Sønderborg, Denmark<br />

Page 12 OCTOBER 2012<br />

PAGE 12 OCTOBER 2012

Interview<br />

www.railimages.co.uk<br />

link will always drag you down – so if you get eight<br />

out of 10 things right, the other two will still drag<br />

you down.’<br />

Planning transport for the Games took seven<br />

years, says Smith. London <strong>Rail</strong> undertook a £3bn<br />

investment programme in preparation. The c<strong>as</strong>e<br />

for the E<strong>as</strong>t London Line project w<strong>as</strong> helped by the<br />

Olympics, while other work would not have gone<br />

ahead were it not for the Games, such <strong>as</strong> the building<br />

of Stratford International station and the North<br />

London Line upgrade. A third of the North London<br />

Line project w<strong>as</strong> paid for by the Olympic Delivery<br />

Authority (ODA).<br />

‘I w<strong>as</strong> out in Beijing four years ago and at that<br />

point we already knew what questions we wanted<br />

to <strong>as</strong>k,’ says Smith. ‘I w<strong>as</strong> speaking to colleagues<br />

at Locog [London Organising Committee of the<br />

Olympic and Paralympic Games] and the ODA and<br />

they were saying that what we can do for Rio is p<strong>as</strong>s<br />

on more information than h<strong>as</strong> ever been done before<br />

about how the Games were organised.<br />

‘Sydney, to some extent, w<strong>as</strong> the l<strong>as</strong>t Anglo Saxon<br />

Games and that w<strong>as</strong> completely different to Beijing.<br />

In Beijing they decided three weeks before that<br />

they were going to inspect everybody’s bags going<br />

into the underground stations and they did it! They<br />

were probably able to fit x-ray machines together in<br />

a factory around the corner in a few days, they had<br />

500,000 People’s Liberation Army personnel to do<br />

the inspections and people queued up outside the<br />

station and volunteered their bags. We just looked<br />

at each other and thought, well that’s not going to<br />

happen here! Sydney did a lot of advanced planning<br />

and we did learn something from that.’<br />

The 7/7 Tube bombings happened just a day<br />

after the announcement that London had won the<br />

Olympics in July 2005. Did that make a difference to<br />

how the planning for the Games w<strong>as</strong> approached?<br />

‘We had some American consultants over who’d<br />

just arrived before 7/7 and they were surprised how<br />

little difference it made,’ says Smith. ‘To some extent,<br />

Londoners have always lived with security issues<br />

because we had the IRA. It’s not like 9/11 where<br />

America had this total impregnability followed by<br />

thinking “Oh my goodness, this can happen in the<br />

middle of town”.’<br />

Growth on London Overground h<strong>as</strong> been<br />

phenomenal, he says, since the brand w<strong>as</strong> launched<br />

five years ago. Before that, the lines were mostly<br />

run by separate operators and often were not that<br />

well used. Now ridership h<strong>as</strong> incre<strong>as</strong>ed by several<br />

times over. ‘The growth h<strong>as</strong> been phenomenal – the<br />

incre<strong>as</strong>e in customer satisfaction h<strong>as</strong> been dramatic.<br />

The problem now is that expectations are so high!’<br />

PPM is running at around 96, making London<br />

Overground one of the most punctual services<br />

in the country. ‘Now we’re looking at dealing<br />

with incre<strong>as</strong>ing capacity because of the growth in<br />

ridership. The trains that run through from Clapham<br />

up to Highbury are starting to run more frequently<br />

– the mayor wants it to move to five car. On the E<strong>as</strong>t<br />

London Line, we’ve also been incre<strong>as</strong>ing seats. And<br />

the people keep coming, which is a nice problem to<br />

have.<br />

‘Londoners are just so much more aware of<br />

London Overgound now. The Games helped with<br />

this, <strong>as</strong> people were looking for alternative routes<br />

and you could see p<strong>as</strong>sengers on platforms looking<br />

at the maps and trying to work out where it could<br />

take them. I wouldn’t be surprised if we got a two<br />

to three per cent permanent incre<strong>as</strong>e from people<br />

who’ve now discovered it and didn’t know about<br />

it before. The North London Line used to be the<br />

best kept secret – part of the incre<strong>as</strong>e h<strong>as</strong> come<br />

from putting it on TfL maps. The Olympics made<br />

people realise there were these beautiful new air<br />

conditioned trains they hadn’t discovered before!’<br />

Smith is also responsible for the cable car that<br />

crosses the Thames carrying people from the<br />

Greenwich Peninsula to the Royal Docks. Opened in<br />

June of this year, it’s known <strong>as</strong> the Emirates Air Line,<br />

<strong>as</strong> it w<strong>as</strong> sponsored by Emirates airline. It w<strong>as</strong> well<br />

used during the Games and became popular with<br />

celebrity visitors.<br />

‘Everybody thought it w<strong>as</strong> fraught with risks<br />

in terms of the Olympics, but it’s been stunningly<br />

successful. On Saturday, we moved 31,000<br />

people – the highest ever in a single day. Arnold<br />

Schwartzenegger and Boris Johnson needed<br />

escorting from the b<strong>as</strong>ketball at North Greenwich<br />

across to the Closing Ceremony. Huge screaming<br />

crowds gathered to watch them cross and ITN had a<br />

camera crew. When I signed up at Waterloo general<br />

offices for, sort of, £8 a week or something in 1986,<br />

I thought I’d see life, but not quite <strong>as</strong> I have!’ he<br />

laughs.<br />

With the Paralympics still to come at the time of<br />

our interview, the DLR’s big moment w<strong>as</strong> perhaps<br />

still to come. It had a key role in the Paralympics<br />

because the service is fully accessible. In terms of<br />

Curriculum vitae<br />

1964 Born in Hampton Court, west London<br />

1986 BSc from the London School of Economics<br />

1986 British <strong>Rail</strong> graduate trainee<br />

1987 Manager of Balham station in London<br />

1992 Strategic Studies manager for <strong>Rail</strong>freight<br />

Distribution, British <strong>Rail</strong><br />

1997 Managing director of Allied Continental<br />

Intermodal Services, an EWS/SNCF/<br />

Intercontainer joint venture<br />

1998 Planning and development director,<br />

Docklands Light <strong>Rail</strong>way<br />

2000 Director of Docklands Light <strong>Rail</strong>way<br />

2004 Chief operating officer, TfL London <strong>Rail</strong><br />

OCTOBER 2012 Page 13

Interview<br />

www.railimages.co.uk<br />

planning, the Olympic schedules were planned<br />

meticulously.<br />

‘We actually ran the Olympic timetable for days<br />

on end before the Games, so we knew everything<br />

worked and we knew that with record numbers of<br />

trains out on the system, we weren’t going to come<br />

up against software or power problems. In theory,<br />

you can do all this from a text book but it helps to<br />

try it in practice.’<br />

Like London Overground, the DLR h<strong>as</strong> seen<br />

huge growth in p<strong>as</strong>senger numbers. It is predicted<br />

to carry about 100 million p<strong>as</strong>sengers this year, up<br />

from around 30 million a year when Smith first took<br />

responsibility for it in 1998.<br />

When Crossrail is finished in 2017/18, he will<br />

take charge of finding an operator for it – it will<br />

be run <strong>as</strong> a concession under a similar arrangement<br />

to London Overground. For now, he oversees the<br />

funding of it. His final area of responsibility is<br />

Croydon Tramlink.<br />

‘L<strong>as</strong>t year we moved into the sunny uplands of<br />

expanding,’ he says of Tramlink. ‘We now move<br />

nearly 30 million p<strong>as</strong>sengers. Compared to any Toc,<br />

it’s phenomenal how intensively the kit on every<br />

tram is used. Two have to be out of service every day.’<br />

New trams have just been provided by Stadler, which<br />

were originally built for use in Bergen but were<br />

quickly rebranded for Croydon when the trams were<br />

required at short notice. Tramlink had been hoping<br />

to get unused trams from the stalled Edinburgh<br />

Tram project, but the trams didn’t materialise.<br />

‘Croydon Council chipped in £3m for the new<br />

trams, which for a c<strong>as</strong>h strapped local authority is a<br />

bit of a commitment, but they see the trams <strong>as</strong> being<br />

an iconic part of Croydon.’<br />

When Croydon’s centre w<strong>as</strong> set on fire during l<strong>as</strong>t<br />

year’s riots, causing damage to tram infr<strong>as</strong>tructure,<br />

everyone rallied around to get the repairs done <strong>as</strong><br />

quickly <strong>as</strong> possible – it w<strong>as</strong> back to normal in three<br />

days.<br />

‘When the Reeves store burnt down there were<br />

staff that night giving people lifts home in their new<br />

cars,’ says Smith of the community spirit that the<br />

trams inspire.<br />

Looking to the future, TfL h<strong>as</strong> been working<br />

with London mayor Boris Johnson to bring more of<br />

London’s railways under TfL’s control. If approved,<br />

the plans would see the London-b<strong>as</strong>ed sections of<br />

franchises hived off, with local services and stations<br />

run <strong>as</strong> a concession on TfL’s behalf.<br />

‘We believe Overground h<strong>as</strong> been a success. In<br />

London – this is not a prescription for the rest of the<br />

country – but in the capital, journeys are integrated.<br />

TfL sets the fares and the market’s definitely a<br />

commuting market that is largely driven by central<br />

London employment. There’s a huge c<strong>as</strong>e for<br />

integration with other types of transport, so in those<br />

circumstances the party best placed to specify the<br />

railway – not to run it – is TfL.<br />

‘You have to decide what’s in London and what<br />

we can add most to. With some services they divide<br />

into inner and outer commuters, some don’t. For<br />

example, C2C is working well – it meets its targets,<br />

why would you change that, other than a power<br />

grab? Chiltern h<strong>as</strong> a long franchise, so it’s not going<br />

to be available. Tocs you could look at, then, are<br />

West Anglia and Southe<strong>as</strong>tern’s inners. The mayor’s<br />

been saying we should transfer those to the model<br />

used for Overground. So separate them out from<br />

the wider Tocs, transfer the subsidy that those parts<br />

of the network get to TfL and allow TfL to specify<br />

them with performance at their heart rather then<br />

running them for spin-the-bottle revenue risk.’<br />

What would happen if the plans went head is<br />

that in the c<strong>as</strong>e of the West Anglia franchise, for<br />

example, longer distance trains running through to<br />

Liverpool Street would still be run by the franchisee,<br />

with the final through stations now managed by TfL.<br />

Suburban services from the outskirts of London into<br />

the centre would no longer be part of the franchise,<br />

but would be let <strong>as</strong> part of the new concession.<br />

‘It would involve about 80 stations,’ he explains.<br />

‘Network <strong>Rail</strong> would continue to run the tracks,<br />

ORR would specify it, exactly the same <strong>as</strong> the<br />

North London Line’. The plans are currently being<br />

considered by the government, with a response<br />

expected in the autumn. Some transport groups are<br />

less keen on bidding for TfL concessions than they<br />

are on tendering for DfT specified franchises. The<br />

difference between the two is that the franchises are<br />

far more risk b<strong>as</strong>ed, with the opportunity for greater<br />

rewards for the franchisee, but also the possibility<br />

of dis<strong>as</strong>ter if the bid h<strong>as</strong> over-estimated future<br />

demand. In TfL-specified concessions, the operator is<br />

simply paid to run the trains on time. Both are quite<br />

complicated arrangements in practice, of course, but<br />

that is the difference in a nutshell. Tramlink, DLR<br />

and London Overground are all run <strong>as</strong> concessions.<br />

‘We’ve got no philosophical view about the rest<br />

of the country,’ Smith clarifies. ‘It’s not having a<br />

pop at train operators. What we’re saying is that<br />

they respond to the incentives they have under the<br />

contract, and what they have under the contract<br />

for suburban services leads them to do what they<br />

do – provide a pretty b<strong>as</strong>ic service and invest <strong>as</strong><br />

much <strong>as</strong> they can within a seven-year horizon, bid<br />

the maximum amount of revenue they can, then<br />

frantically look at the FT to see if it’s doing <strong>as</strong> well <strong>as</strong><br />

it should.’<br />

If you are the managing director of a DfT Toc,<br />

Smith quips, you get up and read the Financial Times<br />

to see where central London employment’s going.<br />

If you’re the MD of one of Transport for London’s<br />

concessions, you wake up in the morning and look at<br />

your pager to see if your trains are running on time.<br />

With that, I am ushered out of Howard Smith’s<br />

office by a TfL press officer, <strong>as</strong> Smith hurries off to<br />

another meeting. But I do manage to have a quick<br />

look at the roof terrace on this unique building – the<br />

hub of operations for London’s public transport for<br />

almost 100 years.<br />

Page 14 OCTOBER 2012

PM 1000 URM<br />

RU 800 S<br />

SUZ 500<br />

APT 1500 R<br />

09-4X<br />

BDS 2000<br />

High Speed Solutions for High Speed <strong>Rail</strong><br />

PM 1000 URM Complete formation rehabilitation.<br />

RU 800 S Combined ball<strong>as</strong>t cleaning and track renewal.<br />

SUZ 500 Track laying and relaying.<br />

APT 1500 R <br />

09-4X Express tamping and stabilisation.<br />

BDS 2000 Complete ball<strong>as</strong>t management.<br />

<br />

Swietelsky Bauges.m.b.H.<br />

Klein Neusiedlerstraße 27<br />

2401 Fischamend, Austria.<br />

+43 (2230) 80270<br />

Swietelsky International UK & Ireland<br />

7 Clairmont Gardens<br />

Gl<strong>as</strong>gow, G3 7LW.<br />

+44 (0) 141 353 1915<br />

www.swietelsky.com<br />

Swietelsky Construction Company Ltd<br />

Holybrook House, 63 C<strong>as</strong>tle Street, Reading, Berkshire, RG1 7SN, United Kingdom.<br />

+44 (0) 118 950 3380

Opinion<br />

In the p<strong>as</strong>senger seat<br />

SMART(ER)<br />

TICKETS?<br />

Is the move towards smartcard ticketing being driven by the industry or by p<strong>as</strong>sengers’ needs?<br />

Anthony Smith looks at what p<strong>as</strong>sengers want from more sophisticated tickets<br />

I<br />

recently made the journey from Tooting to North Berwick<br />

and back in a day. W<strong>as</strong> my recent journey cruelly hampered<br />

by the lack of one smart ticket to take me on the train,<br />

train, plane, coach and train journey and back? No, it w<strong>as</strong> all<br />

facilitated by one very smart card – my credit card - with four<br />

bits of paper produced <strong>as</strong> evidence of what I had paid for.<br />

No problems with information either – it w<strong>as</strong> very e<strong>as</strong>y to<br />

find out about all the steps.<br />

So what is it that p<strong>as</strong>sengers really<br />

want with smarter ticketing? Is there a<br />

danger of products looking for markets<br />

setting the debate rather than really<br />

b<strong>as</strong>ing the future around p<strong>as</strong>senger<br />

needs?<br />

The Department for Transport h<strong>as</strong><br />

<strong>as</strong>ked us to do a large-scale piece of<br />

research about p<strong>as</strong>sengers and smarter<br />

ticketing. The first part of this will<br />

be published this autumn, looking at<br />

the South E<strong>as</strong>tern Fares and Ticketing<br />

project.<br />

We will soon start looking at<br />

current smart ticketing schemes,<br />

evaluating them from the p<strong>as</strong>senger<br />

perspective and putting forward<br />

what p<strong>as</strong>sengers might want from<br />

future schemes. One emerging theme<br />

is the continued desire among some<br />

p<strong>as</strong>sengers to compartmentalise their<br />

transport spend and the reluctance to<br />

get out and wave around bank cards or<br />

mobile phones in stations.<br />

The p<strong>as</strong>senger experience with<br />

Oyster h<strong>as</strong> set the benchmark. As a<br />

system it h<strong>as</strong> a number of features:<br />

• Trust: p<strong>as</strong>sengers are sheltered by<br />

the knowledge of what they have loaded on, the overall cap<br />

and, <strong>as</strong> long <strong>as</strong> you touch in and out, a reliable back office<br />

system. Disputes, and who is responsible for them, are<br />

sorted out;<br />

• Simplicity: fares are relatively clear and the back office<br />

complexity hidden from p<strong>as</strong>sengers; and<br />

• Business c<strong>as</strong>e: the reduction in the cost of retailing had made<br />

the huge investment in Oyster worth it.<br />

A v<strong>as</strong>t number of rail journeys are now made using<br />

Oyster pay-<strong>as</strong>-you-go and the rate of revenue incre<strong>as</strong>e is still<br />

impressive. So, what next? Some train companies would like<br />

Oyster-like products to spread further out. While London and<br />

the south e<strong>as</strong>t h<strong>as</strong> unique travel patterns, the features of Oyster<br />

could be spread to other major urban are<strong>as</strong>. The Department for<br />

Transport h<strong>as</strong> been pushing for ITSO implementation for some<br />

time.<br />

The government’s recent fares and ticketing consultation<br />

represents the latest attempt to clear up some of the broader<br />

problems with rail ticketing. But with yield management,<br />

regulated fares, 2,500-plus stations and incre<strong>as</strong>ing devolution,<br />

replicating Oyster simplicity is never<br />

going to be e<strong>as</strong>y.<br />

Information must play a key role<br />

in this – if you could ‘read’ your ticket<br />

in a more intelligent way, many of the<br />

‘see restrictions’, ‘HS1 only’ and ‘any<br />

valid route’ type problems go away.<br />

The complexity of the rail fares system,<br />

currently dumped on p<strong>as</strong>sengers to<br />

navigate, must be m<strong>as</strong>ked. The crucial<br />

element of overall trust, lacking at the<br />

moment, could then be built into the<br />

system.<br />

So will these new tickets be loaded<br />

on to smartcards, mobile phone or<br />

paper tickets? It will probably be a<br />

combination of all of these <strong>as</strong> the<br />

future retailing landscape looks<br />

incre<strong>as</strong>ing diverse. Or is something<br />

more radical about to happen?<br />

Everyone is looking for a universally<br />

accepted, trusted and value for money<br />

retailing system that can cope with<br />

v<strong>as</strong>t numbers of relatively small<br />

transactions. Only debit and credit card<br />

and telephone billing systems fit the<br />

bill.<br />

Could the future be the incre<strong>as</strong>ed<br />

use of bank cards – trusted, accepted and<br />

used worldwide with a back office system already built? Could<br />

an urban travelcard be loaded onto a bank card, which then acts<br />

<strong>as</strong> the Oyster, Mango Swift or whatever?<br />

Or it may be that the future is b<strong>as</strong>ed around zonal pre-paid<br />

smartcards for urban intermodal travel – again, these could<br />

be loaded onto bank cards or Oyster style travel cards. Other<br />

rail tickets? They could be put on either, <strong>as</strong> long <strong>as</strong> they can<br />

be e<strong>as</strong>ily read. Maybe the desire to travel around the country<br />

on one card is already a reality and we just don’t know it? The<br />

important thing, which will decide whether the innovation<br />

lives or dies, is that it is designed with the needs of the<br />

p<strong>as</strong>senger <strong>as</strong> the starting point.<br />

Anthony Smith is the chief executive of P<strong>as</strong>senger Focus.<br />

Page 16 OCTOBER 2012

Europe<br />

Burnard Kunz, managing director of Hupac<br />

Cross-border co-operation<br />

Ron Smith meets the head of a Swiss freight operator, which is part private and<br />

part public owned, to find out why rail liberation is important for freight operators<br />

in all business models<br />

Hupac (from the German word<br />

Huckepack, meaning ‘piggyback’)<br />

w<strong>as</strong> formed in 1967 in Chi<strong>as</strong>so, on<br />

the Swiss/Italian border. Its shareholders<br />

are 72 per cent private transport<br />

companies, and 28 per cent Swiss national<br />

railways. Hupac is concerned solely with<br />

transporting intermodal freight, and h<strong>as</strong><br />

the most energy efficient, effective and<br />

busy terminals in Europe at Busto Arsizio,<br />

Italy.<br />

Its volumes transported show a<br />

continual growth, taking out fluctuations<br />

caused by economic crises, with its<br />

traditional routes being from the North<br />

Sea ports to Italy, including rolling road<br />

from Germany to Italy. Incre<strong>as</strong>ingly, it is<br />

moving more traffic e<strong>as</strong>t to west, including<br />

founding a Russian subsidiary Intermodal<br />

Express LLC in Moscow in July 2011.<br />

Hupac believes strongly in a liberated<br />

railway market.<br />

RP: You have recently expressed your<br />

views on the state of the open market for<br />

rail. What do you see <strong>as</strong> the problem?<br />

Burnard Kunz, managing director of<br />

Hupac (BK): The European Commission<br />

h<strong>as</strong> set itself some ambitious goals in the<br />

2010 White Paper – 30 per cent of long<br />

distance traffic should be handled by rail<br />

by 2030, with a target of 50 per cent by<br />

2050. Yet the railway system enters the<br />

race with considerable handicaps. In many<br />

c<strong>as</strong>es, national and geopolitical interests<br />

dominate the state owned railways.<br />

As a result, while the EU calls for the<br />

creation of a European rail market, certain<br />

railways are delaying the implementation<br />

of liberalisation, harmonisation and<br />

interoperability; in fact they are raising<br />

the barriers even higher. The only winner<br />

in this game is the road – all of us are the<br />

losers.<br />

RP: What do you suggest?<br />

BK: Europe needs an open, efficient<br />

market for rail freight transport if it is<br />

to achieve its transport policy objectives.<br />

Hupac aims to stimulate the future of the<br />

railways with a 10-point plan and a call of<br />

‘Just do it’.<br />

RP: Liberalisation so far h<strong>as</strong> not produced<br />

many new entrants into the rail freight<br />

market – why do you think this is?<br />

BK: There w<strong>as</strong> plenty of optimism when<br />

the liberalisation process began more<br />

than a decade ago. Many new railway<br />

undertakings (RUs) entered the freight<br />

market and on the axes where competition<br />

worked, the market flourished. The<br />

number of private RUs still in existence<br />

today is more sobering. The young<br />

companies suffered greatly from the 2008<br />

crisis, which led to much consolidation in<br />

the market. Forced to rely on the private<br />

capital market for money, the RUs faced<br />

liquidity problems during the crisis and<br />

were no longer supported by the banks.<br />

Such problems are unfamiliar to the<br />

state-owned rail freight companies, which<br />

survive despite large deficits on their<br />

balance sheets.<br />

RP: There h<strong>as</strong> also been a consolidation<br />

of the market where, for instance,<br />

Deutsche Bahn h<strong>as</strong> bought up some of the<br />

independent operators – where do you see<br />

the market going?<br />

BK: <strong>Rail</strong> freight is a capital-intensive<br />

business. A number of new railway<br />

undertakings had to give up. We strongly<br />

believe in the benefits of an open rail<br />