Conventional Machining Methods for Rapid Prototyping

Conventional Machining Methods for Rapid Prototyping

Conventional Machining Methods for Rapid Prototyping

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

11<br />

<strong>Conventional</strong> <strong>Machining</strong> <strong>Methods</strong> <strong>for</strong> <strong>Rapid</strong> <strong>Prototyping</strong> and Direct<br />

Manufacturing<br />

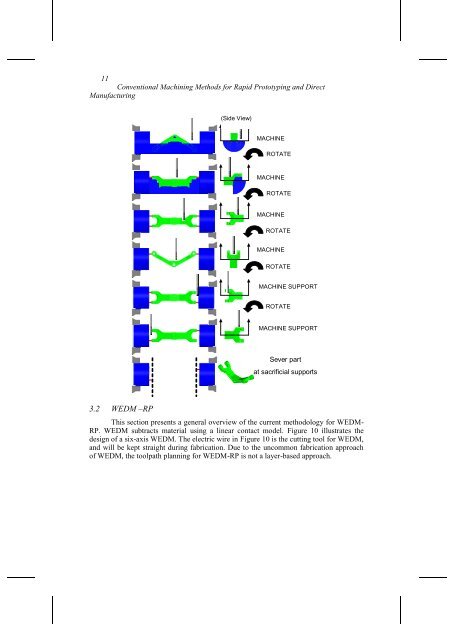

(Side View)<br />

MACHINE<br />

ROTATE<br />

MACHINE<br />

ROTATE<br />

MACHINE<br />

ROTATE<br />

MACHINE<br />

ROTATE<br />

MACHINE SUPPORT<br />

ROTATE<br />

MACHINE SUPPORT<br />

Sever part<br />

at sacrificial supports<br />

3.2 WEDM –RP<br />

This section presents a general overview of the current methodology <strong>for</strong> WEDM-<br />

RP. WEDM subtracts material using a linear contact model. Figure 10 illustrates the<br />

design of a six-axis WEDM. The electric wire in Figure 10 is the cutting tool <strong>for</strong> WEDM,<br />

and will be kept straight during fabrication. Due to the uncommon fabrication approach<br />

of WEDM, the toolpath planning <strong>for</strong> WEDM-RP is not a layer-based approach.