Safety solutions using Preventa - Elmatik AS

Safety solutions using Preventa - Elmatik AS

Safety solutions using Preventa - Elmatik AS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Automation and control<br />

<strong>Safety</strong> <strong>solutions</strong> <strong>using</strong> <strong>Preventa</strong><br />

Catalogue<br />

January<br />

04

Art. 61231 - DIA6ED2030901EN<br />

Art. 67341 - MKTED203111EN<br />

2004<br />

<strong>Safety</strong> <strong>solutions</strong><br />

<strong>using</strong> <strong>Preventa</strong><br />

2003<br />

Distributed I/O<br />

Advantys STB<br />

Art. 55053 - MKTED203041EN<br />

<strong>AS</strong>-Interface<br />

cabling system<br />

2003<br />

Data-processing,<br />

Communication<br />

Control and Protection,<br />

Detection,<br />

Data-processing,<br />

Man-Machine dialogue<br />

Control and Protection,<br />

Detection,<br />

Data-processing,<br />

Man-Machine dialogue,<br />

Communication<br />

The<br />

Essential guide<br />

Art. 54752 - MKTED203031EN<br />

To be issued: 1st quarter 2004<br />

2003<br />

Global Detection<br />

Electronic and<br />

electromechanical sensors<br />

Art. 16666 - MKTED299002EN<br />

2000<br />

Telemecanique<br />

Control and connection<br />

components<br />

Art. 28697 - MKTED299014EN<br />

2001<br />

Telemecanique<br />

Components for<br />

Human-Machine interfaces<br />

Detection<br />

Panel-building and cabling accessories<br />

Man-Machine dialogue

AUTC201108140EN<br />

Transparent factory<br />

The future of automation<br />

AUTC201104124EN<br />

2003 Momentum<br />

automation platform<br />

AUTC201384126EN<br />

2002<br />

Quantum<br />

automation platform<br />

2003<br />

2003<br />

AUTC201496125EN<br />

Premium<br />

automation platform<br />

2001<br />

AUTC101272123EN<br />

Nano<br />

programmable controllers<br />

and<br />

Micro<br />

automation platform<br />

FAAED202032EN<br />

2002<br />

Twido<br />

Telemecanique<br />

Programmable controller<br />

An overview<br />

of the product range<br />

- <strong>Safety</strong> <strong>solutions</strong> <strong>using</strong> <strong>Preventa</strong>,<br />

- Global Detection,<br />

- <strong>AS</strong>-Interface,<br />

- Control and connection components,<br />

- Motor starter <strong>solutions</strong><br />

(Control and protection components),<br />

- Soft starters and variable speed drives<br />

AUTCD21124207EN<br />

AUTC20176206EN<br />

2003<br />

Twin Line<br />

Motion control<br />

Data-processing,<br />

Man-Machine dialogue,<br />

Communication,<br />

Supervision<br />

Art. 46753 - MKTED203011EN<br />

2002<br />

Lexium<br />

Motion control<br />

Soft starters and<br />

variable speed drives<br />

Art. 27501 - MKTED201001EN<br />

2003<br />

2001<br />

Motor starter <strong>solutions</strong><br />

Control and protection<br />

components<br />

Control and protection

Automation <strong>solutions</strong><br />

An overview of the product range<br />

Products listed in this catalogue<br />

Products listed in other catalogues (see previous pages).<br />

Control and<br />

protection<br />

Contactors<br />

from 6 to 16 A<br />

Contactors Contactors<br />

from 9 to 150 A from 115 to 800 A<br />

Modular<br />

contactors<br />

Mini-Vario and Vario switch disconnectors,<br />

open and enclosed versions<br />

Enclosed thermal-magnetic<br />

motor-circuit breakers<br />

Measurement and<br />

control relays<br />

Thermal overload relays<br />

Motor starters open version<br />

DIrect on-line starters, enclosed version<br />

Star-delta starters,<br />

enclosed version<br />

Control and<br />

protection<br />

Soft starters open and<br />

enclosed version<br />

Soft start-soft stop units for<br />

asynchronous motors<br />

Variable speed drives for asynchronous motors<br />

Ready assembled<br />

variable speed drives<br />

Power supplies<br />

Transformers<br />

Detection<br />

Photo-electric<br />

detectors<br />

Inductive, capacitive, magnet and<br />

ultrasonic proximity sensors<br />

Connectors<br />

Encoders<br />

Limit switches for safety applications<br />

Metal and plastic Lever operating head Automatic reset<br />

Limit switches<br />

Electromechanical pressure<br />

and vacuum switches<br />

Electronic pressure<br />

and vacuum switches<br />

Inductive indentification system<br />

<strong>Safety</strong> light curtains<br />

Data processing<br />

Zelio Logic<br />

smart relays<br />

Twido programmable Nano programmable Micro automation<br />

controllers<br />

controllers<br />

platform<br />

Premium automation<br />

platform<br />

Quantum automation<br />

platform<br />

Momentum automation<br />

platform<br />

TBX distributed I/O<br />

Advantys STB<br />

distributed I/O<br />

Connection<br />

accessories<br />

Interfaces<br />

Telefast ® 2<br />

pre-wired system<br />

Electronic<br />

timing relays<br />

Control<br />

relays<br />

<strong>Preventa</strong> <strong>Safety</strong> modules for PLCs Power supply modules<br />

safety modules Micro Premium<br />

Human-machine<br />

dialogue<br />

Emergency stop<br />

Ø 22 pushbuttons<br />

Control stations<br />

for Ø 22 units<br />

Cam switches<br />

Pendant<br />

control stations<br />

Operator dialogue terminals<br />

Industrial control<br />

stations<br />

Integrated Human-<br />

Machine interfaces<br />

Illuminated beacons<br />

and indicator banks<br />

Rotating<br />

beacons<br />

Sirens<br />

Foot switches<br />

Two-hand control stations<br />

Emergency stop<br />

trip wire switches<br />

Keyboards<br />

Communication<br />

Communication architecture: Ethernet network, Modbus Plus network, Fipway network, <strong>AS</strong>-Interface, Fipio bus,<br />

CANopen bus, Uni-Telway bus, Modbus bus, INTERBUS, Profibus DP, asynchronous serial links<br />

Advanced dialogue <strong>solutions</strong><br />

Supervision<br />

Magelis IPC industrial PC<br />

Vijeo Look software<br />

Monitor PRO software<br />

Panel building<br />

and cabling<br />

accessories<br />

Wall-mounted<br />

enclosures<br />

Floor-standing<br />

enclosures<br />

Uprights, mounting plates, mounting rail,<br />

cable ducting and cable clips<br />

Prefabricated busbar systems and power<br />

distribution systems<br />

Tego Dial<br />

Tego Power<br />

Profil front panel<br />

Terminal blocks Cable ends Marking accessories<br />

Tools<br />

Power<br />

distribution<br />

Prefadis service poles and posts,<br />

lighting poles<br />

Canalis busbar trunking for lighting distribution<br />

Canalis busbar trunking for low and medium power distribution<br />

Canalis busbar trunking for high power distribution<br />

Mobile distribution: Canalis track section and cable carriers<br />

Services<br />

Product reference index<br />

Technical information<br />

Schneider Electric worldwide<br />

Our company’s policy is one of continuous development and improvement and we reserve the right to supply product which may differ from those illustrated in this catalogue.<br />

Our products are sold subject to our Standard Conditions of Sale, copies of which are available on request.<br />

A specific "information concerning the transition of Schneider Electric Industries SA products, equiments and applications to the year 2000 is available on request.

General contents<br />

<strong>Safety</strong> <strong>solutions</strong> <strong>using</strong> <strong>Preventa</strong><br />

1 – <strong>Safety</strong> automation system <strong>solutions</strong><br />

Selection guide <strong>Preventa</strong> safety controllers ......................page1/2<br />

<strong>Preventa</strong> safety controllers ....................................page1/6<br />

Selection guide <strong>Preventa</strong> safety modules .......................page1/48<br />

<strong>Safety</strong> modules for Emergency stop and limit switch monitoring . . .page 1/64<br />

<strong>Safety</strong> modules for Emergency stop, limit switch and<br />

safety light curtain monitoring ................................page1/79<br />

<strong>Safety</strong> modules for Emergency stop, limit switch, safety mat<br />

and edge, or safety light curtain monitoring .....................page1/89<br />

<strong>Safety</strong> modules for enabling switch monitoring ..................page1/94<br />

<strong>Safety</strong> modules for electrical monitoring of switches combined<br />

in pairs. ...................................................page1/98<br />

<strong>Safety</strong> modules for electrical monitoring of two-hand<br />

control stations. ...........................................page1/102<br />

<strong>Safety</strong> modules for increasing the number of safety contacts .....page1/107<br />

<strong>Safety</strong> modules for safety time delays .........................page1/111<br />

<strong>Safety</strong> modules for monitoring of coded magnetic switches ......page1/115<br />

<strong>Safety</strong> modules for the “muting” function of type 4<br />

safety light curtains ........................................page1/122<br />

<strong>Safety</strong> modules for zero speed detection ......................page1/127<br />

<strong>Safety</strong> modules for lift control. ...............................page1/133<br />

<strong>Safety</strong> modules for amplifier relay applications .................page1/135<br />

<strong>Safety</strong> module for dynamic valve monitoring on linear presses ....page1/137<br />

<strong>Safety</strong> modules for dynamic monitoring of double-bodied<br />

solenoid valves. ...........................................page1/141<br />

<strong>Safety</strong> modules for safety stop with automatic overtravel<br />

monitoring and control .....................................page1/146<br />

Selectionguide<strong>AS</strong>-Interfacesafety<strong>solutions</strong> ..................page1/150<br />

<strong>AS</strong>-i safety monitors and interfaces ...........................page1/154<br />

Selection guide <strong>Preventa</strong> safety modules ......................page1/160<br />

<strong>Safety</strong> modules for Emergency stop and limit switch monitoring . .page 1/164<br />

2 – <strong>Safety</strong> selection <strong>solutions</strong><br />

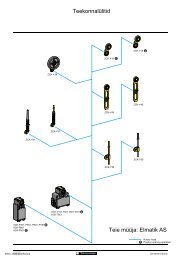

Selectionguidesafetyswitches.................................page2/2<br />

<strong>Safety</strong> switches : general, presentation ..........................page2/6<br />

Key operated safety switches .................................page2/18<br />

Metal safety witches, turret head ..............................page2/20<br />

Plastic safety switches, double insulated, fixed head .............page2/32<br />

Plastic safety switches, double insulated, turret head .............page2/36<br />

Plastic safety switches with rotary lever or spindle operator,<br />

double insulated, turret head .................................page2/48<br />

Coded magnetic switches ....................................page2/54<br />

Miniature design safety limit switches, metal ....................page2/60<br />

Compact design safety limit switches, metal or platic .............page2/62<br />

Limit switches with manual reset, plastic, double insulated ........page2/66<br />

4

Selectionguidesafetymats..................................page2/78<br />

<strong>Safety</strong> mats ...............................................page2/82<br />

Selectionguidesafetylightcurtains...........................page2/86<br />

<strong>Safety</strong> light curtains ........................................page2/88<br />

3 – <strong>Safety</strong> dialogue <strong>solutions</strong><br />

Selection guide dialogue components ..........................page3/2<br />

Harmony® Emergency stop mushroom head Ø 22 pushbuttons ....page3/4<br />

XAL control stations for Ø 22 control and signalling units ........page3/12<br />

Enabling switches for safety circuits ..........................page3/16<br />

Two-hand ergonomic control stations .........................page3/18<br />

Emergency stop trip wire switches ............................page3/24<br />

Metal foot switches with positive opening operation on release ......page3/38<br />

Illuminated beacons and indicator banks Ø 70 mm. ..............page3/50<br />

4 – <strong>Safety</strong> control and protection <strong>solutions</strong><br />

SelectionguideMini-VARIOandVARIOswitchdisconnectors......page4/2<br />

Mini-VARIO switch disconnectors for standard applications. .......page4/8<br />

Selectionguidedirectstartersforsafetyapplications............page4/26<br />

Thermal-magnetic motor circuit breakers model GV2-ME .........page4/28<br />

Enclosed D.O.L. starters for motor control .....................page4/34<br />

Selectionguidecontactorsfrom6to2750A....................page4/44<br />

5 – General<br />

Industrial accidents: the hard facts .............................page5/2<br />

Safeoperation:aglobalconcept...............................page5/3<br />

Hazards,dangerousphenomena...............................page5/4<br />

Danger zones: definitions, examples ...........................page5/5<br />

Machinesafety..............................................page5/6<br />

Categories of parts of control systems relating to safety ..........page5/8<br />

Riskevaluation ............................................page5/10<br />

Examplesofsafetypowercircuitsoftypicalapplications.........page5/12<br />

TheMachineryDirective,theHealthand<strong>Safety</strong>Directive .........page5/16<br />

Europeanstandards........................................page5/20<br />

Dangerous machines and safety components . . . ...............page5/23<br />

<strong>Safety</strong>techniques..........................................page5/24<br />

Electricalhazards..........................................page5/28<br />

6 – Services<br />

Index. .....................................................page6/2<br />

Technical information ........................................page6/4<br />

5

Contents<br />

1-<strong>Safety</strong> automation system <strong>solutions</strong><br />

Selection guide <strong>Preventa</strong> safety controllers ......................page1/2<br />

1<br />

b <strong>Preventa</strong> safety controllers with pre-defined functions<br />

v Type XPS MP ............................................page 1/6<br />

b <strong>Preventa</strong> safety controllers<br />

v Type XPS MC ...........................................page 1/19<br />

v Functions ..............................................page 1/20<br />

Selection guide <strong>Preventa</strong> safety modules .......................page1/48<br />

b <strong>Preventa</strong> safety modules : general .............................page 1/56<br />

b <strong>Preventa</strong> safety modules for Emergency stop and<br />

limit switch monitoring<br />

v Type XPS AC ...........................................page 1/64<br />

v Types XPS AV and XPS AT ................................page 1/68<br />

v Type XPS AF ...........................................page 1/75<br />

b <strong>Preventa</strong> safety modules for Emergency stop, limit switch and safety<br />

light curtain monitoring<br />

v Type XPS AFL ..........................................page 1/79<br />

v Type XPS AR ...........................................page 1/83<br />

b <strong>Preventa</strong> safety modules for Emergency stop, limit switch,<br />

safety mat and edge, or safety light curtain monitoring<br />

v Type XPS AK ...........................................page 1/89<br />

b <strong>Preventa</strong> safety modules for enabling switch monitoring<br />

v Type XPS VC ...........................................page 1/94<br />

b <strong>Preventa</strong> safety modules for electrical monitoring<br />

of switches combined in pairs<br />

v Type XPS FB ...........................................page 1/98<br />

b <strong>Preventa</strong> safety modules for electrical monitoring<br />

of two-hand control stations<br />

v Types XPS BA, XPS BC and XPS BF .......................page 1/102<br />

b <strong>Preventa</strong> safety modules for increasing the number of safety contacts<br />

v Types XPS ECM and XPS ECP ............................page 1/107<br />

b <strong>Preventa</strong> safety modules for safety time delays<br />

v Types XPS TSA and XPS TSW ............................page 1/111<br />

b <strong>Preventa</strong> safety modules for monitoring of coded magnetic switches<br />

v Types XPS DMB and XPS DME. ...........................page 1/115<br />

b <strong>Preventa</strong> safety modules for the “muting” function<br />

of type 4 safety light curtains<br />

v Types XPS LMS and XPS LMR ............................page 1/122<br />

b <strong>Preventa</strong> safety modules for zero speed detection<br />

v Type XPS VN ..........................................page 1/127<br />

b <strong>Preventa</strong> safety modules for lift control<br />

v Type XPS DA ..........................................page 1/133<br />

b <strong>Preventa</strong> safety modules for amplifier relay applications<br />

v Type XPS NS ..........................................page 1/135<br />

1/0 Schneider Electric

<strong>Preventa</strong> safety module for dynamic valve monitoring<br />

on linear presses<br />

v Type XPS PVT. ........................................ page 1/137<br />

1<br />

b <strong>Preventa</strong> safety modules for dynamic monitoring of double-bodied<br />

solenoid valves<br />

v Type XPS PVK ........................................ page 1/141<br />

b <strong>Preventa</strong> safety modules for safety stop with automatic overtravel<br />

monitoring and control<br />

v Type XPS OT. ......................................... page 1/146<br />

Selectionguide<strong>AS</strong>-Interfacesafety<strong>solutions</strong>..................page1/150<br />

b <strong>AS</strong>-Interface safety monitors<br />

v Type <strong>AS</strong>I SAFEMON .................................... page 1/154<br />

b <strong>AS</strong>-Interface safety interfaces<br />

v Type <strong>AS</strong>I SSL ......................................... page 1/158<br />

Selection guide <strong>Preventa</strong> safety modules .....................page1/160<br />

b <strong>Preventa</strong> safety modules for Emergency stop and limit switch<br />

monitoring<br />

v Type TSX DPZ, integrated in Micro PLCs .................... page 1/164<br />

v Type TSX PAY, integrated in Premium PLCs ................. page 1/170<br />

Schneider Electric<br />

1/1

Selection guide<br />

0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers<br />

1<br />

Applications<br />

Modules Controllers for 2 simultaneous safety functions independent from each other. User selection of 2 functions out of 15.<br />

Configuration on product front panel<br />

Functions<br />

MonItoring of Emergency stops, limit switches, enabling switches, safety mats and sensitive edges and relay-output<br />

light curtains, etc.<br />

Conformity to standards<br />

Product Category 4 conforming to EN 954-1, EN 1088<br />

EN 61496-1 (type 4), EN 1780<br />

EN 60947-5-3<br />

Machine assemblies IEC 204-1, EN 292, EN 418<br />

EN 60204-1<br />

Product certifications<br />

UL, CSA<br />

Number of circuits<br />

<strong>Safety</strong><br />

6 N/O (3 N/O per function)<br />

Additional<br />

3 solid-state outputs for signalling to PLC<br />

Display<br />

Supply<br />

12 LEDs<br />

c 24 V<br />

Module type<br />

XPS MP<br />

Pages 1/5<br />

1/2

0<br />

1<br />

1<br />

Controllers for several independent safety functions, with selection of safety functions by configuration software running on Windows.<br />

16 or 32 inputs and 8 independent safety outputs.<br />

Monitoring of Emergency stops, limit switches, two-hand controls, light curtains with or without “muting” function, enabling switches, coded magnetic<br />

switches, safety mats, solenoid valves on hydraulic presses, safety stop at top dead centre on eccentric presses and zero speed detection.<br />

Category 4 conforming to EN 954-1, EN 1088, EN 61496-1, EN 60947-5-3, EN 574<br />

IEC 204-1, EN 292, EN 418, EN 60204-1<br />

UL, CSA<br />

2 N/O + 6 solid-state outputs for signalling to PLC<br />

1 "muting" signalling output<br />

LED display on front face<br />

c 24 V<br />

XPS MC<br />

1/19<br />

1/3

Operating principle<br />

0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

1<br />

Operating principle<br />

<strong>Preventa</strong> safety modules - monitors<br />

XPS MP are designed to conform<br />

with category 4 of the standard<br />

EN 954-1.<br />

They enable two independent safety<br />

functions (selected from a choice of<br />

15 pre-defined configurations) to be<br />

performed <strong>using</strong> the same product.<br />

Configuration selection is easily<br />

made <strong>using</strong> 3 buttons on the front<br />

face of the module.<br />

The 15 preprogrammed safety functions provide a solution for the majority of safety applications up to level 4<br />

conforming to the standard EN 954-1, for example monitoring Emergency stops, limit switches, safety mats and edges,<br />

enabling switches, monitoring type 4 safety light curtains conforming to EN 61946-1 which have relay outputs (for<br />

example, XUS LT type curtains, see pages 2/103 and 2/104) and monitoring magnetic switches.<br />

XPS MP monitors incorporate 6 safety outputs (3 per function) and 3 solid-state signalling outputs for signalling to the<br />

process PLC.<br />

To aid diagnostics, the modules have LEDs on the front face which provide information on the monitoring circuit status.<br />

They also indicate and assist selection of the 2 required configurations.<br />

Configuration<br />

Synchronisation<br />

time<br />

Type of start (1) Start test Notes<br />

Automatic or unmonitored Monitored<br />

Functions disabled 0 – – – – Factory setting<br />

Emergency stop monitoring,<br />

1-channel wiring (category 2)<br />

Emergency stop monitoring,<br />

2-channel wiring, or<br />

guard monitoring (category 4)<br />

Guard monitoring for injector press<br />

or blowing machine (category 4)<br />

Enabling switches with handle<br />

(3 position limit switch)<br />

(category 4)<br />

<strong>Safety</strong> mats and edges monitoring<br />

(category 3)<br />

Relay output safety light curtain<br />

monitoring (category 4)<br />

Monitoring of coded magnetic<br />

switches (category 4)<br />

1 – X – – –<br />

2 – – X – –<br />

3 Unlimited X – X –<br />

4 Unlimited – X X –<br />

5 1.5 s X – X –<br />

6 1.5 s – X X –<br />

7 Unlimited X – – –<br />

8 Unlimited – X – –<br />

9 1.5 s – X X Uses both safety outputs (2)<br />

10 – X – X The start button acts as<br />

start-up preparation<br />

11 – X – – Mats with circuit making<br />

12 – – X –<br />

contacts<br />

13 0.5 s – X X –<br />

14 1.5 s X – – Magnetic switches with 2<br />

15 1.5 s – X –<br />

contacts 1 N/O and 1 N/C<br />

(1) Automatic start: there is no start contact or it is shunted.<br />

Unmonitored start: the output is activated on closing of the start contact.<br />

Monitored start: the start input is monitored so that there is no start-up in the event of the start contact being shunted or the start circuit being closed for more<br />

than 10 seconds.<br />

Start-up is triggered following activation of the start button (push-release function) on opening of the contact.<br />

(2) Tool zone guard with 3rd limit switch.<br />

Additional rear guard (optional) with automatic start. The opening of the guard cuts all outputs.<br />

1/4

Characteristics<br />

0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

Characteristics<br />

Module type XPS MP11123 XPS MP11123P<br />

1<br />

Product designed for max. use in<br />

Category 4 max.<br />

safety related parts of control<br />

systems (conforming to EN 954-1)<br />

Supply<br />

- voltage V c 24<br />

- voltage limits - 20…+ 20 %<br />

Consumption W ≤ 5<br />

Module inputs fuse protection<br />

Start button monitoring<br />

Control unit voltage<br />

Between input terminals C1-I1, C2-I2,<br />

C3-I3, C4-I4, C5-I5 or C6-I6<br />

Calculation of wiring resistance RL<br />

between input terminals<br />

V<br />

Ω<br />

Internal, electronic<br />

Yes/No (depending on configuration selected)<br />

24 (at nominal supply voltage)<br />

100 max.<br />

Maximum cable length: 2000 m<br />

Synchronisation time between s 0.5, 1.5 or unlimited, depending on configuration selected<br />

inputs<br />

Outputs<br />

- voltage reference Volt-free<br />

- number and type of safety circuits 3 N/O per function (6 N/O total) (13-14, 23-24, 33-34, 43-44, 53-54, 63-64)<br />

- number and type of additional circuits 3solid-state<br />

- breaking capacity in AC-15 VA C300: inrush 1800, maintained 180<br />

- breaking capacity in DC-13 24 V/1.25 A L/R = 50 ms<br />

- breaking capacity of solid-state<br />

24 V/20 mA<br />

outputs<br />

- max. thermal current (Ithe) for each<br />

group of 3 outputs<br />

3.3 A for all 3 outputs, or 6 A for 1 output and 2 A for the other 2 outputs, or 2 A for 1 output and 4 A for the<br />

other 2 outputs<br />

- max. total thermal current A 20<br />

- output fuse protection A 4 gG or 6 fast acting (conforming to IEC/EN 60947-5-1, DIN VDE 0660 part 200)<br />

- minimum current mA 10<br />

- minimum voltage V 17<br />

Electrical durability See page 1/60<br />

Response time on input opening ms

References<br />

0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

103248<br />

References<br />

Description<br />

Type of<br />

terminal<br />

block<br />

connection<br />

Number<br />

of safety<br />

circuits<br />

Additional<br />

outputs<br />

Supply Reference Weight<br />

kg<br />

1<br />

Modules for<br />

2 independent<br />

safety functions<br />

Integrated<br />

in module<br />

3 N/O per 3solid<br />

function state<br />

(6 N/O total)<br />

c 24 V XPS MP11123 0.320<br />

XPS MP11123<br />

103249<br />

Separate,<br />

can be<br />

removed<br />

from module<br />

3 N/O per<br />

function<br />

(6 N/O total)<br />

3solid<br />

state<br />

c 24 V XPS MP11123P 0.320<br />

XPS MP11123P<br />

1/6

Dimensions<br />

0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

AM1 DP200 rail mounting<br />

XPS MPpppp<br />

XPS MPppppP<br />

1<br />

99<br />

99<br />

Key to LEDs<br />

114 45<br />

114 45<br />

1<br />

2<br />

3<br />

4<br />

56789101112<br />

F1<br />

F2<br />

OK<br />

1-2-3 Function 1 configuration code<br />

4 K1/K2 state (function 1, N/O safety outputs closed)<br />

5-6-7 Function 2 configuration code<br />

8 K3/K4 state (function 1, N/O safety outputs closed)<br />

9 A1-A2 supply voltage<br />

10 Fault<br />

11 Function 1 configuration<br />

12 Function 2 configuration<br />

F1, F2, OK: Configuration buttons<br />

1/7

Connections, 0<br />

functional diagrams<br />

0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

1<br />

XPS MP<br />

Emergency stop monitoring, 1-channel wiring<br />

Configuration 1 (1-channel Emergency stop, automatic or unmonitored start) = function 1.<br />

Configuration 2 (1-channel Emergency stop, monitored start) = function 2.<br />

+ 24 V<br />

F1<br />

Emergency<br />

stop<br />

F1<br />

S1<br />

K11<br />

K12<br />

ESC<br />

F1<br />

Start<br />

F1<br />

S3<br />

(1)<br />

To PLC<br />

A1 C3 C2 C1<br />

I1 I2<br />

I3 13 23<br />

33<br />

43<br />

53<br />

63<br />

Y+ Y74 Y84 Y94<br />

Logic<br />

channel 1<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K1<br />

K3<br />

Logic<br />

channel 2<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K2<br />

K4<br />

Fault<br />

Funct. 1<br />

XPS MP<br />

Funct. 2<br />

A2<br />

C6 C5 C4<br />

I4 I5<br />

I6 14 24<br />

34<br />

44<br />

54<br />

64<br />

Emergency<br />

stop 1<br />

F2<br />

S4.1<br />

ESC<br />

F2<br />

(2)<br />

(3)<br />

Emergency<br />

stop 2<br />

F2<br />

S4.2<br />

K02<br />

K02<br />

Start<br />

F2<br />

S6<br />

K11<br />

K12<br />

K21<br />

K22<br />

0 V<br />

Function 1 Function 1 Function 2 Function 2<br />

(1) Automatic start.<br />

(2) Function 1 safety outputs.<br />

(3) Function 2 safety outputs.<br />

ESC = External start conditions.<br />

Functional diagrams<br />

Configuration 1 Configuration 1<br />

Automatic start<br />

Unmonitored start<br />

Key<br />

0<br />

Input 1, Emergency stop<br />

C1-I1, (C4-I4)<br />

Input 2, ESC<br />

C2-I2, (C5-I5)<br />

Automatic start<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

1<br />

Power-up (Self-test accomplished)<br />

Emergency stop<br />

not activated<br />

Emergency<br />

stop<br />

activated<br />

Emergency stop<br />

not activated<br />

Key<br />

0<br />

Input 1, Emergency stop<br />

C1-I1, (C4-I4)<br />

Input 2, ESC<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

1<br />

Power-up (Self-test accomplished)<br />

Emergency stop<br />

not activated<br />

Emergency<br />

stop<br />

activated<br />

Emergency stop<br />

not activated<br />

Configuration 2<br />

Monitored start<br />

Key<br />

0<br />

Input 1, Emergency stop<br />

C1-I1, (C4-I4)<br />

Input 2, ESC<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

1<br />

Power-up (Self-test accomplished)<br />

Emergency stop<br />

not activated<br />

Emergency<br />

stop<br />

activated<br />

Emergency stop<br />

not activated<br />

1/8

Connections, 0<br />

functional diagrams<br />

(continued) 0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

XPS MP<br />

Guard monitoring with start test<br />

Configuration 3 (locking of guard with start test, automatic or unmonitored start) = function 1.<br />

Configuration 4 (locking of guard with start test, monitored start) = function 2.<br />

+ 24 V<br />

F1<br />

1<br />

Function 1<br />

Guard<br />

closed<br />

Open<br />

Start<br />

F1<br />

S3 (1)<br />

K11<br />

S1<br />

S2<br />

K12<br />

To PLC<br />

ESC<br />

F1<br />

A1 C3 C1 I1 C2<br />

I2 I3<br />

13 23<br />

33<br />

43<br />

53<br />

63<br />

Y+ Y74 Y84 Y94<br />

Logic<br />

channel 1<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K1<br />

K3<br />

Logic<br />

channel 2<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K2<br />

K4<br />

Fault<br />

Funct. 1<br />

XPS MP<br />

Funct. 2<br />

A2<br />

C6 C4 I4 C5<br />

I5 I6<br />

14 24<br />

34<br />

44<br />

54<br />

64<br />

ESC<br />

F2<br />

(2) (3)<br />

S4<br />

S5<br />

K21<br />

K22<br />

0 V<br />

Function 2<br />

Guard<br />

closed<br />

(1) Automatic start.<br />

(2) Function 1 safety outputs.<br />

(3) Function 2 safety outputs.<br />

ESC = External start conditions.<br />

Open<br />

Start<br />

F2<br />

S6<br />

K11 K12 K21 K22<br />

Function 1 Function 1 Function 2 Function 2<br />

Functional diagrams<br />

Configuration 3 Configuration 3<br />

Automatic start<br />

Unmonitored start<br />

Power-up (Self-test accomplished)<br />

Key 0<br />

1<br />

1<br />

Guard closed Guard Guard closed<br />

Key 0<br />

open<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Automatic start<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

Configuration 4<br />

Monitored start<br />

Key 0<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

1<br />

No start-up (1)<br />

Power-up (Self-test accomplished)<br />

Guard closed<br />

Guard<br />

open<br />

t =<br />

Guard closed<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94) No<br />

t = t < 10 s<br />

start-up (1)<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

Power-up (Self-test accomplished)<br />

Guard closed<br />

No start-up (1)<br />

Guard<br />

open<br />

(1) Prevention of start-up necessary: to check the sensors connected, open and<br />

reclose the guard.<br />

t =<br />

Guard closed<br />

1/9

Connections, 0<br />

functional diagrams<br />

(continued) 0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

1<br />

XPS MP<br />

Guard monitoring with start test and synchronisation time = 1.5 ms<br />

Configuration 5 (locking of guard with start test, automatic or unmonitored start) = function 1.<br />

Configuration 6 (locking of guard with start test, monitored start) = function 2.<br />

+ 24 V<br />

F1<br />

Function 1<br />

Guard<br />

closed<br />

Open<br />

Start<br />

F1<br />

S3 (1)<br />

K11<br />

S1<br />

S2<br />

K12<br />

To PLC<br />

ESC<br />

F1<br />

A1 C3 C1 I1 C2<br />

I2 I3<br />

13 23<br />

33<br />

43<br />

53<br />

63<br />

Y+ Y74 Y84 Y94<br />

Logic<br />

channel 1<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K1<br />

K3<br />

Logic<br />

channel 2<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K2<br />

K4<br />

Fault<br />

Funct. 1<br />

XPS MP<br />

Funct. 2<br />

A2<br />

C6 C4 I4 C5<br />

I5 I6<br />

14 24<br />

34<br />

44<br />

54<br />

64<br />

ESC<br />

F2<br />

(2) (3)<br />

S4<br />

S5<br />

K21<br />

K22<br />

0 V<br />

Function 2<br />

Guard<br />

closed<br />

(1) Automatic start.<br />

(2) Function 1 safety outputs.<br />

(3) Function 2 safety outputs.<br />

ESC = External start conditions.<br />

Open<br />

Start<br />

F2<br />

S6<br />

K11 K12 K21 K22<br />

Function 1 Function 1 Function 2 Function 2<br />

Functional diagrams<br />

Configuration 5 Configuration 5<br />

Automatic start<br />

Unmonitored start<br />

Power-up (Self-test accomplished)<br />

Key 0<br />

1<br />

Guard closed Guard Guard closed<br />

1<br />

0<br />

open<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Automatic start<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

Configuration 6<br />

Monitored start<br />

Key<br />

0<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

1<br />

No start-up (1)<br />

Power-up (Self-test accomplished)<br />

Guard closed<br />

No start-up<br />

(1)<br />

Guard<br />

open<br />

Guard closed<br />

Key<br />

End of travel 1<br />

C1-I1, (C4-I4)<br />

End of travel 2<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

Power-up (Self-test accomplished)<br />

Guard closed<br />

No start-up (1)<br />

Guard<br />

open<br />

Guard closed<br />

(1) Prevention of start-up necessary: to check the sensors connected, open and<br />

reclose the guard.<br />

1/10

Connections, 0<br />

functional diagrams<br />

(continued) 0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

0<br />

XPS MP<br />

Emergency stop monitoring, 2-channel wiring<br />

Configuration 7 (2-channel Emergency stop, automatic or unmonitored start) = function 1.<br />

Configuration 8 (2-channel Emergency stop, monitored start) = function 2.<br />

+ 24 V<br />

F1<br />

1<br />

Start<br />

F1<br />

S3<br />

(1)<br />

Emergency<br />

stop<br />

F1<br />

S1<br />

K11<br />

K12<br />

ESC<br />

F1<br />

To PLC<br />

A1 C3 C2 C1<br />

I1 I2<br />

I3 13 23<br />

33<br />

43<br />

53<br />

63<br />

Y+ Y74 Y84 Y94<br />

Logic<br />

channel 1<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K1<br />

K3<br />

Logic<br />

channel 2<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K2<br />

K4<br />

Fault<br />

Funct. 1<br />

XPS MP<br />

Funct. 2<br />

A2<br />

C6 C5 C4<br />

I4 I5<br />

I6 14 24<br />

34<br />

44<br />

54<br />

64<br />

S4.1<br />

Emergency<br />

stop 1<br />

F2<br />

ESC<br />

F2<br />

K21<br />

(2)<br />

(3)<br />

S4.2<br />

Emergency<br />

stop 2<br />

F2<br />

Start<br />

F2<br />

K22<br />

S6<br />

K11<br />

K12<br />

K21<br />

K22<br />

0 V<br />

Function 1 Function 1 Function 2 Function 2<br />

(1) Automatic start.<br />

(2) Function 1 safety outputs.<br />

(3) Function 2 safety outputs.<br />

ESC = External start conditions.<br />

Functional diagrams<br />

Configuration 7 Configuration 7<br />

Automatic start<br />

Unmonitored start<br />

Key 0<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Automatic start<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

Configuration 8<br />

Monitored start<br />

Key<br />

0<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

Power-up (Self-test accomplished)<br />

1 Emergency stop Emergency Emergency stop<br />

not activated stop<br />

not activated<br />

Key 0<br />

activated<br />

Input 1<br />

C1-I1, (C4-I4)<br />

1<br />

Power-up (Self-test accomplished)<br />

Emergency stop<br />

not activated<br />

No<br />

start-up (1)<br />

Emergency<br />

stop<br />

activated<br />

Emergency stop<br />

not activated<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

1<br />

Power-up (Self-test accomplished)<br />

Emergency stop Emergency<br />

not activated stop<br />

activated<br />

Emergency stop<br />

not activated<br />

(1) Start button control: the start button must not be activated on power-up.<br />

1/11

Connections, 0<br />

functional diagrams<br />

(continued) 0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

1<br />

XPS MP<br />

Guard monitoring for injector press or blowing machine<br />

Configuration 9 (this configuration uses both functions of the monitor. Only function 1 is configured).<br />

+ 24 V<br />

F1<br />

S3<br />

<strong>Safety</strong> valve<br />

Tool zone guard,<br />

closed<br />

Open<br />

S1<br />

S2<br />

To PLC<br />

A1 C3 C1 I1 C2<br />

I2 I3<br />

13 23<br />

33<br />

43<br />

53<br />

63<br />

Y+ Y74 Y84 Y94<br />

Logic<br />

channel 1<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K1<br />

K3<br />

Logic<br />

channel 2<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K2<br />

K4<br />

Fault<br />

Funct. 1<br />

XPS MP<br />

Funct. 2<br />

A2<br />

C6 C4 I4 C5<br />

I5 I6<br />

14 24<br />

34<br />

44<br />

54<br />

64<br />

(1) (1)<br />

ESC<br />

F1<br />

(2)<br />

(3)<br />

S4<br />

S5<br />

K11<br />

K12<br />

0 V<br />

Guard outside tool<br />

zone, closed<br />

Open<br />

S6<br />

Start<br />

K11<br />

(1) If sensors S4 and S5 are not used, terminals C4-I4 and C5-I5 must be linked.<br />

(2) <strong>Safety</strong> outputs for tool zone.<br />

(3) <strong>Safety</strong> outputs for rear access safety doors.<br />

In configuration mode 9, the N/C contacts of the relays or contactors controlled via outputs 43-44, 53-54, 63-64 cannot be monitored by the feedback loop (ESC).<br />

ESC = External start conditions.<br />

K12<br />

Tool zone Tool zone<br />

Functional diagram<br />

Configuration 9<br />

Key<br />

0<br />

End of travel 1<br />

C1-I1<br />

End of travel 2<br />

C2-I2<br />

End of travel 3<br />

C3-I3<br />

End of travel 4<br />

C4-I4<br />

End of travel 5<br />

C5-I5<br />

Start button<br />

C6-I6<br />

N/O output<br />

13-14/23-24/33-34<br />

Signalling output<br />

Y84<br />

N/O output<br />

43-44/53-54/63-64<br />

Signalling output<br />

Y94<br />

1<br />

Power-up (Self-test accomplished)<br />

Both guards<br />

closed<br />

No start-up (1)<br />

Guard for<br />

tool zone<br />

open<br />

Both guards<br />

closed<br />

Guard outside<br />

tool zone open<br />

t < 1,5 s t < 10 s t = t < 10 s<br />

Both guards<br />

closed<br />

(1) Prevention of start-up necessary: to check the sensors connected, open and reclose the guard.<br />

1/12

Connections, 0<br />

functional diagrams<br />

(continued) 0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

XPS MP<br />

Enabling switch, safety mat monitoring<br />

Configuration 10 (enabling switch, with or without start-up preparation) = function 1.<br />

Configuration 11 (safety mat monitoring, automatic or unmonitored start) = function 2.<br />

+ 24 V<br />

F1<br />

1<br />

S12<br />

K11<br />

01 2 1<br />

2<br />

Validation F1<br />

5<br />

6<br />

3<br />

4<br />

K12<br />

To PLC<br />

ESC<br />

F1<br />

A1 C3 C2 C1<br />

I1 I2<br />

I3 13 23<br />

33<br />

43<br />

53<br />

63<br />

Y+ Y74 Y84 Y94<br />

Logic<br />

channel 1<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K1<br />

K3<br />

Logic<br />

channel 2<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K2<br />

K4<br />

Fault<br />

Funct. 1<br />

XPS MP<br />

Funct. 2<br />

A2<br />

C6 C5 C4<br />

I4 I5 I6<br />

14 24<br />

34<br />

44<br />

54<br />

64<br />

S45<br />

ESC<br />

F2<br />

(4) (5)<br />

K21<br />

K22<br />

0 V<br />

(1) S3 = start-up preparation F1.<br />

(2) Without start-up preparation.<br />

(3) Automatic start.<br />

(4) Function 1 safety outputs.<br />

(5) Function 2 safety outputs.<br />

ESC = External start conditions.<br />

XY2 TP<br />

<strong>Safety</strong> mat F2<br />

Start<br />

F2<br />

S6<br />

(3)<br />

K11 K12 K21 K22<br />

Function 1 Function 1 Function 2 Function 2<br />

Functional diagrams<br />

Configuration 10<br />

Enabling switch<br />

1<br />

Key 0<br />

Switching level:<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Input 3<br />

C3-I3, (C6-I6)<br />

Input 3<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

Power-up (Self-test accomplished)<br />

1 0 1 0<br />

1 2 1 0<br />

1<br />

2<br />

1 With start-up preparation<br />

2 Without start-up preparation<br />

Configuration 11<br />

<strong>Safety</strong> mat with automatic start<br />

Power-up (Self-test accomplished)<br />

Configuration 11<br />

<strong>Safety</strong> mat with unmonitored start<br />

Power-up (Self-test accomplished)<br />

Key<br />

0<br />

Input 1<br />

C1-I1, (C4-I4)<br />

1<br />

<strong>Safety</strong><br />

mat/edge<br />

not activated<br />

<strong>Safety</strong><br />

mat/edge<br />

activated<br />

<strong>Safety</strong><br />

mat/edge<br />

not activated<br />

<strong>Safety</strong><br />

mat/edge<br />

activated<br />

Key<br />

0<br />

Input 1<br />

C1-I1, (C4-I4)<br />

1<br />

<strong>Safety</strong><br />

mat/edge<br />

not activated<br />

<strong>Safety</strong><br />

mat/edge<br />

activated<br />

<strong>Safety</strong><br />

mat/edge<br />

not activated<br />

<strong>Safety</strong><br />

mat/edge<br />

activated<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Automatic start<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

1/13

Connections, 0<br />

functional diagrams<br />

(continued) 0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

1<br />

XPS MP<br />

<strong>Safety</strong> mat monitoring, safety light curtain monitoring<br />

Configuration 12 (safety mat/edge monitoring, monitored start) = function 1.<br />

Configuration 13 (safety light curtain monitoring, monitored start ; synchronisation time = 0.5 s) = function 2.<br />

+ 24 V<br />

F1<br />

<strong>Safety</strong> mat<br />

F1<br />

S12<br />

Start<br />

F1<br />

K11<br />

S3<br />

K12<br />

To PLC<br />

XY2 TP<br />

ESC<br />

F1<br />

A1 C3 C2 C1<br />

I1 I2<br />

I3 13 23<br />

33<br />

43<br />

53<br />

63<br />

Y+ Y74 Y84 Y94<br />

Logic<br />

channel 1<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K1<br />

K3<br />

Logic<br />

channel 2<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K2<br />

K4<br />

Fault<br />

Funct. 1<br />

XPS MP<br />

Funct. 2<br />

A2<br />

C6 C5 C4<br />

I4 I5<br />

I6 14 24<br />

34<br />

44<br />

54<br />

64<br />

<strong>Safety</strong> light<br />

curtain F2<br />

S45<br />

OSSD1<br />

ESPE<br />

output<br />

OSSD2<br />

ESC<br />

F2<br />

K21<br />

K22<br />

(1) (2)<br />

Start<br />

F2<br />

S6<br />

K11<br />

K12<br />

K21<br />

K22<br />

0 V<br />

(1) Function 1 safety outputs.<br />

(2) Function 2 safety outputs.<br />

ESC = External start conditions.<br />

Function 1 Function 1 Function 2 Function 2<br />

Functional diagrams<br />

Configuration 12 Configuration 13<br />

<strong>Safety</strong> mat/edge with monitored start<br />

<strong>Safety</strong> light curtain with monitored start<br />

Power-up<br />

(Self-test accomplished)<br />

Power-up<br />

(Self-test accomplished)<br />

Key<br />

0<br />

1<br />

<strong>Safety</strong> mat/edge<br />

not activated<br />

<strong>Safety</strong><br />

mat/edge<br />

activated<br />

<strong>Safety</strong> mat/edge<br />

not activated<br />

<strong>Safety</strong><br />

mat/edge<br />

activated<br />

Key<br />

0<br />

1<br />

Light curtain<br />

beams made<br />

Light curtain<br />

beam(s)<br />

broken<br />

Light curtain<br />

beams made<br />

Light curtain<br />

beam(s)<br />

broken<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

t < 10 s<br />

No<br />

start-up (1)<br />

t < 10 s<br />

Signalling output<br />

Y84, (Y94)<br />

No<br />

start-up (1)<br />

t < 0,5 s<br />

t < 10 s<br />

(1) Start button control:<br />

the start button must not be activated on power-up.<br />

1/14

Connections, 0<br />

functional diagrams<br />

(continued) 0<br />

<strong>Safety</strong> automation system <strong>solutions</strong><br />

1<br />

<strong>Preventa</strong> safety controllers type XPS MP<br />

With pre-defined functions<br />

XPS MP<br />

Monitoring of coded magnetic switches<br />

Configuration 14 (automatic or unmonitored start, synchronisation time = 1.5 s) = function 1.<br />

Configuration 15 (monitored start, synchronisation time = 1.5 s) = function 2.<br />

+ 24 V<br />

F1<br />

Magnetic switch<br />

not activated F1<br />

Start<br />

F1<br />

S3<br />

(1)<br />

1<br />

K11<br />

S12<br />

BK WH<br />

BU BN<br />

XCS DM<br />

K12<br />

ESC<br />

F1<br />

To PLC<br />

A1 C3 C2 C1 I1 I2<br />

I3 13 23<br />

33<br />

43<br />

53<br />

63<br />

Y+ Y74 Y84 Y94<br />

Logic<br />

channel 1<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K1<br />

K3<br />

Logic<br />

channel 2<br />

Function 1<br />

(F1)<br />

Function 2<br />

(F2)<br />

K2<br />

K4<br />

Fault<br />

Funct. 1<br />

Funct. 2<br />

XPS MP<br />

A2<br />

C6 I4<br />

C4 C5<br />

I5 I6 14 24<br />

34<br />

44<br />

54<br />

64<br />

S45<br />

BK WH<br />

BU BN<br />

XCS DM<br />

ESC<br />

F2<br />

K21<br />

(2) (3)<br />

K22<br />

Coded magnetic<br />

switch<br />

Start<br />

F2<br />

S6<br />

K11<br />

K12<br />

K21<br />

K22<br />

0 V<br />

(1) Automatic start.<br />

(2) Function 1 safety outputs.<br />

(3) Function 2 safety outputs.<br />

ESC = External start conditions.<br />

Function 1 Function 1 Function 2 Function 2<br />

Functional diagrams<br />

Configuration 14 Configuration 14<br />

Automatic start<br />

Unmonitored start<br />

Key 0<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Automatic start<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

1<br />

Power-up (Self-test accomplished)<br />

Actuator part<br />

present<br />

Actuator part<br />

absent<br />

Configuration 15<br />

Monitored start<br />

Power-up (Self-test accomplished)<br />

Key 0<br />

1<br />

Actuator part Actuator part<br />

present absent<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

t < 10 s t < 1,5 s<br />

Actuator part<br />

present<br />

t < 1,5 s<br />

Actuator part<br />

present<br />

t < 10 s<br />

Key 0<br />

Input 1<br />

C1-I1, (C4-I4)<br />

Input 2<br />

C2-I2, (C5-I5)<br />

Start button<br />

C3-I3, (C6-I6)<br />

N/O output<br />

13-14/23-24/33-34,<br />

(43-44/53-54/63-64)<br />

Signalling output<br />

Y84, (Y94)<br />

Power-up (Self-test accomplished)<br />

1<br />

Actuator part Actuator part<br />

present absent<br />

Actuator part<br />

present<br />

t < 1,5 s<br />

1/15

Presentation 1<br />

<strong>Safety</strong><br />

automation system <strong>solutions</strong> 1<br />

<strong>Preventa</strong> safety controllers<br />

Type XPS MC<br />

1<br />

Presentation<br />

<strong>Safety</strong> controllers XPS MCppX are designed to meet the requirements of safety<br />

applications requiring conformity to category 4 of standard EN 954-1.<br />

b They are available in 2 versions:<br />

v XPS MC16X with 16 inputs and 10 independent safety outputs,<br />

v XPS MC32X with 32 inputs and 10 independent safety outputs.<br />

XPS MC16X with screw connector XPS MCTS16<br />

v The safety inputs are supplied by the various control outputs, in such a manner so<br />

as to monitor for short-circuits between the inputs, short-circuits between each input<br />

and earth or the presence of residual voltages. The controller, assisted by the control<br />

outputs, continuously tests all the connected inputs. As soon as an error is detected<br />

on an input, all the outputs associated with this input are disconnected. <strong>Safety</strong><br />

outputs associated with other inputs remain active.<br />

v The 10 safety outputs comprise 4 contact guided relay outputs and 6 solid-state<br />

outputs.<br />

b <strong>Safety</strong> controllers XPS MC incorporate a Modbus communication interface for<br />

configuration and diagnostics. The Modbus interface enables the controller to be<br />

connected to a PC, PLC or an operator dialogue terminal.<br />

b Configuration of the safety functions is carried out <strong>using</strong> software XPS MCWIN.<br />

22 certified safety functions are available with this software and they are easily<br />

assignable to the safety outputs. The safety functions have multiple combination<br />

possibilities and various starting conditions.<br />

XPS MC32X with screw connector XPS MCTS32<br />

b <strong>Safety</strong> controllers XPS MCppX can be fitted as required:<br />

v with screw connectors XPS MCTSpp,<br />

v or with spring clip connectors XPS MCTCpp.<br />

v These connectors are to be ordered separately.<br />

<strong>Safety</strong> functions<br />

The safety functions are certified in accordance with category 4 of standard EN 9541-1<br />

and configurable in the XPS MC controller <strong>using</strong> software XPS MCWIN.<br />

Main safety functions<br />

Application schemes and functional diagrams, see pages:<br />

Emergency stop monitoring, with or without time delay,<br />

1/20 and 1/21<br />

1 or 2-channel wiring.<br />

Two-hand control (type III-C conforming to EN 574-1). 1/22<br />

Guard monitoring with 1 or 2 limit switches. 1/23 to 1/27<br />

Guard monitoring for injector presses and blowing machines. 1/28 to 1/29<br />

Magnetic switch monitoring. 1/30<br />

Sensing mat monitoring. 1/32<br />

Light curtain (type 4 conforming to EN 61496, relay or solid-state 1/34 to 1/37<br />

output) monitoring.<br />

Zero speed detection. 1/38<br />

Dynamic monitoring of hydraulic valves on linear presses. 1/39<br />

Monitoring safety stop at top dead centre on eccentric press. 1/40 to 1/43<br />

<strong>Safety</strong> time delays. 1/44<br />

"Muting" function of light curtains. 1/45<br />

Enabling switch monitoring, 2 or 3 contact. 1/46 and 1/47<br />

Characteristics:<br />

page 1/18<br />

1/16<br />

References, dimensions:<br />

page 1/19<br />

Functions:<br />

pages 1/20 to 1/47

Description 1<br />

<strong>Safety</strong><br />

automation system <strong>solutions</strong> 1<br />

<strong>Preventa</strong> safety controllers<br />

Type XPS MC<br />

1<br />

2<br />

6<br />

5<br />

4<br />

Description<br />

Front face of controllers XPS MCppX<br />

1 LED display and system diagnostics.<br />

2 Solid-state safety output and "muting" indicator light terminals.<br />

3 Power supply (c 24 V) and relay safety output terminals.<br />

4 Control output terminals for power supply to safety inputs and safety input<br />

terminals.<br />

5 RJ45 type connector.<br />

6 RESET button (reinitialisation).<br />

1<br />

3<br />

Controller XPS MC32X with screw connector<br />

5<br />

7 9<br />

LED details<br />

1<br />

2<br />

3<br />

4<br />

PWR<br />

CNF<br />

E In<br />

E Ex<br />

RUN<br />

COM<br />

6 8<br />

Illuminated display<br />

1 PWR: green LED, power on.<br />

2 CNF: yellow LED, on or flashing in configuration mode.<br />

3 E In: red LED, internal error.<br />

4 E Ex: red LED, external error.<br />

5 Run: green LED, on or flashing depending on service mode.<br />

6 COM: green LED, controller communicating via TER connection.<br />

7 green LEDs, solid-state outputs.<br />

8 green LEDs, relay outputs.<br />

9 green LEDs, inputs.<br />

Operator<br />

dialogue<br />

terminal<br />

(Magelis)<br />

Modbus<br />

PLC<br />

(Premium)<br />

Operator<br />

dialogue<br />

terminal<br />

(Magelis)<br />

1<br />

2<br />

Network architecture<br />

b <strong>Safety</strong> controllers XPS MCppX communicate on the Modbus network for<br />

diagnostics <strong>using</strong> an operator dialogue terminal (Magelis) or an industrial PLC<br />

(Premium).<br />

For direct connection to a Magelis operator dialogue terminal, use the following<br />

connection accessories:<br />

1 Adaptor XPS MCCPC,<br />

2 Connecting cable XBT Z968.<br />

XPS MC XPS MC XPS MC<br />

PC<br />

2<br />

Profibus DP<br />

1<br />

LA9 P307<br />

XPS MC<br />

b <strong>Safety</strong> controllers XPS MCppX communicate with a PC, running software<br />

XPS MCWIN, for configuration of the safety functions.<br />

Connection accessories:<br />

1 Adaptor XPS MCCPC,<br />

2 Connecting cable TSX PCX 1031.<br />

b <strong>Safety</strong> controllers XPS MCppX communicate on the Profibus DP network <strong>using</strong><br />

communication gateway LA9 P307.<br />

XPS MC<br />

Characteristics:<br />

page 1/18<br />

References, dimensions:<br />

page 1/19<br />

Functions:<br />

pages 1/20 to 1/47<br />

1/17

Characteristics 1<br />

<strong>Safety</strong><br />

automation system <strong>solutions</strong> 1<br />

<strong>Preventa</strong> safety controllers<br />

Type XPS MC<br />

1<br />

Characteristics<br />

Controller type<br />

XPS MC16X, XPS MC32X<br />

Product designed for max. use in safety related parts of<br />

Category 4 conforming to EN 954-1<br />

control systems<br />

Supply voltage V c 24 ± 20%<br />

Maximum consumption W 12<br />

Fuse protection A 16 gG (gl) max.<br />

Start button monitoring<br />

Yes/No (depending on configuration selected)<br />

Control circuit voltage<br />

28.8 V/13 mA (between input terminals C1-I1 to C8-I16)<br />

Calculation of wiring resistance RL Ω 100 max, maximum cable length: 2000 m (Between input terminals)<br />

Synchronisation time between inputs s Depending on configuration selected<br />

Outputs Relay Voltage reference Volt-free<br />

<strong>Safety</strong> circuit 2 N/O per function (4 N/O total) (13-14, 23-24, 33-34, 43-44)<br />

Breaking capacity in AC-15 VA C300: inrush 1800, maintained 180<br />

Breaking capacity in DC-13<br />

24 V/1.5 A L/R = 50 ms<br />

Thermal current (Ithe) for each<br />

group of 2 outputs<br />

A 6 for 1 output and 2 for the other, or 4 for both outputs.<br />

Current limit A Ith y 16 (with several relay output circuits simultaneously loaded)<br />

Output fuse protection A 4 gG (gl) or 6 fast acting<br />

Minimum current mA 10 (1)<br />

Minimum voltage V 17 (1)<br />

Solid-state Breaking capacity 24 V/2 A<br />

Destruction power<br />

c 24 V/2 A (for each safety output)<br />

<strong>Safety</strong> circuit 6 solid-state (O1, O2, O3, O4, O5, O6)<br />

Current limit A Ith y 6.5 (with several relay output circuits simultaneously loaded<br />

Electrical durability See page 1/60<br />

Response time on input opening ms < 20<br />

Rated insulation voltage (Ui) V 300 (degree of pollution 2 conforming to IEC 60647-5-1, DIN VDE 0110 parts 1 and 2)<br />

Rated impulse withstand voltage (Uimp.) kV 4 (overvoltage category III, conforming to IEC 60647-5-1, DIN VDE 0110 parts 1 and 2)<br />

LED indicators<br />

30 (XPS MC16X), 46 (XPS MC32X)<br />

Temperature Operating °C -10…+55<br />

Storage °C -25…+85<br />

Degree of protection<br />

IP 20 conforming to IEC 60529 (connector and enclosure)<br />

Connections Type (2) Separate plug-in screw connector<br />

XPS MCTSpp<br />

Separate plug-in spring clip connector<br />

XPS MCTCpp<br />

Power supply and relay output terminals<br />

1 conductor Without cable end Solid or flexible cable: 0.2…2.5 mm², AWG 24-12<br />

With cable end mm² Without bezel, flexible cable: 0.25…2.5<br />

mm² With bezel, flexible cable: 0.25…2.5<br />

2 conductors Without cable end mm² Solid or flexible cable: 0.2…1.5 –<br />

With cable end mm² Without bezel, flexible cable: 0.25…1.5 –<br />

mm² Double, with bezel, flexible cable: 0.5…1.5 Double, with bezel, flexible cable: 0.5…1<br />

Tightening torque of screw contacts Nm 0.5…0.6 –<br />

Wire stripping length mm 10<br />

Other terminals<br />

1 conductor Without cable end Solid or flexible cable: 0.14…1.5 mm², AWG 28-16<br />

With cable end mm² Without bezel, flexible cable: 0.25…1.5<br />

mm² With bezel, flexible cable: 0.25…0.5<br />

2 conductors Without cable end mm² Solid cable: 0.14…0.5<br />

–<br />

Flexible cable: 0.14…0.75<br />

With cable end mm² Without bezel, flexible cable: 0.25…0.34 –<br />

mm² Double, with bezel, flexible cable: 0.5 –<br />

Enclosure fixing (conforming to DIN EN 50022)<br />

Metal adaptor for fixing on standard 5 35 mm rail<br />

(1) The controller is also capable of switching low power loads (17 V/10 mA minimum) provided that the contact has not been used for switching high power loads,<br />

ca<strong>using</strong> possible contamination or wear of the gold layer on the contact tips.<br />

(2) To be ordered separately.<br />

Presentation:<br />

page 1/16<br />

Description:<br />

page 1/17<br />

References, dimensions:<br />

page 1/19<br />

Functions:<br />

pages 1/20 to 1/47<br />

1/18

References,<br />

dimensions 1<br />

<strong>Safety</strong> automation system <strong>solutions</strong> 1<br />

<strong>Preventa</strong> safety controllers<br />

Type XPS MC<br />

References<br />

<strong>Safety</strong> controllers (connector not included)<br />

Number of Number of outputs Reference Weight<br />

inputs Relay Solid-state<br />

kg<br />

16 4 6 XPS MC16X 0.820<br />

1<br />

32 4 6 XPS MC32X 0.840<br />

XPS MC16X<br />

with screw connector<br />

XPS MCTS16<br />

XPS MC32X<br />

with screw connector<br />

XPS MCTS32<br />

Connector (to be ordered separately)<br />

Description For use with Reference Weight<br />

kg<br />

Screw<br />

connectors<br />

XPS MC16X XPS MCTS16 0.080<br />

XPS MC32X XPS MCTS32 0.110<br />

Spring clip<br />

connectors<br />

XPS MC16X XPS MCTC16 0.080<br />

XPS MC32X XPS MCTC32 0.110<br />

TSX PCX 1031<br />

XPS MCCPC<br />

Accessories (to be ordered separately)<br />

Description Usage Length<br />

From To<br />

(m)<br />

Connecting<br />

cables<br />

XPS MCppX<br />

Reference<br />

Weight<br />

kg<br />

Magelis operator 2.5 XBT Z968 0.180<br />

dialogue terminal<br />

PC 2.5 TSX PCX 1031 0.170<br />

Adaptor Link between XPS MCppX and PC or XPS MCppX XPS MCCPC 0.011<br />

and Magelis operator dialogue terminal<br />

Configuration software CD-ROM<br />

XPS MCWIN 0.200<br />

For Windows 95, 98, NT, Me, 2000 and XP.<br />

Power supply unit c 24 V ABL 7RP2410 2.200<br />

Dimensions, mounting<br />

XPS MCppX<br />

(1)<br />

59<br />

16<br />

151,5<br />

74<br />

17<br />

= =<br />

40<br />

74<br />

6 139,5<br />

6<br />

(1) With connector XPS MCTSpp: 153 mm.<br />

With connector XPS MCTCpp: 151.4mm.<br />

Presentation:<br />

page 1/16<br />

Description:<br />

page 1/17<br />

Characteristics:<br />

page 1/18<br />

Functions:<br />

pages 1/20 to 1/47<br />

1/19

Functions 1<br />

<strong>Safety</strong><br />

automation system <strong>solutions</strong> 1<br />

<strong>Preventa</strong> safety controllers<br />

Type XPS MC<br />

1<br />

Emergency stop monitoring, with or without time delay, 1-channel wiring, with automatic start<br />

Application scheme<br />

230 V 230 V<br />

+ 24 V + 24 V<br />

Control<br />

outputs<br />

F1<br />

F2<br />

F3<br />

(1) (1) (1)<br />

S1 S2 S3<br />

Emer.<br />

stop<br />

1<br />

Emer.<br />

stop<br />

2<br />

Emer.<br />

stop<br />

3<br />

(2)<br />

A1<br />

C8 C7 C6 C5 C4 C3 C2 C1 I1 I2 I3 I4 … I16<br />

I17 … I32<br />

13 23 H1 33 43<br />

XPS MC<br />

T<br />

24 V<br />

5 V<br />

Logic<br />

µC 1<br />

K0<br />

Ter<br />

K1<br />

K3<br />

µC 2<br />

Channel<br />

1<br />

Channel<br />

2<br />

Channel<br />

1<br />

Channel<br />

2<br />

Channel<br />

1<br />

Channel<br />

2<br />

Channel<br />

1<br />

Channel<br />

2<br />

Channel<br />

1<br />

Channel<br />

2<br />

Channel<br />

1<br />

Channel<br />

2<br />

K2<br />

K4<br />

A2 GND GND GND<br />

O1 O2 O3 O4 O5 O6<br />

14 24 34 44<br />

Category 1<br />

emergency stop<br />

A shunt between the two terminals of an emergency stop will not be detected.<br />

Short-circuits between I1, I2, I3 will be detected.<br />

Category 0<br />

emergency stop<br />

0 V 0 V<br />

(1) Technical characteristics for maximum rating of fuses, see page 1/18.<br />

(2) Only applicable to XPS MC32X.<br />

Functional diagram<br />

Run Emergency stop Run Emergency stop Run<br />

Input<br />

Emergency stop 1<br />

Input<br />

Emergency stop 2<br />

Input<br />

Emergency stop 3<br />

Relay outputs K1/K2<br />

Stop category 0<br />

Relay outputs K3/K4<br />

Stop category 1<br />

tv = 0…300 s<br />

tv = 0…300 s<br />

Key<br />

0<br />

1<br />

tv = delay time<br />

Presentation:<br />

page 1/16<br />

1/20<br />

Characteristics:<br />

page 1/18<br />

References, dimensions:<br />

page 1/19

Functions (continued) 1<br />

<strong>Safety</strong><br />

automation system <strong>solutions</strong> 1<br />

<strong>Preventa</strong> safety controllers<br />

Type XPS MC<br />

Emergency stop monitoring, with or without time delay, 2-channel wiring, with start button<br />

Application scheme<br />

+ 24 V + 24 V<br />

1<br />

F1<br />

(1)<br />

Control<br />

outputs<br />

S1<br />

S2<br />

S3<br />

Emer.<br />

stop<br />

1<br />

Emer.<br />