Service Advisor Study Guide - Pro-Cut USA On-Car Brake Lathes

Service Advisor Study Guide - Pro-Cut USA On-Car Brake Lathes

Service Advisor Study Guide - Pro-Cut USA On-Car Brake Lathes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RMS for <strong>Service</strong> <strong>Advisor</strong>s<br />

for <strong>Pro</strong>-<strong>Cut</strong>’s Rotor Matching System<br />

Training & Marketing <strong>Pro</strong>gram 1/2<br />

You balance wheels. You match rotors.<br />

q<br />

Please complete this guide and take the<br />

<strong>Service</strong> <strong>Advisor</strong> Quiz for certification<br />

before your <strong>Pro</strong>-<strong>Cut</strong> Rep returns to complete<br />

installation of RMS.<br />

As your shop’s <strong>Service</strong> <strong>Advisor</strong>, you have a key role in understanding<br />

and selling Rotor Matching. Your expertise will help<br />

you communicate effectively with customers — and sell a service<br />

that makes you profits with every brake job.<br />

Key Points to Understand About <strong>Brake</strong> Work Today<br />

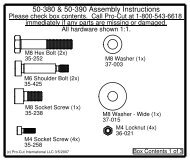

Our RMS Point-of-Sale<br />

materials will help you<br />

sell the service.<br />

Our premium stainless and aluminum rotor<br />

runout display model and countermat will<br />

help you show the value of Rotor Matching<br />

to your customers.<br />

1. First, with today’s vehicle braking assemblies it’s critical that all components<br />

are matched almost perfectly true for the best possible braking performance.<br />

According to most new vehicle manufacturers, brake rotors must rotate<br />

with less than half the thickness of a human hair (.002”) of lateral runout (wobble)<br />

in order for them to function safely and provide no unwanted noise or vibrations.<br />

<strong>Brake</strong>s spinning with more than that tiny amount of lateral runout will make<br />

contact with brake pads even when pads are not applied, wearing away<br />

at the brake rotor with every rotation. This results in thickness variation, which is<br />

the cause of most brake pedal pulsation complaints. Simply installing a new<br />

brake rotor or machining the rotor with a bench lathe will not ensure a true match<br />

between rotor and hub, and may result in a comeback for noise or pulsation.<br />

With RMS, your shop is able to computer-match brake rotors to each vehicle’s<br />

hub—ensuring a top-quality brake job for your customer. Selling Rotor<br />

Matching as a service is becoming common practice—just like<br />

balancing wheels.<br />

• 8.5” wide x 5.5” tall rotor model<br />

• 20 x 16 countermat<br />

2. Lateral runout in the face of the rotor can effectively “kick back” the caliper<br />

pistons so there is a longer travel distance for the brake pads to contact the<br />

rotor when the brake pedal is applied. This distance, although small, requires<br />

(CONTINUED ON PAGE 2)<br />

Becoming a Certified Rotor Matching<br />

Center assures your customers of<br />

your commitment to top-quality<br />

brake work.<br />

PRO-CUT 10 TECHNOLOGY DRIVE #4, W. LEBANON, NH 03784 <strong>USA</strong> P. 800.543.6618 / 603.298.5200 FAX. 603.298.8404 INFO@PROCUT<strong>USA</strong>.COM WWW.PROCUT<strong>USA</strong>.COM

RMS Launch <strong>Guide</strong> for <strong>Service</strong> <strong>Advisor</strong>s<br />

for <strong>Pro</strong>-<strong>Cut</strong>’s Rotor Matching System 2/2<br />

more time to overcome, increasing reaction time and making the stopping<br />

times and distances potentially longer.<br />

How RMS Benefits Your Shop<br />

Learn more.<br />

Visit www.procutusa.com to<br />

learn more about <strong>Pro</strong>-<strong>Cut</strong>’s<br />

Rotor Matching System.<br />

Your shop may choose to sell this service a la carte like wheel balancing, with<br />

a flat charge per rotor, or by increasing the overall price of your brake job<br />

(check with your Shop Manager to see which method your shop will use.) The<br />

RMS procedure is identical for 3-lug Smart <strong>Car</strong>s on up to 10-lug dual-wheel 1-ton<br />

trucks, requiring a consistent 7–10 minutes per rotor. You can easily estimate jobs<br />

and control work flow through the shop while booking more hours for all types of<br />

work. If you bill a flat rate, any vehicles with captured rotors (which include trucks<br />

like F150 and Colorado/ Canyons) will be a labor sale home-run for your shop.<br />

How RMS Benefits Your Customer<br />

1 Rotor matching will eliminate the chance of future pedal pulsation,<br />

giving customers quicker, quieter, smoother stopping from the minute<br />

they leave your shop.<br />

2 A new rotor replacement alone cannot ensure a match between the rotor and<br />

hub without substantial additional labor. Even a new rotor will develop<br />

pulsation in as little as 5,000 miles if not matched properly.<br />

3 Use the OEM Summary <strong>Guide</strong> (in packet) to show customers the list of auto<br />

manufacturers who have made the <strong>Pro</strong>-<strong>Cut</strong> lathe OEM Essential Equipment<br />

for their dealers. Become familiar with the list of manufacturers, and let your<br />

customers know your shop provides the same level of service and accuracy<br />

with rotor matching that today’s vehicles require.<br />

With the above information in mind, you are ready to take the <strong>Service</strong> <strong>Advisor</strong><br />

Quiz for certification to sell <strong>Pro</strong>-<strong>Cut</strong>’s Rotor Matching System. Your Rep will<br />

discuss selling RMS with you and sign your certificate. Please ask your Rep for<br />

Point-of-Sale material display tips, and help your Shop Manager get the Computer<br />

Op-Code for Rotor Matching ready!<br />

Now you’re ready to sell the service!<br />

PRO-CUT 10 TECHNOLOGY DRIVE #4, W. LEBANON, NH 03784 <strong>USA</strong> P. 800.543.6618 / 603.298.5200 FAX. 603.298.8404 INFO@PROCUT<strong>USA</strong>.COM WWW.PROCUT<strong>USA</strong>.COM