TEA PROCESSING Introduction: A small tea processing ... - smallB

TEA PROCESSING Introduction: A small tea processing ... - smallB

TEA PROCESSING Introduction: A small tea processing ... - smallB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TEA</strong> <strong>PROCESSING</strong><br />

<strong>Introduction</strong>:<br />

A <strong>small</strong> <strong>tea</strong> <strong>processing</strong> unit that will satisfy the need of the <strong>small</strong> <strong>tea</strong> growers has a very good<br />

market prospect. The <strong>small</strong> cottage <strong>tea</strong> industries established in the states like Meghalaya and<br />

Assam have been running successfully as a profit earning venture. The quality of the product<br />

produced by these units have been found to be better and thus greatly in demand than the large<br />

unit’s produce.<br />

Market Potential:<br />

The processed <strong>tea</strong> (CTC Black Tea) produced by the only unit at Sarupathar (Assam) under<br />

Dhansiri under Golaghat District is being sold like hot cakes in Sarupathar locality.<br />

The Cottage made CTC Tea has great demand among the users due to its special manufacturing<br />

process, which imparts its quality and aroma. Besides, cottage organic Tea (CTC and Orthodox),<br />

Bio-Tea may be produced, which will have great market potential. So a couple of cottage <strong>tea</strong><br />

factory could be set up in concentrated <strong>tea</strong> growing areas which will have a s<strong>tea</strong>dy market for its<br />

products.<br />

MANUFACTURING PROCESS :<br />

1. Withering :<br />

Natural Withering :<br />

The fresh <strong>tea</strong> leaves are laid out in thin layers on tats staked one above another<br />

and dried in the fresh air for at least 20 hours.<br />

Artificial Withering :<br />

The leaves are laid out in layers of up to 20cm. thick on a mesh. The meshes are<br />

placed in a tunnel ; through which warm air mixed with fresh air is forced. This<br />

considerably reduces the total withering time. Around 60-62% residual moisture<br />

suitable for <strong>tea</strong> <strong>processing</strong> of the withered green leaves.<br />

2. Breaking Up :<br />

A circular table fitted in the center with a cone and across the surface with slats called<br />

battens. A jacket, or bottomless circular box with a pressure cap, stands a top of the<br />

table. Table and jacket rotate eccentrically in opposite directions, and the leaf placed in<br />

the jacket is twisted and rolled over the cone and battens in a fashion similar to land<br />

rolling.<br />

(C) CTC Method (Crushing, <strong>tea</strong>ring and curling) :<br />

This machine consists of two separated metal rollers, placed close together and revolving<br />

at unequal speeds, which cut, <strong>tea</strong>r and twist the leaf. CTC machines are widely used, for<br />

example in Assam.<br />

(D) Fermentation :<br />

During fermentation, the oxidation process which had begun during rolling is continued.<br />

Fermentation takes place in separate fermentation rooms, which need to be kept<br />

extremely clean to avoid bacterial infection of the <strong>tea</strong>. The <strong>tea</strong> leaves are placed in 3.5 –<br />

7.5 cm. Layers on aluminium trays. The thickness of the layers depends on the room<br />

temperature. As soon as the <strong>tea</strong> has acquired a copper red colour, the correct degree of<br />

fermentation has been reached, and the process must be halted by drying.<br />

196

Drying :<br />

The drying process carried on a 4 plates system vanician typed drier.Hot air up to 90<br />

degree C. is blown against the leaves, which should have reached 80- degree C. by the<br />

time drying has been completed, in order for the polyphenol oxidize enzyme to be<br />

properly inactivated. The moisture content should be reduced to 3.5% whereby the<br />

aroma becomes established and the leaves take on their typical black coloration.<br />

MACHINERY :<br />

Plant & Machinery :<br />

(a) CTC Machine (3CUT) 3 Pair 8” Roller (8-10-8 TPI)<br />

with 3 HP motor complete.<br />

(b) Furnace including heat exchange & Chimney.<br />

(c) Drier (VaniceanType)<br />

includes Blower with 1 HP motor.<br />

(d) Humidifier.<br />

(e) Pivot Balance.<br />

(f) Spring Balance.<br />

(g) Rolling Table-30 kg. batch (with 1 HP motor).<br />

(h) 12.5 KVA Diesel Generator set.<br />

Forced Green Leaves de-humidification Chamber,<br />

Capacity 600 green leaves holding<br />

(j) Fiber Separator.<br />

Total :<br />

SUGGESTED CAPACITY:<br />

Rs. 8.40 lakhs.<br />

600 kg/day for 200 days working days in a year because <strong>tea</strong> leaves are grown seasonally.<br />

Number of shift per day is one.<br />

INFRASTRUCTURE :<br />

The major infrastructure requirements are :<br />

LOCATIONS:<br />

Building 2000 sq.ft.<br />

Power<br />

20 KW<br />

Water<br />

200 litres/day.<br />

This unit can be set up at any <strong>tea</strong> growing areas or where green leaves are available readily, in<br />

NER including Sikkim.<br />

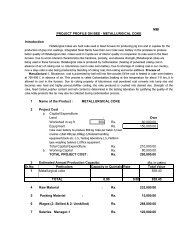

TOTAL CAPITAL REQUIREMENT :<br />

The project cost comprising fixed capital and margin money on working capital is Rs 16.82<br />

lakhs.<br />

Rs. Lakhs.<br />

Fixed Capital :<br />

Land & Building 5.50<br />

Plant & Equipments 8.40<br />

Misc. Fixed Assets. 1.20<br />

Preliminary & Pre-op.expenses. 0.70<br />

Total (A) : 15.80<br />

197

Working Capital :<br />

Raw materials 2 months. 2.27<br />

Finished goods. 1 week. 0.56<br />

Working expenses 1 month 0.24<br />

Receivables 7 days. 1.02<br />

Total-(B) : 4.09<br />

Note :<br />

Working capital may be financed as –<br />

Bank finance : Rs. 3.07 lakhs.<br />

Margin Money : Rs. 1.02 lakhs.<br />

Total<br />

Rs 4.09 lakhs<br />

MEANS OF FINANCING :<br />

The project cost of Rs 16.82 lakhs may be financed as under –<br />

Rs. Lakhs<br />

Promoter’s contribution(35%) 5.89<br />

Term loan(65%) 10.93<br />

Total : 16.82<br />

OPERATING EXPENSES :<br />

The annual operating expenses are estimated at Rs.16.24 lakhs as under :<br />

Rs. Lakhs<br />

Raw materials – 1,20,000 Kgs<br />

Green leaves @ Rs 8/- per Kg. 9.60<br />

Utilities 0.86<br />

Wages & salaries 2.00<br />

Other overheads 0.24<br />

Selling expenses @ 5% on annual<br />

Sales. 1.02<br />

Interest 1.68<br />

Depreciation-10% 0.84<br />

Total : 16.24<br />

SALES REALISATION :<br />

Sl.No. Particulars Amount in<br />

lakhs<br />

1. Green leaves <strong>processing</strong> per year<br />

= 600 kg. per day x 200 days<br />

= 1,20,000 kg. of leaves.<br />

= Total Production of Made Tea<br />

@ 20% yield.<br />

20.40<br />

= 24000 Kg of Made Tea x @ Rs.85/Kg<br />

PROFITABILITY :<br />

Based on the sales realization and the operating expenses, the profit at 100% capacity utilization<br />

would be Rs 4.16 lakhs per year. This works out to a return on investment of 25%. The unit would<br />

break even at about 58% of the rated capacity.<br />

198

HIGHLIGHTS :<br />

The major highlights of the project are as follows :<br />

Total capital requirement : Rs 16.82 lakhs.<br />

Promoter’s contribution : Rs 5.89 lakhs<br />

Annual sales realization : Rs 20.40 lakhs<br />

Annual operating expenses : Rs 16.24 lakhs<br />

Annual profit (Pre-tax) : Rs 4.16 lakhs<br />

Pre-tax return on sales. : 20%<br />

Break-Even Point. : 58%<br />

No. of persons employed. : 10<br />

MACHINERY SUPPLIER :<br />

M/s Avery India Ltd.<br />

12 B, Russel Street,<br />

P.Box – 9329<br />

Kolkata – 700 071.<br />

M/s Bansal Engg. & Steel Co. Pvt. Ltd.,<br />

Rotary Road,<br />

Dibrugarh,<br />

Assam..<br />

199