April 1993 - American Bonanza Society

April 1993 - American Bonanza Society

April 1993 - American Bonanza Society

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

lock in place to protect the control<br />

sutfaces from ever-present dangers.<br />

Since I've been unable to find<br />

good inf0n11ation on this matter, J did<br />

my own Iitlle test during the last annual.<br />

\Vith the aircraft on jacks, the<br />

nose w heel was rotated with the gust<br />

lock bOlh in and out. We could neither<br />

feel nor measure any Significant<br />

difference in the fo rce required to<br />

turn the nose w heel. This suggests<br />

that towing the ai rcraft (which<br />

requires turning [he nose wheel) with<br />

the gust lock installed poses no threat<br />

to control linkages.<br />

Second. I've had knowledgeable<br />

old ABS salts tell me that when my<br />

gas gaps (Shaw Aero type) start closing<br />

hard and little cracks show upon<br />

the large O-rings, that it's time [Q<br />

replace the rings. I have found, however,<br />

tha( even new rings treated with<br />

Parker Iiale O-ring Lube show cracking<br />

in a very short time and that caps<br />

close ha rd because the earning<br />

surfaces are galled, or more commonly,<br />

lack lubrication.<br />

A drop o r two of silicone, or a dab<br />

of O-ring lube on the bearing surface<br />

where the gas cap lever rides against<br />

the top of the cap housing will work<br />

wonders. In fact, without some small<br />

lubrication here, it can be very difficult<br />

to close the caps or check for proper<br />

adjllSUTIent of the cap. On more than<br />

one occasion. I've seen ov,TJlers putting<br />

the muscle to caps to close them. This<br />

can lead to galling and is easily solved<br />

by a drop of lube. - Robert Can· , ABS<br />

19257, East lansing, Mich.<br />

Checking belt tension. In the December<br />

1992 issue, both Noml Colvin and<br />

Lew Gage had some conunems on<br />

checking belt tension on those engines<br />

that have belt driven genera(Qrs or<br />

alternators. I would like to add my two<br />

cents worth. In these inflationary times,<br />

it may even be worth four cenrs.<br />

EveI)' so often, it is worthwhile to<br />

pay atte ntion to what your enenlies are<br />

saying. In this case, the enemy is<br />

Lycoming. Lycoming Service Instruction<br />

' 0. 1129A describes an extremely<br />

easy, neat and reliable method for<br />

checking belt tension.<br />

You simply use a torque wrench<br />

and derennine the torque necessary to<br />

make the genermor or alternator pulley<br />

slip against the belt. Since l ycoming<br />

did not take the trouble to copyright<br />

the ir service instruction, I shall quote it<br />

directly.<br />

a. Apply a lOrque indicating wrench<br />

lO the nut that anaches the pulley to the<br />

generalOf and tum it in a clockwise direction.<br />

Observe the torque shown on<br />

the wrench at the instant the pulley<br />

slips.<br />

b. Check the torque indicated in step<br />

(a) with torque specified in the follow~<br />

ing chan. Adjust belt tension accordingly.<br />

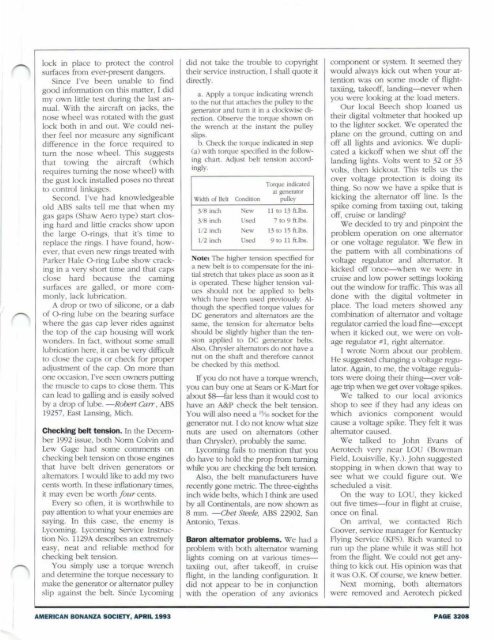

Torque indicJted<br />

at generator<br />

Width of Belt Condition pulley<br />

3/ 8 inch New 11 to 13 ft.lbs.<br />

3/ 8 inch Used 7 to 9 rUbs.<br />

1/2 inch New 13 to 15 ft.lbs.<br />

1/2 inch Used 9 (0 11 ft.lbs.<br />

Note: The higher tension specified for<br />

a new belt is to compensate fo r the inilial<br />

stretch 1hm takes place as soon as it<br />

is operated. These higher (cnsion va l<br />

LIes should not be applied LO belts<br />

which have been used preViously. Although<br />

the specified torque values for<br />

DC generators and alre mators are the<br />

same, the tension for alternator belts<br />

should be slighlly higher than the tension<br />

applied [0 DC gener-dtor belts.<br />

Also, Chrysler alternators do not have a<br />

nut on the shaft and therefore cannol<br />

be checked by this method.<br />

If you do not have a torque wrench,<br />

you can buy one at Sears or K-Mart for<br />

about $8-far less than it would cost to<br />

have an A&P dleck the belt tension.<br />

You w ill also need a ' y" socket for the<br />

generator nul. I do not know what size<br />

nurs are used on alte rnators (other<br />

than Chrysle r), probably the same.<br />

Lycoming fa ils to mention that you<br />

do have to hold the prop from turning<br />

while you are checking the belt tension.<br />

Also, the belt manufacturers have<br />

recently gone meLric. The three-eighths<br />

inch w ide belts, which I think are used<br />

by all Continentals, are now shown as<br />

8 mm. -Chet Steele, ABS 22902, San<br />

Antonio, Texas.<br />

Baron alternator problems. We had a<br />

problem with both alternator waming<br />

lights coming on at various timestaxiing<br />

out, afte r takeoff, in cmise<br />

night, in the landing configuration. It<br />

did not appear to be in conjunction<br />

with the operation of any avionics<br />

component or system. It seemed they<br />

would always kick out when your attcntion<br />

was on some mooe of flighttaxiing,<br />

takeoff, landing-never when<br />

you were looking at the load meters.<br />

Our local Beech shop loaned us<br />

their digital voltmeter that hooked up<br />

to the lighter socket. We operated d,e<br />

plane o n the ground. cutting on and<br />

off all lights and avionics. We duplicated<br />

a kickoff when we shut off tl,e<br />

landing lights. Volts went to 32 o r 33<br />

volts, the n kickoul. This tells us the<br />

over voltage protection is doing its<br />

thing. $0 now we h~lve a spike that is<br />

kicking dle alternator off line. Is d,e<br />

spike coming from taxiing out, taking<br />

off, cruise or landing?<br />

We decided to try and pinpoint the<br />

problem operation on one alternator<br />

or one voltage regulawr. \Vle flew in<br />

the pattern with all combinations of<br />

voltage regulator and alternator. It<br />

kicked off once-when we were in<br />

cruise and low power settings looking<br />

out the window for traffic. This was all<br />

done with the digital voltmete r in<br />

place. The load meters showed any<br />

combination of alternator and voltage<br />

regulator carried the load fine-except<br />

when it kicked out, we were on vohage<br />

regulator ':1, right alternator.<br />

I wrote Norm about our problem.<br />

He suggested changing a voltage regulator.<br />

Again, to me, dle voltage regulators<br />

were doing their thing~ver voltage<br />

trip when we get over voltage spikes.<br />

We talked to our local avionics<br />

shop to see if they had any ideas on<br />

which avionics component would<br />

cause a voltage spike. They felt it was<br />

alternator caused.<br />

We talked to John Evans of<br />

Aerotech very ncar LOU (Bowman<br />

Field , Louisville, Ky. ). John suggested<br />

stopping in when down (hat way to<br />

see w hat we could figu re o u t. \Ve<br />

scheduled a visit.<br />

On the way to LO U, they kicked<br />

alit five times-four in flight at cruise,<br />

once on fmai.<br />

On arrival, we contaaed Rich<br />

Coover, service manager for Kennlcky<br />

Flying Service (KFS). Rich wanted to<br />

run up the plane whUe it was still hot<br />

from the flight. We could not get anything<br />

to kick out. His opinion \vas that<br />

it was O.K. Of course, we knew bener.<br />

Next morning, both alternators<br />

were removed and Aerotech picked<br />

AMERICAN BONANZA SOCIETY, APRIL <strong>1993</strong><br />

PAGE 3208