Fixture MicroThread - Astra Tech

Fixture MicroThread - Astra Tech

Fixture MicroThread - Astra Tech

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

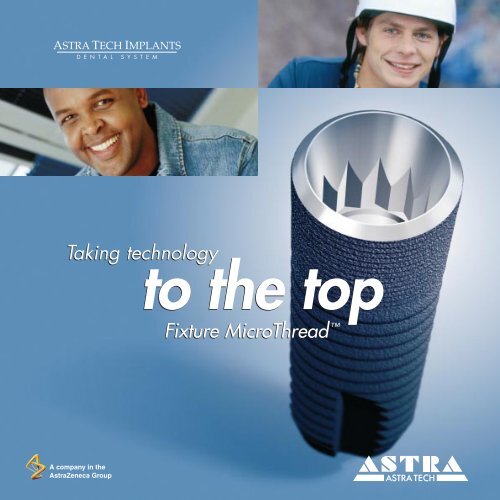

Taking technology<br />

to the top<br />

<strong>Fixture</strong> <strong>MicroThread</strong>

Now Introdu<br />

Follow the thread<br />

– for top performance!<br />

The <strong>Astra</strong> <strong>Tech</strong> <strong>Fixture</strong> ST was the first dental<br />

implant to employ a landmark innovation in<br />

implant technology – the patented microthread<br />

retention elements at the fixture neck. Clinical<br />

and preclinical documentation on the microthreads<br />

has proved it to be uniquely successful<br />

in maintaining the marginal bone. 1<br />

This success is the rationale for introducing<br />

microthreads on all <strong>Astra</strong> <strong>Tech</strong> implants under<br />

the brand name <strong>Fixture</strong> <strong>MicroThread</strong> – a<br />

concept that will continue to revolutionize the<br />

design and use of dental implants.<br />

2

A major innovation backed by extensive research,<br />

experience, and documentation...<br />

cing <strong>Fixture</strong> <strong>MicroThread</strong> <br />

<strong>MicroThread</strong> – success defined!<br />

<strong>Fixture</strong> <strong>MicroThread</strong> is a self-tapping implant. Its This<br />

key features are a fine, shallow microthread on<br />

the cervical part of the fixture, plus a coarser<br />

thread on the lower portion. The whole fixture<br />

has the unique and well-documented surface<br />

1-5, 7, 9-18<br />

texture – TiOblast.<br />

combination of macro- and micro-retention<br />

elements provides a superior bone-to-implant<br />

interlock, with an increased capacity to withstand<br />

functional load and maintain the marginal bone.<br />

<strong>Fixture</strong> <strong>MicroThread</strong> – One line<br />

of fixtures for all requirements<br />

3.5 4.0 ST 4.5 ST 5.0 ST<br />

<strong>Fixture</strong> <strong>MicroThread</strong> is an implant for all clinical situations –<br />

for single-tooth replacement, for the partially or totally<br />

edentulous jaw, for narrow and wide spaces, and for both<br />

the mandible and the maxilla.<br />

Three of the <strong>MicroThread</strong> fixtures – 4.0 ST, 4.5 ST, and<br />

5.0 ST – have an internal ‘double hex’ design, providing<br />

indexing of the abutments.<br />

3

Stimulate bone formation!<br />

<strong>Fixture</strong> <strong>MicroThread</strong> – designed to carry load<br />

Like all bone in the human body, the jawbone needs<br />

stimulation to regenerate. Thus, a dental implant<br />

should exert a favorable level of mechanical stress<br />

on the surrounding bone when loaded.<br />

<strong>Astra</strong> <strong>Tech</strong> has conducted in-depth studies<br />

of the effect of various thread profiles on the<br />

surrounding bone tissue. This research resulted in<br />

the development of the optimized <strong>MicroThread</strong><br />

concept, which plays an important role in tissue<br />

13, 14<br />

response to the implant.<br />

Documented experimental and clinical research<br />

clearly shows that the presence of the <strong>MicroThread</strong><br />

retention elements at the fixture neck results in<br />

exceptionally uniform stress distribution and low<br />

stress peaks.<br />

This is the fundamental reason why <strong>MicroThread</strong><br />

preserves the marginal bone and actually stimulates<br />

1, 15<br />

bone regeneration.<br />

<strong>Fixture</strong> <strong>MicroThread</strong> <br />

– the only implant design that<br />

• is designed to carry load.<br />

• increases the functional load bearing<br />

capacity at least threefold.<br />

• optimizes the immediate loading<br />

protocol.<br />

4

FEA (Finite Element Analysis) graphics<br />

showing optimized and evenly distributed<br />

stress at the implant neck – induced by the<br />

<strong>MicroThread</strong> retention elements.<br />

5

Eliminate “black triangles”<br />

Do not accept bone loss<br />

A high and maintained marginal bone level not<br />

only ensures secure anchoring of the implant, but<br />

also promotes and supports healthy soft tissues.<br />

<strong>Fixture</strong> <strong>MicroThread</strong> therefore preserves the<br />

integrity of both hard and soft tissues, which is<br />

fundamental for long-lasting esthetics.<br />

With <strong>Fixture</strong> <strong>MicroThread</strong> you have no need<br />

to compromise.<br />

For you, the dentist, a satisfied patient is<br />

the primary goal of dental implant treatment.<br />

To be satisfied, the patient demands a functional<br />

result and long-lasting esthetics without “black<br />

triangles”.<br />

The key to optimal esthetics and functional outcome<br />

is maintenance of the marginal bone.<br />

Healthy bone and<br />

soft tissue means no<br />

“black triangles”,<br />

giving optimal<br />

esthetics.<br />

6

Baseline x-ray<br />

showing <strong>Fixture</strong><br />

<strong>MicroThread</strong> in<br />

place.<br />

X-ray at 5 years<br />

showing preservation<br />

of high<br />

levels of marginal<br />

bone.<br />

Baseline x-ray<br />

showing <strong>Fixture</strong><br />

<strong>MicroThread</strong><br />

installed in a<br />

periodontically<br />

compromised<br />

situation.<br />

X-ray 5 years later<br />

showing bone<br />

regeneration.<br />

CLINICAL PERFORMANCE<br />

– A 5-year prospective study<br />

0.5<br />

Marginal bone (mm)<br />

The thread design<br />

provides excellent<br />

bone-to-implant<br />

contact.<br />

0.0<br />

– 0.5<br />

Baseline<br />

5 years<br />

Palmer et al., 2000<br />

Long-term data confirm<br />

the integrity of the<br />

bone and thereby the<br />

maintained soft tissue<br />

appearance. 1<br />

7

The New <strong>MicroThread</strong> Package<br />

<strong>Fixture</strong> <strong>MicroThread</strong> is supplied premounted<br />

in an innovative sterile package design<br />

that facilitates easy handling.<br />

Lift out the implant, manually<br />

or with the Contra Angle, and<br />

place it directly into the<br />

prepared installation site!<br />

8

The various fixture sizes<br />

are now color-coded, for<br />

ease of use.<br />

<strong>Fixture</strong> <strong>MicroThread</strong> Length mm:<br />

3.5 mm<br />

4.0 mm ST<br />

4.5 mm ST<br />

5.0 mm ST<br />

8 9 11 13 15 17 19<br />

9

Advantage <strong>Astra</strong> <strong>Tech</strong>!<br />

<strong>MicroThread</strong>, view from electron microscope.<br />

TiOblast, as seen in the electron microscope.<br />

Conical Seal Design.<br />

<strong>MicroThread</strong> <br />

The unique design for optimized load transfer and preservation<br />

of the marginal bone.<br />

This provides increased durability and stability of the<br />

implant, leading to predictable esthetic and functional<br />

1, 10-12, 16<br />

results.<br />

TiOblast <br />

The fixture has a well-defined rough surface, TiOblast,<br />

with proven biomechanical benefits for bone formation<br />

and implant retention. The excellent properties of the<br />

TiOblast surface have been verified in animal and human<br />

1-5, 7, 9, 15-17<br />

histology studies and in long-term clinical trials.<br />

Conical Seal Design <br />

The conical relation between fixture and abutment is the<br />

6, 8, 19-21<br />

backbone of the <strong>Astra</strong> <strong>Tech</strong> Dental Implant System.<br />

It provides strength and a tight seal between the two<br />

components, minimizing the risk of micro-leakage and<br />

component loosening. 20-21 It also distributes loads over a<br />

larger surface area, reducing stress peaks. The self-guiding<br />

nature of the Conical Seal Design simplifies handling and<br />

ensures easy and precise seating of the components.<br />

Our Mission<br />

The <strong>Astra</strong> <strong>Tech</strong> Dental Implant System is based on<br />

years of scientific research and clinical documentation.<br />

The result is a unique system with a perfect balance<br />

of Simplicity, Reliability, and Esthetics proven in<br />

long-term clinical studies. <strong>Astra</strong> <strong>Tech</strong> is committed to<br />

forming long-term working relationships with dental<br />

professionals, offering products and services that<br />

improve the quality of life.<br />

10

Comparison with other dental implants<br />

Compared to flat-top dental implants<br />

without microthreads, <strong>Astra</strong> <strong>Tech</strong><br />

Dental Implants offer you:<br />

• higher marginal bone levels.<br />

• increased bone stability and quality.<br />

• healthier soft tissues with no black<br />

triangles.<br />

• no microleakage between<br />

components.<br />

Bone level<br />

<strong>Astra</strong> <strong>Tech</strong><br />

implants<br />

Bone level<br />

other<br />

implants<br />

1. Palmer, R. M. et al.<br />

A 5-Year Prospective Study of <strong>Astra</strong> Single Tooth<br />

Implant. Clin Oral Impl Res 2000;11:179-182<br />

2. Gotfredsen, K. et al.<br />

Histomorphometric and Removal Torque Analysis for<br />

TiO 2 -Blasted Titanium Implants.<br />

Clin Oral Impl Res 1992;3:77-84<br />

3. Ericsson, I. et al.<br />

A Histomorphometric Evaluation of Bone-to-Implant<br />

Contact on Machine-Prepared and Roughened<br />

Titanium Dental Implants.<br />

Clin Oral Impl Res 1994;5:202-206<br />

4. Abrahamsson, I. et al.<br />

The Peri-Implant Hard and Soft Tissues at Different<br />

Implant Systems. Clin Oral Impl Res 1996;7:212-219<br />

5. Ivanoff, C-J. et al.<br />

Histologic Evaluation of the Bone Integration of TiO 2<br />

Blasted and Turned Titanium Microimplants in<br />

Humans. Clin Oral Impl Res 2001;12:128-134<br />

6. Makkonen, T. A. et al.<br />

A 5-Year Prospective Clinical Study of <strong>Astra</strong> <strong>Tech</strong><br />

Dental Implants Supporting Fixed Bridges or<br />

Overdentures in the Edentulous Mandible.<br />

Clin Oral Impl Res 1997;8:469–475<br />

7. Åstrand, P. et al.<br />

<strong>Astra</strong> <strong>Tech</strong> and Brånemark System Implants: A<br />

Prospective 5-Year Comparative Study. Results after<br />

One Year. Clin Impl Dent Rel Res 1999;1:1:17-26<br />

8. Gotfredsen, K. et al.<br />

Implant-Supported Mandibular Overdentures Retained<br />

with Ball or Bar Attachments: A Randomized<br />

Prospective 5-Year Study.<br />

Int J Prosthodont 2000;13:125-130<br />

9. van Steenberghe, D. et al.<br />

A Prospective Split-Mouth Comparative Study of Two<br />

Screw-shaped Self-Tapping Pure Titanium Implant<br />

Systems. Clin Oral Impl Res 2000;11:202-209<br />

10. Norton, M.<br />

The <strong>Astra</strong> <strong>Tech</strong> Single-Tooth Implant System: A Report<br />

on 27 Consecutively Placed and Restored Implants.<br />

Int J Periodont Rest Dent 1997;17:575-583<br />

11. Norton, M.<br />

Marginal Bone Levels at Single Tooth Implants with a<br />

Conical <strong>Fixture</strong> Design. The Influence of Surface<br />

Macro- and Microstructure.<br />

Clin Oral Impl Res 1998;9:91-99<br />

12. Puchades-Roman, L. et al.<br />

A Clinical, Radiographic, and Microbiologic<br />

Comparison of <strong>Astra</strong> <strong>Tech</strong> and Brånemark Single Tooth<br />

Implants. Clin Impl Dent Rel Res 2000;2:2:78-84<br />

13. Hansson, S. et al.<br />

On the Role of the Thread Profile for Bone Implants<br />

with Special Emphasis on Dental Implants. In Towards<br />

an Optimized Dental Implant and Implant Bridge<br />

Design: A Biomechanical Approach. Thesis Hansson S,<br />

Chalmers University of <strong>Tech</strong>nology, Göteborg, 1997<br />

14. Hansson, S.<br />

The Implant Neck: Smooth or Provided with Retention<br />

Elements. Clin Oral Implant Res 1999;10:394-405<br />

15. Rasmusson, L. et al.<br />

Effects of Implant Design and Surface on Bone<br />

Regeneration and Implant Stability: An Experimental<br />

Study in the Dog Mandible.<br />

Clin Impl Dent Rel Res 2001;3:1:2-8<br />

16. Cooper, L. et al.<br />

A Multicenter 12-Month Evaluation of Single-Tooth<br />

Implants Restored 3 Weeks After 1-Stage Surgery.<br />

Int J Oral Maxillofac Implants 2001;16:182-192<br />

17. Gotfredsen, K. et al.<br />

A Prospective 5-Year Study of Fixed Partial Prostheses<br />

Supported by Implants with Machined and TiO 2 -<br />

Blasted Surface. J Prosthodont 2001;10:1:2-7<br />

18. Hansson, S<br />

Surface Roughness Parameters as Predictors of<br />

Anchorage Strength in Bone: A Critical Analysis.<br />

J Biomechanics 2000;33:1297-1303<br />

19. Hansson, S<br />

Implant-Abutment Interface: Biomechanical Study of<br />

Flat Top versus Conical.<br />

Clin Impl Dent Rel Res 2000;2:1:33-41<br />

20. Norton, M<br />

An in vitro Evaluation of the Strength of an Internal<br />

Conical Interface Compared to a Butt Joint Interface in<br />

Implant Design. Clin Oral Impl Res 1997;8:290-298<br />

21. Norton, M<br />

In vitro Evaluation of the Strength of the Conical<br />

Implant-to-Abutment Joint in Two Commercially<br />

Available Systems.<br />

J Prosthet Dent 2000;83:567-571<br />

11

75253-USX-0208<br />

<strong>Fixture</strong> <strong>MicroThread</strong> <br />

• Increased bone quality and stability<br />

• Healthier and stable soft tissues<br />

• Higher success rate<br />

• Improved esthetic results<br />

• More clinical options<br />

Denmark<br />

<strong>Astra</strong> <strong>Tech</strong> A/S, Husby Allé 19, DK-2630 Taastrup.<br />

Tel: +45 43 71 33 77. Fax: +45 43 71 78 65.<br />

www.astratech.dk<br />

Finland<br />

<strong>Astra</strong> <strong>Tech</strong> Oy, PL 96, FIN-02231 Espoo.<br />

Tel: +358 9 8676 1626. Fax: +358 9 8044 128.<br />

www.astratech.fi<br />

France<br />

Société de Matériel Médical, <strong>Astra</strong> <strong>Tech</strong> France,<br />

Groupe Pharmaceutique <strong>Astra</strong>Zeneca,<br />

7, rue E & A Peugeot, FR-92500 Rueil-Malmaison.<br />

Tel: +33 1 41 39 02 40. Fax: +33 1 41 39 02 44.<br />

www.astratech.fr<br />

Germany<br />

<strong>Astra</strong> <strong>Tech</strong> GmbH, An der kleinen Seite 8, DE-65604 Elz.<br />

Tel: +49 6431 9869 0. Fax: +49 6431 9869 500.<br />

www.astratech.de<br />

Italy<br />

<strong>Astra</strong> <strong>Tech</strong> S.p.A<br />

Via M. Luther King n. 38/2, IT-40132 Bologna.<br />

Tel: +39 051 641 6511. Fax: +39 051 641 7742.<br />

www.astratech.it<br />

The Netherlands<br />

<strong>Astra</strong> <strong>Tech</strong> BV, Signaalrood 55, NL-2718 SG Zoetermeer.<br />

Tel: +31 79 360 1950. Fax: +31 79 362 3748.<br />

www.astratech.nl<br />

Norway<br />

<strong>Astra</strong> <strong>Tech</strong> AS, Postboks 160, NO-1471 Lørenskog.<br />

Tel: +47 67 92 05 50. Fax: +47 67 92 05 60.<br />

www.astratech.no<br />

Spain<br />

<strong>Astra</strong> <strong>Tech</strong> S.A.,<br />

Calle Ciencias nº 73 derecha. Nave 9, Polígono<br />

Industrial Pedrosa, ES-08908 L´Hospitalet de Llobregat.<br />

Tel. Servicio al cliente: +34.902.101.558.<br />

Tel: +34.932.643.560. Fax: +34.933.363.231.<br />

www.es.astratech.com<br />

Sweden<br />

<strong>Astra</strong> <strong>Tech</strong> AB, P.O. Box 14, SE-431 21 Mölndal.<br />

Tel: +46 31 776 30 00. Fax: +46 31 776 30 10.<br />

www.astratech.se<br />

United Kingdom<br />

<strong>Astra</strong> <strong>Tech</strong> Ltd., Brunel Way, Stonehouse, Glos GL10 3SX.<br />

Tel: +44 1453 791763. Fax: +44 1453 791001.<br />

www.astratechuk.com<br />

USA<br />

<strong>Astra</strong> <strong>Tech</strong> Inc.<br />

430 Bedford Street, Suite 100, Lexington, MA 02420.<br />

Tel: +1 781 861 7707. Fax: +1 781 861 7787.<br />

www.astratechusa.com<br />

Japan<br />

<strong>Astra</strong> <strong>Tech</strong> Division, <strong>Astra</strong>Zeneca K.K.<br />

Tokyo Regional Office<br />

Koraku Mori Bldg. 11F, 1-4-14, Koraku<br />

Bunkyo-ku, Tokyo 112-0004.<br />

Tel: +81 3 5840 1113. Fax: +81 3 5840 1160.<br />

Other Markets<br />

<strong>Astra</strong> <strong>Tech</strong> AB, Export Department,<br />

P.O. Box 14, SE-431 21 Mölndal, Sweden.<br />

Tel: +46 31 776 30 00. Fax: +46 31 776 30 23.<br />

www.astratech.com<br />

/Printed in Sweden by Typografia Olsén<br />

<strong>Astra</strong> <strong>Tech</strong> AB, P.O. Box 14, SE-431 21 Mölndal, Sweden. Tel: +46 31 776 30 00. Fax: +46 31 776 30 10. www.astratech.com