development of the detector based on cvd - diamond for use in t

development of the detector based on cvd - diamond for use in t

development of the detector based on cvd - diamond for use in t

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DEVELOPMENT OF A DETECTOR BASED ON A CVD-DIAMOND FOR<br />

THE USE IN RADIOTHERAPY FACILITIES<br />

S.V. Akul<strong>in</strong>ichev, V.S. Klenov, L.V. Kravchuk, S.G. Lebedev, A.V. Feschenko, V.E. Yants<br />

Institute <strong>for</strong> Nuclear Research <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> Russian Academy <str<strong>on</strong>g>of</str<strong>on</strong>g> Sciences<br />

60-th October Anniversary Prospect, 7A, Moscow, 117312<br />

E-mail: klenov@<strong>in</strong>r.ru<br />

High radiati<strong>on</strong> hardness, chemical resistance, high temperature operati<strong>on</strong> capabilities stimulate a grow<strong>in</strong>g <strong>in</strong>terest<br />

to <strong>use</strong> diam<strong>on</strong>d materials as <str<strong>on</strong>g>detector</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> i<strong>on</strong>iz<strong>in</strong>g radiati<strong>on</strong>. Samples <str<strong>on</strong>g>of</str<strong>on</strong>g> CVD-diam<strong>on</strong>d materials <strong>in</strong> sizes 4×3 mm<br />

and 4×1 mm with thickness from 50 micr<strong>on</strong>s up to 500 micr<strong>on</strong>s have been grown <strong>in</strong> INR RAS us<strong>in</strong>g a DC glow discharge<br />

<strong>in</strong> a mixture <str<strong>on</strong>g>of</str<strong>on</strong>g> gases CH4/H2 <strong>on</strong> molybdenum substrates.<br />

PACS: 29.40.Wk; 81.05.T<br />

1. INTRODUCTION<br />

A number <str<strong>on</strong>g>of</str<strong>on</strong>g> unique properties <str<strong>on</strong>g>of</str<strong>on</strong>g> diam<strong>on</strong>d such as<br />

extremely high radiati<strong>on</strong> hardness, chemical resistance<br />

aga<strong>in</strong>st all chemicals, absolute n<strong>on</strong>-toxicity call <strong>for</strong> an<br />

<strong>in</strong>creas<strong>in</strong>g <strong>in</strong>terest to <strong>use</strong> diam<strong>on</strong>d materials as <str<strong>on</strong>g>detector</str<strong>on</strong>g>s<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> i<strong>on</strong>iz<strong>in</strong>g radiati<strong>on</strong> operat<strong>in</strong>g <strong>in</strong> hostile envir<strong>on</strong>ments<br />

or <strong>in</strong> c<strong>on</strong>diti<strong>on</strong>s, impos<strong>in</strong>g special requirements to stability<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> measurement <str<strong>on</strong>g>of</str<strong>on</strong>g> a doze, <strong>for</strong> example, <strong>in</strong> medical<br />

<strong>in</strong>stallati<strong>on</strong>s <strong>for</strong> radio<str<strong>on</strong>g>the</str<strong>on</strong>g>rapy. Moreover, <str<strong>on</strong>g>the</str<strong>on</strong>g> atomic<br />

number <str<strong>on</strong>g>of</str<strong>on</strong>g> diam<strong>on</strong>d Z = 6 that is close to <str<strong>on</strong>g>the</str<strong>on</strong>g> effective<br />

atomic number <str<strong>on</strong>g>of</str<strong>on</strong>g> a s<str<strong>on</strong>g>of</str<strong>on</strong>g>t tissue Z = 7.4, so <str<strong>on</strong>g>the</str<strong>on</strong>g> diam<strong>on</strong>d<br />

is a nearly tissue equivalent, that allows avoid<strong>in</strong>g energy<br />

dependent correcti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>detector</str<strong>on</strong>g> signal. Initially,<br />

natural diam<strong>on</strong>ds with suitable electr<strong>on</strong>ic properties<br />

were <strong>use</strong>d <strong>in</strong> radiati<strong>on</strong> detecti<strong>on</strong> [1]. The ma<strong>in</strong> disadvantage<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> natural diam<strong>on</strong>d <str<strong>on</strong>g>detector</str<strong>on</strong>g>s is a high cost due<br />

to extremely rare <str<strong>on</strong>g>detector</str<strong>on</strong>g>-grade natural diam<strong>on</strong>d (Type<br />

IIa), which limits <str<strong>on</strong>g>the</str<strong>on</strong>g> availability <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>se <str<strong>on</strong>g>detector</str<strong>on</strong>g>s and<br />

moreover, electr<strong>on</strong>ic properties <str<strong>on</strong>g>of</str<strong>on</strong>g> diam<strong>on</strong>d st<strong>on</strong>es with<strong>in</strong><br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> Type IIa category can vary str<strong>on</strong>gly. There<strong>for</strong>e,<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> producti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> sufficiently cheap diam<strong>on</strong>d plates with<br />

sizes at least 4 mm and thickness 50…500 µm with sufficient<br />

quality to build <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>detector</str<strong>on</strong>g> is ra<str<strong>on</strong>g>the</str<strong>on</strong>g>r an urgent<br />

problem.<br />

The promis<strong>in</strong>g technology <strong>for</strong> syn<str<strong>on</strong>g>the</str<strong>on</strong>g>sis <str<strong>on</strong>g>of</str<strong>on</strong>g> diam<strong>on</strong>d<br />

materials is <str<strong>on</strong>g>the</str<strong>on</strong>g> Chemical Vapour Depositi<strong>on</strong> (CVD)<br />

technology, which allows grow<strong>in</strong>g diam<strong>on</strong>d material<br />

plates <strong>in</strong> c<strong>on</strong>trollable vacuum with specified thickness<br />

and sizes, which are determ<strong>in</strong>ed by sizes <str<strong>on</strong>g>of</str<strong>on</strong>g> substrates<br />

and durati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> process. However, <str<strong>on</strong>g>the</str<strong>on</strong>g> CVD-diam<strong>on</strong>d<br />

has a polycrystall<strong>in</strong>e structure with crystallites<br />

sizes about 10…20% <str<strong>on</strong>g>of</str<strong>on</strong>g> thickness <str<strong>on</strong>g>of</str<strong>on</strong>g> grown plates, and<br />

crystallites bounders could act as <str<strong>on</strong>g>the</str<strong>on</strong>g> traps and decrease<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> charge collecti<strong>on</strong> efficiency [2, 3].<br />

2. APPARATUS FOR CVD-DIAMOND<br />

PLATES SYNTHESIS<br />

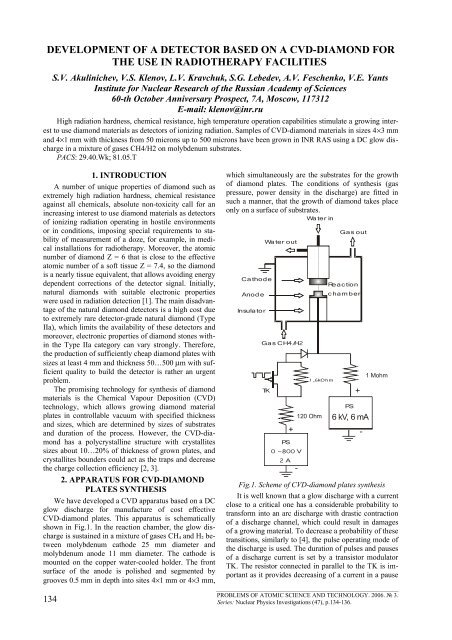

We have developed a CVD apparatus <str<strong>on</strong>g>based</str<strong>on</strong>g> <strong>on</strong> a DC<br />

glow discharge <strong>for</strong> manufacture <str<strong>on</strong>g>of</str<strong>on</strong>g> cost effective<br />

CVD-diam<strong>on</strong>d plates. This apparatus is schematically<br />

shown <strong>in</strong> Fig.1. In <str<strong>on</strong>g>the</str<strong>on</strong>g> reacti<strong>on</strong> chamber, <str<strong>on</strong>g>the</str<strong>on</strong>g> glow discharge<br />

is susta<strong>in</strong>ed <strong>in</strong> a mixture <str<strong>on</strong>g>of</str<strong>on</strong>g> gases CH 4 and H 2 between<br />

molybdenum cathode 25 mm diameter and<br />

molybdenum anode 11 mm diameter. The cathode is<br />

mounted <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> copper water-cooled holder. The fr<strong>on</strong>t<br />

surface <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> anode is polished and segmented by<br />

grooves 0.5 mm <strong>in</strong> depth <strong>in</strong>to sites 4×1 mm or 4×3 mm,<br />

134<br />

which simultaneously are <str<strong>on</strong>g>the</str<strong>on</strong>g> substrates <strong>for</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> growth<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> diam<strong>on</strong>d plates. The c<strong>on</strong>diti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> syn<str<strong>on</strong>g>the</str<strong>on</strong>g>sis (gas<br />

pressure, power density <strong>in</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> discharge) are fitted <strong>in</strong><br />

such a manner, that <str<strong>on</strong>g>the</str<strong>on</strong>g> growth <str<strong>on</strong>g>of</str<strong>on</strong>g> diam<strong>on</strong>d takes place<br />

<strong>on</strong>ly <strong>on</strong> a surface <str<strong>on</strong>g>of</str<strong>on</strong>g> substrates.<br />

Water <strong>in</strong><br />

Cathode<br />

Anode<br />

Insulator<br />

Water out<br />

Gas CH4/H2<br />

TK<br />

+<br />

PS<br />

0 - 800 V<br />

2 A<br />

-<br />

1 ,6kOhm<br />

120 Ohm<br />

Gas out<br />

Reacti<strong>on</strong><br />

chamber<br />

+<br />

PS<br />

6 kV, 6 mA<br />

-<br />

1 Mohm<br />

Fig.1. Scheme <str<strong>on</strong>g>of</str<strong>on</strong>g> CVD-diam<strong>on</strong>d plates syn<str<strong>on</strong>g>the</str<strong>on</strong>g>sis<br />

It is well known that a glow discharge with a current<br />

close to a critical <strong>on</strong>e has a c<strong>on</strong>siderable probability to<br />

trans<strong>for</strong>m <strong>in</strong>to an arc discharge with drastic c<strong>on</strong>tracti<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> a discharge channel, which could result <strong>in</strong> damages<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> a grow<strong>in</strong>g material. To decrease a probability <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>se<br />

transiti<strong>on</strong>s, similarly to [4], <str<strong>on</strong>g>the</str<strong>on</strong>g> pulse operat<strong>in</strong>g mode <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> discharge is <strong>use</strong>d. The durati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> pulses and pa<strong>use</strong>s<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> a discharge current is set by a transistor modulator<br />

TK. The resistor c<strong>on</strong>nected <strong>in</strong> parallel to <str<strong>on</strong>g>the</str<strong>on</strong>g> TK is important<br />

as it provides decreas<strong>in</strong>g <str<strong>on</strong>g>of</str<strong>on</strong>g> a current <strong>in</strong> a pa<strong>use</strong><br />

____________________________________________________________<br />

PROBLEMS OF ATOMIC SCIENCE AND TECHNOLOGY. 2006. № 3.<br />

Series: Nuclear Physics Investigati<strong>on</strong>s (47), p.134-136.

not to zero, but up to a magnitude ~0.15I nom, which facilitates<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> subsequent transiti<strong>on</strong> to <str<strong>on</strong>g>the</str<strong>on</strong>g> rated current<br />

and rises stability <str<strong>on</strong>g>of</str<strong>on</strong>g> operati<strong>on</strong>. Fur<str<strong>on</strong>g>the</str<strong>on</strong>g>rmore, <str<strong>on</strong>g>the</str<strong>on</strong>g> transistor<br />

modulator TK provides fast (~10 μs) switch<strong>in</strong>g-<str<strong>on</strong>g>of</str<strong>on</strong>g>f a<br />

discharge current source <strong>in</strong> case <str<strong>on</strong>g>the</str<strong>on</strong>g> discharge starts to<br />

trans<strong>for</strong>m <strong>in</strong>to an arc mode and a current exceeds a preset<br />

value. The additi<strong>on</strong>al power supply with a c<strong>on</strong>stant<br />

voltage <str<strong>on</strong>g>of</str<strong>on</strong>g> 6 kV is c<strong>on</strong>nected to <str<strong>on</strong>g>the</str<strong>on</strong>g> discharge gap <strong>in</strong> series<br />

with 1 MOhm resistor <strong>for</strong> provid<strong>in</strong>g a discharge igniti<strong>on</strong><br />

<strong>in</strong> case <str<strong>on</strong>g>of</str<strong>on</strong>g> accidental ext<strong>in</strong>cti<strong>on</strong>.<br />

Syn<str<strong>on</strong>g>the</str<strong>on</strong>g>sis <str<strong>on</strong>g>of</str<strong>on</strong>g> CVD-diam<strong>on</strong>d plates was carried out<br />

under <str<strong>on</strong>g>the</str<strong>on</strong>g> follow<strong>in</strong>g c<strong>on</strong>diti<strong>on</strong>s <strong>in</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> reacti<strong>on</strong> chamber:<br />

typical gas mixture – 2.5%CH 4 <strong>in</strong> H 2, gas pressure<br />

300 Torr, discharge voltage 540 V, discharge current<br />

1.7 A, current duty factor 95%.<br />

Oscillogram <str<strong>on</strong>g>of</str<strong>on</strong>g> discharge current is shown <strong>in</strong> Fig.2.<br />

Material growth rate <strong>in</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>se c<strong>on</strong>diti<strong>on</strong>s was around<br />

12…15 μm/hour.<br />

crystallites borders can serve as traps <strong>for</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> charges <strong>in</strong>duced<br />

<strong>in</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>detector</str<strong>on</strong>g> by i<strong>on</strong>iz<strong>in</strong>g particles.<br />

Fig.3. Scann<strong>in</strong>g electr<strong>on</strong> microscope (SEM) image <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

growth side 100 µm thickness plate<br />

80<br />

70<br />

Fig.2. Oscillogram <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> discharge current<br />

3. CHARACTERIZATION OF THE GROWN<br />

MATERIAL<br />

In depositi<strong>on</strong> runs lasted from 3 to 35 hours CVD diam<strong>on</strong>d<br />

plates with <str<strong>on</strong>g>the</str<strong>on</strong>g> sizes 4×1 mm and 4×3 mm and<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> thickness from 50 to 500 μm have been grown. After<br />

depositi<strong>on</strong> and cool<strong>in</strong>g down <str<strong>on</strong>g>the</str<strong>on</strong>g> CVD-diam<strong>on</strong>d<br />

plates can be easily detached from <str<strong>on</strong>g>the</str<strong>on</strong>g> substrates due to<br />

different <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal expansi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> diam<strong>on</strong>d and molybdenum.<br />

The grown material has a polycrystall<strong>in</strong>e structure<br />

with a clearly visible <strong>in</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> cracked samples crystallites<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> columnar shape el<strong>on</strong>gated al<strong>on</strong>g <str<strong>on</strong>g>the</str<strong>on</strong>g> growth directi<strong>on</strong>.<br />

The facets <str<strong>on</strong>g>of</str<strong>on</strong>g> about 0.1…0.2 plate thickness can be observed<br />

<strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> crystallites at a growth side <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> plate.<br />

Fig.3 shows <str<strong>on</strong>g>the</str<strong>on</strong>g> image <str<strong>on</strong>g>of</str<strong>on</strong>g> growth side <str<strong>on</strong>g>of</str<strong>on</strong>g> plate with<br />

thickness 100 µm (scann<strong>in</strong>g electr<strong>on</strong> microscope). Fig.4<br />

shows <str<strong>on</strong>g>the</str<strong>on</strong>g> spectra <str<strong>on</strong>g>of</str<strong>on</strong>g> Raman scatter<strong>in</strong>g analysis, which<br />

was per<strong>for</strong>med with arg<strong>on</strong> laser <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> wavelength<br />

λ =514 nm, narrow diam<strong>on</strong>d peak at 1333 cm-1 is clear<br />

visible.<br />

X-ray diffracti<strong>on</strong> analysis <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> plates was made us<strong>in</strong>g<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> diffractometer DRON-3 with CuKα1 l<strong>in</strong>e with<br />

λ = 0.154057 nm. Fig.5 shows a XRD pattern measured<br />

at <str<strong>on</strong>g>the</str<strong>on</strong>g> growth side <str<strong>on</strong>g>of</str<strong>on</strong>g> 500 μm plate.<br />

4. CVD-DIAMOND DETECTION PER-<br />

FORMANCE<br />

The surface morphology <str<strong>on</strong>g>of</str<strong>on</strong>g> plates from a growth<br />

side and from a substrate side is essentially different.<br />

Whereas <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> growth side <str<strong>on</strong>g>the</str<strong>on</strong>g> typical sizes <str<strong>on</strong>g>of</str<strong>on</strong>g> crystallites<br />

make up tens <str<strong>on</strong>g>of</str<strong>on</strong>g> micr<strong>on</strong>, <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> substrate side <str<strong>on</strong>g>the</str<strong>on</strong>g>se<br />

sizes do not exceed a micr<strong>on</strong>. The numerous defects <strong>on</strong><br />

Intensity, a.u.<br />

60<br />

50<br />

40<br />

30<br />

20<br />

1200 1300 1400 1500 1600<br />

Raman shift, cm -1<br />

Fig.4. Raman spectra at growth surface <str<strong>on</strong>g>of</str<strong>on</strong>g> CVD diam<strong>on</strong>d<br />

plate<br />

Arbitrary units,N<br />

10000<br />

8000<br />

6000<br />

4000<br />

2000<br />

0<br />

(111)<br />

(220)<br />

20 40 60 80 100 120<br />

Angles, 2Q<br />

(311)<br />

Fig.5. XRD pattern <strong>for</strong> 500 µm plate<br />

(400)<br />

In order to decrease an <strong>in</strong>fluence <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>se traps, <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

coplanar type detect<strong>in</strong>g device [5] was made with both<br />

electrodes located <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> growth side <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> plate. The<br />

distance between <str<strong>on</strong>g>the</str<strong>on</strong>g> electrodes makes up 200 micr<strong>on</strong>.<br />

135<br />

____________________________________________________________<br />

PROBLEMS OF ATOMIC SCIENCE AND TECHNOLOGY. 2006. № 3.<br />

Series: Nuclear Physics Investigati<strong>on</strong>s (47), p.134-136.

For measurement <str<strong>on</strong>g>of</str<strong>on</strong>g> efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> collecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

charges <strong>in</strong>duced by <strong>in</strong>cident alpha-particles, <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>in</strong>stallati<strong>on</strong><br />

schematically represented <strong>on</strong> Fig.6 has been assembled.<br />

238Pu alpha source<br />

Bias<br />

Voltage<br />

M/Chan.<br />

Analyzer<br />

CVD<br />

diam <strong>on</strong>d<br />

plate<br />

Charge/Sens.<br />

Pream p.<br />

Shap<strong>in</strong>g<br />

Am p.<br />

Fig.6. A schematic diagram <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> charge collecti<strong>on</strong> efficiency<br />

measurement<br />

We <strong>use</strong>d a 238Pu α-particles source which emits<br />

α-particles with <str<strong>on</strong>g>the</str<strong>on</strong>g> energy Eα = 5.5 MeV.<br />

The estimated range <str<strong>on</strong>g>of</str<strong>on</strong>g> this particle <strong>in</strong> a diam<strong>on</strong>d is<br />

~ 13 µm. The total charge Q<strong>in</strong>d, <strong>in</strong>duced by α-particle<br />

<strong>in</strong> a diam<strong>on</strong>d Q<strong>in</strong>d = eEα/ε, where ε = 13 eV is <str<strong>on</strong>g>the</str<strong>on</strong>g> energy<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> electr<strong>on</strong>-hole creati<strong>on</strong> <strong>in</strong> diam<strong>on</strong>d. The charge<br />

collected by n<strong>on</strong>-uni<strong>for</strong>m <strong>in</strong>ter-electrode field <str<strong>on</strong>g>of</str<strong>on</strong>g> bias<br />

voltage feed at entrance <str<strong>on</strong>g>of</str<strong>on</strong>g> charge sensitive preamplifier<br />

followed by a shap<strong>in</strong>g amplifier (Schlumberger Type<br />

7129) and multichannel analyzer (Norland 5300). Pulse<br />

height specters were measured as differences <str<strong>on</strong>g>of</str<strong>on</strong>g> counts<br />

with and without α-source <strong>for</strong> excepti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> electr<strong>on</strong>ic<br />

noise <str<strong>on</strong>g>of</str<strong>on</strong>g> a system. Pulse height spectra <strong>for</strong> a bias voltage<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> 40 V are shown <strong>in</strong> Fig.7. The charge collecti<strong>on</strong> efficiency<br />

was estimated as a ratio <str<strong>on</strong>g>of</str<strong>on</strong>g> collected and <strong>in</strong>duced<br />

charges and comes to around 1%.<br />

5. CONCLUSION<br />

Our measurements have dem<strong>on</strong>strated that relatively<br />

cheap CVD diam<strong>on</strong>d, produced by glow discharge, is<br />

suitable <strong>for</strong> detect<strong>in</strong>g <str<strong>on</strong>g>of</str<strong>on</strong>g> charged particles. Fur<str<strong>on</strong>g>the</str<strong>on</strong>g>r <strong>in</strong>vestigati<strong>on</strong>s<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> radiati<strong>on</strong> hardness and stability should<br />

be made <strong>in</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> radiological center <str<strong>on</strong>g>of</str<strong>on</strong>g> INR RAS <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

beams <str<strong>on</strong>g>of</str<strong>on</strong>g> 200 MeV prot<strong>on</strong>s and 6 MeV phot<strong>on</strong>s.<br />

Counts (a.u.)<br />

4000<br />

3000<br />

2000<br />

1000<br />

0<br />

0 20 40 60 80 100<br />

Channel number<br />

Fig.7. Pulse height spectra <strong>for</strong> bias voltage 40 V<br />

ACKNOWLEDGMENTS<br />

Special thanks are given to I.I. Vlasov (GPI RAS)<br />

<strong>for</strong> per<strong>for</strong>m<strong>in</strong>g <str<strong>on</strong>g>of</str<strong>on</strong>g> Raman analysis and V. Vlasenko<br />

(CryoLab, MSU) <strong>for</strong> SEM images.<br />

REFERENCES<br />

1. S.F. Kozlov, E.A. K<strong>on</strong>orova, Y.A. Kuznetsov et<br />

al. // IEEE Trans. Nucl. Sci. 1977, NS-24, p.235.<br />

2. C. Bauer, I. Baumann, C. Colledani et al. // Recent<br />

results from RD-42 Diam<strong>on</strong>d Detector Collaborati<strong>on</strong><br />

// Nucl. Instr. and Methods. 1996,<br />

A383, p.64-74.<br />

3. T. Bacci, E. Borchi, M. Bruzzi et al. Syn<str<strong>on</strong>g>the</str<strong>on</strong>g>sis <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

low leakage current chemical vapour depositi<strong>on</strong><br />

(CVD) diam<strong>on</strong>d <strong>for</strong> particle detecti<strong>on</strong> // Nucl.<br />

Physics B (Proc. Suppl.). 1998, v.61B, p.303-<br />

310.<br />

4. S. Sciort<strong>in</strong>o, S. Lagomars<strong>in</strong>o, F. Pieralli et al.<br />

Polycrystall<strong>in</strong>e diam<strong>on</strong>d syn<str<strong>on</strong>g>the</str<strong>on</strong>g>sis by means <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

high power pulsed plasma glow discharge CVD<br />

// Diam<strong>on</strong>d and Rel. Materials. 2002, v.11,<br />

p.573-578.<br />

5. A. Galbiati, M.B.H. Breese, A.P. Knights et al.<br />

Characterizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a coplanar CVD diam<strong>on</strong>d radiati<strong>on</strong><br />

<str<strong>on</strong>g>detector</str<strong>on</strong>g> // Nucl. Instr. and Methods.<br />

2001, v.A466, p.52-57.<br />

РАЗРАБОТКА ДЕТЕКТОРА НА ОСНОВЕ CVD-АЛМАЗА ДЛЯ ИСПОЛЬЗОВАНИЯ<br />

В УСТАНОВКАХ ЛУЧЕВОЙ ТЕРАПИИ<br />

С.В. Акулиничев, В.С. Кленов, Л.В. Кравчук, С.Г. Лебедев, А.В. Фещенко, В.Э. Янц<br />

Высокая радиационная стойкость, стойкость к химическим воздействиям, температурная стабильность<br />

вызывают повышенный интерес к использованию алмазных материалов в качестве детекторов ионизирующих<br />

излучений. Образцы CVD-алмазных материалов размерами 4×3 и 4×1 мм толщиной от 50 до 500 мкм<br />

выращены в ИЯИ РАН методом газофазного осаждения в тлеющем разряде в смеси газов СН 4/Н 2 на подложках<br />

из молибдена.<br />

РОЗРОБКА ДЕТЕКТОРА НА ОСНОВІ CVD-АЛМАЗУ ДЛЯ ВИКОРИСТАННЯ<br />

В УСТАНОВКАХ ПРОМЕНЕВОЇ ТЕРАПІЇ<br />

С.В. Акулінічев, В.С. Кльонов, Л.В. Кравчук, С.Г. Лебедєв, А.В. Фещенко, В.Є. Янц<br />

Висока радіаційна стійкість, стійкість до хімічних впливів, температурна стабільність викликають<br />

підвищений інтерес до використання алмазних матеріалів як детектори іонізуючих випромінювань. Зразки<br />

CVD-алмазних матеріалів розмірами 4×3 та 4×1 мм товщиною від 50 до 500 мкм вирощені в ІЯІ РАН<br />

методом газофазного осадження в жевріючому розряді в суміші газів СН 4/Н 2 на підкладках з молібдену.<br />

136