Managing HFE in Projects - PDO

Managing HFE in Projects - PDO

Managing HFE in Projects - PDO

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Shell Global Solutions<br />

Confidential<br />

OGP Project Services<br />

User Guide<br />

Project Value Process No.13: <strong>Manag<strong>in</strong>g</strong> Human Factor Eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong> <strong>Projects</strong>

OG.03.30714<br />

User Guide<br />

Project Value Process No. 13<br />

<strong>Manag<strong>in</strong>g</strong> Human Factor Eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong> <strong>Projects</strong><br />

Custodian: R. Huisman Shell Global Solutions, OGNL-OGP/1<br />

Owner: H. Goudsmit Shell Global Solutions, OGNL-OGP<br />

Keywords: Project Management, Value Process, <strong>HFE</strong><br />

Confidential<br />

This document is made available subject to the condition that the recipient will neither use nor disclose the contents except as agreed <strong>in</strong> writ<strong>in</strong>g<br />

with the copyright owner. Copyright is vested <strong>in</strong> Shell Global Solutions International B.V., The Hague.<br />

© Shell Global Solutions International B.V., 2003. All rights reserved.<br />

Neither the whole nor any part of this document may be reproduced or distributed <strong>in</strong> any form or by any means (electronic, mechanical,<br />

reprographic, record<strong>in</strong>g or otherwise) without the prior written consent of the copyright owner.<br />

Shell Global Solutions<br />

Shell Global Solutions is a trad<strong>in</strong>g style used by a network of technology companies of the Royal Dutch/Shell Group.

OG.03.30714 1 Confidential<br />

Document History:<br />

Date Issue Reason for change Author Name / Ref.Ind. Approved Name / Ref.Ind.<br />

Signature<br />

May<br />

2003<br />

A<br />

Approved for<br />

Implementation<br />

H. Clarijs,<br />

OGNL-OGP/8<br />

H. Goudsmit,<br />

OGNL-OGP<br />

The controlled copy of this document is held by Shell Global Solutions, OGP Project Support Group.<br />

All paper copies are uncontrolled.

OG.03.30714 2 Confidential<br />

Table of Contents<br />

1. INTRODUCTION 3<br />

2. OVERVIEW 4<br />

2.1 OBJECTIVES 4<br />

2.2 SYSTEMATIC APPROACH 4<br />

2.3 BENEFITS AND COST OF APPLYING EMIS ® 8<br />

3. WHEN 10<br />

4. HOW / WHY 11<br />

4.1 <strong>HFE</strong> AWARENESS (FED-1) 11<br />

4.2 <strong>HFE</strong> DESIGN ANALYSIS (FED-2) 11<br />

4.3 <strong>HFE</strong> IMPLEMENTATION (FED-3) 12<br />

4.4 <strong>HFE</strong> SUPPORT (IMPLEMENTATION) 12<br />

5. WHAT 13<br />

5.1 ACTIONS AND DELIVERABLES 13<br />

5.2 CONSIDERATIONS IN APPLICATION OF THE PROCESS 13<br />

6. WHO 14<br />

6.1 PROJECT MANAGER 14<br />

6.2 <strong>HFE</strong> COORDINATOR 14<br />

6.3 <strong>HFE</strong> ENGINEER 14<br />

7. APPLICABLE KPI’S 15<br />

7.1 PROCESS RELATED KPIS: 15<br />

7.2 END RESULT RELATED KPIS 15<br />

8. TOOLS 16<br />

9. DEFINITIONS / REFERENCES 17<br />

APPENDIX A: OVERVIEW OF EMIS ® 18<br />

APPENDIX B: <strong>HFE</strong> - OVERVIEW OF ACTIVITIES FOR EACH PROJECT PHASE 19<br />

APPENDIX C-1: <strong>HFE</strong> – ACTIVITY MATRIX DURING FED-1 20<br />

APPENDIX C-2: <strong>HFE</strong> – ACTIVITY MATRIX DURING FED-2 21<br />

APPENDIX C-3: <strong>HFE</strong> – ACTIVITY MATRIX DURING FED-3 22

OG.03.30714 3 Confidential<br />

1. INTRODUCTION<br />

Project Value Processes (PVPs) are a series of facilitated work processes to assist Shell Global Solutions<br />

staff <strong>in</strong> develop<strong>in</strong>g and implement<strong>in</strong>g capital projects. The use of PVPs is a requirement for all projects<br />

executed under the responsibility of the Shell Global Solutions OGP bus<strong>in</strong>ess group as def<strong>in</strong>ed <strong>in</strong> ‘OGP<br />

Governance: Project Development and Implementation’ (Ref 0). These PVPs assist project managers,<br />

project eng<strong>in</strong>eers and others <strong>in</strong>volved <strong>in</strong> the development and implementation of capital projects to<br />

create maximum ‘value’ for the project through fit-for-purpose designs, strategies and plans.<br />

The purpose of this User Guide is to provide the Project Team with guidel<strong>in</strong>es and relevant <strong>in</strong>formation<br />

for the correct execution of this Project Value Process. In addition, it will assists <strong>in</strong> creat<strong>in</strong>g an<br />

awareness of relevant aspects of the value process and transferr<strong>in</strong>g knowledge on the subject to other<br />

parties, such as project sponsors, stakeholders, contractors, etc.<br />

The ‘product’ result<strong>in</strong>g from the application of PVPs should be viewed as an ‘agreement’ between those<br />

parties that were actively engaged <strong>in</strong> execut<strong>in</strong>g these value processes. This agreement complements or<br />

ref<strong>in</strong>es the already agreed scope, objectives and plans for the project <strong>in</strong>to more detailed and precise<br />

description or def<strong>in</strong>ition.<br />

As PVPs are an <strong>in</strong>tegral element of OGP’s bus<strong>in</strong>ess process for projects, maximum benefits are derived<br />

from us<strong>in</strong>g them with relevant facilitation and <strong>in</strong> comb<strong>in</strong>ation with the Project Development and<br />

Implementation Process and Project Guides.

OG.03.30714 4 Confidential<br />

2. Overview<br />

2.1 Objectives<br />

Human Factors Eng<strong>in</strong>eer<strong>in</strong>g (<strong>HFE</strong>) or ergonomics eng<strong>in</strong>eer<strong>in</strong>g (which can be considered synonyms), is<br />

the process of <strong>in</strong>tegrat<strong>in</strong>g human capabilities <strong>in</strong> the design of products, work places or work systems<br />

(plant/facility). <strong>HFE</strong> focuses on the <strong>in</strong>teraction between people and their work<strong>in</strong>g environment. The<br />

objective is safe, healthy and effective people <strong>in</strong> comb<strong>in</strong>ation with efficient work systems, which<br />

translates <strong>in</strong>to strong operational performance.<br />

People are a major factor <strong>in</strong> determ<strong>in</strong><strong>in</strong>g the success of a bus<strong>in</strong>ess, especially where this <strong>in</strong>volves<br />

complex manufactur<strong>in</strong>g or process<strong>in</strong>g activities. This is <strong>in</strong> spite of advances over the last few years <strong>in</strong><br />

key areas of technology, such as comput<strong>in</strong>g, process <strong>in</strong>strumentation and control, automation and even<br />

robotics.<br />

Successful companies are aware that operators and other such personnel are large determ<strong>in</strong>ants of the<br />

efficiency of work systems. The effective adaptation of the technical systems to human capacities, e.g.<br />

<strong>in</strong> operat<strong>in</strong>g and ma<strong>in</strong>tenance tasks, is a precondition to a strong operational performance. When<br />

design<strong>in</strong>g systems it is important to consider <strong>HFE</strong> aspects at an appropriate stage of design, along with<br />

all economic and technical requirements. This approach <strong>in</strong> the energy and process <strong>in</strong>dustry is to<br />

<strong>in</strong>stitutionalise <strong>HFE</strong> so that it becomes <strong>in</strong>tegrated <strong>in</strong> all bus<strong>in</strong>ess processes and projects.<br />

2.2 Systematic Approach<br />

In order to get <strong>HFE</strong> demands systematically translated <strong>in</strong>to all design specifications, Shell has<br />

developed an Ergonomics Management and Information System (EMIS ® ). This system is based on best<br />

practice and learn<strong>in</strong>g from past projects. EMIS ® is a Quality Assurance system, that uses a hierarchy of<br />

procedures and tools to:<br />

o Develop an <strong>HFE</strong> scope for the project<br />

o Carry out analysis based on this scope<br />

o Ensure that design requirements are implemented <strong>in</strong>to the design of the project, through an<br />

<strong>HFE</strong>IP and agreed KPI’s<br />

o Ensure that design requirements are assured dur<strong>in</strong>g FED-3<br />

o Evaluate <strong>HFE</strong> <strong>in</strong> the project dur<strong>in</strong>g the Post Implementation Review<br />

It ensures that the end user’s demand are systematically identified and <strong>in</strong>cluded <strong>in</strong> all design and<br />

eng<strong>in</strong>eer<strong>in</strong>g requirements for the new facility.

OG.03.30714 5 Confidential<br />

EMIS ® has been developed us<strong>in</strong>g two approaches:<br />

1. By project function, i.e.:<br />

o Information and Tra<strong>in</strong><strong>in</strong>g tools (IT)<br />

o Project Management and Quality Assurance tools (PMQ)<br />

o Eng<strong>in</strong>eer<strong>in</strong>g tools (ET)<br />

o Procurement Management tools (VM)<br />

o Construction Management tools (CM)<br />

2. Into four quality management levels based on the requirements of the project:<br />

Level 1: Policy<br />

Level 1 documents provide an overview of the EMIS ® system and expla<strong>in</strong> purpose and objectives<br />

of <strong>HFE</strong>. It facilitates creat<strong>in</strong>g an awareness of the various <strong>HFE</strong> aspects and how these <strong>in</strong>fluence the<br />

operations and ma<strong>in</strong>tenance of a plant. Target audience are the end-users of the new facility,<br />

bus<strong>in</strong>ess representatives, and project team members.<br />

Level 2: Procedure<br />

The level 2 documents describe the <strong>HFE</strong> activities of the various project development phases,<br />

<strong>in</strong>clud<strong>in</strong>g the roles and responsibilities of the persons <strong>in</strong>volved. It specifies which <strong>HFE</strong> activities<br />

should be carried out <strong>in</strong> each project phase, and who is <strong>in</strong>volved <strong>in</strong> execut<strong>in</strong>g them. This level is<br />

important for the project team and the design and eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong>dividuals <strong>in</strong>volved.<br />

Three ma<strong>in</strong> procedures are dist<strong>in</strong>guished: (a) plant and equipment design, (b) build<strong>in</strong>g and<br />

workplace development, and (c) <strong>in</strong>formation design. Furthermore, specific tools have been<br />

developed to support projects <strong>in</strong> the area of: (a) human performance improvement, i.e. human<br />

behaviour and error reduction, (b) operational excellence, i.e. <strong>in</strong>vestment justification analysis for<br />

upgrad<strong>in</strong>g exist<strong>in</strong>g operations, and (c) health ergonomics, i.e. physical and mental stress<br />

reduction.<br />

Level 3: Tools and Methods<br />

The level 3 documents <strong>in</strong>clude specifications and design guidel<strong>in</strong>es. This level also deals with<br />

topics that are relevant for various projects, e.g. control room design, computer <strong>in</strong>terface design,<br />

office build<strong>in</strong>g design, plant lay-out, VDU screen design, development of light<strong>in</strong>g plans, general<br />

<strong>HFE</strong> tra<strong>in</strong><strong>in</strong>g, process equipment specifications, vendor specification, and construction<br />

specifications. These documents are important for the project team, process design and discipl<strong>in</strong>e<br />

eng<strong>in</strong>eers, and operations and ma<strong>in</strong>tenance personnel.<br />

Level 4: Standards<br />

Level 4 documents are <strong>HFE</strong> standards such as ISO standards relat<strong>in</strong>g to topics such as noise,<br />

light<strong>in</strong>g and temperatures, safety and clearances of mach<strong>in</strong>ery, controls and display design, and<br />

usability specifications. These documents are to be used by project team, discipl<strong>in</strong>e eng<strong>in</strong>eers, <strong>HFE</strong><br />

focal po<strong>in</strong>t, dur<strong>in</strong>g the development of the BOD, BDP and project specification documents.<br />

An important pr<strong>in</strong>ciple of the application of EMIS ® is the process of identify<strong>in</strong>g, understand<strong>in</strong>g and<br />

specify<strong>in</strong>g the detailed <strong>HFE</strong> design requirements at an appropriately early stage <strong>in</strong> the design process,<br />

such that these ‘requirements’ are <strong>in</strong>corporated with<strong>in</strong> the design as reflected <strong>in</strong> the BOD, BDP and PS.

OG.03.30714 6 Confidential<br />

While further ref<strong>in</strong>ement activities may be required at a later phase dur<strong>in</strong>g detailed design, this frontend<br />

development pr<strong>in</strong>ciple avoids the need to change the design at a late stage to <strong>in</strong>clude <strong>HFE</strong><br />

requirements retroactively. This process <strong>in</strong>cludes the follow<strong>in</strong>g steps:<br />

Identification of Design Hotspots and Performance Issues<br />

This is achieved us<strong>in</strong>g the <strong>HFE</strong> Focus<strong>in</strong>g Tool and the Work Systems Analysis Tool.<br />

The <strong>HFE</strong> Focus<strong>in</strong>g Tool <strong>in</strong>cludes an assessment of the 10 Performance Factors for the project:<br />

1. Efficiency <strong>in</strong> design<br />

Is there an opportunity to achieve higher levels of operational efficiency on specified end user<br />

tasks through improvements <strong>in</strong> design. Examples: a more logical and shorter operator’s round;<br />

easier and fewer manual valve operations; easier and more efficient pigg<strong>in</strong>g operations; easier<br />

change-out of removable items such as filters & consumables; pump start-up by one <strong>in</strong>stead of two<br />

operators, etc.<br />

2. Ma<strong>in</strong>ta<strong>in</strong>ability<br />

Is there a need to ensure a high level of ma<strong>in</strong>ta<strong>in</strong>ability for critical items through more focused<br />

attention to operator task demands. Examples: to assure achievement of availability targets; <strong>in</strong><br />

exploit<strong>in</strong>g shorter shutdown or change-out periods; to reduce the likelihood of ma<strong>in</strong>tenance errors<br />

on safety critical equipment; to reduce wait<strong>in</strong>g time; to reduce adverse work<strong>in</strong>g postures; to<br />

provide hoist<strong>in</strong>g equipment which is easier to use; sav<strong>in</strong>g on scaffold<strong>in</strong>g cost, etc.<br />

3. Safety & Reliability<br />

Is there an opportunity to improve safety & reliability through specific attention to human<br />

operations. Examples: reduc<strong>in</strong>g the likelihood & impact of identified critical human errors (e.g.<br />

reduced switch<strong>in</strong>g errors through a well designed overview; quicker and more effective<br />

urgent/emergency <strong>in</strong>tervention; prevent<strong>in</strong>g un<strong>in</strong>tended control actions, etc.).<br />

4. Health<br />

Would the application of targeted design features assist <strong>in</strong> achiev<strong>in</strong>g worker health standards?<br />

Examples: reduced exposure to hazardous materials; less force required <strong>in</strong> manual handl<strong>in</strong>g;<br />

better work<strong>in</strong>g/liv<strong>in</strong>g environment; fewer adverse work<strong>in</strong>g positions such as work<strong>in</strong>g when<br />

bend<strong>in</strong>g, crouch<strong>in</strong>g, on one leg, with the body twisted, less pull<strong>in</strong>g, push<strong>in</strong>g, lift<strong>in</strong>g, reduced<br />

bolt<strong>in</strong>g effort, etc.<br />

5. Usability & IT<br />

Do specific usability issues need to be addressed to assure IT product effectiveness? For example,<br />

software usability, decision support tools for trip management, etc.<br />

6. End users needs<br />

Does the success of this project depend on systematically assess<strong>in</strong>g end users’ needs <strong>in</strong> relation to<br />

specific task demands? Examples: through timely and systematic capture & <strong>in</strong>corporation of end<br />

users’ knowledge of work systems <strong>in</strong> early design (for example by schedul<strong>in</strong>g a front-end<br />

ergonomics evaluation session).<br />

7. 3rd party customers<br />

Will external (3rd party) customers <strong>in</strong>terface with the designed Shell facility/product? I.e. requir<strong>in</strong>g<br />

a broader range of end users’ needs to be accommodated <strong>in</strong> the design - e.g. design of office<br />

build<strong>in</strong>g entrances, the design of a motor oil bottle; design of fill<strong>in</strong>g stations for 3rd party or<br />

external use etc).<br />

8. Unfamiliar project or technology<br />

Is this the first project of its k<strong>in</strong>d or the first use of a new design/technology? If so, this may require

OG.03.30714 7 Confidential<br />

e.g. trial use by end users of new work systems (hardware/software) to improve usability; task<br />

analysis of new tasks <strong>in</strong> order to understand hazards and opportunities & assist design.<br />

9. <strong>HFE</strong> competency of design contractors competent<br />

Would the project benefit if design contractors to be used had <strong>HFE</strong> competence to deal<br />

with/identify <strong>HFE</strong> needs and opportunities? i.e. without that competence and an agreed approach<br />

<strong>HFE</strong> opportunities/result<strong>in</strong>g operational improvements may not be exploited.<br />

10. <strong>HFE</strong> audit trail<br />

Is an audit trail required to demonstrate that <strong>HFE</strong> has been <strong>in</strong>corporated <strong>in</strong>to the design of the<br />

project? Examples: as required by regulations (e.g. for a safety case where authorities require an<br />

explicit treatment of Human factors <strong>in</strong> design); or for <strong>in</strong>surance purposes (e.g. reduced premiums<br />

for reduced risks).<br />

The project specific actions derived at with the <strong>HFE</strong> Focus<strong>in</strong>g Tool are recorded <strong>in</strong> the Work Systems<br />

Analysis Tool. This <strong>in</strong>dicates whether requirements are <strong>in</strong>cluded <strong>in</strong> the design through the application<br />

of standards, or whether an additional assessment and analysis is required.<br />

Identify <strong>HFE</strong> Scope of Work<br />

Based on the outcome of the previous process step, a detailed scope of work is developed that<br />

<strong>in</strong>dicates which actions need to be executed by whom and when.<br />

Develop <strong>HFE</strong> Plan and <strong>in</strong>clude <strong>in</strong> BOD<br />

This <strong>in</strong>cludes document<strong>in</strong>g <strong>HFE</strong> requirements and work plan for the project, also <strong>in</strong>dicat<strong>in</strong>g the<br />

<strong>in</strong>teraction with future end-users, and what steps must be taken to ensure that these requirements will<br />

be fully supported by design features.<br />

Conduct <strong>HFE</strong> Analysis and <strong>in</strong>clude <strong>in</strong> BDP<br />

When specified <strong>in</strong> the <strong>HFE</strong> Scope of Work further analysis and def<strong>in</strong>ition of <strong>HFE</strong> requirements is<br />

carried out. A design report is produced <strong>in</strong>dicat<strong>in</strong>g the additional needs.<br />

Develop <strong>HFE</strong> Implementation Plan and <strong>in</strong>clude <strong>in</strong> PS<br />

A project specific <strong>HFE</strong> implementation plan is produced, specify<strong>in</strong>g all activities required by draw<strong>in</strong>g<br />

on the results from the Work Systems Analysis Tool and any subsequent analyses. The plan should also<br />

<strong>in</strong>dicate what additional activities are required <strong>in</strong> the subsequent project phase to confirm/further<br />

specify requirements, as a result of any additional <strong>in</strong>formation.<br />

Execute <strong>HFE</strong> Activities<br />

All <strong>HFE</strong> activities that were identified dur<strong>in</strong>g the previous steps are executed snd results fed back <strong>in</strong>to<br />

design and eng<strong>in</strong>eer<strong>in</strong>g specifications. Reviews are carried out to ensure proper co-ord<strong>in</strong>ation and<br />

communication.<br />

Develop Construction Plan<br />

A project specific construction plan for use dur<strong>in</strong>g the implementation phase is developed <strong>in</strong>clud<strong>in</strong>g all<br />

identified <strong>HFE</strong> requirements. The purpose of the <strong>HFE</strong> construction plan is to guide the construction<br />

contractor with respect to the typical <strong>HFE</strong> requirements. This <strong>in</strong>cludes a methodology to deal with ‘field<br />

run’ <strong>in</strong>stalled equipment (e.g. small bore pip<strong>in</strong>g, light<strong>in</strong>g fixtures, secondary cable trays etc.). This will<br />

ensure that the <strong>HFE</strong> specifications are properly implemented dur<strong>in</strong>g the construction phase.<br />

Implement Construction Plan<br />

It may be necessary to <strong>in</strong>sert relevant requirements <strong>in</strong>to the <strong>in</strong>stallation contractors’ work scope, as well<br />

as monitor<strong>in</strong>g and verify<strong>in</strong>g that these needs are met. This process can be met through:

OG.03.30714 8 Confidential<br />

Awareness sessions with on-site contractors.<br />

Execution of <strong>HFE</strong> verification rounds.<br />

A procedure, which advises the contractor how to deal with a situation, diagnosed as ergonomically<br />

undesirable.<br />

Post Implementation Review<br />

Evaluate the success and the learn<strong>in</strong>g po<strong>in</strong>ts of application of the <strong>HFE</strong> process <strong>in</strong> the project. This<br />

evaluation should <strong>in</strong>clude:<br />

Ergonomics evaluations dur<strong>in</strong>g operations to verify that ergonomics hazards have been properly<br />

identified and secured <strong>in</strong> the design and to identify other possible issues that were not adequately dealt<br />

with.<br />

Organisational design issues to verify that organisational demands were adequately identified and<br />

dealt with dur<strong>in</strong>g the design phase.<br />

Identify the costs and benefits of <strong>HFE</strong> <strong>in</strong>volvement <strong>in</strong> the project.<br />

2.3 Benefits and Cost of Apply<strong>in</strong>g EMIS ®<br />

There is significant evidence that ‘human-centred’ systems result <strong>in</strong> <strong>in</strong>creased productivity, enhanced<br />

quality of work, reduction <strong>in</strong> support and tra<strong>in</strong><strong>in</strong>g costs, and improved user satisfaction. Although the<br />

human-mach<strong>in</strong>e <strong>in</strong>terface <strong>in</strong> process <strong>in</strong>dustry projects has always been considered to be an <strong>in</strong>tegral<br />

part of a sound eng<strong>in</strong>eer<strong>in</strong>g design, many misfits <strong>in</strong> operability, ma<strong>in</strong>ta<strong>in</strong>ability, system reliability and<br />

product design have been experienced after implementation. <strong>HFE</strong> is an approach to system design<br />

focused on usability to enhance user effectiveness, efficiency and work<strong>in</strong>g conditions. Achiev<strong>in</strong>g a<br />

human centred design ‘right first time’ requires <strong>in</strong>tegration <strong>in</strong> the technical design process <strong>in</strong> the early<br />

development phases, and structured consultation to def<strong>in</strong>e end user requirements to support bus<strong>in</strong>ess<br />

needs.<br />

Benefits of correctly apply<strong>in</strong>g <strong>HFE</strong> aspects <strong>in</strong> the development and implementation of projects are:<br />

• Balanced <strong>in</strong>put of operational, process and health and safety criteria <strong>in</strong>to the facilities design<br />

• Increased awareness of the “people issues” among key project team members and contractors<br />

• Greater emphasis on the needs of operators and ma<strong>in</strong>tenance staff dur<strong>in</strong>g the early stages of<br />

design<br />

• Reduction <strong>in</strong> the number of approval cycles dur<strong>in</strong>g the design phase<br />

• Reduction <strong>in</strong> the level of rework dur<strong>in</strong>g eng<strong>in</strong>eer<strong>in</strong>g and construction<br />

• Enhanced layout, operability, reliability and ma<strong>in</strong>ta<strong>in</strong>ability of plant and equipment<br />

• Raised productivity and quality<br />

• Reduced project life-cycle cost<br />

• Improved health, safety and well- be<strong>in</strong>g of workers plus greater job satisfaction<br />

Based on the results of cost/benefit evaluations and user feedback the cost benefits are:<br />

• Capex reductions of up to 5%<br />

• Cuts <strong>in</strong> eng<strong>in</strong>eer<strong>in</strong>g hours of up to 10%

OG.03.30714 9 Confidential<br />

• Reductions <strong>in</strong> life-cycle operational and ma<strong>in</strong>tenance costs of 3–6%<br />

The cost of correctly executed <strong>HFE</strong> activities dur<strong>in</strong>g the front-end development and<br />

implementation phases are <strong>in</strong> the order of 0.4 – 1.0 % of total eng<strong>in</strong>eer<strong>in</strong>g costs, or 0.06 – 0.2 of<br />

TIC.<br />

The cost and benefits of apply<strong>in</strong>g <strong>HFE</strong> elements for a particular project can be assessed and<br />

justified by us<strong>in</strong>g the Investment Justification Model (Ref. 4).

OG.03.30714 10 Confidential<br />

3. When<br />

The application of <strong>HFE</strong> is an <strong>in</strong>tegral part of the FED process. <strong>HFE</strong> activities are executed dur<strong>in</strong>g each<br />

of the FED-1, FED-2, and FED-3 phases, as illustrated <strong>in</strong> the table <strong>in</strong> Appendix B.

OG.03.30714 11 Confidential<br />

4. HOW / WHY<br />

An important pr<strong>in</strong>ciple <strong>in</strong> the approach to meet<strong>in</strong>g the <strong>HFE</strong> requirements is that the process of<br />

identify<strong>in</strong>g, understand<strong>in</strong>g and specify<strong>in</strong>g the <strong>HFE</strong> strategies and detailed design requirements should<br />

be started at an early stage <strong>in</strong> the design process, such that these ‘requirements’ are <strong>in</strong>corporated <strong>in</strong><br />

the project deliverables. While further ref<strong>in</strong>ement activities may be required at later stages (e.g., <strong>in</strong><br />

detailed design), this avoids the need to change design at a late stage.<br />

4.1 <strong>HFE</strong> Awareness (FED-1)<br />

Dur<strong>in</strong>g FED-1 a general awareness of <strong>HFE</strong> <strong>in</strong>volvement is developed, and the <strong>HFE</strong> <strong>in</strong>put to the project<br />

identified.<br />

Us<strong>in</strong>g the <strong>HFE</strong> Focuss<strong>in</strong>g Tool and Work Systems Analysis Tool (Ref. 3) the <strong>HFE</strong> process and activities<br />

for all project phases are identified, and the <strong>in</strong>volvement of the <strong>HFE</strong>-eng<strong>in</strong>eer agreed.<br />

Effective l<strong>in</strong>k<strong>in</strong>g of the results of the Project Value Processes – Design Class (Ref. 5) and Value<br />

Eng<strong>in</strong>eer<strong>in</strong>g (Ref. 6) will offer an efficient way to improve the <strong>HFE</strong> scope def<strong>in</strong>ition and tailor the<br />

subsequent <strong>HFE</strong> analysis to the need of the bus<strong>in</strong>ess client.<br />

The purpose is to develop an awareness of the value of us<strong>in</strong>g <strong>HFE</strong>, to identify value add<strong>in</strong>g <strong>HFE</strong> scope<br />

and to agree how <strong>HFE</strong> activities are <strong>in</strong>cluded <strong>in</strong> the project development and implementation. The cost<br />

and benefits of apply<strong>in</strong>g <strong>HFE</strong> elements for a particular project can be assessed and justified by us<strong>in</strong>g<br />

the Investment Justification Model (Ref. 4).<br />

4.2 <strong>HFE</strong> Design Analysis (FED-2)<br />

Dur<strong>in</strong>g this phase an analysis is carried out of operational, ma<strong>in</strong>tenance and other critical tasks,<br />

lead<strong>in</strong>g to the identification of <strong>HFE</strong> design requirements for the project by us<strong>in</strong>g the Front End<br />

Ergonomics Evaluation Matrix (FEEEM ® ).<br />

FEEEM ® was orig<strong>in</strong>ally developed for Plant and Equipment design only. Based on its success similar<br />

tools has been developed <strong>in</strong> other design areas where the human mach<strong>in</strong>e <strong>in</strong>terface can be critical <strong>in</strong><br />

terms of system performance:<br />

• Human L<strong>in</strong>k – and Relationship (HLR ® ) analysis for build<strong>in</strong>g development;<br />

e.g. control room, workshop, laboratory and office build<strong>in</strong>gs.<br />

• Workplace design;<br />

e.g. <strong>in</strong>novative office configurations, DCS console design, entrance desk design, etc.<br />

• Attention Hierarchy (AH ® ) cod<strong>in</strong>g for <strong>in</strong>formation presentation design;<br />

e.g. graphical display and pictorial <strong>in</strong>formation design.<br />

• Human Performance Improvement tools;<br />

i.e. Human Error Quantification & Reduction tools (HEQIT ® ).<br />

• Physical and mental stress reduction;<br />

i.e. Stress Thermometer (ST ® ) monitor<strong>in</strong>g & analysis for stress monitor<strong>in</strong>g and respond<strong>in</strong>g to<br />

stress dur<strong>in</strong>g organisational changes.<br />

A standard part of apply<strong>in</strong>g the FEEEM ® dur<strong>in</strong>g plant lay out development is an analysis of critical<br />

valves (IVA ® ), identify<strong>in</strong>g <strong>in</strong>put to the development of the Operational Implementation Plan (OIP) and

OG.03.30714 12 Confidential<br />

the development of a strategy with respect to implement<strong>in</strong>g <strong>HFE</strong> <strong>in</strong> long-delivery items and package<br />

units.<br />

The purpose of this work is to identify the scope of apply<strong>in</strong>g <strong>HFE</strong> <strong>in</strong> the design and eng<strong>in</strong>eer<strong>in</strong>g of the<br />

project, and to capture the design requirements <strong>in</strong> the FEEEM ® report that is subsequently <strong>in</strong>tegrated <strong>in</strong><br />

the Project Specification document.<br />

4.3 <strong>HFE</strong> Implementation (FED-3)<br />

On basis of the FEEEM ® , the <strong>HFE</strong> requirements for the project are communicated with basic<br />

eng<strong>in</strong>eer<strong>in</strong>g or project def<strong>in</strong>ition contractors.<br />

The deliverables from the FED-3 phase are verified aga<strong>in</strong>st the actions identified <strong>in</strong> the FEEEM ® . An<br />

<strong>HFE</strong> Implementation Plan (<strong>HFE</strong>IP) and an <strong>HFE</strong> Construction Plan (<strong>HFE</strong>CP) is prepared to secure <strong>HFE</strong><br />

requirements for the Implementation phase.<br />

The purpose of shar<strong>in</strong>g the FEEEM ® report with contractors is to ensure a proper understand<strong>in</strong>g of the<br />

<strong>HFE</strong> requirements for the project, and to jo<strong>in</strong>tly identify opportunities for improvements.<br />

4.4 <strong>HFE</strong> Support (Implementation)<br />

The <strong>HFE</strong>IP and <strong>HFE</strong>CP form the basis of the <strong>HFE</strong> work executed by the detail eng<strong>in</strong>eer<strong>in</strong>g, procurement<br />

and construction contractor(s).<br />

Dur<strong>in</strong>g detailed eng<strong>in</strong>eer<strong>in</strong>g critical design details as per FEEEM ® report specifications are checked<br />

aga<strong>in</strong>st the actual development status e.g. through (3D CAD) model reviews to assure that <strong>in</strong>tentions<br />

and selected solutions are implemented. Furthermore a strong focus will be on the management of<br />

vendors. In particular a more up-front ‘change management’ approach to skid-mounted or packaged<br />

unit suppliers has proven beneficial <strong>in</strong> terms of operational and ma<strong>in</strong>tenance quality improvement<br />

aga<strong>in</strong>st (extra) cost.<br />

The objective of the <strong>HFE</strong> plan for construction is to ensure that the operational and ma<strong>in</strong>tenance <strong>HFE</strong><br />

requirements criteria stipulated dur<strong>in</strong>g the eng<strong>in</strong>eer<strong>in</strong>g phases are satisfied.<br />

The above-mentioned objective is achieved by:<br />

• Includ<strong>in</strong>g requirements <strong>in</strong> construction contracts;<br />

• Brief<strong>in</strong>g (CD-ROM/tra<strong>in</strong><strong>in</strong>g) construction contractor staff;<br />

• Address<strong>in</strong>g responsibilities;<br />

• Conduct<strong>in</strong>g weekly/fortnightly <strong>HFE</strong> verification rounds;<br />

• Giv<strong>in</strong>g awareness tra<strong>in</strong><strong>in</strong>g to construction personnel <strong>in</strong>volved;<br />

• Conduct<strong>in</strong>g audits.<br />

The benefits identified are:<br />

• Better plant lay out,<br />

• Reduction of re-work,<br />

• Schedule advantage,<br />

• Reduction of operations and ma<strong>in</strong>tenance life-cycle costs,<br />

• Improvement of ‘client commitment level’.<br />

The purpose dur<strong>in</strong>g this phase is a proper implementation of the <strong>HFE</strong> aspects identified for the project.

OG.03.30714 13 Confidential<br />

5. WHAT<br />

5.1 Actions and Deliverables<br />

Ma<strong>in</strong> actions and deliverables related to this PVP are summarised <strong>in</strong> the overview <strong>in</strong> Appendix B.<br />

Detailed processes, actions and deliverables are <strong>in</strong>cluded <strong>in</strong> EMIS®. A fit-for-purpose project specific<br />

plan should be developed that aligns and <strong>in</strong>tegrates <strong>HFE</strong> activities with the other project work.<br />

5.2 Considerations <strong>in</strong> Application of the Process<br />

The process of <strong>in</strong>tegration of <strong>HFE</strong> with<strong>in</strong> a project will ensure that the facility design supports the<br />

effective and efficient function<strong>in</strong>g of human be<strong>in</strong>gs, thereby improv<strong>in</strong>g usability <strong>in</strong> operational and<br />

ma<strong>in</strong>tenance tasks. Early <strong>in</strong>tegration of <strong>HFE</strong> <strong>in</strong> a ‘right first time’ manner can deliver cost and time<br />

sav<strong>in</strong>gs <strong>in</strong> both the def<strong>in</strong>ition and implementation phases of the project, and over the life of the new<br />

facilities. A reduction <strong>in</strong> design phase approval cycles and re-work is possible through the front-end<br />

capture and specification of stakeholders’ needs and expectations.<br />

Effective use of the output of other Project Value Processes, e.g. Design Class and Value Eng<strong>in</strong>eer<strong>in</strong>g<br />

offers an efficient way to improve <strong>HFE</strong> scope def<strong>in</strong>ition tailored to the bus<strong>in</strong>ess needs.<br />

A key risk is a failure to execute the front end <strong>HFE</strong> evaluation / stakeholder requirements review at an<br />

early phase and <strong>in</strong> an efficient manner. Ideally this should be undertaken just after the Design Class<br />

Selection workshop <strong>in</strong> FED 1.<br />

Other risks <strong>in</strong>clude:<br />

• Not correctly understand<strong>in</strong>g critical tasks and subsequent design criteria leads to reduced<br />

performance and <strong>in</strong>creased human error likelihood.<br />

• Incorrectly application of <strong>HFE</strong> development process may lead to human - and system<br />

<strong>in</strong>efficiency.

OG.03.30714 14 Confidential<br />

6. WHO<br />

6.1 Project Manager<br />

The Project Manager has the overall responsibility of:<br />

• Nom<strong>in</strong>at<strong>in</strong>g a <strong>HFE</strong> Coord<strong>in</strong>ator for the project<br />

• Ensur<strong>in</strong>g that <strong>HFE</strong> is executed as per PVP<br />

• Approv<strong>in</strong>g the scope of <strong>HFE</strong> <strong>in</strong>put for the project<br />

6.2 <strong>HFE</strong> Coord<strong>in</strong>ator<br />

The <strong>HFE</strong> Coord<strong>in</strong>ator has the responsibility of:<br />

• Engage with the <strong>HFE</strong> Eng<strong>in</strong>eer<br />

• Ensur<strong>in</strong>g that the scope of <strong>HFE</strong> <strong>in</strong>put for the project is identified and approved<br />

• Ensur<strong>in</strong>g that the agreed <strong>HFE</strong> elements are executed accord<strong>in</strong>g to the agreed plan<br />

• Ensur<strong>in</strong>g that relevant solutions are selected and agreed with the stakeholders<br />

• Ensur<strong>in</strong>g that <strong>HFE</strong> requirements are <strong>in</strong>cluded <strong>in</strong> the project’s deliverables<br />

6.3 <strong>HFE</strong> Eng<strong>in</strong>eer<br />

• Provides for awareness tra<strong>in</strong><strong>in</strong>g and facilitation of workshops and meet<strong>in</strong>gs<br />

• Advises on the necessary <strong>HFE</strong> <strong>in</strong>put for the project<br />

• Assists with implement<strong>in</strong>g selected <strong>HFE</strong> solutions<br />

• Provides the FEEEM ® report<br />

• Assists <strong>in</strong> prepar<strong>in</strong>g the <strong>HFE</strong>IP and the <strong>HFE</strong>CP<br />

• Participates <strong>in</strong> <strong>HFE</strong> reviews and audits dur<strong>in</strong>g detailed design, procurement and<br />

construction

OG.03.30714 15 Confidential<br />

7. APPLICABLE KPI’s<br />

7.1 Process related KPIs:<br />

• Key mile stones of specified deliverables achieved;<br />

i.e. correctly executed front-end <strong>HFE</strong> scop<strong>in</strong>g study (e.g. FEEEM ® ) with clear <strong>HFE</strong> action plan<br />

signed off by customer and project manager (correct execution <strong>in</strong>cludes study be<strong>in</strong>g executed<br />

to co<strong>in</strong>cide with Design Class Selection <strong>in</strong> FED-1 and updated <strong>in</strong> FED-2; all key stakeholders<br />

attended FEEEM ® session)<br />

• Audit trail of deliverables from FED-3 aga<strong>in</strong>st FEEEM ® action plan items and % FEEEM ® items<br />

closed out (FEEEM ® <strong>in</strong>dex).<br />

• 0 measurement and target;<br />

e.g. re. <strong>HFE</strong> competence of project team<br />

• 0 measurement and target;<br />

re. understand<strong>in</strong>g of added value <strong>HFE</strong> by project team<br />

7.2 End result related KPIs<br />

Full client satisfaction with consultation on expectations re <strong>HFE</strong> and operational facility performance.

OG.03.30714 16 Confidential<br />

8. TOOLS<br />

Ergonomics Management and Information System (EMIS ® )<br />

custodian is Shell International Health Services B.V.<br />

Front End Ergonomics Eng<strong>in</strong>eer<strong>in</strong>g Matrix (FEEEM ® ).<br />

custodian is Shell International Health Services B.V.

OG.03.30714 17 Confidential<br />

9. DEFINITIONS / REFERENCES<br />

Ref. 0 - OGP Governance – Project Development and Implementation, OG.03.30540.<br />

Ref. 1 - M<strong>in</strong>imum Health Management Standard Human Factor Eng<strong>in</strong>eer<strong>in</strong>g, Shell HSE Panel,<br />

2001<br />

Ref. 2 - Project Guide 1A 'HSE & SD <strong>in</strong> <strong>Projects</strong>', OG.03.30302<br />

Ref. 3 - <strong>HFE</strong> <strong>in</strong> projects eng<strong>in</strong>eer<strong>in</strong>g, DEP 30.00.60.10<br />

Ref. 4 - <strong>HFE</strong> Investment justification, DEP 30.00.60.12<br />

Ref. 5 - PVP 6 'Design Class', OG.03.30185<br />

Ref. 6 - PVP 8 'Value Eng<strong>in</strong>eer<strong>in</strong>g'

OG.03.30714 18 Confidential<br />

Appendix A: Overview of EMIS ®<br />

Management <strong>in</strong>formation on the implementation of ergonomics <strong>in</strong> eng<strong>in</strong>eer<strong>in</strong>g and projects (MG1)<br />

EMIS® Summary<br />

(MG1A)<br />

Information and<br />

tra<strong>in</strong><strong>in</strong>g tools (IT)<br />

Project Mgt. & Quality<br />

Assurance tools (PMQ)<br />

Eng<strong>in</strong>eer<strong>in</strong>g tools (ET)<br />

Procurement<br />

management tools<br />

(VM)<br />

Construction<br />

management tools<br />

(CM)<br />

01 Economical and noneconomical<br />

benefits of<br />

human centred design<br />

02 Video The human<br />

dimension<br />

03 Workshop “Ergonomic<br />

design <strong>in</strong><br />

petrochemical<br />

<strong>in</strong>dustry”<br />

03A Ergonomic misfits <strong>in</strong><br />

staircase design<br />

03B Case study<br />

Cost/benefit analysis<br />

03C Case study<br />

Vertical pump design<br />

03D Case study skid<br />

Packaged Unit<br />

03E Case study Control<br />

room<br />

03F Case study Graphical<br />

display lay-out<br />

04 Project Ergonomic<br />

Team tra<strong>in</strong><strong>in</strong>g<br />

05 Tra<strong>in</strong><strong>in</strong>g oper./-ma<strong>in</strong>t.<br />

Personnel<br />

06 Focal Po<strong>in</strong>t Ergonomic<br />

Design course<br />

07 Workshop “Ergonomic<br />

design <strong>in</strong><br />

projects”<br />

01 <strong>Manag<strong>in</strong>g</strong> Human<br />

Factors eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong><br />

projects procedure<br />

01A Control room design<br />

procedure<br />

01B Plot plan development<br />

procedure<br />

02 FEEEM® design<br />

analysis<br />

02A Operator/emergency<br />

route development<br />

procedure<br />

03 Identification of valves<br />

analysis (IVA®) 04<br />

04A Procedure <strong>HFE</strong> PIR<br />

05 Construction<br />

Ergonomics Procedure<br />

06 Human reliability and<br />

error analysis<br />

HEQIT®<br />

07 Benefits of ergonomic<br />

design, part 1<br />

Quantification model,<br />

part 2 Case studies<br />

07A Quick reference guide<br />

benefits ergonomic<br />

design<br />

08 Checklist Model<br />

review<br />

09 Quality audit<br />

Eng<strong>in</strong>eer<strong>in</strong>g<br />

contractor<br />

10 International<br />

Standards/ guidel<strong>in</strong>es<br />

01 Best practice human<br />

computer <strong>in</strong>terface<br />

and control room<br />

design<br />

01A Checklist control room<br />

ergonomics<br />

02 Questionnaire control<br />

room design<br />

03 Information transfer<br />

procedure<br />

03A Hierarchy Attention®<br />

cod<strong>in</strong>g for graphical<br />

display design<br />

04 Checklist Human<br />

Computer Interface<br />

05 Best practice office<br />

build<strong>in</strong>gs<br />

06 Best practice<br />

ergonomic office layout<br />

07 Best practice vertical<br />

pump lay-out (3 D<br />

CAD)<br />

07A Best practice<br />

horizontal pump layout<br />

(3 D CAD)<br />

07B Best practice heat<br />

exchanger lay-out<br />

08 Best practice hoist<strong>in</strong>g<br />

equipment<br />

09 Best practice mobile<br />

elevat<strong>in</strong>g platforms<br />

10 Best practice for<br />

application of mobile<br />

actuators for valve<br />

operations<br />

11 Shell Ergonomic<br />

Checkcard System<br />

(SECS©)<br />

12 Best practice (handheld)<br />

tools evaluation<br />

13 Best practice checklist<br />

ergonomic<br />

considerations<br />

14 Best practice<br />

development design<br />

<strong>in</strong>door light<strong>in</strong>gsystems<br />

01 Best practice Vendor<br />

<strong>in</strong>formation for<br />

application of<br />

ergonomics <strong>in</strong><br />

packaged units<br />

02 Best practice checklist<br />

basis requirements for<br />

ergonomic design of<br />

packaged unit<br />

03 Packaged unit<br />

procurement<br />

ergonomics procedure<br />

01 Best practice<br />

specification for<br />

application of<br />

ergonomics<br />

with<strong>in</strong><br />

construction<br />

eng<strong>in</strong>eer<strong>in</strong>g,<br />

fabrication &<br />

<strong>in</strong>stallation work<br />

02 Construction<br />

contractor<br />

tra<strong>in</strong><strong>in</strong>g<br />

02A CD ROM<br />

‘Management of<br />

‘Field run<br />

equipment’<br />

03 Best practice<br />

construction<br />

contractors<br />

checklist<br />

04 Ergonomic<br />

Verification<br />

Report<br />

Use of an EMIS® document <strong>in</strong> isolation may lead to unsuccessful implementation of Human Factors Eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong><br />

<strong>Projects</strong>.

OG.03.30714 19 Confidential<br />

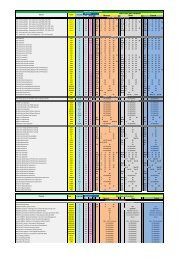

Appendix B: <strong>HFE</strong> - Overview of Activities for Each Project Phase<br />

FED-1 FED-2 FED-3 Implementation<br />

What<br />

<strong>HFE</strong> Awareness<br />

<strong>HFE</strong> Design Analysis<br />

<strong>HFE</strong> Implementation<br />

<strong>HFE</strong> Support<br />

Develop an awareness of the<br />

value of us<strong>in</strong>g <strong>HFE</strong> and to agree<br />

how the <strong>HFE</strong> process is <strong>in</strong>cluded<br />

<strong>in</strong> the project development and<br />

execution by:<br />

• Execut<strong>in</strong>g awareness<br />

presentation and tra<strong>in</strong><strong>in</strong>g.<br />

• Use of the <strong>HFE</strong> Focuss<strong>in</strong>g<br />

and Work Analysis<br />

Protocol.<br />

Develop and specify <strong>HFE</strong> design<br />

and eng<strong>in</strong>eer<strong>in</strong>g requirements<br />

by:<br />

• Carry out FEEEM ® analysis<br />

and use IVA ® for plant<br />

layout and equipment<br />

design.<br />

• Develop specific design<br />

requirements us<strong>in</strong>g EMIS ® .<br />

Transfer of <strong>HFE</strong> requirements to<br />

basic eng<strong>in</strong>eer<strong>in</strong>g and project<br />

def<strong>in</strong>ition contractors, and<br />

prepare for implementation by:<br />

• Shar<strong>in</strong>g of the FEEEM ®<br />

results.<br />

• Review<strong>in</strong>g, challeng<strong>in</strong>g and<br />

confirm<strong>in</strong>g the selected<br />

design and eng<strong>in</strong>eer<strong>in</strong>g<br />

solutions.<br />

Verification of <strong>HFE</strong> aspects <strong>in</strong><br />

constructed plant by:<br />

• Review of detail<br />

eng<strong>in</strong>eer<strong>in</strong>g, procurement<br />

and construction work.<br />

• Provision of expert support.<br />

• Agree on <strong>HFE</strong> process and<br />

activities for follow<strong>in</strong>g<br />

project phases and the<br />

<strong>in</strong>volvement of the<br />

<strong>HFE</strong>-eng<strong>in</strong>eer.<br />

• Preparation of EIP and ECP<br />

to secure <strong>HFE</strong> requirements<br />

for the Implementation<br />

phase<br />

How Workshop. Develop<strong>in</strong>g the FEEEM ®<br />

specifications.<br />

Focussed discipl<strong>in</strong>e meet<strong>in</strong>gs.<br />

Focussed reviews and audits.<br />

When When Draft BOD available. When draft PFSs are available.. Throughout Phase. Throughout Phase.<br />

Deliverable <strong>HFE</strong> Plan. Completed FEEEM ® . Confirmed FEEEM ® , and<br />

completed <strong>HFE</strong>IP and <strong>HFE</strong>CP.<br />

Accepted plant.

OG.03.30714 20 Confidential<br />

Appendix C-1: <strong>HFE</strong> – Activity Matrix dur<strong>in</strong>g FED-1<br />

This activity matrix is meant as a guidel<strong>in</strong>e for execut<strong>in</strong>g the work related to ‘Human Factor Eng<strong>in</strong>eer<strong>in</strong>g’ dur<strong>in</strong>g FED-1.<br />

The actual sequence and content of each step can be customised to tailor the requirements for an <strong>in</strong>dividual project.<br />

Activity<br />

Ref.<br />

Activity Responsibility Procedure or<br />

User Guide<br />

Standard<br />

Tools<br />

1 Assign <strong>HFE</strong> Coord<strong>in</strong>ator for the project. Project Manager User guide<br />

2 Review project objectives and targets for <strong>HFE</strong>. <strong>HFE</strong> Coord<strong>in</strong>ator User guide<br />

3 Contact SI-HE/2 and arrange content and<br />

plann<strong>in</strong>g of <strong>HFE</strong> activities.<br />

<strong>HFE</strong> Coord<strong>in</strong>ator User guide SI-HE/2 <strong>HFE</strong> toolbox<br />

4 Execute agreed <strong>HFE</strong> activities. <strong>HFE</strong> Eng<strong>in</strong>eer DEP<br />

30.00.60.10<br />

5 Deliver <strong>HFE</strong> Plan <strong>HFE</strong> Eng<strong>in</strong>eer DEP<br />

30.00.60.10<br />

SI-HE/2 <strong>HFE</strong> toolbox<br />

SI-HE/2 <strong>HFE</strong> toolbox<br />

6 Manage <strong>in</strong>corporation of workshop results <strong>in</strong><br />

project scope.<br />

7 Validate project deliverables are <strong>in</strong> l<strong>in</strong>e with<br />

<strong>HFE</strong> Plan<br />

<strong>HFE</strong> Coord<strong>in</strong>ator User guide<br />

<strong>HFE</strong> Coord<strong>in</strong>ator User guide

OG.03.30714 21 Confidential<br />

Appendix C-2: <strong>HFE</strong> – Activity Matrix dur<strong>in</strong>g FED-2<br />

This activity matrix is meant as a guidel<strong>in</strong>e for execut<strong>in</strong>g the work related to ‘Human Factor Eng<strong>in</strong>eer<strong>in</strong>g’ dur<strong>in</strong>g FED-2.<br />

The actual sequence and content of each step can be customised to tailor the requirements for an <strong>in</strong>dividual project.<br />

Activity<br />

Ref.<br />

Activity Responsibility Procedure or<br />

User Guide<br />

Standard<br />

Tools<br />

1 Assign <strong>HFE</strong> Coord<strong>in</strong>ator for the project. Project Manager User guide<br />

2 Review project objectives and targets for <strong>HFE</strong>. <strong>HFE</strong> Coord<strong>in</strong>ator User guide<br />

3 Contact SI-HE/2 and arrange content and<br />

plann<strong>in</strong>g of <strong>HFE</strong> activities.<br />

<strong>HFE</strong> Coord<strong>in</strong>ator User guide SI-HE/2 <strong>HFE</strong> toolbox<br />

4 Execute agreed <strong>HFE</strong> activities. <strong>HFE</strong> Eng<strong>in</strong>eer DEP<br />

30.00.60.10<br />

5 Deliver FEEEM ® . <strong>HFE</strong> Eng<strong>in</strong>eer DEP<br />

30.00.60.10<br />

SI-HE/2 <strong>HFE</strong> toolbox<br />

SI-HE/2 <strong>HFE</strong> toolbox<br />

6 Manage <strong>in</strong>corporation of workshop results <strong>in</strong><br />

project scope.<br />

7 Validate project deliverables are <strong>in</strong> l<strong>in</strong>e with<br />

FEEEM ® .<br />

<strong>HFE</strong> Coord<strong>in</strong>ator User guide<br />

<strong>HFE</strong> Coord<strong>in</strong>ator User guide

OG.03.30714 22 Confidential<br />

Appendix C-3: <strong>HFE</strong> – Activity Matrix dur<strong>in</strong>g FED-3<br />

This activity matrix is meant as a guidel<strong>in</strong>e for execut<strong>in</strong>g the work related to ‘Human Factor Eng<strong>in</strong>eer<strong>in</strong>g’ dur<strong>in</strong>g FED-3.<br />

The actual sequence and content of each step can be customised to tailor the requirements for an <strong>in</strong>dividual project.<br />

Activity<br />

Ref.<br />

Activity Responsibility Procedure or<br />

User Guide<br />

Standard<br />

Tools<br />

1 Assign <strong>HFE</strong> Coord<strong>in</strong>ator for the project. Project Manager User guide<br />

2 Review project objectives and targets for <strong>HFE</strong>. <strong>HFE</strong> Coord<strong>in</strong>ator User guide<br />

3 Contact SI-HE/2 and arrange content and<br />

plann<strong>in</strong>g of <strong>HFE</strong> activities.<br />

<strong>HFE</strong> Coord<strong>in</strong>ator User guide SI-HE/2 <strong>HFE</strong> toolbox<br />

4 Execute agreed <strong>HFE</strong> activities. <strong>HFE</strong> Eng<strong>in</strong>eer DEP<br />

30.00.60.10<br />

SI-HE/2 <strong>HFE</strong> toolbox<br />

5 Confirm FEEEM ® , and deliver <strong>HFE</strong>IP and<br />

<strong>HFE</strong>CP.<br />

6 Manage <strong>in</strong>corporation of workshop results <strong>in</strong><br />

project scope.<br />

7 Validate project deliverables are <strong>in</strong> l<strong>in</strong>e with<br />

FEEEM ® , <strong>HFE</strong>IP and <strong>HFE</strong>CP.<br />

<strong>HFE</strong> Eng<strong>in</strong>eer DEP<br />

30.00.60.10<br />

<strong>HFE</strong> Coord<strong>in</strong>ator User guide<br />

<strong>HFE</strong> Coord<strong>in</strong>ator User guide<br />

SI-HE/2 <strong>HFE</strong> toolbox