Shell Exploration & Production Contractor HSE Management - PDO

Shell Exploration & Production Contractor HSE Management - PDO

Shell Exploration & Production Contractor HSE Management - PDO

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Shell</strong> <strong>Exploration</strong> & <strong>Production</strong><strong>Contractor</strong> <strong>HSE</strong><strong>Management</strong>EP2005-0110EP BUSINESS <strong>HSE</strong>CONTROL FRAMEWORKVolume 1<strong>HSE</strong> <strong>Management</strong> SystemECCN: Not subject to EAR -No US contentRestrictedPrinted copies are uncontrolled

SummaryThis <strong>HSE</strong> document is prepared by <strong>Shell</strong> International <strong>Exploration</strong> and <strong>Production</strong> B.V. (SIEP), The Hague as a serviceunder arrangements in existence with companies of the Royal Dutch/<strong>Shell</strong> Group. It refers to Group standards andprovides guidance for the management of Health, Safety and Environmental issues in <strong>Shell</strong> operations.The EP Business <strong>HSE</strong> Control Framework replaces the previous EP <strong>HSE</strong> Manual EP95-0000. The Frameworkcomprises three volumes, each including a number of separate sections. The replacement of the separate sections isbeing phased during the period 2004-2005, during this time those EP95000 sections that have not be replaced by theirEP2005-0000 equivalent will remain valid.The Framework describes the elements necessary to develop, implement and maintain an <strong>HSE</strong> management System for<strong>Exploration</strong> and <strong>Production</strong> activities and describes the tools and techniques available to do this. In line with the <strong>Shell</strong>strategy to adopt Industry or International Standards wherever possible, the <strong>HSE</strong> <strong>Management</strong> System in thisFramework has been based on the guidelines prepared by the International Association of Oil & Gas Producers (OGP).CopyrightThe copyright of the EP Business <strong>HSE</strong> Control Framework is vested in <strong>Shell</strong> International <strong>Exploration</strong> and <strong>Production</strong>B.V. (SIEP), The Hague, the Netherlands.This document is classified as Restricted to <strong>Shell</strong> Personnel Only. '<strong>Shell</strong> Personnel' includes all staff with a personalcontract with a <strong>Shell</strong> Group Company, designated Associate Companies and <strong>Contractor</strong>s working on <strong>Shell</strong> projects whohave signed a confidentiality agreement with a <strong>Shell</strong> Group Company. Issuance of this document is restricted to staffemployed by a <strong>Shell</strong> Group Company. Neither the whole nor any part of this document may be disclosed to Non-<strong>Shell</strong>Personnel without the prior written consent of the copyright owners.Copyright 2004 SIEP B.V.DisclaimerSIEP is not aware of any inaccuracy or omission from this document but no responsibility is accepted by SIEP or by anyperson or company concerned with furnishing information or data used herein, for the accuracy of any information oradvice given in or any omission from this document, nor for any consequences whatsoever resulting directly or indirectlyfrom reliance on or adoption of this document, even if there was a failure to exercise reasonable care on the part of SIEPor any person or company as aforesaid.OGPThe International Association of Oil & Gas producers (OGP) encompasses most of the world’s leading publicly traded,private and state-owned oil & gas companies, oil & gas associations and major upstream service companies.The association was formed in 1974 to develop effective communications between the upstream industry and anincreasingly complex network of international regulators. Originally called the E&P Forum, in 1999 the name InternationalAssociation of Oil & Gas Producers (OGP) was adopted. <strong>Shell</strong> participated in a task force set up by the E&P forum todevelop guidelines for the development and application of Health, Safety and Environment <strong>Management</strong> Systems.These were published in July 1994.

EP2005 Volume 1<strong>HSE</strong> <strong>Management</strong> inthe BusinessEP2005-0110 <strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>RestrictedEP2005 Document Approval Sheet 5EP2005-0110-ST: <strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong> 90. Revision Information………………………………………………………………………… 91. Introduction…………………………………………………………………………………… 92. Scope and Application……………………………………………………………………... .93. EP Policy………………………………………………………………………………………94. EP Standard……….………………………………………………………………………….94.1 Key Roles and Responsibilities……………………………………………………………..94.2 Planning: Assess <strong>HSE</strong> Risks and <strong>Contractor</strong> Capability………………………………. 104.3 Execution: Manage Contract………………………………………………………………114.4 Analyse/Improve…………………………………………………………………………….125. Key Performance Indicators……………………………………………………………….126. Related EP Controlling Documents……………………………………………………… 135. Other References…………………………………………………………………………...13App. 1: Activity Responsibility Matrix……………………………………………………….………14App. 2: <strong>HSE</strong> Responsibilities………………………………………………………………………..15EP2005-0110-PR-10: <strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong> (including stoplight) 171. Revision Information………………………………………………………………………..172. Objective……………………………………………………………………………………..173. Scope….…………………………………………………………………………………….. 174. Risk Domain and Risk……………………………………………………………………... 175. Input to Activity……………………………………………………………………….….…. 176. Output to Activity..………………………………………………………………………….. 187. Activity Responsibility Matrix……………………………………………………………… 198. Task Explanation – Planning………………………………………………….………….. 209. Task Explanation – Execution……………………………………………………………..2310. Task Explanation – Analyse and Improve………………………………………………. 2711. Records…..…………………………………………………………………………………. 2813. Related Controlling Documents………………………………………………………….. 2914. Other References…………………………………………………………………………...29EP2005-0110-SP-01: Contract Holder and Company Site Representative HSSECompetences 310. Revision Information……………………………………………………………………….. 311. Scope…………………………………………………………………….………………….. 312. External Requirements……………………………………………………………………..313. External References……………………………………………………………………….. 314. EP Specification……………………………………………………………………………. 314.1 Definitions…………………………………………………………………………………… 314.2 Roles………………………………………………………………………………………… 314.3 Competence Requirements………………………………………………………………. 324.4 Safe Systems of Work/Personal Safety Competences………………………………… 335. Related EP Controlling Documents……………………………………………………….336. Other References…………………………………………………………………………...33EP2005-0110-SP-02: <strong>Contractor</strong> <strong>HSE</strong> Capability Points System 350. Revision Information……………………………………………………………………….. 355. Scope…………………………………………………………………….………………….. 356. External Requirements……………………………………………………………………..357. External References……………………………………………………………………….. 358. EP Specification……………………………………………………………………………. 364.1 <strong>Contractor</strong>’s Evaluation……………………………………………………………………. 365. EP and External References……………………………………………………………... 41

EP2005 Volume 1<strong>HSE</strong> <strong>Management</strong> inthe BusinessEP2005-0110 <strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>RestrictedEP2005-0151-T0-80: <strong>Contractor</strong> <strong>HSE</strong> Capability Questionnaire 431. General guidelines for preparation of questionnaire External References………….. 432. Questionnaire for <strong>Contractor</strong> <strong>HSE</strong> Capability Assessment …………………………… 43EP2005-0151-T0-81: <strong>HSE</strong> Plan Checklist for Major Contracts 531. <strong>HSE</strong> Plan Definition Guideline……………………………………………………………. 532. <strong>HSE</strong> <strong>Management</strong> System ………………………………………………………………..543. Detailed checklists for <strong>HSE</strong> Plan………………………………………………………….55EP2005-0151-T0-82: <strong>HSE</strong> Plan Checklist for Small Contracts 711. <strong>HSE</strong> Plan Definition Guideline……………………………………………………………. 712. Checklist for <strong>HSE</strong> Plan………….………………………………………………………….713. Small Contract Typical <strong>HSE</strong> Plan Performa…………………………………………….73

EP2005 Volume 1<strong>HSE</strong> ToolEP2005 Document ApprovalSheetRestrictedEP2005-0140-TO-84C. Optional acknowledgement and reviewNameRegion/ Nature of involvement Date SignatureFunctionKrishna Bala EPA Principal AuthorNumpang Suntai EPA ReviewerSuzanne Russel EPE ReviewerLarissa Schapkova EPR ReviewerBilly Stidham EPW ReviewerDoc. No.:EP200412282462Version:2Date:30 August 2006Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content2 of 2Printed copies are uncontrolledEP200406291204/Tool EP2005-0140-TO-84, version 1

EP2005 Volume 1<strong>HSE</strong> Standard<strong>Contractor</strong> <strong>HSE</strong><strong>Management</strong>RestrictedEP2005-0110-STSTANDARD: CONTRACTOR <strong>HSE</strong> MANAGEMENTThis <strong>HSE</strong> document may set requirements supplemental to applicable law. However,nothing herein is intended to replace, amend, supersede or otherwise depart from anyapplicable law relating to the subject matter of this <strong>HSE</strong> document. In the event of anyconflict or contradiction between the provisions of this <strong>HSE</strong> document and applicablelaw as to the implementation and governance of this <strong>HSE</strong> document, the provisions ofapplicable law shall prevail.This <strong>HSE</strong> document shall be subject to formal adoption as specified in EP Standard ‘<strong>HSE</strong>Control Documentation <strong>Management</strong>’ [9].0. Revision Information• Amended EP Procedure ‘<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong> (including stoplight)’;• Introduced new EP Specification ‘Contract Holder and CSR HSSE Competences’;• Removed EP Specification ‘<strong>HSE</strong> Contract Modes’* 1 .1. IntroductionContracted work accounts for 70-75% of EP’s total exposure hours and much of it involves High<strong>HSE</strong> Risk hence working with contractors and early planning are essential to improve <strong>HSE</strong> at theworkplace.This Standard is aligned with EP.13 ‘Manage Supply Chain – Global Category <strong>Management</strong>’ [25]of the EP Business Model (EPBM) and draws heavily on the Oil and Gas Producers Association(OGP) document ‘<strong>HSE</strong> <strong>Management</strong> – Guideline for working together in a contract environment’[22].2. Scope and ApplicationThis Standard and the associated controlling documents set the <strong>HSE</strong> requirements forcontracting in the EP Business and apply to Global and Regional framework arrangements andindividual contracts.Italicised terms within this Standard are defined EP Specification ‘EP2005 <strong>HSE</strong> Glossary ofDefinitions’ [7].3. EP Policy• Requires contractors to manage <strong>HSE</strong> in line with the EP <strong>HSE</strong> Policy [21].• <strong>Management</strong> controls shall be appropriate for the level of risk, the organisational relationshipwith the contractor and the capabilities of the contractor.4. EP StandardCompliance with this Standard shall be achieved by implementing EP Procedure ‘<strong>Contractor</strong><strong>HSE</strong> <strong>Management</strong> (including stoplight)’ [3]. The activity responsibility matrix of this Procedure isshown in [App. 1].4.1 Key Roles and ResponsibilitiesThe following Supply Chain <strong>Management</strong> (SCM) roles, defined in [25], have <strong>HSE</strong>-specificresponsibilities see [App. 2] under this Standard and associated controlling documents:1The content of the Specification has been integrated into Task 2 of EP Procedure ’<strong>Contractor</strong> <strong>HSE</strong><strong>Management</strong> (inc. Stoplight) [3].Doc. No.: Version:EP200406372785 2Org. Doc No.: EP2005-0110-STDate:30 August 2006Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EARPage:No US content1 of 7Printed copies are uncontrolled

EP2005 Volume 1<strong>HSE</strong> Standard<strong>Contractor</strong> <strong>HSE</strong><strong>Management</strong>RestrictedEP2005-0110-ST• Contract Owner (CO);• Contract Holder (CH);• Company Site Representative (CSR) and Contract Users;• Tender Boards or equivalent (TB);• Global Category Manager (GCM);• Category Focal Point (CFP);• Regional Focal Point (RFP);• Contracting and Procurement staff (C&P);• <strong>HSE</strong> Adviser.4.2 Planning: Assess <strong>HSE</strong> Risks and <strong>Contractor</strong> CapabilityContract <strong>HSE</strong> RiskEach contract shall be categorised as Low <strong>HSE</strong> Risk, Medium <strong>HSE</strong> Risk or High <strong>HSE</strong> Riskdepending on the highest risk inherent in the contract scope determined using the Group (YG)‘Risk Assessment Matrix’ (RAM) [24, §2.1]. To minimise effort and to ensure consistencyreference shall be made to the relevant hazard & environmental aspects registers of the EPCompany and other <strong>HSE</strong> risk assessments maintained at the SCM category level or by industry(e.g. OGP).Contract ModeAccountability for <strong>HSE</strong> management shall be clearly defined between the EP Company and thecontractor and between the contractor and their subcontractors for the duration of the contract orindividual phases of the contract.On the basis of these accountabilities contracts and subcontracts shall be categorised as Mode1, Mode 2 or Mode 3:Mode 1 contracts:‘The contractor provides people and tools for the execution of the work under the supervision,instructions and <strong>HSE</strong> <strong>Management</strong> System of the company. The contractor has a <strong>Management</strong>System to provide assurance that the personnel for whom he is responsible are qualified andhealthy for the job and that the tools and machinery he is providing are properly maintained andsuitable for the job’ 2 .Mode 2 contracts:‘The contractor executes all aspects of the job under its own <strong>HSE</strong> <strong>Management</strong> System,provides the necessary instructions and supervision and verifies the proper functioning of its<strong>HSE</strong> <strong>Management</strong> System. The company is responsible for verifying the overall effectiveness ofthe <strong>HSE</strong> management controls put in place by the contractor, and assuring that both thecompany’s and the contractor’s <strong>HSE</strong>-MS are appropriately compatible’ 2 .Mode 3 contracts:<strong>Contractor</strong> operates within its own <strong>HSE</strong> MS that has no interfaces with the EP Company <strong>HSE</strong>MS and is not required to report <strong>HSE</strong> performance data including incidents to EP. However, thisdoes not exclude the possibility that the EP Company may wish to guide and influence <strong>HSE</strong>performance under the contract.Appointment of Contract HoldersThe task of being a CH of Mode 1 and Mode 2 Medium <strong>HSE</strong> Risk and High <strong>HSE</strong> Risk contractsis deemed to be an <strong>HSE</strong> critical task and hence subject to the requirements of EP Specification‘Contract Holder and CSR HSSE Competences’ [1].Contract <strong>HSE</strong> Clauses<strong>HSE</strong> clauses for each contract shall be selected, with advice from SCM and the relevant <strong>HSE</strong>Adviser, to suit the:• Type of activity;2 Definition from OGP <strong>HSE</strong> <strong>Management</strong> – ‘Guideline for working together in a contract environment [22]’Doc. No.: Version:EP200406372785 2Org. Doc No.: EP2005-0110-STDate:30 August 2006Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EARPage:No US content2 of 7Printed copies are uncontrolled

EP2005 Volume 1<strong>HSE</strong> Standard<strong>Contractor</strong> <strong>HSE</strong><strong>Management</strong>RestrictedEP2005-0110-ST• Contract-specific <strong>HSE</strong> risks;• Contract mode.<strong>Contractor</strong> Capability AssessmentAn <strong>HSE</strong> capability assessment shall be made of all contractors considered for Mode 1 or Mode 2Medium <strong>HSE</strong> Risk or High <strong>HSE</strong> Risk contracts to assess their ability to manage the <strong>HSE</strong> risksassociated with the contract work scope. The <strong>HSE</strong> capability assessment shall be based on:• A standardised <strong>HSE</strong> capability questionnaire;• Past <strong>HSE</strong> performance (completeness and effectiveness of their <strong>HSE</strong> MS implementationusing previous performance closeout reports and historical <strong>HSE</strong> incident statistics);• On-site audits (if deemed required).On the basis of this <strong>HSE</strong> capability assessment contractors shall be categorised into three‘stoplight’ bands (green, amber and red, reflecting reducing <strong>HSE</strong> management capabilities) foruse in selection of eligible contractors to bid and during bid evaluation.The <strong>HSE</strong> Capability Assessment is not required for:• Mode 1 or Mode 2 Low <strong>HSE</strong> Risk contracts. However, contractors’ ability to manage the<strong>HSE</strong> risks associated with the contract work scope and their historical <strong>HSE</strong> performanceshall be evaluated and deemed acceptable;• Mode 3 (Low/Medium/High <strong>HSE</strong> Risk).Tendering/Bidding or Negotiating and Award of ContractThe banding of a contractor in the red ‘stoplight’ band implies an <strong>HSE</strong> management capabilitybelow EP Company requirements and hence a red-banded contractor shall not be invited totender/bid or enter into negotiations or be awarded a contract if an amber or green-bandedcontractor is available on the short list. Any deviations to this rule shall be authorised by therelevant Tender Board.4.3 Execution: Manage ContractContract <strong>HSE</strong> PlansFor all Mode 1 and Mode 2 contracts a Contract <strong>HSE</strong> Plan shall be approved by the EPCompany before contracted work is started. The plan shall indicate those pre-start-up activities,which must be completed before contracted work may start. These activities shall includecommunicating the requirements of the Contract <strong>HSE</strong> Plan to the relevant responsible parties.Contract <strong>HSE</strong> Plans shall document the level of <strong>HSE</strong> risk inherent in the contract scope:• For Mode 2 Medium <strong>HSE</strong> Risk and Mode 2 High <strong>HSE</strong> Risk contracts the Contract <strong>HSE</strong> Plan,using the check list in [5], shall:o Provide a demonstration that the <strong>HSE</strong> risks of the contract hazards and effects areidentified and reduced to as low as reasonably practicable (ALARP) in accordance withEP Standard ‘ Hazards and Effects <strong>Management</strong> System (HEMP)’[10]; ando Include the contract specific <strong>HSE</strong> objectives in line with the phasing of the contract;• For Mode 1 (Low, Medium or High <strong>HSE</strong> Risk) and Mode 2 Low <strong>HSE</strong> Risk contracts theContract <strong>HSE</strong> Plan shall document how the <strong>HSE</strong> risks of the contract scope will be managedin accordance with [6].Pre-mobilisation and Mobilisation ActivitiesFor all Mode 1 and Mode 2 contracts completion of pre-start-up activities in the Contract <strong>HSE</strong>Plan shall be verified prior to commencement of work and a kick-off meeting shall be held.Pre-job inspections shall be held for all Mode 1 and Mode 2 contracts, which are Medium <strong>HSE</strong>Risk or High <strong>HSE</strong> Risk. Start-up <strong>HSE</strong> audits may be required depending on the contract size andcomplexity.Doc. No.: Version:EP200406372785 2Org. Doc No.: EP2005-0110-STDate:30 August 2006Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EARPage:No US content3 of 7Printed copies are uncontrolled

EP2005 Volume 1<strong>HSE</strong> Standard<strong>Contractor</strong> <strong>HSE</strong><strong>Management</strong>RestrictedEP2005-0110-ST6. Related EP Controlling DocumentsNo. Title Reference[1] EP Specification ‘Contract Holder and CSR HSSEEP2005-0110-SP-01Competences’[2] EP Specification ‘<strong>Contractor</strong> <strong>HSE</strong> Capability Points System’ EP2005-0110-SP-02[3] EP Procedure ’<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong> (inc. Stoplight)’ EP2005-0110-PR-10[4] EP Tool ‘<strong>Contractor</strong> <strong>HSE</strong> Capability Questionnaire’ EP2005-0110-TO-80[5] EP Tool ‘<strong>HSE</strong> Plan Checklist for Major Contracts’ EP2005-0110-TO-81[6] EP Tool ‘<strong>HSE</strong> Plan Checklist for Small Contracts’ EP2005-0110-TO-82[7] EP Specification ‘EP2005 <strong>HSE</strong> Glossary of Definitions’ EP2005-0100-SP-01[8] EP Standard ‘EP2005 <strong>HSE</strong> Roles and Responsibilities’ EP2005-0103-SP-01[9] EP Standard ‘<strong>HSE</strong> Control Documentation <strong>Management</strong>’ EP2005-0140-ST[10] EP Standard ‘Hazards and Effects <strong>Management</strong> Process(HEMP)’EP2005-0300-STNote:EP Specification ‘<strong>HSE</strong> Contract Modes’ has been removed; see Revision Information for furtherinformation.7. Other ReferencesNo. Title Reference[21] EP <strong>HSE</strong> Policy, June 2004 SWW[22] OGP <strong>HSE</strong> management – ‘Guideline for working together in a WWWcontract environment’; Report No. 6.64/291; September 1999[23] Group (YG) 3 ‘Incident Classification, Investigation andSWWReporting’; February 2002[24] Group (YG) 3 ‘Risk Assessment Matrix’ (RAM); April 2006 SWW[25] EP.13 ‘Manage Supply Chain – Global Category <strong>Management</strong>’ SWW3 Group Yellow Guide, issued by the Health, Safety and Environment Advisers PanelDoc. No.: Version:EP200406372785 2Org. Doc No.: EP2005-0110-STDate:30 August 2006Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EARPage:No US content5 of 7Printed copies are uncontrolled

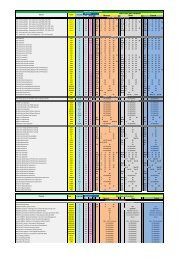

EP2005 Volume 1<strong>HSE</strong> Standard<strong>Contractor</strong> <strong>HSE</strong><strong>Management</strong>RestrictedEP2005-0110-STAppendix 1: Activity Responsibility MatrixTask definition<strong>HSE</strong>AdvisorEP/Dir/Reg/OpCoContractHolder(CH)SCM/C&P staffplusRFP*/CFP* andGCM*(Tasks 15-17)ContractOwner(CO)TenderBoard(TB)EP CompanySite Rep(CSR)ContractUserRemarks/Ref to other EP 2005-0110documentsPlanning1 Assess and analyse<strong>HSE</strong> risksContract User to be consultedparticularly for call-off typecontracts2 Categorise mode ofcontract3 Verify CH competence If M/H <strong>HSE</strong> Risk, Refer to EP2005-0110-SP-034 Select contract <strong>HSE</strong>clauses5Identify eligiblecontractors6 Evaluate <strong>HSE</strong> capabilityquestionnaire7 Evaluate historical <strong>HSE</strong>performance8 Evaluate the needfor/execute an <strong>HSE</strong>audit/review9 Band contractors10 Define evaluationcriteria and issuetender/bidor negotiate11 Evaluate bids/offers &select contractor forawardExecution12 Define and approveContract <strong>HSE</strong> PlanIf contract is Mode 1/2 Low <strong>HSE</strong>Risk go toTask 10.If contract is Mode 3 remainingTasks 6 -18 are not required.Refer toEP2005-0110-TO-80EP2005-0110-SP-02Refer to EP2005-0180-STGreen, Amber or Red -decreasing capability to manage<strong>HSE</strong> risks in contractDefine type of Contract <strong>HSE</strong> Planto be prepared by contractors (TO-81or TO-82 )<strong>Contractor</strong>s submit draft Contract<strong>HSE</strong> Plan: how <strong>HSE</strong> risks will bemanaged and the <strong>HSE</strong>management capabilities of anysubcontractors<strong>Contractor</strong> updates draft planTO-81or TO-8213 Execute pre-mob. andmob. activities14 Monitor implem. ofContract <strong>HSE</strong> PlanCSR/Contract User responsiblefor day to day monitoringAnalyse/Improve15 Sharing learning andgood practice(contractor <strong>HSE</strong>forums)16 Report to the TenderBoard17Steer <strong>HSE</strong> performanceimprovements18 Closeout of contractRFP/CFPRFP/CFPGCM/RFP/CFP*EP/Dir/Reg/OpCo: EP/Directorate/Region/Operating CompanySCM/C&P: Supply Chain <strong>Management</strong>/Contracting & ProcurementCFP: Category Focal Point RFP: Regional Focal PointExecute (executing); Performing a taskContribute (contributory); Contribute to a taskCheck (controlling); Check, verify resultsGCM: Global Category ManagerApprove (Approving); Approve resultsReceiving informationDoc. No.: Version:EP200406372785 2Org. Doc No.: EP2005-0110-STDate:30 August 2006Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EARPage:No US content6 of 7Printed copies are uncontrolled

EP2005 Volume 1<strong>HSE</strong> Standard<strong>Contractor</strong> <strong>HSE</strong><strong>Management</strong>RestrictedEP2005-0110-STAppendix 2: <strong>HSE</strong> ResponsibilitiesContract Owner (CO):• Appoint competent CH and endorse contract award and approve Contract <strong>HSE</strong> Plans.Contract Holder (CH):• The CH roles are deemed to be <strong>HSE</strong> critical for Medium and High <strong>HSE</strong> Risk contracts andare therefore subject to EP Standard ‘Competence Assurance of <strong>HSE</strong> Critical Positions’ [8](not a requirement for Low <strong>HSE</strong> Risk contracts);• Assess and analyse activity <strong>HSE</strong> risks;• Select contract mode and relevant <strong>HSE</strong> contract terms and conditions;• Define the stoplight band for eligible contractors;• Support C&P staff in contractor selection (tender, negotiate and award);• Define, discuss and agree Contract <strong>HSE</strong> Plan with the contractor(s);• Execute pre-mobilisation and mobilisation activities;• Monitor compliance with Contract <strong>HSE</strong> plan;• Steer <strong>HSE</strong> performance improvement during the contract and closeout of contract.Company Site Representative/Contract User (CSR/CU):• To have knowledge of the contract work scope and associated <strong>HSE</strong> risks, <strong>HSE</strong> capability ofcontractor and the required level of supervision;• Perform routine monitoring to verify compliance with Contract <strong>HSE</strong> Plan;• Support the CH in analysing <strong>HSE</strong> risks, preparation of Contract <strong>HSE</strong> Plan and during premobilisationand mobilisation activities;• Support the <strong>HSE</strong> Adviser in sharing learning.Tender Board (TB) or equivalent Chairman:• Challenge the CH and/or CO on compliance with EP/Dir/Reg/OpCo <strong>HSE</strong> standardsincluding this Standard;• Approve deviations during contract tender, negotiation, bid evaluation and award;• Approve award of contract.Regional Focal Point (RFP) and Category Focal Point (CFP):• Ensure umbrella/frame arrangements and approved contractors at the category level meetthe requirements of the EP <strong>HSE</strong> Standards (EP2005-0000 suite of <strong>HSE</strong> ControllingDocuments and any <strong>HSE</strong> requirements specific to the Category/Region). The RFP/CFPshall be supported by discipline expertise at the EP/Regional level (e.g. <strong>HSE</strong>, Legal,Seismic, Wells, Projects) for the following:o Maintaining general and activity specific <strong>HSE</strong> clauses;o Performing <strong>HSE</strong> MS audits or reviews, to assess the <strong>HSE</strong> capability of key contractorsbeing assessed and approved at the category Global or Regional level).• Support the <strong>HSE</strong> Adviser and CH in steering <strong>HSE</strong> performance improvements.Global Category Manager (GCM):Support the <strong>HSE</strong> Adviser and CH in steering <strong>HSE</strong> performance improvements.Contract & Procurement staff (C&P):• Support the CH in assessing <strong>HSE</strong> risks and in the identification of eligible contractors;• Support the <strong>HSE</strong> Adviser to assess contractor capability to manage <strong>HSE</strong> risks;• Define evaluation criteria and issue tender/bid or negotiate;• Evaluate bids/offers & select contractor for award.<strong>HSE</strong> Adviser (EP/Directorate/Region/OpCo):• Support the CH in assessing <strong>HSE</strong> risks and categorising contract mode;• Assess contractor capability to manage <strong>HSE</strong> risks in the contract work scope;• Share learning e.g. using contractor <strong>HSE</strong> forums and steer <strong>HSE</strong> performance improvement.Doc. No.: Version:EP200406372785 2Org. Doc No.: EP2005-0110-STDate:30 August 2006Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EARPage:No US content7 of 7Printed copies are uncontrolled

This page intentionally left blank

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10Procedure: <strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong> (including stoplight)This <strong>HSE</strong> document may set requirements supplemental to applicable law. However, nothingherein is intended to replace, amend, supersede or otherwise depart from any applicable lawrelating to the subject matter of this <strong>HSE</strong> document. In the event of any conflict orcontradiction between the provisions of this <strong>HSE</strong> document and applicable law as to theimplementation and governance of this <strong>HSE</strong> document, the provisions of applicable law shallprevail.This <strong>HSE</strong> document shall be subject to formal adoption as specified in EP Standard ‘<strong>HSE</strong>Control Documentation <strong>Management</strong>’ [8].Revision informationObjectiveDescription• Removed EP Specification ‘<strong>HSE</strong> Contract Modes’* 1 ;• Introduced new EP Specification ‘Contract Holder and CSR HSSECompetences’;• Amended Roles and Responsibilities of Global Category Manager (GCM),Category Focal Point (CFP) and Contract Holder (CH);• Introduced Role of Regional Focal Point;• Amended Task 5 and 16.• Updated Risk Domain in accordance with EP BMS updateTo work together with contractors to continually improve <strong>HSE</strong>performance by implementing <strong>HSE</strong> management controls that areappropriate for the level of <strong>HSE</strong> risk, the organisational relationshipwith the contractor and the capabilities of the contractor.ScopeAll contracts awarded by or on behalf of EP Companies. ThisProcedure is applied in three phases.(1) Planning: assess <strong>HSE</strong> risks and the capability of contractors tomanage those risks. The stoplight method is used, in whichcontractors are categorised into three bands - green, amber andred - according to their <strong>HSE</strong> management capabilities.(2) Execution: requires engagement protocols with contractorsaccording to their <strong>HSE</strong> management capabilities.(3) Analyse and Improve: capture and share learning at both thecontract and Supply Chain <strong>Management</strong> (SCM) category level.Risk domain and risk Risk Domain Risk(s):<strong>HSE</strong>Inadequate management of <strong>Contractor</strong> <strong>HSE</strong>Reputation Damage to the Group (license to operate)because <strong>Shell</strong> appears not to be able to conductits activities in a responsible manner.Input to activityInput From IT systemCH’s individual competencerecordsCH’s Line Manager CBD/<strong>Shell</strong>PeopleContracted activity and risk Process requesting -informationcontracted services<strong>Contractor</strong>s’ historical <strong>HSE</strong>performance(<strong>Shell</strong> and industry)<strong>Shell</strong> databasesVendor databasesFountain1 The content of the Specification has been integrated into Task 2 of thisProcedure.Doc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content1 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10Input From IT systemCompany/<strong>Shell</strong> assessments e.g. audit reports, -of contractors’ <strong>HSE</strong> MS closeout reports<strong>Contractor</strong> <strong>HSE</strong> performancefeedback<strong>HSE</strong> review process -Output of activity Output To Activity / Doc. NoStoplight band<strong>HSE</strong> capability and contractmanagement proceduresContract <strong>HSE</strong> clauses ContractDoc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content2 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10Activity ResponsibilityMatrixDetails on <strong>HSE</strong> roles and responsibilities and related abbreviationsare contained in ‘EP Supply Chain <strong>Management</strong> Key Roles’ [22] andEP Specification ‘EP2005 <strong>HSE</strong> Roles and Responsibilities’ [7].Task definition<strong>HSE</strong>AdvisorEP/Dir/Reg/OpCoContractHolder(CH)SCM/C&P staffplusRFP*/CFP* andGCM*(Tasks 15-17)ContractOwner(CO)TenderBoard(TB)EP CompanySite Rep(CSR)ContractUserRemarks/Ref to other EP 2005-0110documentsPlanning1 Assess and analyse<strong>HSE</strong> risksContract User to be consultedparticularly for call-off typecontracts2 Categorise mode ofcontract3 Verify CH competence If M/H <strong>HSE</strong> Risk, Refer to EP2005-0110-SP-034 Select contract <strong>HSE</strong>clauses5Identify eligiblecontractors6 Evaluate <strong>HSE</strong> capabilityquestionnaire7 Evaluate historical <strong>HSE</strong>performance8 Evaluate the needfor/execute an <strong>HSE</strong>audit/review9 Band contractors10 Define evaluationcriteria and issuetender/bidor negotiate11 Evaluate bids/offers &select contractor forawardExecution12 Define and approveContract <strong>HSE</strong> PlanIf contract is Mode 1/2 Low <strong>HSE</strong>Risk go toTask 10.If contract is Mode 3 remainingTasks 6 -18 are not required.Refer toEP2005-0110-TO-80EP2005-0110-SP-02Refer to EP2005-0180-STGreen, Amber or Red -decreasing capability to manage<strong>HSE</strong> risks in contractDefine type of Contract <strong>HSE</strong> Planto be prepared by contractors (TO-81or TO-82 )<strong>Contractor</strong>s submit draft Contract<strong>HSE</strong> Plan: how <strong>HSE</strong> risks will bemanaged and the <strong>HSE</strong>management capabilities of anysubcontractors<strong>Contractor</strong> updates draft planTO-81or TO-8213 Execute pre-mob. andmob. activities14 Monitor implem. ofContract <strong>HSE</strong> PlanCSR/Contract User responsiblefor day to day monitoringAnalyse/Improve15 Sharing learning andgood practice(contractor <strong>HSE</strong>forums)16 Report to the TenderBoard17Steer <strong>HSE</strong> performanceimprovements18 Closeout of contractRFP/CFPRFP/CFPGCM/RFP/CFP* EP/Dir/Reg/OpCo: EP/Directorate/Region/Operating Company GCM: Global Category Manager RFP: Regional Focal PointSCM/C&P: Supply Chain <strong>Management</strong>/Contracting & ProcurementCFP: Category Focal PointExecute (executing); Performing a taskApprove (Approving); Approve resultsContribute (contributory); Contribute to a taskReceiving informationCheck (controlling); Check, verify resultsDoc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content3 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10PlanningTask 1: Assess and analyse <strong>HSE</strong> risksCategorise each contract as Low <strong>HSE</strong> Risk, Medium <strong>HSE</strong> Risk orHigh <strong>HSE</strong> Risk corresponding to the highest risk inherent in thecontract scope as follows:1. Identify all Hazards associated with activities in the contractwork scope, covering but not limited to the following:• Nature of the work - work methods, staffing, materials,equipment, tools to be used and associated hazards e.g.lifting, working at heights, transport, etc;• Nature of the product or service i.e. is the contractorrequired to perform an <strong>HSE</strong> critical activity (such as thedesign <strong>HSE</strong>-critical equipment) as opposed to a hazardousactivity (such as working at height);• Location of the work - vicinity of shops, schools, hospitals,offices, houses; environmentally sensitive locations(beaches, coral reefs, fishing areas, etc), and associatedhazards e.g. H 2 S, asbestos, chemicals and heat;• Local constraints;• Number of concurrent operations or contractors on site;• Potential consequences – environmental harm, injury,illness, asset damage, impact on local societal sensitivities,reputation with Non-Governmental Organisations (NGO) orGovernments, etc.To minimise the assessment effort and to ensure consistencyassessors shall refer to the relevant hazards & environmentalaspects registers of the EP Company, the EP Standard ‘Hazardsand Effects <strong>Management</strong> Process’ (HEMP) [11] and other <strong>HSE</strong>risk assessments maintained at the SCM Category level or byindustry (e.g. OGP).2. Assess the <strong>HSE</strong> risk of each Hazard using the Group (YG) ‘RiskAssessment Matrix’ (RAM) [23, §2.1].3. Document the <strong>HSE</strong> risk assessment.Task 2: Categorise mode of contractCategorise the contract as Mode1, Mode 2 or Mode 3:Mode 1 contract:‘The contractor provides people and tools for the execution of thework under the supervision, instructions and <strong>HSE</strong> <strong>Management</strong>System of the company. The contractor has a <strong>Management</strong> Systemto provide assurance that the personnel for whom he is responsibleare qualified and healthy for the job and that the tools and machineryhe is providing are properly maintained and suitable for the job’ 2 .Mode 2 contract:‘The contractor executes all aspects of the job under its own <strong>HSE</strong><strong>Management</strong> System, provides the necessary instructions andsupervision and verifies the proper functioning of its <strong>HSE</strong><strong>Management</strong> System. The company is responsible for verifying theoverall effectiveness of the <strong>HSE</strong> management controls put in placeby the contractor, and assuring that both the company’s and thecontractor’s <strong>HSE</strong>-MS are appropriately compatible’ 2 .2 Definition from OGP <strong>HSE</strong> <strong>Management</strong> – ‘Guideline for working together ina contract environment [25]’Doc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content4 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10Mode 3 contract:<strong>Contractor</strong> operates within its own <strong>HSE</strong> MS that has no interfaceswith the EP Company <strong>HSE</strong> MS and is not required to report <strong>HSE</strong>performance data including incidents to EP. However, this does notexclude the possibility that the EP Company may wish to guide andinfluence <strong>HSE</strong> performance under the contract.The <strong>HSE</strong> contract mode is assigned as follows:• Determine whether each activity within the contract scope is aWork Related Activity as defined by the Group (YG) ‘IncidentClassification, Investigation and Reporting’ [24, § 2.1];• For those Work Related Activities select the accountability for<strong>HSE</strong> management by assigning them as either Mode 1 or Mode;• Assign those activities, which are not Work Related as Mode 3;• Assign a contract mode based on the aggregated modesassigned to the activities in the contract scope taking intoaccount the numbers and significance of those activities andtheir <strong>HSE</strong> risks;• In mixed mode contracts identify and document those elementswith a mode different from the overall contract mode.Subcontracts shall also be assigned a mode, in which case thecontractor who subcontracts one or more of the scope elements isresponsible for assigning the mode to each subcontract according tothis Task.Task 3: Verify Contract Holder’s competenceFor Mode 1 or Mode 2 Medium <strong>HSE</strong> Risk or High <strong>HSE</strong> Riskcontracts verify the Contract Holder’s (CH) competence according toEP Specification ‘Contract Holder and CSR HSSE Competences’ [2]and their ability to execute their assigned tasks in this Procedure.Task 4: Select contract <strong>HSE</strong> clausesSelect <strong>HSE</strong> contract clauses based on:• Output from Task 1 (<strong>HSE</strong> risks of work activities); and• Output from Task 2 (mode of contract).Refer to SCM/C&P staff and consult with the relevant <strong>HSE</strong> Adviser(EP/Dir/Reg/OpCo) for guidance on the formulation of activityspecific clauses and technical requirements.Task 5: Identify eligible contractorsPrepare a list of eligible contractors:• List eligible contractors on the basis of historical experience orexpert judgment or as directed by JV agreements or localregulation;• Mode 1 or Mode 2 Medium <strong>HSE</strong> Risk or High <strong>HSE</strong> Riskcontracts - Eligible contractors who have not had their <strong>HSE</strong>capability assessed within the last three years and who wish tobe considered shall complete and submit the questionnaire inEP Tool ‘<strong>Contractor</strong> <strong>HSE</strong> Capability Questionnaire’ [4];• Mode 1 or Mode 2 Low <strong>HSE</strong> Risk contracts - Eligible contractors’ability to manage the <strong>HSE</strong> risks associated with the contractwork scope and their historical <strong>HSE</strong> performance shall beevaluated and deemed acceptable. However they are exemptfrom the <strong>HSE</strong> capability assessment (see Tasks 6 - 9); the nextrelevant task for them is Task 10. This exemption may also beapplied at the discretion of the Contract Owner (CO) to MediumDoc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content5 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10<strong>HSE</strong> Risk contracts which are Mode 1 and have a restrictedscope of work (e.g. one or two person welding job or a one weekpainting job using scaffolding);• Mode 3 (L/M/H <strong>HSE</strong> Risk) contracts - Eligible contractors areexempt from the <strong>HSE</strong> capability assessment. The remainingTasks 6 -18 are not required.Task 6: Evaluate <strong>HSE</strong> capability questionnaireEvaluate contractors’ ‘<strong>HSE</strong> Capability Questionnaire’ [4] andassociated supporting documents.Task 7: Evaluate historical <strong>HSE</strong> performance• Evaluate the contractors’ <strong>HSE</strong> performance in previous work forEP Companies. Verify answers given in contractors’ <strong>HSE</strong>capability questionnaire returns where possible, usinginformation from previous audit reports, contract closeoutreports, feedback forms, RFPs, CFPs and SCM/C&P staff.• Evaluate the contractors’ historical <strong>HSE</strong> statistics taking intoaccount the following:o The relevance of the data to the work locations and <strong>HSE</strong>risks of the activities within the contract scope;o The level and quality of near-miss/unsafe condition/unsafeact reporting and other pro-active indicators being trackedand reported;o Use 12 month rolling average data to avoid statisticalanomalies;o The severity of typical incident reportable cases [24, App. 1],total exposure hours and possible differences inperformance between Corporate, Regional and Localcontractor entities;o Treat internal <strong>Shell</strong> statistics as leading benchmarks, ifavailable. External statistics may be less specific to the EPBusiness than internal <strong>Shell</strong> statistics.Task 8: Evaluate the need for/execute an <strong>HSE</strong> MS audit/reviewFor contractors being considered for Mode 2 High <strong>HSE</strong> Riskcontracts conduct an <strong>HSE</strong> MS audit/review if little recent (less thanthree years old) independent information held at EP/Dir/Reg/OpColevel (e.g. audit reports) is available on their <strong>HSE</strong> capabilities.It is recommended that when the contract scope is significant interms of exposure hours or area of operations or contact with localstakeholders or impact on EP Company assets that this requirementis extended to Mode 2 Medium <strong>HSE</strong> Risk contracts.The <strong>HSE</strong> MS review/audit has three main objectives:1. To verify the completeness and degree of implementation of thecontractor’s <strong>HSE</strong> MS and identify where to supplement themonitoring of the contractor’s work.2. To provide the contractor with a deeper understanding of the EPCompany’s <strong>HSE</strong> MS requirements.3. To verify the contractor’s responses to the <strong>HSE</strong> CapabilityQuestionnaire [4].The <strong>HSE</strong> MS audits/reviews shall meet the following requirements:• Audit/review leader is nominated by the EP Company;Doc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content6 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10• Auditor(s) meet the <strong>HSE</strong> auditor competence criteria for Internal<strong>HSE</strong> Audits as defined in EP Specification ‘<strong>HSE</strong> AuditorCompetence Criteria’ [10, §4.2.3];• The Terms of Reference (TOR) for the <strong>HSE</strong> MS audit/review areto be based on [4];• Conducted on the contractor’s premises/sites;• Findings are discussed with the contractor and agreedimprovement actions should be included in the contractor’s <strong>HSE</strong>MS improvement plan(s);• The relevant CHs with RFP and/or CFP and <strong>HSE</strong> Advisersupport shall monitor the contractor’s follow-up of the <strong>HSE</strong> MSimprovement plan. If a contractor has multiple active EPCompany contracts the relevant CHs shall support thismonitoring along with their routine monitoring of their specificContract <strong>HSE</strong> Plan(s).Task 9: Band <strong>Contractor</strong>sAdjudicated scoring is a consolidation of the outputs from Tasks 6, 7and 8. The output is a score based on EP Specification ‘<strong>Contractor</strong><strong>HSE</strong> Capability Points System’ [3]. This is not intended to be apurely quantitative process, but one where experience is brought tobear on the contractors’ responses:1. Based on [3] the contractors are banded on adjudicated scoresfor each question (based on max. points = 280). They arecategorised in red (or equal to 178 points) bands:• Red denotes ‘capability is below Company requirements’;• Amber denotes ‘capability conditionally meets Companyrequirements’;• Green denotes ‘capability unconditionally meets Companyrequirements’.2. Inform the contractors in writing of their stoplight banding.3. Document the results of the capability assessment including anyaudit/reviews and record or reference in the relevant SCMcontractor management database/system(s). Documentationshall include but not limited to:• Audit/review reports;• Responses to the <strong>HSE</strong> Capability Questionnaire [4] and theresults of applying the <strong>Contractor</strong> <strong>HSE</strong> Capability PointsSystem [3];• <strong>HSE</strong> performance data used for the capability assessment;• Stoplight band.4. Share the results of the <strong>HSE</strong> capability assessment acrossEP/Dir/Reg/OpCo as this will help to leverage best practicelearning and reduce effort/cost in performing contractor <strong>HSE</strong>capability assessments.Note: Tasks 1 - 9 can be performed at the SCM category level whenestablishing umbrella/frame arrangements or a list of globallyapproved contractors.The RFP and/or CFP shall ensure that:• Umbrella/frame arrangements and/or approved contractorsmaintained at the category level meet the requirements of theEP <strong>HSE</strong> standards (EP2005-0000 suite of <strong>HSE</strong> ControllingDoc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content7 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10Documents and any <strong>HSE</strong> requirements specific to theCategory/Region). The CFP and/or RFP shall be supported bydiscipline expertise at the EP/Regional level (e.g. <strong>HSE</strong>, Legal,Seismic, Wells, Projects) for the following:o Maintaining general and activity specific <strong>HSE</strong> clauses;o Performing <strong>HSE</strong> MS audits or reviews, to assess the <strong>HSE</strong>capability of key contractors being assessed and approvedat the category Global or Regional level).If a CH plans to invite bids from a contractor on such an approvedlist maintained by the relevant RFP and/or CFP, Tasks 4 - 9 do nothave to be repeated for their specific contract unless the contractorhas not performed work for an EP Company for more than threeyears.Task 10: Define evaluation criteria, issue tender/bid or negotiate1. Red-banded contractor shall not be invited to tender/bid or enterinto negotiation if amber or green-banded contractors areavailable on the potential bid/negotiation list. Any deviations tothis rule shall be authorised by the relevant Tender Board (TB)and the justification shall be clearly documented in the TBmeeting minutes.2. Provide candidate contractors with access to the contractspecific <strong>HSE</strong> requirements, including the type of Contract <strong>HSE</strong>Plan to be prepared in draft.3. Provide candidate contractors the opportunity to assess forthemselves the <strong>HSE</strong> risks of the contract scope (e.g. site visits,access to EP Companies <strong>HSE</strong> risk assessments and requirethem as part of their submission to document how they willmanage the specific <strong>HSE</strong> risks of the contract as part of theirdraft Contract <strong>HSE</strong> Plan.4. Bid evaluation models shall make provision for additionalresources (e.g. supervision, training, equipment), which in theopinion of the CH are required for red and amber bandedcontractors to meet the <strong>HSE</strong> requirements of the contract.5. Bid evaluation models which are based on points/weightings forthe different evaluation aspects (e.g. commercial, technical,<strong>HSE</strong>) then the <strong>HSE</strong> element shall have a total contribution asfollows:• High <strong>HSE</strong> Risk contracts: Not less than 30%;• Medium <strong>HSE</strong> Risk contracts: Not less then 15%;• Low <strong>HSE</strong> Risk contracts: Not less than 5%.Deviations from these percentages shall be authorised by therelevant TB and the justification shall be clearly documented inthe TB meeting minutes.Task 11: Evaluate bids/offers & select contractor for awardMake the selection based on consolidation of commercial, technical,<strong>HSE</strong> and local aspects in line with [21] with the condition that acontract shall not be awarded to a red-banded contractor if an amberor green-banded contractor is available on the short list. Anydeviations to this rule shall be authorised by the relevant TB and thejustification shall be clearly documented in the TB meeting minutes.Doc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content8 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10Execution(not required forMode 3 contracts)Task 12: Define and approve Contract <strong>HSE</strong> PlanThe contractor, in conjunction with the CH, prepares a documentedContract <strong>HSE</strong> Plan before contracted work is started:• For Mode 1 contracts the plan is owned by the CH with inputfrom the contractor and approved by the CO;• For Mode 2 contracts the plan is owned by the contractor withinput from the CH/CSR/<strong>HSE</strong> Adviser and approved by the CO;• This <strong>HSE</strong> Plan shall document the level of <strong>HSE</strong> risk in thecontract scope (including work in subcontractor yards andworkshops if they are Mode 1/2 activities) and document theinterface arrangements for <strong>HSE</strong> management between parties(e.g. contractor, subcontractors and EP Company) to ensurethat responsibilities for maintaining <strong>HSE</strong> controls are completeand understood;• The plan shall indicate those pre-start-up activities, which mustbe complete before contracted work may start, includingcommunicating the requirements of the Contract <strong>HSE</strong> Plan tothe relevant responsible parties;• The plan shall list conditions and circumstances that couldchange the <strong>HSE</strong> risk profile of the contract scope i.e. updatingthe <strong>HSE</strong> risk assessment from Low <strong>HSE</strong> Risk to Medium/High<strong>HSE</strong> Risk.Specific requirements for <strong>HSE</strong> Plans depend on the contract modeand contract <strong>HSE</strong> risk as follows:1. Mode 2 Medium <strong>HSE</strong> Risk or Mode 2 High <strong>HSE</strong> Risk contracts:Document the <strong>HSE</strong> hazard/risk control requirements in aContract <strong>HSE</strong> Plan which provides a demonstration that the <strong>HSE</strong>risks of the contract hazards and effects are identified andreduced to as low as reasonably practicable (ALARP) inaccordance with [11] and EP Tool ‘<strong>HSE</strong> Plan Checklist for MajorContracts’ [5] and the following:• Identify subcontractors and categorises their <strong>HSE</strong> contractmode as Mode 1, Mode 2 or Mode 3;• Make reference to the relevant <strong>HSE</strong> MS or <strong>HSE</strong> Case(s) orEP Company project <strong>HSE</strong> Plan(s) to avoid unnecessaryduplication;• Include <strong>HSE</strong> improvement targets;• Include a periodic review (at least quarterly for red-bandedcontractors) of <strong>HSE</strong> improvement progress and performanceagainst Contract <strong>HSE</strong> Plan;• Include on-site <strong>HSE</strong> supervision by EP Company for redbandedcontractors. The CO shall approve deviations to thisrule.2. Mode 1 (Low/Medium/High <strong>HSE</strong> Risk) or Mode 2 Low <strong>HSE</strong> Riskcontracts:Document the <strong>HSE</strong> hazard and risk control requirements in aContract <strong>HSE</strong> Plan using EP Tool ‘Contract <strong>HSE</strong> Plan Checklistfor Small Contracts’ [6].Task 13: Execute pre-mobilisation and mobilisation activities1. The pre-start-up activities defined in the Contract <strong>HSE</strong> Plan shallbe verified complete prior to commencement of work.The issues covered by this step include:• Consortium partnership issues (cooperation of a leadingcontractor with one or more other specialised contractors);Doc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content9 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10• Actions to be completed prior to mobilisation;• Number and competence of <strong>HSE</strong> professionals;• The matrix below defines activities required during premobilisation,and mobilisation:Activity Mode 1/Mode 2Authorisation to startYesmobilisation/workKick-off meetingYesPre-mob/job inspections, YesMedium <strong>HSE</strong> Risk and High<strong>HSE</strong> Risk contractsPre-mob/job inspections, Low Dependent upon size/<strong>HSE</strong> Risk contractscomplexity of contractStart-up Audits for Medium and Dependent upon size/High <strong>HSE</strong> Risk workcomplexity of contractEarly testing of contingency Yesplanning2. Hold a kick-off meeting to verify that the contractor's workforceand supervisors are aware of the relevant parts of the Contract<strong>HSE</strong> Plan including but not limited to:• Promoting the EP Companies commitment to <strong>HSE</strong> and thathealth and safety takes priority over other contractobjectives, KPIs and requirements;• Site hazards of the operation detailed in the scope of work;• Familiar with:o <strong>HSE</strong> working procedures;o Rules and regulations;o Alarms and signals;o Emergency communications and procedures.The meeting may be structured as an <strong>HSE</strong> workshop, withparticipation by both EP Company and contractor management.3. Conduct pre-mobilisation/job inspection(s), using the relevantparts of the Contract <strong>HSE</strong> Plan as a TOR.Conduct specialist review(s) (e.g. <strong>Shell</strong> Aircraft International airoperations reviews or STASCO vessel inspections) prior tomobilisation.4. Authorise the contractor to start mobilisation/work.5. Conduct <strong>HSE</strong> start-up audits as required:• For Mode 1 contracts, the need for an audit shall dependupon the size and complexity of the contract;• For Mode 2 contracts it is recommended to conduct an <strong>HSE</strong>start-up audit in accordance with the relevant parts of the EPStandard ‘<strong>HSE</strong> Auditing’ [9] if such contracts are:o High <strong>HSE</strong> Risk; oro Medium <strong>HSE</strong> Risk, which are complex operations ormanaged by contractors new to EP/Dir/Reg.6. Ensure inspection and audit findings are followed-up, closed andsubject to the following:• Serious/High findings [24, §5]:<strong>Contractor</strong> or the EP Company shall take corrective actionsbefore the relevant parts of the work can commence;• Medium/Low findings [24, §5]:<strong>Contractor</strong> or the EP Company shall take corrective actionDoc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content10 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10but this may be allowed to take place in parallel withinitiating the execution phase.Further guidance on Steps 1 to 3 above can be found in §6.1, 6.2and 6.3 of OGP <strong>HSE</strong> <strong>Management</strong> – ‘Guidelines for workingtogether in a contract environment’ [25].Task 14: Monitor implementation of the Contract <strong>HSE</strong> Plan andsteer performance improvement during the contractThe CH/CSR/Contract User to be visible in promoting the EPCompanies commitment to <strong>HSE</strong> (e.g. attending <strong>HSE</strong> talks andmeetings and regularly re-enforcing that health and safety takepriority over other contract objectives).The CSR/Contract User shall assist the CH in monitoring the day-todayimplementation of the Contract <strong>HSE</strong> Plan including closeout ofagreed actions, <strong>HSE</strong> performance, and any changes in the <strong>HSE</strong> riskprofile of the current and future activities within the contract scope:1. For Mode 1 contracts: The CH/CSR/Contract User supervisesthe contractor and is directly responsible for the effectiveimplementation of the Contract <strong>HSE</strong> Plan.2. For Mode 2 Contracts: The CH/CSR/Contract User isresponsible to verify and monitor the contractor.3. For both Mode 1 and Mode 2 contracts: The CSR/Contract Userverifies the agreed handover procedures are implemented forcrew changes.Demonstrate that the <strong>HSE</strong> MSs of contractors (includingsubcontractors) are subject to continuous improvement in the courseof project execution, which shall include, if applicable, monitoring thecontractor’s follow-up of actions agreed at the SCM category level.Analyse/Improve(not required for Mode 3contracts)Task 15: Sharing learning and good practice (contractor <strong>HSE</strong>forums)Hold periodic forum sessions for contractors, grouped by SCMCategory or by project, which are executing Medium <strong>HSE</strong> Risk orHigh <strong>HSE</strong> Risk contracts in order to:• Share learning and best practices;• Address contractor interface issues;• Conduct <strong>HSE</strong> performance self-assessments.Task 16: Report to the Tender BoardReview at least annually with the Tender Board or equivalent thesignificant changes in stoplight bands of contractors involved withMedium <strong>HSE</strong> Risk contracts or High <strong>HSE</strong> Risk contracts. Use thesereviews to discuss issues and strategies and obtain guidance fromsenior management, and to obtain benchmarks from SCMdatabases.Task 17: Steer <strong>HSE</strong> performance improvementsThe CH steers <strong>HSE</strong> performance improvement during the contract,while the <strong>HSE</strong> Adviser annually updates and reviews with theCH/CO and GCM/CFP the stoplight bands of the current portfolio ofcontractors in order to recognise and improve performance. Forexample, performance improvement can be recognised by a specialletter, sustained good performance by a plaque, etc.Doc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content11 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10If a contractor has not performed work for an EP Company for morethan three years a full <strong>HSE</strong> capability assessment shall be repeated(i.e. Tasks 1 - 9 of this Procedure) relevant to the contract(s)scope(s) for which they are being assessed.Note: This step shall also be repeated at the EP level for thoseinternational contractors who work in several EP contract categoriesand for those international contractors working in a single EPcontract category (e.g. geophysical acquisition, drilling rigs).Task 18: Closeout of contract1. For Medium <strong>HSE</strong> Risk and High <strong>HSE</strong> Risk contracts prepare adocumented report of the <strong>HSE</strong> performance throughout theproject, including lessons learnt. The report should be followedup with face-to-face review meetings with the <strong>Contractor</strong>Representative who shall agree/sign-off on the report, notingthose aspects not agreed.RecordsEnter this final closeout report into the relevant contractordatabases.2. For Low <strong>HSE</strong> Risk, Medium <strong>HSE</strong> and High <strong>HSE</strong> Risk contractsenter the <strong>HSE</strong> performance data into the relevant contractordatabases.For the different stages in the SCM process, minimum <strong>HSE</strong> recordkeeping shall include the following:Record/DocumentPlanning:Contract scope risk assessmentrecordsOwner/CustodianCO -IT system<strong>Contractor</strong> <strong>HSE</strong> performance feedback <strong>HSE</strong> Fountain<strong>HSE</strong> Capability Questionnaires [4] and SCM -associated documentsActivity <strong>HSE</strong> risk assessment record CO -Categorisation (stoplight) record SCM -ExecutionOriginal contracts and contractmanagement plansIncl. Contract <strong>HSE</strong> PlanSCM -Reports on contractor <strong>HSE</strong>CO -performanceMinutes of meeting with contractor CH -Analyse/Improve<strong>HSE</strong> performance records <strong>HSE</strong> FountainContent of contractor databases SCM e.g. FPALRecords shall be retained for at least three years after the expirationdate.Doc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content12 of 13Printed copies are uncontrolled.

EP2005 Volume 1<strong>HSE</strong> Procedure<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>(including Stoplight)RestrictedEP2005-0110-PR-10Related ControllingDocuments No. Title Reference[1] EP Standard ‘<strong>Contractor</strong> <strong>HSE</strong> EP2005-0110-ST<strong>Management</strong>’[2] EP Specification ‘Contract Holderand CSR HSSE Competences’EP2005-0110-SP-01[3] EP Specification ‘<strong>Contractor</strong> <strong>HSE</strong>Capability Points System’EP2005-0110-SP-02[4] EP Tool ‘<strong>Contractor</strong> <strong>HSE</strong> CapabilityQuestionnaire’EP2005-0110-TO-80[5] EP Tool ‘<strong>HSE</strong> Plan Checklist forMajor Contracts’EP2005-0110-TO-81[6] EP Tool ‘<strong>HSE</strong> Plan Checklist forSmall Contracts’EP2005-0110-TO-82[7] EP Specification ‘EP2005 <strong>HSE</strong> EP2005-0103-SP-01Roles and Responsibilities’[8] EP Standard ‘<strong>HSE</strong> ControlEP2005-0140-STDocumentation <strong>Management</strong>[9] EP Standard ‘<strong>HSE</strong> Auditing’ EP2005-0180-ST[10] EP Specification ‘<strong>HSE</strong> Auditor EP2005-0180-SP-03Competence Criteria’[11] EP Standard ‘Hazards and Effects<strong>Management</strong> Process’EP2005-0300-STNote:EP Specification ‘<strong>HSE</strong> Contract Modes’ has been removed; seeRevision Information for further information.Other references No. Title Reference[21] EP Business Model Process.13 SWW‘Manage Supply Chain – GlobalCategory <strong>Management</strong>’ (EPBM v4).[22] EP Supply Chain <strong>Management</strong> Key SWWRoles; Version 5, June 2003[23] Group (YG) 3 ‘Risk Assessment SWWMatrix’ (RAM); 2006[24] Group (YG) 3 ‘IncidentSWWClassification, Investigation andReporting’; February 2002[25] OGP <strong>HSE</strong> management –‘Guideline for working together in acontract environment’; Report No.6.64/291; September 1999WWW3 Group Yellow Guide, issued by the Health, Safety and EnvironmentAdvisers PanelDoc. No:EP200406372810Version:2Date:30 August 2006Org. Doc. No: EP2005-0110-PR-10Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content13 of 13Printed copies are uncontrolled.

This page intentionally left blank

EP2005 Volume 1<strong>HSE</strong> SpecificationContract Holder and CSR HSSECompetencesRestrictedEP2005-0110-SP-01SPECIFICATION: CONTRACT HOLDER AND CSR 1 HSSECOMPETENCES 2This <strong>HSE</strong> document may set requirements supplemental to applicable law. However,nothing herein is intended to replace, amend, supersede or otherwise depart from anyapplicable law relating to the subject matter of this <strong>HSE</strong> document. In the event of anyconflict or contradiction between the provisions of this <strong>HSE</strong> document and applicable lawas to the implementation and governance of this <strong>HSE</strong> document, the provisions ofapplicable law shall prevail.This <strong>HSE</strong> document shall be subject to formal adoption as specified in EP Standard ‘<strong>HSE</strong>Controlling Documentation <strong>Management</strong>’ [4].0. Revision InformationFirst issue in EP Business HSSE Control Framework.1. SCOPEThis Specification sets the HSSE management competences for the roles of Contract Holder(CH) and Company Site Representative (CSR) for contracts with Medium <strong>HSE</strong> Risks and High<strong>HSE</strong> Risks in the EP Business.Individual positions (jobs) that include a CH or CSR role have an associated Job CompetenceProfile (JCP) (<strong>Shell</strong> People [11] or equivalent HR system), which specifies the Technical,Personal, Business, Leadership and Contracting & Procurement competence requirements andproficiency levels for that position. This document does not change these requirements.2. External RequirementsExternal requirements set by regulatory bodies and / or contractual parties may supersede anyrequirement stated in this Specification. These shall be identified on a country-by-country basisas projects or operations are being established.3. External ReferencesNone.4. EP SPECIFICATION4.1 DefinitionsItalicised terms within this Specification are defined in the Group (YG) ‘Competence Assuranceof HSSE Critical Positions’ [10] and EP Specification ‘EP2005 HSSE Glossary of Definitions’ [2].4.2 RolesContract HoldersEP Standard ‘<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>’ [1] stipulates that CHs roles are deemed to beHSSE critical for Medium <strong>HSE</strong> Risks and High <strong>HSE</strong> Risk contracts only and are subject to therequirements of the EP Standard ‘Competence Assurance of HSSE Critical Positions’ [3].1 Company Site Representative2 For Medium <strong>HSE</strong> Risk and High <strong>HSE</strong> Risk contractsDoc. No.:EP200506208772Version:1Date:30 August 2006Org. Doc. No.: EP2005-0110-SP-01Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content1 of 3Printed copies are uncontrolled

EP2005 Volume 1<strong>HSE</strong> SpecificationContract Holder and CSR HSSECompetencesRestrictedEP2005-0110-SP-01Company Site RepresentativesEP Standard ‘<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>’ [1] does not stipulate that CSRs roles are deemedto be HSSE critical, but where the <strong>HSE</strong> <strong>Management</strong> System (<strong>HSE</strong> MS) or <strong>HSE</strong> Case doesidentify this, then the competence requirements of this Specification and EP Standard‘Competence Assurance of HSSE Critical Positions’ [3] are to be applied.4.3 Competence RequirementsThe competence of CHs and CSRs (where applicable) shall be assured according to [3] for allcontracts within the scope of this Specification. CHs and CSRs are required to have at least theHSSE management competences proficiency levels as specified in Table 4.3.1.Table 4.3.1 HSSE <strong>Management</strong> Competence Requirements for CHs and CSRsCode Competence Element Proficiency Level forCHs forMedium/High <strong>HSE</strong>Risk contractsrequire:CSRs for Medium/High <strong>HSE</strong> Riskcontracts require:<strong>HSE</strong> 1.0 HSSE Leadership and Commitment Knowledge Knowledge<strong>HSE</strong> 2.0 HSSE Policy and Strategic Objectives Knowledge Knowledge<strong>HSE</strong> 3.0 Organisation, Responsibilities, Resources & HSSE SkillSkillRequirements<strong>HSE</strong> 4.1 HSSE Risk <strong>Management</strong> Framework Knowledge* Knowledge<strong>HSE</strong> 4.2 HEMP for Significant Risks/<strong>HSE</strong> Cases Knowledge Knowledge<strong>HSE</strong> 4.3 Emergency Response Knowledge Knowledge<strong>HSE</strong> 4.4 Safe Systems of Work/Personal Safety Skill Skill<strong>HSE</strong> 5.0 HSSE Planning and Procedures Skill Knowledge<strong>HSE</strong> 6.1 HSSE Performance <strong>Management</strong> Knowledge Knowledge<strong>HSE</strong> 6.2 Incident classification, Investigation and Reporting Knowledge Knowledge<strong>HSE</strong> 7.0 HSSE Audit Knowledge Knowledge<strong>HSE</strong> 8.0 HSSE <strong>Management</strong> Review Knowledge Awareness*<strong>HSE</strong> 4.1 KnowledgeThe asterisk is to confirm that CHs require more than a Knowledge proficiency level.Hence, CHs are required to be able to demonstrate the skill to ‘Provide structured support for thesystematic application of HEMP to HSSE risks through establishing systematic HSSEmanagement to maintain compliance with HSSE requirements and continuous performanceimprovement’.A number of approved standard EP JCPs were identified as applicable for the Level 2 HSSECritical Positions, and therefore these JCPs were developed to contain the requisite HSSEcompetences. If the HSSE competences of the applicable JCP are less than those stated inTable 4.3.1, they shall be raised to meet the appropriate level.A person who is to be appointed as a CH or CSR for a Medium <strong>HSE</strong> Risk or High <strong>HSE</strong> Riskcontract shall have the relevant technical discipline competences required for managing the typeof work performed under the contract. This shall be included as part of their JCP, or otherwiseassessed and assured by the Contract Owner as being appropriate for the person to managethe work.No person should be appointed as CH or CSR unless their HSSE management competenceprofile satisfies the requirements set out in Table 4.3.1. If, and for as long as, this requirement isnot satisfied then additional supervision or support by persons whose competence profile doessatisfy the requirements set out in Table 4.3.1 shall be provided. The Contract Owner shallapprove the adequacy of these support provisions.Doc. No.:EP200506208772Version:1Date:30 August 2006Org. Doc. No.: EP2005-0110-SP-01Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content2 of 3Printed copies are uncontrolled

EP2005 Volume 1<strong>HSE</strong> SpecificationContract Holder and CSR HSSECompetencesRestrictedEP2005-0110-SP-014.4 Safe Systems of Work/Personal Safety CompetencesThe HSSE profile in Table 4.3.1 for CHs and CSR roles requires the Skill proficiency level in‘Safe Systems of Work/ Personal Safety’. To do so persons in these roles shall be able to carryout consistently the significant majority of the activities listed below to the required standard:‘Use structured tools and techniques to control physical work activities, which have associatedHSSE hazards:• Identify, assess and record workplace hazards;• Identify the controls necessary to ensure that work can be undertaken with risk at As Low AsReasonably Practicable;• Manage interfaces with concurrent work activities to avoid conflicts;• Conduct site safety checks and audits;• Integrate the safe system of work in the work procedures and planning process includingchanges to work;• Implement safe work systems (e.g. Job Hazard Analysis; Permit To Work);• Provide advice on personal safety controls required for legal /regulatory compliance;• Monitor and implement changes to personal safety requirements (e.g. regulatory changes).’ 3These competences needs to be determined in relation to the activities of the work as performedunder the contract and may require specific training in these.5. EP REFERENCES# Title Number[1] EP Standard ‘<strong>Contractor</strong> <strong>HSE</strong> <strong>Management</strong>’ EP2005-0110-ST[2] EP Specification ‘EP2005 HSSE Glossary of Definitions’ EP2005-0100-SP-01[3] EP Standard ‘Competence Assurance of HSSE Critical Positions’ EP2005–0120-ST[4] EP Standard ‘<strong>HSE</strong> Controlling Documentation <strong>Management</strong>’ EP2005-0140-ST6. OTHER REFERENCES# Title Number[10] Group (YG) ‘Competence Assurance of HSSE Critical Positions’; 2004 SWW[11] <strong>Shell</strong> People SWW3 Extract from ‘Safe Systems of Work/ Personal Safety’ in [10]Doc. No.:EP200506208772Version:1Date:30 August 2006Org. Doc. No.: EP2005-0110-SP-01Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content3 of 3Printed copies are uncontrolled

This page intentionally left blank

EP2005 Volume 1<strong>HSE</strong> Specification<strong>Contractor</strong> <strong>HSE</strong> CapabilityPoints SystemRestrictedEP2005-0110-SP-02SPECIFICATION: CONTRACTOR <strong>HSE</strong> CAPABILITYPOINTS SYSTEMThis <strong>HSE</strong> document may set requirements supplemental to applicable law. However,nothing herein is intended to replace, amend, supersede or otherwise depart from anyapplicable law relating to the subject matter of this <strong>HSE</strong> document. In the event of anyconflict or contradiction between the provisions of this <strong>HSE</strong> document and applicable lawas to the implementation and governance of this <strong>HSE</strong> document, the provisions ofapplicable law shall prevail.This <strong>HSE</strong> document shall be subject to formal adoption as specified in EP Standard ‘<strong>HSE</strong>Control Documentation <strong>Management</strong>’ [4].0. Revision InformationAligned with EP2005 Tool ‘<strong>Contractor</strong> <strong>HSE</strong> Capability Questionnaire’.1. ScopeAll contractors being considered for Mode 1 Medium <strong>HSE</strong> Risk or High <strong>HSE</strong> Risk or for Mode 2Medium <strong>HSE</strong> Risk or High <strong>HSE</strong> Risk contracts shall have their capability to manage the <strong>HSE</strong>risks associated with the activity assessed, including the maturity of their <strong>HSE</strong> <strong>Management</strong>System.<strong>Contractor</strong>s being considered for contracts classified as Low <strong>HSE</strong> Risk or Mode 3 (L/M/H <strong>HSE</strong>Risk) do not require an <strong>HSE</strong> capability assessment.2. External RequirementsLocal legislative requirements may state requirements regarding the relationship between theEP Company and the contractor regarding the accountability for <strong>HSE</strong> management andreporting. Each EP Company shall identify such requirements and comply with them.3. External References• OGP <strong>HSE</strong> <strong>Management</strong> – Guidelines for working together in a contract environment;• ISO 14001 Environmental <strong>Management</strong> Guide.Doc. No.:Version:EP200407200116 2Org. Doc. No.: EP2005-0110-SP-02Date:30 August 2006Custodian:EPS-<strong>HSE</strong>ECCN: Not subject to EAR Page:No US content1 of 7Printed copies are uncontrolled