Accessories - Grundfos

Accessories - Grundfos

Accessories - Grundfos

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Accessories</strong><br />

BMB<br />

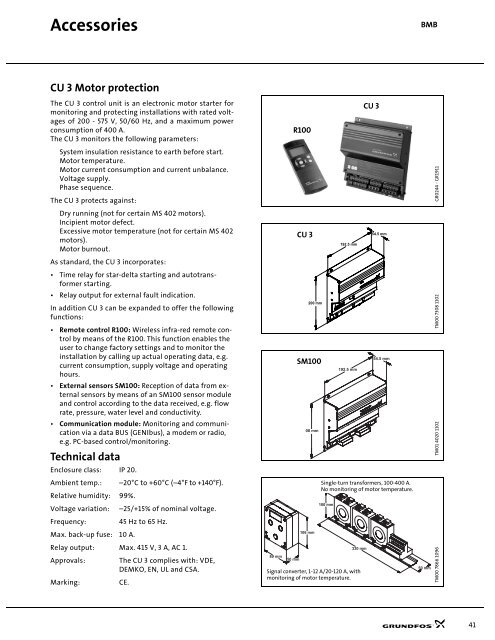

CU 3 Motor protection<br />

The CU 3 control unit is an electronic motor starter for<br />

monitoring and protecting installations with rated voltages<br />

of 200 - 575 V, 50/60 Hz, and a maximum power<br />

consumption of 400 A.<br />

The CU 3 monitors the following parameters:<br />

R100<br />

CU 3<br />

System insulation resistance to earth before start.<br />

Motor temperature.<br />

Motor current consumption and current unbalance.<br />

Voltage supply.<br />

Phase sequence.<br />

The CU 3 protects against:<br />

GR0244 - GR1911<br />

Dry running (not for certain MS 402 motors).<br />

Incipient motor defect.<br />

Excessive motor temperature (not for certain MS 402<br />

motors).<br />

Motor burnout.<br />

CU 3<br />

192.5 mm<br />

54.5 mm<br />

As standard, the CU 3 incorporates:<br />

• Time relay for star-delta starting and autotransformer<br />

starting.<br />

• Relay output for external fault indication.<br />

In addition CU 3 can be expanded to offer the following<br />

functions:<br />

• Remote control R100: Wireless infra-red remote control<br />

by means of the R100. This function enables the<br />

user to change factory settings and to monitor the<br />

installation by calling up actual operating data, e.g.<br />

current consumption, supply voltage and operating<br />

hours.<br />

200 mm<br />

SM100<br />

192.5 mm<br />

54.5 mm<br />

TM00 7308 1102<br />

• External sensors SM100: Reception of data from external<br />

sensors by means of an SM100 sensor module<br />

and control according to the data received, e.g. flow<br />

rate, pressure, water level and conductivity.<br />

• Communication module: Monitoring and communication<br />

via a data BUS (GENIbus), a modem or radio,<br />

e.g. PC-based control/monitoring.<br />

Technical data<br />

00 mm<br />

TM01 4020 1102<br />

Enclosure class: IP 20.<br />

Ambient temp.: –20°C to +60°C (–4°F to +140°F).<br />

Relative humidity: 99%.<br />

Single-turn transformers, 100-400 A.<br />

No monitoring of motor temperature.<br />

Voltage variation:<br />

–25/+15% of nominal voltage.<br />

100 mm<br />

Frequency:<br />

45 Hz to 65 Hz.<br />

Max. back-up fuse: 10 A.<br />

106 mm<br />

Relay output: Max. 415 V, 3 A, AC 1.<br />

Approvals:<br />

The CU 3 complies with: VDE,<br />

DEMKO, EN, UL and CSA.<br />

Marking:<br />

CE.<br />

89 mm<br />

50 mm<br />

330 mm<br />

Signal converter, 1-12 A/20-120 A, with<br />

monitoring of motor temperature.<br />

50 mm<br />

TM00 7866 1096<br />

41

<strong>Accessories</strong><br />

BMB<br />

Product numbers<br />

Product<br />

number<br />

CU 3 - 3 x 400 V<br />

Current range for signal converter [A]<br />

1-12 10-120 100-400<br />

62500293 z<br />

62500294 z<br />

62500295 z<br />

CU 3 - 3 x 460 V<br />

62500247 z<br />

62500248 z<br />

62500249 z<br />

CU 3 - 3 x 575 V<br />

62500253 z<br />

62500254 z<br />

62500255 z<br />

Product<br />

Single-turn transformers<br />

CU 3 expansion possibilities<br />

Range<br />

Product<br />

number<br />

Sensor module SM 100 3 x 400 [V] 00626191<br />

3 x 460 [V] 00626192<br />

Communication module RS 485 - 00626159<br />

DIN-Rail mounting 00626156<br />

Remote control R100<br />

HP printer for R100<br />

Signal converter<br />

-<br />

-<br />

00625333<br />

00620480<br />

1 - 12 [A] 00620497<br />

10 - 120 [A] 00620498<br />

100 - 400 [A] 00626148<br />

Control functions<br />

This table describes the protection provided by CU 3.<br />

Control parameters Function Problem Advantages<br />

Ground failure<br />

Temperature<br />

Overvoltage/<br />

undervoltage<br />

Overload<br />

Dry running<br />

Current unbalance<br />

Phase sequence<br />

Insulation resistance is measured only when the motor is not<br />

operating. A high-impedance voltage is applied to the motor<br />

leads and leakage to ground is measured.<br />

If the factory-set value is higher than the one measured, the<br />

motor cannot be started.<br />

Damaged or decomposed insulation<br />

in<br />

• motor,<br />

• cable or cable joint.<br />

• Overload,<br />

MS 4000 and MS 6000.<br />

• frequent starts/stops,<br />

The actual motor temperature is measured by means of the<br />

built-in Tempcon temperature transmitter and a signal is sent<br />

• operation against blocked<br />

to CU 3 via the phase leads. CU 3 compared the measured temperature<br />

discharge pipe,<br />

with the factory-set value.<br />

• insufficient flow velocity past<br />

the motor.<br />

If the factory-set values are exceeded, a fault indication is<br />

given. If the CU 3 receives a temperature signal, the voltage is<br />

no longer monitored, but the motor will continue to run.<br />

Therefore, the motor and consequently the pump operation<br />

will only be affected by voltage variations critical to the life of<br />

the motor.<br />

If there is no temperature signal, the motor will be stopped in<br />

case of overvoltage/undervoltage.<br />

The motor power input is measured on each of the three<br />

phases. The registered power input is an average of these<br />

three values.<br />

If the factory-set value is exceeded, the motor will stop.<br />

The motor power input is measured on each of the three<br />

phases. The registered power input is an average of these<br />

three values.<br />

If the average value is lower than the factory-set value, the<br />

motor will stop.<br />

The motor power input is measured on each of the three<br />

phases.<br />

CU 3 and motor are installed so that the phase sequence corresponds<br />

to correct direction of rotation.<br />

CU 3 monitors changes in the phase sequences.<br />

• The installation is close to a<br />

transformer,<br />

• the mains do not absorb load<br />

variations.<br />

• Incorrect dimensioning of<br />

pump/motor,<br />

• voltage supply failure,<br />

• defective cable,<br />

• blocking,<br />

• wear or corrosion.<br />

Pump exposed to dry running or<br />

underload, for example caused by<br />

wear.<br />

• Mains load is uneven,<br />

• incipient motor defect,<br />

• phase voltages diverging.<br />

Two phases are wrongly connected.<br />

• Possibility of indication<br />

of failure/of motor,<br />

cable and cable joint,<br />

• service indication.<br />

• Longer motor life,<br />

• safe operating<br />

conditions,<br />

• service indication.<br />

• Important installation<br />

parameter,<br />

• possibility of improving<br />

operating conditions.<br />

• Longer motor life,<br />

• safe operating<br />

conditions,<br />

• service indication.<br />

• Traditional dry-running<br />

protection is no longer<br />

necessary,<br />

• no extra cables.<br />

• Motor protection<br />

against overload,<br />

• service indication.<br />

Ensures correct pump<br />

performance.<br />

42

<strong>Accessories</strong><br />

BMB<br />

MTP 75 Motor protection<br />

Long motor life<br />

The MTP 75 protects against excessive motor temperature.<br />

This is the most simple and the most economical<br />

way of ensuring long motor life. The user is certain that<br />

operating conditions are observed and is given indication<br />

of the time when a service check should be made.<br />

Excessive motor temperature may be caused by:<br />

• Overload<br />

• Frequent starting/stopping (hunting)<br />

• Operation against closed valve/frozen discharge pipe<br />

• Insufficient flow of liquid past the motor<br />

• Pumping of water that is too hot<br />

• Deposits on the motor<br />

• Overvoltage<br />

• Undervoltage<br />

• Current unbalance<br />

• Dry running (Note that the pump is not protected if<br />

the water level is below the pump inlet.<br />

Application and installation<br />

The MTP 75 can be used only for motors with built-in<br />

temperature transmitter and should be installed for<br />

instance in a control cabinet. The MTP 75 may be<br />

installed in any type of control cabinet containing a<br />

thermal relay with differential release and contactor.<br />

The thermal relay is necessary to protect against<br />

blocking or phase failure, since this will cause the<br />

temperature to rise much faster than the MTP 75 is able<br />

to register.<br />

The MTP 75 is supplied with base for mounting on DIN<br />

rail.<br />

Operation<br />

The temperature transmitter will send a high-frequency<br />

signal indicating the motor temperature through the motor<br />

supply cable. The MTP 75 will stop the motor via the<br />

contactor if the temperature rises above 75°C (167°F). The<br />

temperature limit is factory-set and cannot be changed.<br />

Display:<br />

No light: Motor stopped. No supply voltage or electrical<br />

fault at temperature measuring.<br />

Green light: Motor in operation and motor temperature<br />

OK, i.e. below 75°C (167°F).<br />

Red light: Motor stopped and motor temperature too<br />

high, i.e. above 75°C (167°F).<br />

The MTP 75 is reset manually by pressing the reset<br />

button on the front cover or by switching off the voltage<br />

supply to the MTP 75.<br />

No unnecessary downtime<br />

Since the MTP 75 measures only the temperature and no<br />

other parameters causing a temperature rise, the motor<br />

and thus the pump will stop only when the motor<br />

temperature is too high.<br />

Reliability<br />

The MTP 75 is reliable due to its simple construction and<br />

because it requires no extra cables in the piping.<br />

Technical data of MTP 75<br />

Supply voltage:<br />

Control voltage:<br />

Enclosure class: IP 20.<br />

Operating conditions:<br />

Storage:<br />

2 variants:<br />

1 x 200-240 V ±10%, 50/60 Hz.<br />

3 x 380-415 V ±10%, 50/60 Hz.<br />

A transformer is required for<br />

voltages over 415 V.<br />

Contact load:<br />

Maximum 415 V/3 A.<br />

Minimum 12 V/20 mA.<br />

Min. temperature: –20°C (–4°F).<br />

Max. temperature:<br />

+60°C (+140°F).<br />

Relative humidity: 99%.<br />

Min. temperature: –20°C (–4°F).<br />

Max. temperature:<br />

+60°C (+140°F)<br />

Relative humidity: 99%.<br />

Approvals:<br />

Complying with the regulations<br />

of VDE and DEMKO.<br />

Product numbers<br />

MTP 75 without plug-in base, capacitor and signal transformer:<br />

Voltage range [V]<br />

GR 1915<br />

Product number<br />

1 x 200-240 00625178<br />

3 x 380-415 00625179<br />

MTP 75 complete with plug-in base, capacitor and signal<br />

transformer:<br />

Voltage range [V]<br />

78 mm<br />

35 mm<br />

104 mm<br />

Product number<br />

1 x 200-240 00625804<br />

3 x 380-415 00625805<br />

TM00 7874 1102<br />

43

e i us DI Se ce<br />

o t<br />

Ma n<br />

e wo k<br />

C n ec on<br />

o 2<br />

S<br />

<strong>Accessories</strong><br />

BMB<br />

G100 - Gateway for communication<br />

with <strong>Grundfos</strong> products<br />

The G100 offers a wide selection of options for integration<br />

of <strong>Grundfos</strong> products provided with GENIbus interface<br />

into main control and monitoring systems.<br />

The G100 enables a pump installation to meet future<br />

demands for optimum pump operation in terms of reliability,<br />

operating costs, centralization and automation.<br />

GR5940<br />

Central management system<br />

Radio<br />

Radio<br />

Modem<br />

SMS<br />

PLC<br />

Direct<br />

Interbus-S<br />

Profibus-DP<br />

4 digital inputs<br />

Main network<br />

RS-232<br />

Service<br />

port for pc<br />

Heating<br />

UPE TPE UPS<br />

Water treatment<br />

Industry<br />

CU<br />

E-<br />

300 CU 3 CU 3 CU 3 CU 3 pump DME<br />

BMQE-<br />

NE<br />

BMB<br />

BM BMET CRN<br />

Water supply<br />

GENIbus<br />

Multi-E<br />

Control<br />

2000<br />

MGE<br />

E-<br />

pump CU 3<br />

Wastewater<br />

MG<br />

Hydro<br />

2000<br />

SM100 CU 3 CU 3 CU 3 CU 3<br />

CR NK SP-G SP<br />

CU 300<br />

SQE<br />

Multi-E<br />

SM<br />

SM<br />

CU 3<br />

100 100<br />

Sensors<br />

Sensors<br />

AP<br />

Sensors<br />

TM01 1804 1102<br />

44

S<br />

S<br />

<strong>Accessories</strong><br />

BMB<br />

Product description<br />

The G100 Gateway enables communication of operating<br />

data, such as measured values, setpoints, etc., between<br />

<strong>Grundfos</strong> products with GENIbus interface and a main<br />

network for control and monitoring.<br />

As indicated in the illustration on page 44, the G100 is<br />

suitable for use in applications such as water supply,<br />

water treatment, wastewater, building automation and<br />

industry.<br />

Common to above applications is that downtime is<br />

usually costly, and extra investments are therefore often<br />

made to achieve maximum reliability by monitoring<br />

selected operating variables.<br />

The day-to-day operation, such as starting and stopping<br />

of pumps, changing of setpoints, etc., can also be<br />

effected from the main system by communication with<br />

the G100. In addition, the G100 can be set up to send<br />

event-controlled status indications such as alarms via<br />

the SMS to mobile phones, and to make automatic alarm<br />

call-backs to a central management system.<br />

Data logging<br />

Besides the possibility of data communication, the G100<br />

also offers logging of up to 350,000 time-stamped data.<br />

Subsequently, the logged data can be transmitted to the<br />

main system or a PC for further analysis in a spreadsheet<br />

or similar program.<br />

For the data logging, the "PC Tool G100 Data Log" software<br />

tool is used. The tool is part of the PC Tool G100<br />

package, which must be ordered separately.<br />

Other features<br />

• Four digital inputs.<br />

• Stop of all pumps in case of failing communication<br />

with the management system (optional).<br />

• Access code for modem communication (optional).<br />

• Alarm log.<br />

Installation<br />

Installation of the G100 is effected by the system integrator.<br />

The G100 is connected to the GENIbus as well as<br />

to the main network. Subsequently, all units on the<br />

GENIbus can be controlled from a central management<br />

system on the main network.<br />

The "G100 Support Files" CD-ROM supplied with the<br />

G100 contains examples of programs to be used when<br />

the G100 is connected to the various main network<br />

systems. Included is also a description of the data points<br />

available in <strong>Grundfos</strong> products with GENIbus interface.<br />

The "PC Tool G100" software tool can be used for the<br />

G100 installation and use. To be ordered separately.<br />

227 mm<br />

Technical data<br />

Overview of protocols<br />

Main system<br />

INTERBUS-S<br />

PROFIBUS-DP<br />

Radio<br />

Modem<br />

PLC<br />

GSM mobile phone<br />

Other possible connections<br />

GENIbus RS-485:<br />

Service port<br />

RS-232:<br />

Digital inputs: 4.<br />

Connection of up to 32 units.<br />

For direct connection to a PC<br />

or via radio modem.<br />

Voltage supply: 1 x 110-240 V, 50/60 Hz<br />

Ambient temperature: In operation:<br />

–20°C to +60°C (–4°F to +140°F)<br />

Enclosure class: IP 20<br />

Weight:<br />

1.8 kg. (4.0 lbs)<br />

<strong>Accessories</strong><br />

• PC Tool G100 package (to be ordered separately)<br />

• G100 Support Files CD-ROM (supplied with product)<br />

Product numbers<br />

73 mm 165 mm<br />

*Floppy disk with G100 Support Files included.<br />

Software protocol<br />

PCP<br />

DP<br />

Satt Control COMLI/Modbus<br />

Satt Control COMLI/Modbus<br />

Satt Control COMLI/Modbus<br />

SMS, UCP<br />

Product<br />

Product<br />

number<br />

G100 with Interbus-S expansion board* 96411134<br />

G100 with Profibus-DP expansion board* 96411135<br />

G100 with Radio/Modem/PLC-expansion board* 96411136<br />

G100 Basic Version* 96411137<br />

PC Tool G100 package 96415783<br />

TM01 0621 1102<br />

45

<strong>Accessories</strong><br />

BMB 4”<br />

BMB 4"<br />

Photo of parts Description Specification Part no.<br />

TM00 3702 0894<br />

Victaulic coupling liner for welding<br />

ø42 x 30 mm<br />

N-version 00100517<br />

R-version 00100971<br />

TM00 3703 0894<br />

Victaulic coupling liner with external<br />

thread<br />

R 1¼ x 100 mm/BSPT<br />

N-version 00100534<br />

R-version 00100965<br />

TM00 3705 0894<br />

Victaulic style 77 coupling<br />

ø42 mm x 1¼"<br />

NBR seal<br />

FKM seal<br />

00ID6786<br />

00ID6742<br />

NBR seal N-version 00105563<br />

TM00 3707 0894<br />

Connecting kit for welding, straight<br />

NBR seal R-version 00105982<br />

FKM seal N-version 00105565<br />

FKM seal R-version 00105981<br />

TM00 3711 0894<br />

180° bend for welding,<br />

ø42mm/1¼"<br />

Center distance: 165 mm/6.5 inch<br />

Total height: 127 mm/5.0 inch<br />

R-version 00 15 59 26<br />

NBR seal N-version 00105564<br />

TM00 3708 0894<br />

Connecting kit R 1¼"<br />

NBR seal R-version 00105980<br />

FKM seal N-version 00105566<br />

FKM seal R-version 00105979<br />

TM01 9906 3400<br />

Terminal box kit complete, 4" motor with:<br />

• 1 box including all necessary fittings for mounting on the booster<br />

module.<br />

• 1 mounting bracket<br />

• L x W x H = 80 mm x 75 mm x 60 mm<br />

96446948<br />

TM01 9907 3400<br />

Bracket, 4" 96449565<br />

46

<strong>Accessories</strong><br />

BMB 6"<br />

BMB 6"<br />

Photo of parts Description Specification Part no.<br />

TM00 3709<br />

Victaulic coupling liner for welding<br />

ø89 x 50 mm<br />

3" x 2"<br />

N-version 00150574<br />

R-version 00140968<br />

TM00 3711 0894<br />

180° bend for welding,<br />

ø89 mm/3"<br />

Center distance: 300 mm/11.8 inch<br />

Total height = 210 mm/8.3 inch<br />

N-version 00155544<br />

R-version 00155971<br />

TM00 3712 0894<br />

Victaulic style 77 coupling<br />

ø89 mm x 3"<br />

NBR seal<br />

00ID7664<br />

TM00 3714 0894<br />

Connecting kit for welding, straight<br />

NBR seal, N-version 00155542<br />

NBR seal, R-version 00155973<br />

TM00 3715 0894<br />

Connecting kit, 180°<br />

NBR seal, N-version 00155543<br />

NBR seal, R-version 00155972<br />

Terminal box kit complete, 6" motor with:<br />

• 1 box including all necessary fittings for mounting on the<br />

booster module<br />

• L x W x H = 120 mm x 120 mm x 90 mm<br />

TM02 4209 0202<br />

96476716<br />

TM01 9907 3400<br />

Bracket, 6" 96439184<br />

47

<strong>Accessories</strong><br />

BMB 8"<br />

BMB 8"<br />

Photo of parts Description Specification Part no.<br />

TM00 3712 0894<br />

Victaulic style 77 coupling<br />

3": ø89 mm<br />

4": ø114 mm<br />

5": ø139 mm<br />

6": ø168 mm<br />

NBR seal 3"<br />

00ID7664<br />

NBR seal 4" 96415463<br />

NBR seal 5" 96416739<br />

NBR seal 6"<br />

00ID2279<br />

N-version 3" 00150574<br />

TM00 3709<br />

Victaulic coupling liner for welding<br />

Terminal box kit complete, 8" motor with:<br />

• 1 box including all necessary fittings for mounting on the<br />

booster module<br />

• L x W x H = 200 mm x 200 mm x 120 mm<br />

N-version 4" 96416743<br />

N-version 5" 96416744<br />

N-version 6" 96416745<br />

96446950<br />

TM02 4208 0202<br />

TM01 9907 3400<br />

Bracket, 8" 96416762<br />

48