zeqQT

zeqQT

zeqQT

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SLING SELECTION<br />

& WORKING LOAD LIMITS<br />

CHAIN & SLING<br />

INSPECTION, USE & CARE<br />

HOW TO SELECT THE PROPER CHAIN SLING<br />

1. Determine the weight and configuration of the load(s) to be lifted.<br />

2. Determine the type of chain sling required, according to weight and configuration.<br />

3. Determine the size of the body chain according to the working load limits.<br />

Be sure to take into consideration the effect of the required angle (see diagram below).<br />

4. Determine the reach required to give the desired angle. This is measured from<br />

the upper bearing surface of the master link to the bearing surface of the lower attachment.<br />

5. Know share of load on pick points and location of center of gravity.<br />

WHAT DETERMINES A<br />

SLING’S WORKING LOAD LIMIT<br />

The working load limit of slings is based on the following factors:<br />

• Type of hitch<br />

• Material strength<br />

• Design factor<br />

• Diameter of curvature (D/d)<br />

• Angle of loading<br />

For specific information on the working load limit of various slings, see page 31.<br />

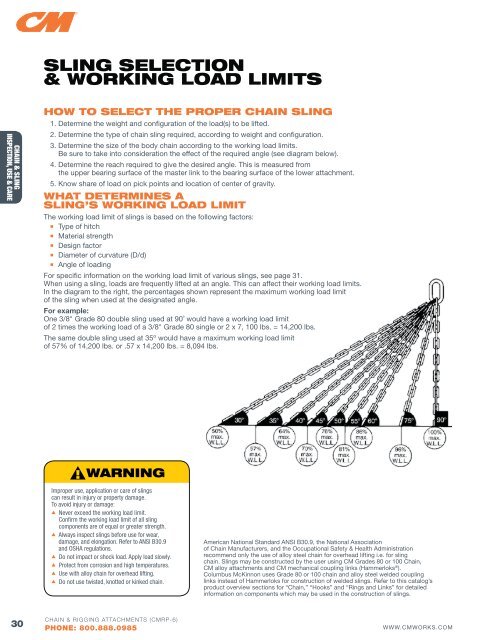

When using a sling, loads are frequently lifted at an angle. This can affect their working load limits.<br />

In the diagram to the right, the percentages shown represent the maximum working load limit<br />

of the sling when used at the designated angle.<br />

For example:<br />

One 3/8" Grade 80 double sling used at 90˚ would have a working load limit<br />

of 2 times the working load of a 3/8" Grade 80 single or 2 x 7, 100 lbs. = 14,200 lbs.<br />

The same double sling used at 35º would have a maximum working load limit<br />

of 57% of 14,200 lbs. or .57 x 14,200 lbs. = 8,094 lbs.<br />

Improper use, application or care of slings<br />

can result in injury or property damage.<br />

To avoid injury or damage:<br />

Never exceed the working load limit.<br />

Confirm the working load limit of all sling<br />

components are of equal or greater strength.<br />

Always inspect slings before use for wear,<br />

damage, and elongation. Refer to ANSI B30.9<br />

and OSHA regulations.<br />

Do not impact or shock load. Apply load slowly.<br />

Protect from corrosion and high temperatures.<br />

Use with alloy chain for overhead lifting.<br />

Do not use twisted, knotted or kinked chain.<br />

American National Standard ANSI B30.9, the National Association<br />

of Chain Manufacturers, and the Occupational Safety & Health Administration<br />

recommend only the use of alloy steel chain for overhead lifting i.e. for sling<br />

chain. Slings may be constructed by the user using CM Grades 80 or 100 Chain,<br />

CM alloy attachments and CM mechanical coupling links (Hammerloks ® ).<br />

Columbus McKinnon uses Grade 80 or 100 chain and alloy steel welded coupling<br />

links instead of Hammerloks for construction of welded slings. Refer to this catalog’s<br />

product overview sections for “Chain,” “Hooks” and “Rings and Links” for detailed<br />

information on components which may be used in the construction of slings.<br />

CHAIN & RIGGING ATTACHMENTS (CMRP-6)<br />

30<br />

PHONE: 800.888.0985<br />

WWW.CMWORKS.COM