Gardner Denver.pdf - inducom

Gardner Denver.pdf - inducom

Gardner Denver.pdf - inducom

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

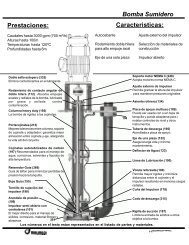

Waterjet Basics - Delivering Power<br />

A waterjet nozzle is simply a flow restriction that causes<br />

water velocity to rapidly increase. For inlet pressure above<br />

7,000 psi, jet velocity increases to supersonic. But the jet<br />

loses power due to turbulence created as it flies through<br />

the air. The turbulent zone travels at lower velocity and<br />

does not have enough energy for effective cleaning. At<br />

greater distances away from the jet, the turbulent zone<br />

grows at the expense of the powerful core, until no cleaning<br />

power remains at all.<br />

Turbulence upstream of the jet makes more turbulence in the jet. So abrupt diameter changes, or flow direction changes<br />

must be avoided. StoneAge Attack Nozzle Tips use a flow<br />

straightening device in the orifice that recovers about half the Effect of Turbulence & Standoff Distance<br />

power lost to upstream turbulence. The best quality jets use a<br />

cone-shaped inlet to the orifice to smoothly accelerate the water<br />

Position Jets Close<br />

velocity. Even with the best quality jets, power drops about<br />

6% at 100 orifice diameters, and 62% at 1000 diameters.<br />

Enough to be Effective<br />

As Few Jets<br />

As Big As Possible<br />

for Power<br />

Control Upstream Flow Turbulence<br />

In order to deliver the most jet<br />

power possible to the surfaces<br />

to be cleaned, it is best to use<br />

as few jets as possible, making<br />

each as big as possible. Jets are<br />

rotated to cover all surfaces to<br />

be cleaned. Jet paths look like<br />

the threads on a bolt. This helical<br />

jet path proves very effective<br />

and powerful.<br />

Relative Performance, %<br />

Control Rotation Rate for Maximum Power<br />

A rotating jet moves sideways on the surface to be cleaned. If rotated too fast, this<br />

sideways velocity seriously deteriorates jet quality. We have found that the jet must<br />

be controlled to no more than 22 ft/sec transverse velocity in order to deliver maximum<br />

power to the surface to be cleaned. Of course the bigger the diameter, the lower<br />

the rotation rate allowed.<br />

There are exceptions, but in<br />

most cases the 22 ft/sec<br />

guideline is used whether<br />

we’re cleaning a small pipe, or<br />

a large storage tank.<br />

Standoff Distance, # Orifice Diameters<br />

Jet Velocity at Wall < 22 ft/sec<br />

Pipe ID 4” 8” 18” 36” 60” 180”<br />

Max. RPM 1240 620 280 140 80 27<br />

R<br />

F<br />

What makes it rotate?<br />

Ports in StoneAge nozzle heads<br />

are drilled offset (R) from the axis<br />

of rotation, providing sufficient<br />

mechanical advantage so that the<br />

jet reaction force (F) can rotate<br />

the unit.<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 2 © 10/03

Made in the USA<br />

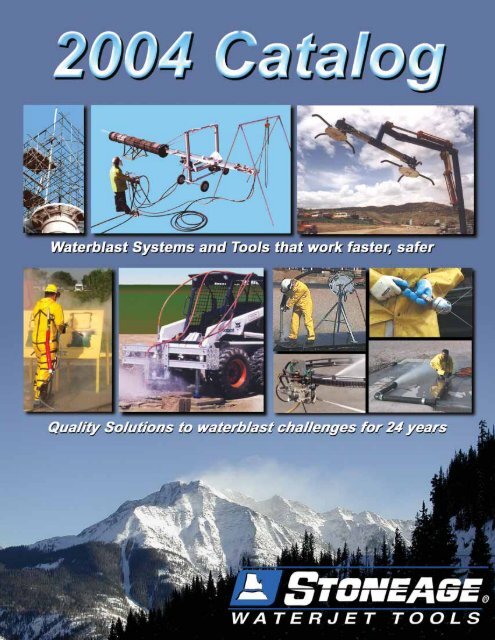

2004 Catalog Contents<br />

33 Pipe & Tubular Cleaner<br />

33 Paper Suction Roll Cleaner<br />

No-Entry Vessel Cleaning<br />

34 Introduction to 3D Applications<br />

35 CyClean & Hurricane TM 3-D Nozzles<br />

37 Simple Boom & Teleboom Positioners<br />

2 Waterjet Basics - Delivering Power<br />

4 Waterjet Safety - A Summary<br />

Surface Cleaning<br />

5 Barracuda TM Hand-Held Gun Nozzle 10 - 20 Kpsi<br />

6 Barracuda TM Hand-Held Gun Nozzle 20 - 40 Kpsi<br />

7 FCSV 15 & 20 Kpsi Floor Cleaners & Surface Prep<br />

8 DBUH 40 Kpsi Deck Blaster<br />

9 SG-30 Free Spin Surface Cleaner<br />

10 SG-40, 50, 60, 70 Rotating Assemblies<br />

11 UH-40, 50 40 Kpsi Rotating Assemblies<br />

Pipe Cleaning - 4” ID and Larger<br />

12 Badger 2-D, 15 Kpsi<br />

13 Gopher 2-D, 20 & 40 Kpsi<br />

14 RJV 2-D, 15 Kpsi<br />

15 BJV-M 2-D, 15 Kpsi<br />

16 BJV-20K 2-D, 20 Kpsi<br />

17 Centralizers for BJV’s<br />

19 UH-80 40 Kpsi Pipe Skid, Line Mole<br />

20 Line Mole Backout Preventers<br />

Sewer Jetting - 3” ID and Larger<br />

21 Warthog WG-1, WH-3/4, & WH-1/2 Models<br />

22 Warthog WS-1/2 & WT-3/8 Models<br />

23 Hogwash Washdown Nozzle & Accessories<br />

Tube Cleaning - 7/8” to 3” ID<br />

24 Marten, Ferret, Weasel Tube Nozzles<br />

26 HRS Air-Powered Hose Reel<br />

Boiler & Big Vessel Cleaning<br />

38 Introduction<br />

38 BFW Big Flow Waterblaster<br />

39 BJV-H 2-D, 10 Kpsi, 200 gpm<br />

39 HWB Waterblast Hose Reel<br />

40 CST Cable Swivel Tool<br />

41 SM-2D & SM-Air<br />

Specialty Systems<br />

42 CDA Concrete Demolition<br />

43 Gearhead 3D Tote & Vessel Cleaner<br />

43 BU Go Anywhere Waterblast Tractor<br />

Swivels, Rotary Couplings<br />

44 Introduction<br />

45 SL & SG Swivel Specifications<br />

46 SH & SM Swivel Specifications<br />

46 UH-H9H6 Swivel, 40 Kpsi<br />

Miscellaneous, Hose Reels,<br />

Nozzle Tips, Fittings<br />

47 Attack AP2 & AP4 Nozzle Tips<br />

48 OCIH & OCL Nozzle Tips<br />

49 OS Sapphire Nozzle Tips<br />

50 Extension Nipples<br />

51 Pipe Fittings & Hose Adaptors<br />

52 20 Kpsi & 40 Kpsi Fittings and Adaptors<br />

53 Maintenance Kits - All Tools<br />

General Information<br />

54 Lubricants, Motors, Threaded Connections<br />

55 Fluid Facts - Formulas & Conversions<br />

56 To Order<br />

Rigid Tube Lancing<br />

27 Rigid Tube Lancing Machines<br />

29 BRUD X-Y Positioner & CB-2D Control Box<br />

30 SA 1900 & 2000 Hand Lancer<br />

31 Lance Tips - 15, 20, & 40 Kpsi<br />

32 Lances<br />

© 10/03<br />

Page 3

Waterjet Safety - A Summary<br />

The plant operator who hires waterblast services cannot afford the interruption presented by an accident<br />

or injury. Incidents require supervision to stop work until the injured workers are tended to, hazards are<br />

investigated, and appropriate preventive measures taken. Even if no one is seriously hurt, time is wasted<br />

- time that costs up to $ 15,000 an hour in lost production alone in many large single line process plants.<br />

The dependable waterblast contractor gets the job done, but does so without accident or injury, and doesn’t<br />

need close safety supervision. Key skills include recognition of hazards, and knowledge of appropriate<br />

precautions to take in complex and changing situations. Trained and experienced waterblast operators<br />

are essential. Finally, safety responsibility should be demanded of the on-site supervisor, as well as each<br />

operator doing the work. Effective safety management promotes teamwork, avoiding a situation where<br />

safety is someone else’s concern.<br />

HAZARDS<br />

Confined spaces, heights, obstructions, tripping hazards, sharp objects, falling objects, moving vehicles<br />

and equipment, rigging, powered equipment, noise, fumes, dust, acids, corrosives, poisons, pathogens,<br />

flying debris, noise to cause permanent hearing loss, burst equipment, missiles, unpredictable waterjet<br />

direction, unpredictable reaction forces, waterjet injury, slipping, falling, muscle strain.<br />

Excellent safety information is available from the organizations listed below, which can be used to build a<br />

comprehensive waterblast safety and training program. The tips we suggest below are important, but not<br />

comprehensive.<br />

1. Minimum personal protective equipment includes hearing<br />

protection, hard hat, safety goggles, rain suit, safety toe<br />

boots with non-skid soles, shin guards, and waterproof<br />

gloves.<br />

2. Control the worksite with safety ribbon and barricades as<br />

needed to keep bystanders out, and prevent people from being<br />

injured by flying debris.<br />

3. Get the “Medical Alert” card from the Waterjet Technology<br />

Association for each worker involved in waterblast operations.<br />

The information for medical emergency room physicians<br />

can be life-saving in the event of an injury.<br />

4. Jet hand-held guns for no more jet reaction force than<br />

1/3 the weight of the operator.<br />

5. Short hand-held guns are dangerous. Don’t use one that<br />

is short enough for the operator to jet himself.<br />

6. Lots of workers in a confined space with hand-held<br />

waterblast guns is a dangerous practice. Instead, invest in a<br />

mechanized system to do the job. It will pay big dividends<br />

in downtime reduction, thorough results, and safety.<br />

7. Don’t look into something being jetted, with pressure<br />

on.<br />

8. Pressure dump or shutoff devices should be controlled<br />

by the operator most likely to get hurt.<br />

9. Do not defeat overpressure protection devices.<br />

10. Use line mole backout preventers to avoid injury<br />

from failed equipment or hose coming out of the pipe<br />

towards the operator.<br />

11. Use rigid pipe or centralizer on inlet line to mole<br />

nozzles that prevent the nozzle from reversing direction.<br />

12. Use rigid pipe or colored leader hose inlet the jetting<br />

nozzle as an indicator that the nozzle is close to<br />

being pulled out of the pipe or vessel being cleaned.<br />

13. Anticipate unbalanced jet reaction forces, by design<br />

or due to jet plugging. Take effective precautions<br />

to keep unbalanced nozzles under control.<br />

Useful Safety Information, Training Aids<br />

Water Jet Technology Association Water Jetting Association<br />

St. Louis, MO, USA<br />

Huntingdon, Cambridgeshire, UK<br />

Phone 314-241-1445 Phone 44-1487-834034<br />

FAX 314-241-1449 FAX 44-1487-832232<br />

www.wjta.org<br />

www.waterjetting.org.uk<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 4 © 10/03

BARRACUDA TM Self-Rotating Nozzle<br />

Model BC-K<br />

2 to 20 Kpsi<br />

4 to 13 gpm<br />

Puts teeth into tough cleaning jobs!<br />

Patent 5,909,848<br />

BC-K Centrifugal Braking Swivel<br />

Integral Rotating Head<br />

Dump Gun by others<br />

AP4 Nozzle Tips<br />

Put real power in your hand-held<br />

waterblasting gun, with rotation<br />

speed control, excellent quality jets<br />

and no-leak seal. The Barracuda<br />

has been the pros’ choice since<br />

1999. Choose between 2-jet or 4-<br />

jet models. All are rated at 20 Kpsi,<br />

with adaptors for use on lower<br />

pressure guns with pipe threads.<br />

Quality and power is less expensive in the long run<br />

Powerful jets, rotate for effective coverage<br />

Specifications<br />

Model MAWP Flow Max. Flow Rating Length Diameter Inlet Adaptors<br />

• Replacable nozzle tips<br />

BC-K 20 Kpsi 15 gpm 0.43 Cv 7.8 in. 1.8 in. 9/16 MP 3/8, 1/2 npt<br />

1380 bar 57 lpm 20 cm 4.6 cm<br />

• Rotation speed control<br />

BC-K Jetting - Flow in gpm<br />

1000 to 2000 rpm<br />

Press.<br />

Nozzle ID, in.<br />

Kpsi .018 .020 .022 .024 .026 .029 .032 .035 .038 .042 .047 .052 .057 .063 .069 .075<br />

2-Jet - Model BC-K-P4<br />

Use AP4 Nozzle, pg. 47<br />

2 8.4 9.7 10.8<br />

3 6.2 7.5 8.8 10.3 11.8<br />

4 5.8 7.2 8.7 10.1 11.9 13.7<br />

5 6.5 8.1 9.7 11.3 13.3<br />

10 5.5 6.5 7.6 9.2 11.4<br />

15 4.4 5.5 6.7 8.0 9.4<br />

20 4.4 5.1 6.4 7.7<br />

4-Jet - Model BC-K-P2<br />

Use AP2 Nozzle, pg. 47<br />

2 7.7 9.2 10.6<br />

3 5.8 6.9 7.9 9.4 11.2<br />

4 5.6 6.7 7.9 9.2 10.9 13.0<br />

5 5.1 6.3 7.5 8.9 10.3 12.1<br />

10 5.2 6.1 7.2 8.8 10.6<br />

15 4.3 5.2 6.3 7.5 8.8<br />

20 4.9 6.1 7.3<br />

AF 065-M9P6, P8 Adaptors<br />

• Recommended use<br />

2-Jet - Thick deposits<br />

4-Jet - Thin, hard coatings<br />

• 3-Minute high pressure<br />

seal replacement<br />

• Proven durability and<br />

performance since 1999<br />

• Maintenance kits and<br />

supplies page 53<br />

© 10/03<br />

Adaptors available to connect the<br />

BC-K to 3/8 or 1/2 npt guns.<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 5

BARRACUDA TM Self-Rotating Nozzle<br />

• Replacable sapphire nozzle tips<br />

• Rotation speed control<br />

1000 to 2000 rpm<br />

• Model BC-UH - 20 to 40 Kpsi<br />

• Only weighs 3 lb<br />

Surface prep to white metal NACE No. 5/SSPC-SP12 standard<br />

Tired of maintaining powered rotary guns?<br />

Save money and improve productivity with<br />

the Barracuda BC-UH self-rotating 40<br />

Kpsi gun nozzle. Ultra-high pressure<br />

waterjetting has become the standard method<br />

of coating removal because of its economy and<br />

environmental advantages.<br />

• Durable stainless steel construction<br />

• Maintenance kits, supplies, page 53<br />

Model BC-UH<br />

20 to 40 Kpsi<br />

3.5 to 7 gpm<br />

BC-UH Centrifugal<br />

Braking Swivel<br />

Integral Rotating Head<br />

Specifications<br />

OS7 Sapphire Nozzle Tips<br />

Model MAWP Flow Max. Flow Rating Length Diameter Inlet<br />

BC-UH 40 Kpsi 10 gpm 0.43 Cv 7.8 in. 1.8 in. 9/16 HP<br />

2760 bar 38 lpm 20 cm 4.6 cm<br />

BC-UH Jetting - Flow in gpm<br />

Press.<br />

Nozzle ID, in.<br />

Kpsi .016 .017 .018 .019 .020 .021 .022 .023 .024<br />

28 4.1 4.5 5.0 5.5 6.0 6.6 7.1<br />

32 3.9 4.4 4.8 5.4 5.9 6.5<br />

36 3.6 4.1 4.6 5.1 5.6 6.2<br />

40 3.8 4.3 4.8 5.4 6.0 Use OS7 Nozzles, pg. 49<br />

Two BC-UH’s - One Pump<br />

Barracuda<br />

BC-UH<br />

Dual Trigger Air 40 Kpsi Gun<br />

Air Side<br />

Air Supply<br />

Air Signal to<br />

Dump or<br />

Shutoff Valve<br />

Energy-Dissipating<br />

Dump or Shutoff Plug<br />

High Pressure<br />

Water Supply<br />

Water Side<br />

40 Kpsi<br />

Tumble Box<br />

If two or more guns are operated on a single pump, provisions must be made to control the sudden change in flow when one<br />

is shut off. If dump guns were used, then pressure would be lost to both guns. In that case the operator who doesn’t expect<br />

loss of pressure will probably fall down due to loss of jet reaction thrust. So different equipment must be used.<br />

The operator must activate both triggers in order to send an air signal to open the valve and send high pressure water to the<br />

gun. When either trigger is let go, the valve will respond to loss of air, closing the high pressure water ports to the gun. The<br />

tumble box illustrated above is called an “air-operated multi-mode flow control valve” by its manufacturer. It can be operated<br />

with an energy dissipating dump or plug for dry shutoff. Dry shutoff<br />

mode is recommended for intensifier style pumps, or other designs that<br />

provide for handling the excess flow when one gun is shut off. A separate<br />

tumble box is required for each gun operated.<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

StoneAge does not manufacture hand-held guns or tumble boxes, but<br />

will refer customers to manufacturers who do.<br />

Page 6 © 10/03

FCSV Waterblast Floor and Surface Cleaner<br />

Clean garages, parking lots, other flat surfaces<br />

Clean paint off paint line gratings and floors<br />

Decontaminate, degrease pavement<br />

Remove coatings, membranes<br />

Scarify concrete for coatings<br />

Clean tank and pit floors<br />

FCSV-15K Illustrated<br />

• Self-rotating 15 Kpsi & 20 Kpsi models<br />

• Easy to operate pressure dump<br />

• Corrosion-resistant zinc plated steel<br />

• Jet height adjustable 1-5 in.<br />

• Optional vacuum system<br />

Specifications<br />

Model<br />

FCSV-15K, 20K<br />

• Built in<br />

pressure<br />

dump<br />

© 10/03<br />

Weight<br />

255 lb<br />

116 kg<br />

Jet Path<br />

24 in.<br />

61 cm<br />

Pressure Dump<br />

Yes<br />

Height Range<br />

1-5 in.<br />

2-12 cm<br />

Capacity *<br />

28 gpm<br />

* More with added weight 110 lpm<br />

Rotation Drive<br />

Jet Reaction<br />

3° - 7° Jet Angle<br />

300-1,000 rpm<br />

Vacuum Connection 4 in. Camlock<br />

Swivel Used<br />

SG-CCN<br />

Nozzle Tips<br />

AP4<br />

• Radiused jet arms<br />

for excellent jets<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 7

DBUH Ultra High Pressure Deck Blaster<br />

The DBUH Deck Blaster features the reliable StoneAge UH-H6H9 Swivel, belt drive rotation, and<br />

bar head for thorough and productive cleaning. Replaceable, excellent quality OS6 Sapphire Nozzle<br />

Tips spread the water flow evenly over the entire width of the jet path. The unit is power driven, so that<br />

forward speed can be adjusted for most productive coating removal. Without this feature, it is very<br />

difficult for an operator to maintain consistent results at the slow forward speeds necessary to remove<br />

epoxy coatings. It is at least twice as productive as a well trained man with a hand-held gun.<br />

Remove epoxy coatings<br />

Surface prep in shipyard, industrial, and<br />

factory applications<br />

Control<br />

Handle<br />

Remove coatings, scale, hard deposits<br />

Surface prep to white metal, NACE<br />

No. 5/SSPC-SP12 standard<br />

Self-<br />

Propulsion<br />

Clutch<br />

• Self-propelled for maximum productivity<br />

• Vacuum recovery of water and debris<br />

• On-board pressure dump valve<br />

• Adjustable height<br />

Dome and<br />

Rotating Jet<br />

Height<br />

• Jet path cleans to 2” from dome edge<br />

• Ergonomic handle adjusts to fit operator<br />

• Control handle operates:<br />

Pressure dump valve<br />

Rotation<br />

Forward motion<br />

• Self-propulsion clutch disengages for easy<br />

turning, backing<br />

• Propulsion speed and rotation rate adjustable<br />

Specifications<br />

Model<br />

DBUH<br />

• Uses OS6 Sapphire Nozzle Tips, pg. 49<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Max. Pressure<br />

40 Kpsi 2760 bar<br />

Rotation Speed<br />

250-1000 rpm<br />

Max. Flow<br />

6.0 gpm 23 lpm<br />

Forward Speed 3-20 ft/min 0.9-6 m/min<br />

Productivity 200-1400 SF/hr .3-2.1 m 2 /hr<br />

Jet Path 14 in. .35 m<br />

# Jets 6<br />

Weight 215 lb 98 kg<br />

Page 8 © 10/03

SG-30 Free Spinner for Surface Cleaning<br />

The simple self-rotating solution<br />

for surface cleaning applications<br />

Clean belts, screens, conveyors<br />

Degrease, decontaminate concrete<br />

Clean airport runways<br />

Scarify concrete for coatings<br />

Clean paint line carriers<br />

Build custom surface cleaners<br />

Boiler Pendant<br />

Tube Skid<br />

Solar<br />

Power Plant<br />

Mirror Cleaner<br />

Examples of custom systems based on the SG-30 Free Spinner<br />

Specifications<br />

Model SG-30-P12 SG-30-A12<br />

Swivel Used SG-CCN-P12K SG-CCN-A12K<br />

Max. Pressure 15 Kpsi 20 Kpsi<br />

1000 bar 1380 bar<br />

Rotation Speed 300 - 1,000 rpm 300 - 1,000 rpm<br />

Rotation Diameter<br />

4-Arm Small 18 in. 46 cm 18 in. 46 cm<br />

4-Arm Large 24 in. 62 cm 24 in. 62 cm<br />

Inlet Ports 3/4 npt 3/4 MP *<br />

0° or 90° 0° or 90°<br />

Flow Capacity 60 gpm 50 gpm<br />

230 l/min 190 l/min<br />

Flow Rating 2.3 Cv 2.0 Cv<br />

Height Overall 13 in 33 cm 13 in. 33 cm<br />

Weight 25 lb 11.3 kg 26 lb 11.8 kg<br />

* Cone & Thread Medium Pressure Connection<br />

Mounting Holes - Four 3/8 in. ID, 2.75 x 3.75 in. spacing<br />

© 10/03<br />

• Self-rotating 15 Kpsi & 20 Kpsi models<br />

• Radiused jet arms for excellent jet quality<br />

• Replaceable 1/4 npt AP4 Nozzle Tips, pg. 47<br />

• Aluminum mounting block<br />

• Balanced, stable, rotating jet assembly<br />

• 18 or 24 in. jet path diameter<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 9

SG-40, 50, 60, 70 Powered Rotation<br />

Runway<br />

Cleaner<br />

Reliable rotation independent of flow or pressure<br />

SG-40, 50<br />

Fast Rotation<br />

Belt Drive<br />

Scarify concrete for coatings<br />

SG-60, 70<br />

Slow Rotation<br />

Gearbox Drive<br />

Clean conveyors, belts, chain<br />

Conveyor<br />

Cleaner<br />

Clean heat exchanger bundles<br />

Remove refractory<br />

Specifications<br />

Clean stacks, tanks, tunnels<br />

Remove paint stripes, rubber<br />

Drive Air SG-40 SG-60<br />

Hydraulic SG-50 SG-70<br />

Surface<br />

Cleaner<br />

Bundle<br />

Blaster<br />

Swivel SG-CCN-P12K SG-P12KML<br />

Max. Pressure 15 Kpsi 1,000 bar 15 Kpsi 1,000 bar<br />

Flow Rating 2.3 Cv 5.0 Cv<br />

Flow Capacity 50 gpm 230 lpm 110 gpm 420 lpm<br />

Inlet Port 3/4 npt 3/4 npt<br />

Outlet Shaft 1-1/8 in. K** 3/4 npt<br />

Swivel SG-CCN-A12K SG-A12KML<br />

Max. Pressure 20 Kpsi 1,380 bar 20 Kpsi 1,380 bar<br />

Flow Rating 2.0 Cv 2.0 Cv<br />

Flow Capacity 50 gpm 190 lpm 50 gpm 190 lpm<br />

Inlet Port 3/4 MP* 3/4 MP*<br />

Outlet Shaft 1-1/8 in. K** 3/4 or 1 MP*<br />

Rotation Speed<br />

Slow 60:1 Ratio NA 8 - 40 rpm<br />

Medium 10:1 Ratio NA 50 - 250 rpm<br />

Fast 2:1 Ratio 250 - 1,000 rpm NA<br />

Mounts Four 5/16-18 NC Four 5/16 in. Holes<br />

2.25 X 8 in. Spacing 2.48 x 3.88 in. Spacing<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Air Supply at 80 psi 40 CFM 20 l/sec 40 CFM 20 l/sec<br />

Weight, without Head 26 lb 11.8 kg 40 lb 18.1 kg<br />

* MP Medium Pressure Cone & Thread **1-1/8 in. Ø O-ring<br />

Page 10 © 10/03

UH-40 40 Kpsi Powered Rotation<br />

The productive solution for coatings, corrosion, or scale removal<br />

• 4-Arm Assembly to 20” jet path diameter<br />

• Bar Head to 12” jet path diameter<br />

• Rugged, high capacity design<br />

• Uses 3/8 in. OS6 Sapphire Nozzle Tips, pg. 49<br />

• Easy to mount, easy to maintain<br />

Specifications<br />

Drive Air UH-40<br />

Hydraulic UH-50<br />

Swivel<br />

UH-H9H6<br />

Max. Pressure 40 Kpsi 2750 bar<br />

Flow Rating<br />

0.64 Cv<br />

Flow Capacity 20 gpm 76 lpm<br />

Inlet Port<br />

9/16 HP*<br />

Outlet Shaft<br />

3/8 HP*<br />

Mounts<br />

Four 5/16-18 NC<br />

2.25 X 8 in. Spacing<br />

Rotation Speed<br />

Fast 2:1 Ratio 250 - 1,000 rpm<br />

The UH-40 & 50 Powered Rotation Assemblies feature<br />

the reliable StoneAge UH-H9H6 Swivel and belt<br />

drive system for thorough and productive surface cleaning.<br />

Replaceable, excellent quality sapphire jets provide<br />

hard-hitting power for epoxy coatings removal or other<br />

surface preparation. Air motor or hydraulic motor drives<br />

are available.<br />

Clean belts, screens, conveyors<br />

Remove epoxy coatings<br />

Clean paint line carriers<br />

Prepare surfaces for coatings<br />

Build custom surface cleaning systems<br />

Do it all with minimum water flow<br />

More productive than hand-held gun<br />

Air Supply at 80 psi 42 CFM 20 l/sec<br />

Weight, without Head 26 lb 11.8 kg<br />

© 10/03<br />

* High Pressure Cone & Thread<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 11

BADGER 2D Self-Rotating Nozzle<br />

Because all pipes<br />

are not straight...<br />

Model BA-P6<br />

5 to 15 Kpsi<br />

10 to 30 gpm<br />

Clean 4” to 12” piping with elbows<br />

Unplug or descale deposits with ease<br />

Clean process and building drains<br />

Clean pneumatic transfer lines<br />

The Badger is the first rotation speed<br />

controlled 2D tool with positive high pressure<br />

seal and replaceable jets that will go<br />

around a 4 in. short radius elbow. In the<br />

past the only choices were between an<br />

expensive hose rotation device, a leaky<br />

seal rotating head, or a non-rotating head.<br />

StoneAge puts real value in your hands<br />

with a technically superior tool, at a reasonable<br />

price.<br />

Hose no larger than 3/8 in. ID is recommended<br />

to keep the hose from binding in<br />

the smaller elbows. The Badger will<br />

handle up to 30 gpm, but small diameter<br />

hose usually limits flow to 20-25 gpm for<br />

maximum power delivery. Call us to discuss<br />

options.<br />

Rigid inlet nipple required for 8” and larger<br />

lines to prevent hazardous reversing<br />

Patent Pending<br />

Badger Viscous Braking Swivel<br />

Integral Rotating Head<br />

AP2 Nozzle Tips<br />

• Viscous fluid rotation speed control<br />

• Up to 100 lb pulling force<br />

• Durable stainless steel construction<br />

• Uses durable, high quality AP2 Nozzle Tips, pg. 47<br />

• Rotating jets - 2 @ 135°, 2 @ 90°, 1 @ 15°<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Specifications<br />

Model<br />

Badger<br />

Max. Pressure 15,000 psi 1000 bar<br />

Rotation Rate<br />

Fast<br />

75-220 rpm<br />

Slow<br />

20-80 rpm<br />

Flow Range<br />

BA-P6-R22 10-19 gpm 38-72 lpm<br />

BA-P6-R14 16-30 gpm 61-114 lpm<br />

Flow Rating<br />

1.6 Cv<br />

Weight 2.5 lb 1.1 kg<br />

Diameter 2.5 in. 63.5 mm<br />

Length 3.51 in. 89 mm<br />

Inlet Port<br />

3/8 npt<br />

Outlet Ports<br />

1/8 npt<br />

Page 12 © 10/03

GOPHER 2D Self-Rotating Nozzle<br />

80°<br />

100°<br />

20 Kpsi & 40 Kpsi Models now available<br />

15°<br />

30°<br />

35°<br />

GO 043-P2<br />

Un-Plugger<br />

Jet Pattern<br />

135°<br />

The tube cleaning version of the<br />

Barracuda. The Gopher uses<br />

the same proven centrifugal rotation<br />

speed control, but with heads<br />

designed to unplug or polish internal<br />

surfaces of straight tubes. Powerful<br />

replaceable tips are used in<br />

the heads - AP2 Tips in the GO-<br />

M9, OS6 Sapphire Tips in the<br />

GO-H9. For lines bigger than 6”<br />

diameter, the BJV-20K is recommended.<br />

Clean piping, evaporator<br />

tubes, process drains<br />

GO 042 Polisher<br />

Jet Pattern<br />

Gopher Centrifugal<br />

Braking Swivel<br />

GO-043-P2 Unplugger Head<br />

AP2 Nozzle Tips<br />

Patent 5,909,848<br />

Power to handle coke,<br />

polymers, coatings, latex<br />

For straight tubes<br />

1-7/8 in. ID and larger<br />

GO 070 Centralizer<br />

Replaceable Skids<br />

8” Diameter<br />

GO 075 Centralizer<br />

One Piece Plastic<br />

3”, or 4.5” Diameter<br />

Specifications<br />

Model GO-M9 GO-H9<br />

Diameter 1-5/8 in. 41 mm 1-5/8 in. 41 mm<br />

Inlet Port 9/16 MP 9/16 HP<br />

Head Diameter 1-5/8 in. 41 mm 1-5/8 in.41 mm<br />

Length Overall 7.8 in. 19.8 cm 7.8 in. 19.8 cm<br />

Weight, with Head 4 lb 1.80 kg 4 lb 1.80 kg<br />

Max. Pressure 20 Kpsi 1380 bar 40 Kpsi 2760 bar<br />

Flow Capacity 25 gpm 95 l/min 12 gpm 45 lpm<br />

Flow Rating 0.84 Cv 0.43 Cv<br />

Rotation Speed 600-1000 rpm 600-1000 rpm<br />

Head Selection<br />

Polisher Lo-Flow 7-13 gpm 27-49 lpm 3.8-6.6 gpm 17-27 lpm<br />

Model GO 042-R.14 GO 342-R.14<br />

Polisher Hi-Flow 14-25 gpm 53-95 lpm 7-12 gpm 29-45 lpm<br />

Model GO 042-R.07 GO 342-R.08<br />

Unplugger Lo-Flow 8-14 gpm 30-53 lpm 4.0-7.0 gpm 17-29 lpm<br />

Model GO 043-R.17 GO 343-R.18<br />

Unplugger Hi-Flow 15-25 gpm 57-95 lpm 7-12 gpm 29-45 lpm<br />

Model GO 043-R.08 GO-343-R.08<br />

© 10/03<br />

• Centrifugal rotation speed control for power<br />

• Replaceable nozzle tips<br />

AP2 for GO-M9, pg. 47<br />

OS4 for GO-H9, pg. 49<br />

• Adaptors available for 15 Kpsi operation<br />

AF 065-M9P6 for 3/8 npt<br />

AF 065-M9P8 for 1/2 npt<br />

• Uses motor oil for lubricant<br />

• Easy field replacement of high pressure seal<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 13

RJV 2D Self-Rotating Nozzle<br />

Clean pipes 3 to 12 in. ID<br />

Clean process drains<br />

Model RJV<br />

15 Kpsi, 35 gpm<br />

Clean totes, closed head drums<br />

Clean water well screens<br />

Clean ducts, exhaust stacks<br />

Handles straight tubes as<br />

small as 2-1/4 in. ID<br />

RJV Viscous Braking Swivel,<br />

RJ 043-P2-6 Head, AP2 Nozzle Tips<br />

BJ 045 Pulling Ring, and optional<br />

RJ 044-P4-6 Head, APF4 Nozzle Tips<br />

RJ 043-P2-7<br />

Nozzle Head<br />

15° port for<br />

unplugging<br />

135°<br />

90°<br />

45°<br />

15°<br />

RJ 070<br />

Centralizer<br />

• Steel collars,plastic skids<br />

• For bigger diameter piping<br />

• Replaceable plastic skids<br />

• 4, 5, 6, 8, or 12 in. diameter<br />

RJ 075<br />

Centralizer<br />

• One piece plastic<br />

• Keeps head from rubbing<br />

• Slip-on plastic sleeve<br />

• 3” or 4.5” diameter<br />

• Durable stainless steel construction<br />

• Easily replaced high pressure seal<br />

• Viscous fluid rotation speed control<br />

• Replaceable 1/4 or 1/8 npt nozzles<br />

• Operates with 2, 4, or 6 jets in balance<br />

Fly ash line cleaned using RJV self-rotating nozzle<br />

Specifications<br />

Model<br />

RJV<br />

Length Overall 6.0 in. 15 cm<br />

Weight, no Head 3 lb 1.4 kg<br />

Maximum Pressure 15 Kpsi 1000 bar<br />

Rotation Speed<br />

Fast<br />

50-250 rpm<br />

Slow<br />

10-100 rpm<br />

Flow Capacity 35 gpm 133 l/min<br />

Flow Rating, Cv 1.6<br />

Ports Inlet 1/2 npt Outlet 1/4 npt<br />

Head RJ 043-P2-6 RJ 044-P4-6<br />

Diameter 2.0 in. 51 mm 2.5 in. 64 mm<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Head Offset .30 in. .15 in. .08 in.<br />

5 Kpsi 4-8 gpm 8-17 gpm 17-35 gpm<br />

10 Kpsi 5-9 gpm 9-18 gpm 18-35 gpm<br />

15 Kpsi 6-11 gpm 11-21 gpm 21-35 gpm<br />

Page 14 © 10/03

BJV 2D Self-Rotating Nozzles<br />

Model BJV-M<br />

15 Kpsi, 100 gpm<br />

Use the biggest, most powerful jets possible with your<br />

pump. Rotate them to cover the entire inside surface.<br />

Powerful, versatile jet angles with controlled<br />

rotation for maximum jet power.<br />

Clean<br />

BJV-M Viscous Braking Swivel<br />

with BJ 044-P4-6 Head and<br />

APF Nozzle Tips<br />

Pipes, drains, 6-72” ID<br />

Stacks, ducts, tunnels<br />

Heat exchanger shells<br />

Coker cyclones, chutes<br />

Tanks, reactors<br />

Process vessels<br />

Water well screens<br />

Asbestos, refractory<br />

BJ 041-P8 Head<br />

Uses extension nipples for bigger diameters<br />

See pages 17, 18 for<br />

Centralizers<br />

90°<br />

BJ 044-P4 Head<br />

For smaller diameter applications<br />

45°<br />

90°<br />

45°<br />

15°<br />

135°<br />

135°<br />

Standard 6-Port<br />

BJ 041-P8-6 Head<br />

HC 090 Pulling Ring<br />

SA 356-P8P4 Extension<br />

Nipples AP4 Nozzle Tips<br />

Standard 6-Port<br />

BJ 044-P4-6 Head<br />

APF4 Nozzle Tips<br />

Optional 7-Port<br />

Unplugging BJ 044Head<br />

APF4 Nozzle Tips<br />

Specifications<br />

Model<br />

BJV-M<br />

• Rugged stainless steel construction<br />

Maximum Pressure 15 Kpsi 1000 bar<br />

Rotation Speed<br />

Fast 40-200<br />

rpm<br />

Slow 5-80 rpm<br />

Flow Capacity 100 gpm 380 l/min<br />

Flow Rating, Cv 4.6<br />

Inlet Port<br />

3/4 npt<br />

Shaft Outlet<br />

3/4 npt<br />

Weight 8.0 lb 3.6 kg<br />

Length 7.25 in. 18.4 cm<br />

Standard Head BJ 044-P4-Rx<br />

Diameter 3.0 in. 76 mm<br />

Ports 6 or 7 6 or 7<br />

1/4 npt 1/4 npt<br />

Weight 3.3 lb 1.5 kg<br />

Optional Head BJ 041-P8-Rx<br />

Diameter 3.5 in. 89 mm<br />

Ports 6 6<br />

1/2 npt 1/2 npt<br />

Weight 5.0 lb 2.3 kg<br />

© 10/03<br />

3/4 npt Connection<br />

National Pipe Tapered<br />

attaches directly to BJV-M<br />

• Simple, effective viscous braking<br />

• Easily replaced high pressure seal<br />

• Sealed, lubricated bearings<br />

Select a Head for the Right Flow Range!<br />

Flow Range in gpm<br />

Offset, R= 0.60 0.35 0.20 0.12<br />

BJV-M 10-18 18-32 32-55 55-100<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 15

BJV 2D Self-Rotating Nozzles<br />

Model BJV-20K<br />

20 Kpsi, 60 gpm<br />

BJV-20K Viscous Braking Swivel<br />

with BJ 144-P4-6 Head and<br />

APF Nozzle Tips<br />

BJV-20K the answer if 15 Kpsi is just not enough!<br />

Patent 6,059,202<br />

If 20 Kpsi power is needed, the BJV-20K is the<br />

answer. Features unique to the BJV-20K include<br />

lubricant fill by syringe, and easy high pressure<br />

seal replacement through the inlet port. Heads<br />

that take nozzle tips directly, and heads that use<br />

extension nipples are available. But 20 Kpsi connections<br />

are different from pipe threads. Centralizers<br />

are available.<br />

20 Kpsi Connections<br />

J-Shaft Connection<br />

to Nozzle Head<br />

1.1” OD , o-ring seal<br />

SA 577-G12P4<br />

Extension Nipples<br />

Require SA 059 O-Ring<br />

1/4 npt other end<br />

BJ 141-P8 Head<br />

Uses extension nipples for bigger diameters<br />

See pages 17, 18 for<br />

Centralizers<br />

90°<br />

BJ 144-P4 Head<br />

For smaller diameter applications<br />

45°<br />

90°<br />

45°<br />

15°<br />

135°<br />

135°<br />

Standard 6-Port<br />

BJ 141-G12-6 Head<br />

HC 090 Pulling Ring<br />

SA 577-G12P4 Extension<br />

Nipples AP4 Nozzle Tips<br />

Select a Head for the Right Flow Range!<br />

Flow Range in gpm<br />

Offset, R= 0.60 0.35 0.20 0.12<br />

BJV-20K 8-15 15-24 24-40 40-60<br />

“M” Hose Fitting has swivel nut,<br />

requires adaptor to MP Threads<br />

Specify thread diameter<br />

Standard 6-Port<br />

BJ 144-P4-6 Head<br />

APF4 Nozzle Tips<br />

LH<br />

Threaded<br />

Collar<br />

Gland<br />

Nut<br />

Optional 7-Port<br />

Unplugging BJ 144Head<br />

APF4 Nozzle Tips<br />

Specifications<br />

Model<br />

BJV-20K<br />

Maximum Pressure 20 Kpsi 1380 bar<br />

Rotation Speed<br />

Fast 70-300 rpm<br />

Slow 15-50 rpm<br />

Flow Capacity 60 gpm 230 lpm<br />

Flow Rating, Cv 2.3<br />

Inlet Port<br />

3/4 MP<br />

Shaft Outlet<br />

StoneAge J-Shaft<br />

Weight 8.0 lb 3.6 kg<br />

Length 8.40 in. 21.3 cm<br />

AF 063-M12<br />

Standard Head BJ 144-P4-Rx<br />

Diameter 3.0 in. 76 mm<br />

Ports 6 or 7 6 or 7<br />

1/4 npt 1/4 npt<br />

Weight 3.3 lb 1.5 kg<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

3/4” MP Hose Fitting<br />

attaches directly<br />

to BJV-20K<br />

Optional Head<br />

BJ 145-G12-Rx<br />

Diameter 3.5 in. 89 mm<br />

Ports 6 6<br />

G12 G12<br />

Weight 4.5 lb 2.0 kg<br />

Page 16 © 10/03

Pipe Centralizers<br />

Designed for the BJV-M self-rotating nozzle, these centering<br />

devices can be adapted to others.<br />

BJ 070<br />

Skid Style<br />

• Works well through elbows<br />

• Fixed size plastic skids<br />

• 6-12 in diameter skid sets available<br />

• Fits 3” OD BJV-M, BJV-20K, & BJV-H<br />

• Change size by replacing skids<br />

• Clamps around BJV<br />

• Approx 5 lb<br />

6-Wheel Collapsing Style<br />

• BJ 286-P12 3/4 npt, 15 Kpsi<br />

• BJ 286-M12 3/4 MP, 20 Kpsi<br />

• For straight pipe runs only<br />

• Adjustable aluminum frame<br />

• Easily convertible 15 Kpsi - 20 Kpsi<br />

• With tough plastic wheels<br />

Three sizes available:<br />

Small 9-18” Ø 13 lb 5.9 kg<br />

Medium 13-37” Ø 23 lb 10.4 kg<br />

Large 20-60” Ø 34 lb 15.4 kg<br />

8-Wheel Welded Frame Style<br />

• BJ 288-P12 3/4 npt, 15 Kpsi<br />

• BJ 288-M12 3/4 MP, 20 Kpsi<br />

Small 17-21” Ø 15 lb 6.8 kg<br />

Medium 22-29” Ø 26 lb 11.8 kg<br />

Large 30-37” Ø 31 lb 14.0 kg<br />

* Extra Large 42-64” Ø 50 lb 22.7 kg<br />

* BJ 289-XL Clamps to BJV-M, not illustrated<br />

© 10/03<br />

• Goes through elbows<br />

• Adjustable steel frame<br />

• Easily convertible 15 - 20 Kpsi<br />

• With tough plastic wheels<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 17

Pipe Centralizers<br />

Positioning devices are important to get the most out of your 2D nozzles!<br />

Offers more uniform coverage. Allows use of extension nipples to create better jets and reduce standoff.<br />

Pulling apparatus<br />

supplied by user<br />

3/4 Schedule 160<br />

Pipe Inlet<br />

• Best to negotiate complex<br />

piping arrangements<br />

• Handles built-up debris<br />

without stopping rotation<br />

• Fixed 19.5” (49.5 cm) diameter<br />

Eye Bolt for<br />

Cable Attachment<br />

BJ 100-SS Ball Style<br />

• Length 24.4” (61.9 cm)<br />

• Maximum 6” extension nipple<br />

• All stainless steel construction<br />

• Weight 14 lb. (6.3 kg)<br />

BJV-M Self-Rotating Nozzle<br />

Sold Separately<br />

BJ 150 for BJV-20K<br />

BJ 097 X Style<br />

• For stacks, and vertical ducts<br />

• Collapsable steel frame fits through manway<br />

• Adjustable diameter<br />

Extra Large 7 ft to 12 ft Ø 34 lb<br />

Large 5 ft to 7 ft Ø 28 lb<br />

Small 3 ft to 5 ft Ø 21 lb<br />

• With tough 4 in. diameter plastic wheels<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 18 © 10/03

UH-80 40 Kpsi Large Pipe Cleaner<br />

40 Kpsi Power quickly removes hard coatings and deposits<br />

Nothing cuts hard coatings and deposits like ultra high pressure. Put over 400 HP on the job with<br />

the UH-80 Pipe Cleaner. Use less water, and save money on collection, solids removal, and water<br />

filtration. The durable gearbox and air motor drive rotates the jets at just the right speed for maximum<br />

power delivery to the pipe walls. The UH-H9H6 Swivel handles up to 20 gpm. Whether the<br />

job is epoxy coating removal, hard polymer deposits, or chemical byproduct scale; the UH-80 is a<br />

great choice.<br />

Maximum Extension<br />

• Air powered rotation for<br />

thorough cleaning and<br />

dependability<br />

• 8-Wheel design goes<br />

around elbows<br />

• Handles pipes from 16.6 to<br />

37.5 in. ID<br />

• Efficient and powerful OS6<br />

Sapphire Nozzle Tips, pg. 49<br />

• Replace wheel assemblies<br />

for larger diameter pipes<br />

Collapsed<br />

Specifications<br />

Model<br />

UH-80<br />

Max. Pressure 40 Kpsi 2760 bar<br />

Flow Rating<br />

0.64 Cv<br />

Flow Capacity 20 gpm 76 lpm<br />

Gear Ratio 10:1<br />

Rotation Speed<br />

60 - 250 rpm<br />

Pipe ID 16.6 - 37.5 in. 420 - 950 mm<br />

© 10/03<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 19

Line Mole Backout Preventers<br />

Safe Line Mole Operations Require:<br />

• Safety Dump Valve - Located as near the pipe<br />

entrance as possible, operated by the person<br />

inserting the mole.<br />

* Rigid Pipe Stinger - Sufficient length of rigid pipe<br />

to prevent mole from turning around inside pipe.<br />

• Mole Backout Preventer - Prevents mole from<br />

backing out due to plugged jet, “hydraulicing”,<br />

hose or mole failure.<br />

Because....<br />

• Jets can plug at any time, causing unbalanced forces,<br />

and unpredictable reactions.<br />

• Long hoses store a great deal of energy, which can be<br />

released in an unpredictable manner if equipment<br />

fails.<br />

• Personal protective equipment designed to protect against<br />

splash-back may not offer adequate protection from<br />

impact of a line mole and hose flying out-of-control.<br />

• Adequate Personal<br />

Protective Equipment<br />

• Follow “Recommended<br />

Practices” of Water Jet<br />

Technology Association<br />

for safe operation.<br />

Available from<br />

StoneAge.<br />

BJ 310<br />

Backout<br />

Preventer<br />

Fits Pipes 4 - 8 in. Ø<br />

• Backout Preventers do not<br />

prevent hose from backing out<br />

BJ 320<br />

Backout<br />

Preventer<br />

• Attach securely to pipe<br />

• Accept 1/4 to 1 inch OD hose<br />

BJ 340<br />

No Flange Kit<br />

• Adapts BJ 320 for secure<br />

fit to pipes without flanges<br />

• Fits pipes of 6 - 36 in. Ø<br />

Kits convert BJ 320 to fit<br />

bigger diameters, or<br />

flangeless pipe<br />

Fits flange bolt circle 5 - 17 in. Ø<br />

BJ 325<br />

Extension Kit<br />

• Expands to fit flange bolt<br />

circle 15 - 36 in. (38 - 90 cm)<br />

diameter<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 20 © 10/03

WARTHOG TM Rotary Sewer Nozzles<br />

Predominant use - Municipal, Industrial, Commercial drain cleaning<br />

Model WG-1<br />

6 to 36 in. Ø Sewers<br />

Models<br />

WH-1/2 and WH-3/4<br />

6 to 18 in. Ø Sewers<br />

WG-1 Viscous Braking Swivel<br />

WG 040-R5 Rotating Head<br />

AP2 Nozzle Tips<br />

WH-1/2 Viscous Braking Swivel<br />

WH 040-R8 Rotating Head<br />

AP2 Nozzle Tips<br />

Controlled<br />

Rotation<br />

Warthog TM<br />

Delivers<br />

Results<br />

Delivers<br />

Power<br />

Specifications<br />

Waterjets do cut roots<br />

Model WG-1 WH-1/2, WH-3/4<br />

Max. Pressure 3 Kpsi 200 bar 8 Kpsi 550 bar<br />

Rotation Speed 150-300 rpm 150-300 rpm<br />

Flow 50-80 gpm 190-300 lpm 10-45 gpm 40-170 lpm<br />

Flow Rating, Cv 4.6 3.0<br />

Inlet Port 1 npt. or BSPP 1/2 , 3/4 npt, or BSPP<br />

Shaft Outlet 3/4 npt 3/8 npt<br />

Body Diameter 2.6 in. 6.6 cm 1.8 in. 4.4 cm<br />

Length 9.1 in. 23.1 cm 7.5 in. 19.1 cm<br />

Standard Head WG 040-R5 WH 040-R3, 45,8<br />

Head Diameter 2.7 in. 6.9 cm 2.4 in. 6.1 cm<br />

Ports Five 1/8 npt Three 1/8 npt<br />

Skid Diameter 4.2 in. 10.7 cm 3.1 in. 7.9 cm<br />

Weight Complete 10.9 lb 4.9 kg 4.7 lb 2.1 kg<br />

Pulling Force 70-100 lb 310-450 nt 18-50 lb 80-220 nt<br />

© 10/03<br />

Pulling force depends on pump power and hose dimensions.<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 21

WARTHOG TM Rotary Sewer Nozzles<br />

Patent 5,964,414<br />

Predominant use - Residential, Light Commercial drain cleaning<br />

Model WS-1/2<br />

4 to 8 in. Ø Sewers<br />

Model WT-3/8<br />

3 to 4 in. Ø Sewers<br />

WS-1/2 Viscous Braking Swivel<br />

WS 040-R3 Rotating Head<br />

AP2 Nozzle Tips<br />

These small Warthog TM Sewer Nozzles<br />

have all the powerful features of the larger<br />

tools, but have the ability to negotiate elbows<br />

and cleanouts commonly found in laterals<br />

from homes, buildings, restaurants, and other<br />

light commercial facilities. They are frequently<br />

operated with a 75-150 ft. length of<br />

3/8 in. hose on the end of a bigger hose reel<br />

on a trailer jetter. The WT-3/8 offers<br />

Warthog TM power for the first time for cart<br />

jetters with as little as 12 hp engines.<br />

WS-1/2 shown here<br />

goes through 4” elbows<br />

and cleanouts<br />

WT-3/8 Viscous Braking Swivel<br />

Integral Rotating Head<br />

AP2 Nozzle Tips<br />

Warthog TM power means faster cleaning, less water, less waste, less-frequent jetting<br />

Effective on sand, silt, scale, soap deposits, grease, debris, and roots<br />

WS-1/2 & WT-3/8<br />

go through elbows<br />

and cleanouts<br />

No more call-backs - When it’s<br />

jetted with a Warthog TM , it’s clean<br />

• No-leak high pressure seal<br />

• Viscous rotation speed control<br />

• Sealed, lubricated bearings<br />

• Replaceable, powerful jets<br />

WS 084 Centralizer<br />

The WT-3/8 WS 084 goes Centralizer through is 3” a safety device. Without it, the<br />

WS-1/2<br />

elbows<br />

might<br />

and<br />

possibly<br />

cleanouts<br />

reverse directions in sewers bigger than<br />

4” diameter. The WS 084 allows safe jetting up to 8” diameter.<br />

Specifications<br />

Model WS-1/2 WT-3/8<br />

• Durable construction<br />

• Easy field maintenance<br />

• Rebuildable forever<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Max. Pressure 4 Kpsi 275 bar 4 Kpsi 275 bar<br />

Rotation Speed 200-500 rpm 300-500 rpm<br />

Flow 8-20 gpm 27-75 lpm 5-12 gpm 20-45 lpm<br />

Flow Rating, Cv 1.3 0.75<br />

Inlet Port 1/2 npt 3/8 npt<br />

Shaft Outlet 3/8 npt None<br />

Body Diameter 1.8 in. 4.4 cm None<br />

Length 4.4 in. 11.2 cm 3.0 in. 7.6 cm<br />

Standard Head WG 040-R3, R5 Integral<br />

Head Diameter 1.7 in. 4.3 cm 1.9 in. 4.8 cm<br />

Ports Three 1/8 npt Three 1/8 npt<br />

Weight Complete 2.8 lb 1.3 kg 1.1 lb 0.5 kg<br />

Pulling force depends on pump power and hose dimensions.<br />

Page 22 © 10/03

Warthog TM power now available for washdown guns<br />

Coverage as good as a fan tip, but much greater power.<br />

The magic of controlled rotation, no-leak seals, and<br />

quality jets means more productivity, and more thorough<br />

cleaning of surfaces. The Hogwash TM is built<br />

from the same reliable viscous braking swivel used in<br />

the WS-1/2 sewer nozzle.<br />

Hogwash Washdown Gun Nozzle<br />

Clean:<br />

Parking lots, drive-thrus, service stations<br />

Decks, walls, boat hulls, shop floors<br />

WSH Viscous<br />

Braking Swivel<br />

AP2 Nozzle Tips<br />

Contaminated surfaces after spills<br />

Puts your trailer jetter in the surface<br />

cleaning business<br />

Specifications<br />

Model<br />

WSH-3/8<br />

Max. Pressure 6 Kpsi 400 bar<br />

Rotation Speed 300-600 rpm<br />

Flow<br />

7-18 gpm 27-68 lpm<br />

Length 4.4 in. 11 cm<br />

Body OD 2.4 in. 6.1 cm<br />

Weight 2.8 lb 1.3 kg<br />

Inlet Port<br />

3/8 npt<br />

Adaptor Available 1/2 npt<br />

Hogwash TM Jetting - Flow in gpm<br />

AP2 1000 1500 2000 2500<br />

Jet ID psi psi psi psi<br />

.052 7.2<br />

22° Head<br />

.057 7.6 8.6<br />

.063 9.2 10.3<br />

.069 10.9 12.1<br />

.075 10.9 12.6 14.0<br />

.082 12.6 14.6<br />

.090 12.0 14.6<br />

.098 13.5 16.6<br />

.106 14.9 17.9<br />

.115 16.4<br />

.125 17.8<br />

16° Head<br />

• No-leak high pressure seal<br />

• Controlled rotation speed<br />

• Sealed, lubricated bearings<br />

• Replaceable, powerful jets<br />

• Durable construction<br />

• Easy field maintenance<br />

Super Centralizer<br />

For WH or<br />

WG Models<br />

© 10/03<br />

Places the Warthog TM<br />

closer to the sewer<br />

centerline, for more powerful<br />

cleaning of the top wall.<br />

It also keeps the nozzle back<br />

from blockage, allowing the<br />

powerful front jet to do its<br />

work. The Super Centralizer<br />

bolts to the standard centralizer.<br />

Custom Manhole Cleaning Equipment<br />

The MH-30 Manhole<br />

Head and guard works with<br />

the WG-1, WH-1/2 or 3/4<br />

Models to prepare manholes<br />

for repair. Whether the manhole<br />

will be coated, lined, or<br />

grouted; the Warthog-based<br />

cleaning equipment is an important<br />

first step.<br />

WARTHOG TM Nozzle Accessories<br />

RJ 200 Case<br />

This heavy duty plastic case is<br />

gasketed, and foam lined to<br />

protect its contents from<br />

breakage, dirt, contamination,<br />

or corrosive industrial or marine<br />

environments.<br />

Descaling Ports<br />

90° jet ports can be added to<br />

the rotating head to enhance<br />

removal of scale from a drain<br />

surface. Tuberculation, corrosion<br />

products, soap scale,<br />

and minerals respond well to<br />

this option.<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 23

WEASEL, FERRET, & MARTEN 2D Tube Nozzles<br />

Concentrated cleaning power with controlled rotation in a compact 2D nozzle<br />

These powerful tube nozzles are<br />

used to unplug and descale<br />

straight heat exchanger tubes,<br />

and other similar conduits. Their<br />

no-leak seal, unique jet design,<br />

and patented rotation speed control<br />

mean better restoration of<br />

heat transfer surfaces, and<br />

quicker turnaround, with less<br />

work. Replace your old fashioned<br />

tools with StoneAge tube<br />

nozzles and stop all that exhausting<br />

hose manipulation!<br />

Discuss maintenance kits with us<br />

when ordering because these<br />

nozzles require some attention<br />

every shift for continued reliable<br />

service.<br />

Marten - For 1.5-3.0 in. ID Tubes<br />

Ferret - For 1.1-2.0 in. ID Tubes<br />

135°<br />

Weasel - For .88-1.5 in. ID Tubes<br />

Unplugger style<br />

jets illustrated<br />

45°<br />

30°<br />

Patent 5,964,414 & 6,059,202<br />

15°<br />

Clean:<br />

Condenser Tubes Evaporator Tubes Reboiler Tubes<br />

Precipitator Tubes Catalyst Injection Tubes Small Diameter Pipelines<br />

Filtrate Lines Cyclone Separator Lines Reformer Tubes<br />

Cooler Tubes Process Sample Lines Blowdown Lines<br />

Fuel Lines Furnace Tubes Crystallizer Tubes<br />

Lab Sewers Centrifuge Feed Lines Slurry Transfer Lines<br />

• Rotation speed controlled by viscous<br />

fluid governor<br />

• Leak free high pressure seal<br />

• Unplugger and Polisher style heads<br />

• Disposable drilled jet heads<br />

• Sealed, lubricated bearings<br />

• Easy lubricant fill with syringe<br />

Specifications<br />

Marten Unplugger makes quick<br />

work of evaporator tubes<br />

Model Weasel Ferret Marten<br />

Body Diameter .66 in. 17 mm 0.91 in. 23 mm 1.25 in. 32 mm<br />

For Tube OD .88-1.5 in.22-38 mm 1.1-2.0 in.29-51 mm 1.5-3.0 in.38-76 mm<br />

Inlet Port 1/4 npt 1/4 npt 1/2 npt<br />

Head Diameter .625 in. 17 mm .875 in. 22 mm 1.25 in. 32 mm<br />

Length Overall 4.60 120 mm 5.60 in. 140 mm 6.75 in. 171 mm<br />

Weight 0.7 lb 0.31 kg 1 lb 0.65 kg 1.5 lb 0.68 kg<br />

Max. Pressure 15 Kpsi 1000 bar 15 Kpsi 1000 bar 15 Kpsi 1000 bar<br />

Flow Capacity 8 gpm 30 l/min 12 gpm 45 l/min 25 gpm 95 l/min<br />

Flow Rating 0.27 Cv 0.4 Cv 0.84 Cv<br />

Rotation Speed 1,200 rpm 1,000 rpm 300-500 rpm<br />

• Easy field replacement of seal<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Weasel demonstrates its<br />

powerful unplugging<br />

capability<br />

Page 24 © 10/03

WEASEL, FERRET, & MARTEN 2D Tube Nozzles<br />

Concentrated cleaning power with controlled rotation in a compact 2D nozzle<br />

Unplugger jets penetrate, surround plugs, and grind away<br />

The Ferret is shown here cleaning a<br />

plug out of a transparent plastic tube.<br />

Extensive testing proved what jet angles<br />

work best. Drilled jets in these heads<br />

provide the most economical life cycle<br />

cost, but they do wear out. Vigilent<br />

maintenance is required to get the best<br />

service from these tube nozzles.<br />

Tube Nozzle Heads<br />

Polisher<br />

Style<br />

Specifications<br />

Unplugger<br />

Style<br />

Model EZ 042 FT 042 MT 042<br />

Jet Style Polisher Polisher Polisher<br />

Diameter, OD 5/8 in. 17 mm 7/8 in. 22 mm 1 in. 25 mm<br />

Model EZ 043 FT 043 MT 045<br />

Jet Style Unplugger Unplugger Unplugger<br />

Diameter, OD 5/8 in. 17 mm 7/8 in. 22 mm 1-1/4 in. 32 mm<br />

The most important maintenance need is<br />

periodic lubricant flush - every 10 hours for<br />

the MT-P8, 4 hours for the FT-P4, and 3<br />

hours for the EZ-P4. Keeping the nozzle<br />

full of the special viscous fluid lubricant extends<br />

life of seals and bearings significantly.<br />

See page 53 for a full list of maintenance<br />

kits and supplies available.<br />

Jetting 10 Kpsi 690 bar 10 Kpsi 690 bar 10 Kpsi 690 bar<br />

Options 8 gpm 30 lpm 10 gpm 38 lpm 15 gpm 57 lpm<br />

Available<br />

10 Kpsi 690 bar 10 Kpsi 690 bar<br />

12 gpm 45 lpm 20 gpm 76 lpm<br />

10 Kpsi 690 bar<br />

25 gpm 95 lpm<br />

15 Kpsi 1030 bar 15 Kpsi 1030 bar 15 Kpsi 1030 bar<br />

8 gpm 30 lpm 10 gpm 38 lpm 15 gpm 57 lpm<br />

15 Kpsi 1030 bar 15 Kpsi 1030 bar<br />

12 gpm 45 lpm 20 gpm 76 lpm<br />

15 Kpsi 1030 bar<br />

25 gpm 95 lpm<br />

© 10/03<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 25

HRS Air-Powered Hose Reel<br />

The HRS ends struggling with hoses,for safer,<br />

more-productive tube cleaning!<br />

Vertical evaporators make tough work. With difficult working conditions<br />

and impatient customers who never allow enough time to complete the<br />

job, how can a contractor deliver true value? The HRS is the answer. It’s<br />

reliable, and boosts productivity so much that many evaporators can be<br />

thoroughly cleaned for the first time ever. Getting the plant back into<br />

production sooner, at rates not achieved before; makes big money. Safety<br />

is also improved compared to manual methods.<br />

• Cleaner tubes, pressure on for<br />

both down & up cycle<br />

• Up to 50% more productive<br />

than manual methods<br />

• Eliminate stand-by crews,<br />

reduce rest schedule<br />

• Less down time means more<br />

production for customer<br />

• Thoroughly restored heat<br />

transfer means more<br />

production for customer<br />

MT 140 Jet Guard<br />

Marten Tube Nozzle - sold separately<br />

Stroke<br />

Speed<br />

Adjustment<br />

Hand Controls<br />

Pressure Dump<br />

Stroke In/Out<br />

Black liquor evaporator cleaning<br />

Specifications<br />

First unit still at work in<br />

rendering plant evaporator<br />

Tripod<br />

Mount<br />

Comes apart to fit<br />

through 18” manway<br />

Optional<br />

Jet Guard<br />

Tube Nozzle<br />

sold separately<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Max. Pressure 15 Kpsi 1000 bar<br />

Inlet Port<br />

1/2 npt<br />

Stroke Speed, Max. 3 ft/sec 0.9 m/sec<br />

Air Supply Required 80 psi 5.5 bar<br />

30 CFM 14 l/sec<br />

Weight 175 lb 78 kg<br />

Model HRS-P8 HRS-P6 HRS-P6<br />

Hose Option HRS 350 HRS 376 HRS 378<br />

Min. Tube ID 1.50 in. 38 mm 1.10 in. 28 mm 0.75 in. 19 mm<br />

Hose Connections 1/2 npt 1/4 npt 1/4 npt<br />

With Tube Nozzle MT-P8 FT-P4 EZ-P4<br />

Stroke 45 ft. 21 m 70 ft 33 m 70 ft 33 m<br />

Hose ID .50 in. 12 mm .33 in. 8 mm 0.25 in. 6 mm<br />

Hose OD 1.0 in. 25 mm .61 in. 16 mm 0.50 in. 12 mm<br />

Flow Rating, Cv 0.70 0.28 0.16<br />

Flow Capacity 27 gpm 102 lpm 12 gpm 45 lpm 8 gpm 30 lpm<br />

Page 26 © 10/03

Rigid Tube Lancing Systems<br />

Lancing System<br />

Components<br />

BRLM 300-15<br />

Lancing Rail<br />

CB-2D<br />

Pneumatic<br />

Control<br />

Box<br />

BRUD XY<br />

Positioner<br />

55 ft Long, 36 Kpsi Lancing<br />

System set up to clean vertical<br />

brine concentrator tubes<br />

BRUD 220<br />

Rear Support<br />

BRUD 200<br />

Wheel Kit<br />

BRLM 3xx-15<br />

Lancing<br />

Package<br />

Safety dump system, high pressure<br />

water supply and air supply hose<br />

not included<br />

StoneAge’s Lancing Systems<br />

have been refined in design to provide<br />

dependability, versatility, and<br />

easy conversion from one operating<br />

pressure level to another. The<br />

system handles more waterjet<br />

power than a man holding a lance<br />

can. It handles waterjet-assisted<br />

drill bits for more unplugging<br />

power than a flexible lance. It is<br />

more consistent and more productive<br />

than any other lancing<br />

method. The rigid lancing system<br />

allows the customer’s plant to be<br />

returned to operation in less time,<br />

making the contractor’s service<br />

more valuable.<br />

Safer, more powerful, thorough, reliable, and<br />

productive than any manual method<br />

Restores heat transfer to new condition<br />

Keeps operator away from hazards of high<br />

pressure water and debris splashback<br />

Returns the bundle to production quicker than<br />

any other method<br />

Consistent results because every tube is jetted<br />

at the same rate<br />

BRUD frame fits over<br />

scaffolding to allow<br />

vertical lancing<br />

Five Easy Steps for a Complete System:<br />

1. Select BRLM 300-15 Lancing Rail, plus BRLM 080<br />

Extensions to get sufficient stroke to handle your<br />

longest tube bundle.<br />

2. Select Lancing Package according to operating pressure<br />

and mode - single rotary, dual rotary, 4-lance non-rotary.<br />

3. Buy a CB-2D Control Box, and BRUD XY Positioner<br />

Decide on standard manual XY positioning or<br />

optional air-operated.<br />

4. Buy Lance Tips to suit the job.<br />

5. Buy lances same length as the total rail.<br />

© 10/03<br />

Features<br />

• Single, Dual Rotary, or 4 Lance Non-Rotary<br />

• Manual or Powered XY Positioner<br />

• 15, 20, or 40 Kpsi pressure rating<br />

• Up to 2 ft/sec travel, 400 lb thrust<br />

• Up to 60 ft stroke with Extension Kits<br />

• Lightweight, corrosion-resistant<br />

• Air or hydraulic power<br />

• Easily converted to different pressure,<br />

length, or lance configuration<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 27

Rigid Tube Lancing Systems<br />

BRLM 300-15<br />

Lancing Rail<br />

3 HP Drive produces<br />

up to 400 lb thrust,<br />

2 ft/sec stroke<br />

Lancing Packages - Slide onto Rail<br />

BRLM 080-xx<br />

Extension Kit<br />

Extensions available<br />

in 5 ft increments to<br />

increase stroke as<br />

needed<br />

Single<br />

Rotary<br />

80-400 rpm<br />

Rotation<br />

Dual<br />

Rotary<br />

120-600 rpm<br />

Rotation<br />

4-Lance<br />

Non-Rotating<br />

Every Lancing System is sold as a<br />

15 ft unit, with additional length<br />

added as Extension Kits. Extension<br />

kits have been used to make systems<br />

up to 60 ft long.<br />

Select a Lancing Package based on<br />

operating pressure and lance configuration<br />

needed.<br />

Compressed Air Required<br />

80-100 psi, 60-90 cfm 4-Lance<br />

80-100 psi, 80-130 cfm Rotary<br />

Hydraulic Option Available<br />

Specifications<br />

Lancing Rail Weight Length Stroke<br />

BRLM 300-15 Lancing Rail & Drive 122 lb 55 kg 15 ft 1.5 m 12.0 ft 3.7 m<br />

Extension Includes Rail, Splice, Chain, Guide Blocks<br />

Kits Length Adds Stroke Weight<br />

BRLM 080-05 5 ft 1.5 m 4.8 ft 1.5 m 26 lb 12 kg<br />

BRLM 080-10 10 ft 3.1 m 9.5 ft 2.9 m 45 lb 20 kg<br />

BRLM 080-15 15 ft 4.6 m 14.0 ft 4.3 m 65 lb 29 kg<br />

BRLM 080-20 20 ft 6.1 m 19.0 ft 5.8 m 86 lb 39 kg<br />

BRLM 080-25 25 ft 7.6 m 24.0 ft 7.3 m 107 lb 49 kg<br />

Lancing 15 Kpsi 20 Kpsi 40 Kpsi<br />

Package * Weight 1030 bar 1380 bar 2760 bar<br />

Single Rotary Package 59 lb 27 kg BRLM 310-15 BRLM 320-15 BRLM 330-15<br />

Dual Rotary Package 62 lb 28 kg BRLM 340-15 BRLM 350-15 BRLM 360-15<br />

4-Lance Non-Rotating 67 lb 30 kg BRLM 370-15 BRLM 380-15 NA<br />

* Handles lances up to 9/16 in. OD, not included.<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Lance Selection for Maximum Power<br />

Jet for flows (gpm) no greater than:<br />

Lance 1/4 3/8 9/16 1/4 3/8 9/16 1/8 1/4<br />

HP HP HP MP MP MP Sch 80 SCH 80<br />

15 ft. 3.1 9.0 24 4.4 20 60 20 50<br />

25 ft. 2.4 6.8 18 3.4 16 45 16 35<br />

35 ft. 2.1 5.8 16 2.9 14 40 14 30<br />

Page 28 © 10/03

BRUD Positioner<br />

BRUD-Manual<br />

with BRUD 200<br />

Wheel Kit<br />

Mounts lancing machine to bundle<br />

Moves lances from tube to tube<br />

BRUD 220<br />

Rear<br />

Support<br />

Vertical<br />

Fore/Aft<br />

Hollow frame tubes<br />

fit on scaffolding<br />

Tubesheet<br />

Brace<br />

For horizontal or vertical lancing<br />

Air or hydraulic powered option<br />

Fits scaffolding for vertical lancing<br />

4.1 Foot square operating window<br />

Horizontal<br />

• Lightweight, strong tubular frame<br />

• Easy mounting of Lancing Machine<br />

• Easy conversion to air operation<br />

• Corrosion-resistant materials and coatings<br />

Specifications<br />

Model BRUD-M BRUD 220 BRUD 200 BRUD 210<br />

XY Positioner Rear Support Wheel Kit Air Power Kit*<br />

XY Range 4.1 ft 1.25 m<br />

Weight 140 lb 64 kg 96 lb 44 kg 175 lb 79 kg 40 lb 18 kg<br />

© 10/03<br />

*Requires CB 200 Control Kit and 30-50 cfm 80-100 psi air supply - Hydraulic motors also available<br />

Specifications<br />

CB-2D Pneumatic Control Box<br />

The CB-2D Control Box is needed to operate the<br />

lancing system’s air motors. It’s simple to set up,<br />

operate, and move about. An air filter and lubricator<br />

are included to keep the air motors going strong.<br />

The CB-2D Control Box will not operate hydraulic<br />

powered lancing systems, and StoneAge does not<br />

make hydraulic controls.<br />

Model CB-2D CB 200 Kit<br />

Rotation<br />

On/Off<br />

Stroke<br />

Fwd/Back<br />

Stroke Speed<br />

Forward<br />

Regulated<br />

Back<br />

Regulated<br />

X Motion (Left/Right) Manual Left/Right<br />

Y Motion (Up/Down) Manual Up/Down<br />

z Motion (Fore/Aft) Manual Fore/Aft<br />

Air Hoses Included 3 6<br />

Weight 51 lb 23 kg 47 lb 21 kg<br />

CB-2D Control Box<br />

Rotation<br />

On/Off<br />

Fwd/Rev<br />

Stroke<br />

Air<br />

Filter<br />

Lubricator<br />

CB 200 Kit<br />

Air<br />

Supply<br />

Forward<br />

Stroke<br />

Speed<br />

Reverse<br />

Stroke<br />

Speed<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 29

Air Powered Hand Lancing Tools<br />

FS<br />

Drive Swivel<br />

Coupling<br />

Air Motor<br />

For unplugging and polishing difficult tubes<br />

Lance<br />

Adaptor<br />

Lance & Lance Tips<br />

sold separately<br />

Lance<br />

Adaptor<br />

HI<br />

Swivel<br />

SA 2000, 2012 SA 1900, 1909<br />

Drive<br />

Coupling<br />

Air Motor<br />

Specifications<br />

Quick setup for small bundles<br />

Compact for use in congested areas<br />

More productive and thorough than<br />

non-rotary lancing<br />

Lance Adaptor Assemblies<br />

15,000 psi Systems<br />

Model SA-1900 SA-2000 SA-1909 SA-2012<br />

Max. Pressure 15 Kpsi 15 Kpsi 20 Kpsi 20 Kpsi<br />

Flow Capacity 20 gpm 60 gpm 20 gpm 50 gpm<br />

Swivel HI-P6P6 FS-P8K HI-A9A9 FS-A12K<br />

Rotation 100-400 rpm 100-300 rpm 100-400 rpm 100-300 rpm<br />

Inlet Port 3/8 npt 1/2 npt 9/16 MP 3/4 MP<br />

Air Supply 60-100 psi 70-100 psi 60-100 psi 70-100 psi<br />

30 CFM 40 CFM 30 CFM 40 CFM<br />

Weight 12 lb 20 lb 13 lb 22 lb<br />

Service Kit HI 600 FS 600 HI 600 FS 600<br />

Overhaul kit HI 610 FS 610 HI 610 FS 610<br />

20,000 psi Systems<br />

Lance Thread SA 1900 SA 2000 Thread SA 1909 SA 2012<br />

1/4” OD 1/4 x 28 SA 056-P6S4 NA 1/4 MP AF 073-M4M9 NA<br />

MP Tubing GP 075-250, 076 AF 072-M4, 071-M4<br />

3/8” OD 1/8 npt SA 056-P6P2 FS 025-KP2 3/8 MP AF 073-M6M9 NA<br />

MP Tubing GP 075-375, 076 GP 076-375, 076 AF 072-M6, 071-M6<br />

9/16” OD 1/4 npt SA 056-P6P4 FS 025-KP4 9/16 MP AF 073-M9M9 FS 020-KA9<br />

MP Tubing GP 075-562, 076 GP 075-562, 076 AF 072-M9, 071-M9 AF 072-M9, 071-M9<br />

3/4” OD NA NA 3/4 MP NA FS 020-KA12<br />

MP Tubing AF 072-M12, 071-M12<br />

1” OD NA NA 1 MP NA FS 020-KA16<br />

MP Tubing AF 072-M16, 071-M16<br />

1/8 Sch 80 1/8 npt SA 056-P6P2 FS 025-KP2 NA NA<br />

Pipe GP 075-405, 076 GP 075-405, 076<br />

1/4 Sch 80 1/4 npt SA 056-P6P4 FS 025-KP4<br />

Pipe GP 075-547, 076 GP 075-547, 076<br />

3/8 Sch 160 3/8 npt GP 052-P6P8 FS 020-KP6<br />

Pipe<br />

1/2 Sch 160 1/2 npt GP 052-P6P8 FS 020-KP8<br />

Pipe<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 30 © 10/03

Select the right tip for your job:<br />

Specifications<br />

TD Tips Go to Work<br />

• Buy tip 1/8 in. smaller diameter than tube<br />

ID to minimize “hydraulicing”<br />

• Buy TC Tip for powerful unplugging<br />

• Buy CD Tip for unplugging and polishing<br />

• Buy TD Tip for economy and versatile jet<br />

patterns<br />

TC Lance Tip<br />

Unplugging heavy deposits,<br />

Maximum jet hitting power<br />

.5- 1.0 in. (12-25 mm) OD<br />

Single 8° Carbide Nozzle<br />

No Carbide Cutter<br />

CD Lance Tip<br />

For removal of hard plugs<br />

from heat exchanger tubes<br />

.31- 1.62 in. (8-41 mm) OD<br />

Drilled Jets, Carbide Cutter<br />

Jet Styles Available:<br />

• 1 @ 5°, 15°, 2 @ 135°<br />

• 1 @ 5° & 15°<br />

CD 012-M9<br />

Tip<br />

Body 3/8 in. 7/16 in. 1/2 in. 5/8 in. 3/4 in.<br />

Diameter 9.5 mm 11.1 mm 12.2 mm 15.9 mm 19.0 mm<br />

Low Pressure<br />

TC 012-M9<br />

Body<br />

OC<br />

Orifice<br />

Insert<br />

TC 010-P4<br />

Body<br />

15 Kpsi 1030 bar MAWP<br />

TD 012-M9<br />

Tip<br />

TD Lance Tip<br />

For economy and versatility<br />

.5- 1.0 in. (12-25 mm) OD<br />

Drilled Jets<br />

No Carbide Cutter<br />

Jet Styles Available:<br />

• 1 @ 10°, 20°, & 30°, 2 @ 135°<br />

• 1 @ 10°, 20°, & 30° • 2 @ 45°, 2 @ 135°<br />

• 2 @ 60° • 2 @ 90°<br />

CD 006-S4 CD 007-S6 CD 008-P2 CD 010-P4 CD 012-P4<br />

TD 006-S4 TD 007-S6 TD 008-P2 TD 010-P4<br />

TC 008-P2 TC 010-P4<br />

Lance 1/4” OD 3/8” OD 1/8” Pipe 1/4” Pipe 1/4” Pipe<br />

Threads 1/4x28 3/8x24 1/8 npt 1/4 npt 1/4 npt<br />

Lance Tips<br />

CD 012-P4<br />

Tip<br />

TD 010-P4<br />

Tip<br />

Medium Pressure<br />

20 Kpsi 1380 bar MAWP - Right-Hand MP Threads<br />

CD 006-S4 CD 007-M6 CD 008-M6 CD 012-M9<br />

TD 006-S4 TD 007-M6 TD 008-M6 TD 012-M9<br />

TC 008-M6 TC 012-M9<br />

Lance 1/4” MP 3/8” MP 3/8” MP 9/16” MP<br />

Threads 1/4x28 3/8x24 3/8x24 9/16x18<br />

High Pressure<br />

40 Kpsi 2760 bar MAWP - Right-Hand HP Threads<br />

TD 008-H6 TD 012-H9<br />

Lance 3/8” HP 9/16” HP<br />

Threads 3/8x24 9/16x18<br />

Lance Selection for Maximum Power<br />

Jet for flows (gpm) no greater than:<br />

Lance 1/4 3/8 9/16 1/4 3/8 9/16 1/8 1/4<br />

HP HP HP MP MP MP Sch 80 SCH 80<br />

15 ft. 3.1 9.0 24 4.4 20 60 20 50<br />

25 ft. 2.4 6.8 18 3.4 16 45 16 35<br />

35 ft. 2.1 5.8 16 2.9 14 40 14 30<br />

© 10/03<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Page 31

Rigid Lances<br />

Equip your Lancing System with dependable, high quality lances<br />

StoneAge offers a limited selection of rigid lances, in the most popular sizes for users of Lancing Systems.<br />

These lances are type 304 stainless steel in the 1/8 hard condition, which we recommend for its stiffness and<br />

resistance to damage in use. We do not stock lances at our Durango factory because lances over 25 ft long<br />

cannot be shipped. So lances are shipped from our supplier in Houston. Lances are an expendable item,<br />

making it advantageous for users to develop dependable local sources.<br />

Lance Selection, Specify Length<br />

Rating,<br />

Thread<br />

OD,<br />

ID,<br />

Description<br />

StoneAge Part #<br />

Kpsi<br />

Connection<br />

in.<br />

in.<br />

Material<br />

3/8 in. OD Tubing<br />

SA 535-P2P2<br />

15<br />

1/8 npt<br />

.375<br />

.245<br />

304 SS 1/8 Hard<br />

9/16 in. MP Tubing<br />

SA 567-P4P4<br />

15<br />

1/4 npt<br />

.563<br />

.312<br />

304 SS 1/8 Hard<br />

3/8 in MP Tubing<br />

SA 537-M6M6R<br />

20<br />

3/8 MP LH/RH<br />

.375<br />

.203<br />

304 SS 1/8 Hard<br />

9/16 in. MP Tubing<br />

SA 567-M9M9R<br />

20<br />

9/16 MP LH/RH<br />

.563<br />

.312<br />

304 SS 1/8 Hard<br />

3/8 in. HP Tubing<br />

SA 539-H6H6R<br />

40<br />

3/8 HP LH/RH<br />

.375<br />

.125<br />

304 SS 1/8 Hard<br />

9/16 in. HP Tubing<br />

SA 569-H9H9R<br />

40<br />

9/16 HP LH/RH<br />

.563<br />

.188<br />

304 SS 1/8 Hard<br />

npt - National Pipe Thread MP - Cone & Thread Connection HP - Cone & Thread Connection<br />

Lance Pressure Drop, psi / 25 ft. Length<br />

Lance MAWP** OD ID Cv 2 4 6 8 10 15 20<br />

gpm gpm gpm gpm gpm gpm gpm<br />

1/8” Sch 80 Pipe 15 Kpsi .405 .215 0.23 77 310 700 1200 1900 4400 7700<br />

3/8” OD Tubing 15 Kpsi .375 .245 0.32 40 160 360 650 1000 2300 4000<br />

1/4” Sch 80 Pipe 15 Kpsi .540 .300 0.52 15 59 130 230 370 820 1500<br />

9/16” Ø MP Tubing 15 Kpsi .563 .312 0.58 12 48 110 190 300 680 1200<br />

1/2” Sch 160 Pipe 15 Kpsi .840 .464 1.56 2 7 15 26 41 93 170<br />

1/4” Ø MP Tubing 20 Kpsi .250 .109 0.04 2300 * * * * * *<br />

3/8” Ø MP Tubing 20 Kpsi .375 .203 0.20 100 410 930 1700 2600 5800 *<br />

9/16” Ø MP Tubing 20 Kpsi .563 .312 0.58 12 48 110 190 300 680 1200<br />

1/4” Ø MP Tubing 40 Kpsi .250 .083 0.02 9000 * * * * * *<br />

3/8” Ø HP Tubing 40 Kpsi .375 .125 0.06 1200 4700 * * * * *<br />

9/16” Ø HP Tubing 40 Kpsi .563 .188 0.16 150 610 1400 2400 3800 8500 *<br />

** Pressure ratings depend on materials of construction. * Pressure drop 9000 psi or greater.<br />

Durango, Colorado Phone 970-259-2869<br />

www.stoneagetools.com FAX 970-259-2868<br />

Ordering Notes<br />

• Order the same length lance as the rail length of your StoneAge<br />

Lancing System<br />

• For MP and HP connections, anti- vibe glands are recommended<br />

where the lance connects to the swivel.<br />

• Consider pressure drop when selecting operating pressures,<br />

lances, and lance tips. Jet power deteriorates rapidly if lance<br />

pressure drop exceeds 1/3 of pump discharge pressure.<br />

Page 32 © 10/03

Custom Lancing Machines<br />

The BRLM lancing rail, with special modification fits a variety of waterblast jobs<br />