KOBELT.com

KOBELT.com

KOBELT.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

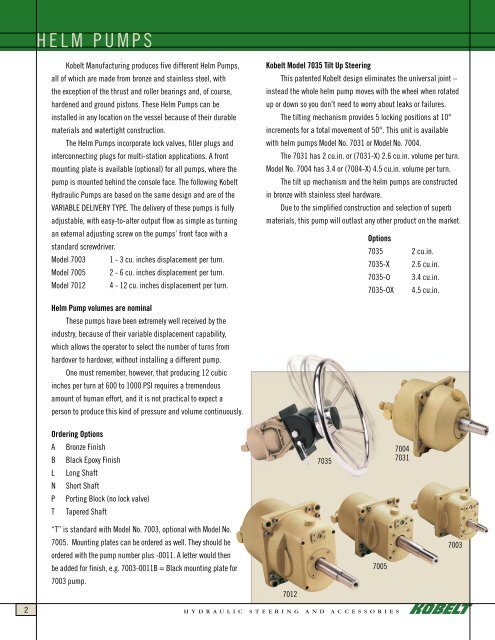

helm pumps<br />

Kobelt Manufacturing produces five different Helm Pumps,<br />

all of which are made from bronze and stainless steel, with<br />

the exception of the thrust and roller bearings and, of course,<br />

hardened and ground pistons. These Helm Pumps can be<br />

installed in any location on the vessel because of their durable<br />

materials and watertight construction.<br />

The Helm Pumps incorporate lock valves, filler plugs and<br />

interconnecting plugs for multi-station applications. A front<br />

mounting plate is available (optional) for all pumps, where the<br />

pump is mounted behind the console face. The following Kobelt<br />

Hydraulic Pumps are based on the same design and are of the<br />

VARIABLE DELIVERY TYPE. The delivery of these pumps is fully<br />

adjustable, with easy-to-alter output flow as simple as turning<br />

an external adjusting screw on the pumps’ front face with a<br />

standard screwdriver.<br />

Model 7003 1 - 3 cu. inches displacement per turn.<br />

Model 7005 2 - 6 cu. inches displacement per turn.<br />

Model 7012 4 - 12 cu. inches displacement per turn.<br />

Kobelt Model 7035 Tilt Up Steering<br />

This patented Kobelt design eliminates the universal joint –<br />

instead the whole helm pump moves with the wheel when rotated<br />

up or down so you don’t need to worry about leaks or failures.<br />

The tilting mechanism provides 5 locking positions at 10°<br />

increments for a total movement of 50°. This unit is available<br />

with helm pumps Model No. 7031 or Model No. 7004.<br />

The 7031 has 2 cu.in. or (7031-X) 2.6 cu.in. volume per turn.<br />

Model No. 7004 has 3.4 or (7004-X) 4.5 cu.in. volume per turn.<br />

The tilt up mechanism and the helm pumps are constructed<br />

in bronze with stainless steel hardware.<br />

Due to the simplified construction and selection of superb<br />

materials, this pump will outlast any other product on the market.<br />

Options<br />

7035 2 cu.in.<br />

7035-X 2.6 cu.in.<br />

7035-O 3.4 cu.in.<br />

7035-OX 4.5 cu.in.<br />

Helm Pump volumes are nominal<br />

These pumps have been extremely well received by the<br />

industry, because of their variable displacement capability,<br />

which allows the operator to select the number of turns from<br />

hardover to hardover, without installing a different pump.<br />

One must remember, however, that producing 12 cubic<br />

inches per turn at 600 to 1000 PSI requires a tremendous<br />

amount of human effort, and it is not practical to expect a<br />

person to produce this kind of pressure and volume continuously.<br />

Ordering Options<br />

A Bronze Finish<br />

B Black Epoxy Finish<br />

L Long Shaft<br />

N Short Shaft<br />

P Porting Block (no lock valve)<br />

T Tapered Shaft<br />

7035<br />

7004<br />

7031<br />

“T” is standard with Model No. 7003, optional with Model No.<br />

7005. Mounting plates can be ordered as well. They should be<br />

ordered with the pump number plus -0011. A letter would then<br />

be added for finish, e.g. 7003-0011B = Black mounting plate for<br />

7003 pump.<br />

7012<br />

7005<br />

7003<br />

2<br />

hydraulic steering and accessories