Brass Check Valves - Watts Industries

Brass Check Valves - Watts Industries

Brass Check Valves - Watts Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BRASS CHECK VALVES<br />

SAFETY CLASS EA<br />

4<br />

Application<br />

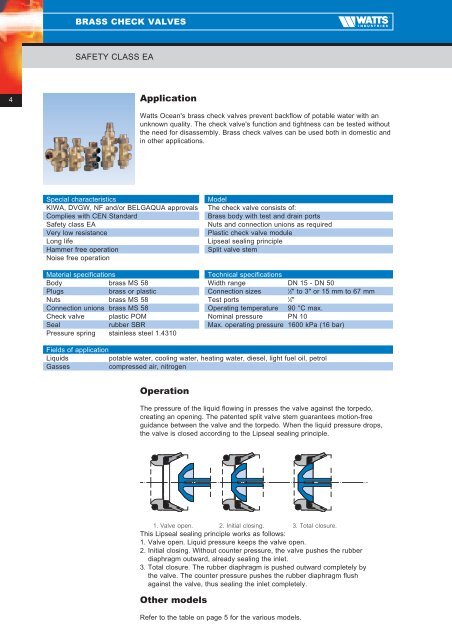

<strong>Watts</strong> Ocean's brass check valves prevent backflow of potable water with an<br />

unknown quality. The check valve's function and tightness can be tested without<br />

the need for disassembly. <strong>Brass</strong> check valves can be used both in domestic and<br />

in other applications.<br />

Special characteristics<br />

KIWA, DVGW, NF and/or BELGAQUA approvals<br />

Complies with CEN Standard<br />

Safety class EA<br />

Very low resistance<br />

Long life<br />

Hammer free operation<br />

Noise free operation<br />

Material specifications<br />

Body brass MS 58<br />

Plugs<br />

brass or plastic<br />

Nuts brass MS 58<br />

Connection unions brass MS 58<br />

<strong>Check</strong> valve plastic POM<br />

Seal<br />

rubber SBR<br />

Pressure spring stainless steel 1.4310<br />

Model<br />

The check valve consists of:<br />

<strong>Brass</strong> body with test and drain ports<br />

Nuts and connection unions as required<br />

Plastic check valve module<br />

Lipseal sealing principle<br />

Split valve stem<br />

Technical specifications<br />

Width range DN 15 - DN 50<br />

Connection sizes<br />

1<br />

⁄2" to 3" or 15 mm to 67 mm<br />

Test ports 1<br />

⁄4"<br />

Operating temperature 90 °C max.<br />

Nominal pressure PN 10<br />

Max. operating pressure 1600 kPa (16 bar)<br />

Fields of application<br />

Liquids<br />

potable water, cooling water, heating water, diesel, light fuel oil, petrol<br />

Gasses<br />

compressed air, nitrogen<br />

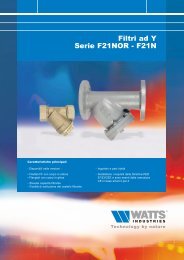

Operation<br />

The pressure of the liquid flowing in presses the valve against the torpedo,<br />

creating an opening. The patented split valve stem guarantees motion-free<br />

guidance between the valve and the torpedo. When the liquid pressure drops,<br />

the valve is closed according to the Lipseal sealing principle.<br />

1. Valve open. 2. Initial closing. 3. Total closure.<br />

This Lipseal sealing principle works as follows:<br />

1. Valve open. Liquid pressure keeps the valve open.<br />

2. Initial closing. Without counter pressure, the valve pushes the rubber<br />

diaphragm outward, already sealing the inlet.<br />

3. Total closure. The rubber diaphragm is pushed outward completely by<br />

the valve. The counter pressure pushes the rubber diaphragm flush<br />

against the valve, thus sealing the inlet completely.<br />

Other models<br />

Refer to the table on page 5 for the various models.