Architectural hot dip galvanizing - hdgasa

Architectural hot dip galvanizing - hdgasa

Architectural hot dip galvanizing - hdgasa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Architectural</strong> <strong>hot</strong> <strong>dip</strong> <strong>galvanizing</strong><br />

Rondebosch On Main Shopping Centre<br />

The Rondebosch On Main Shopping<br />

Centre in Main Road, Rondebosch,<br />

was an exciting challenge presented by<br />

the Developers, Acucap.<br />

The site for the proposed two level<br />

parking garage was small and it had to<br />

be architecturally appealing and<br />

enhance the aesthetics of the Centre<br />

from the river side.<br />

Furthermore, the Centre had a history<br />

of vandalism from vagrants living in<br />

and around the river. This had to be<br />

overcome.<br />

Lastly, materials had to be used that<br />

would keep maintenance to an<br />

absolute minimum.<br />

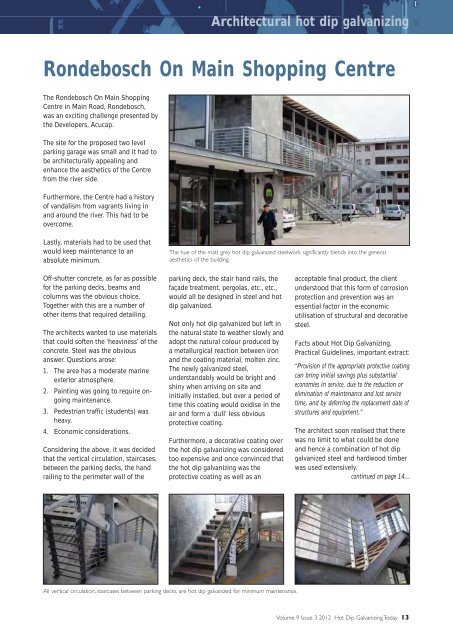

The hue of the matt grey <strong>hot</strong> <strong>dip</strong> galvanized steelwork significantly blends into the general<br />

aesthetics of the building.<br />

Off-shutter concrete, as far as possible<br />

for the parking decks, beams and<br />

columns was the obvious choice.<br />

Together with this are a number of<br />

other items that required detailing.<br />

The architects wanted to use materials<br />

that could soften the ‘heaviness’ of the<br />

concrete. Steel was the obvious<br />

answer. Questions arose:<br />

1. The area has a moderate marine<br />

exterior atmosphere.<br />

2. Painting was going to require ongoing<br />

maintenance.<br />

3. Pedestrian traffic (students) was<br />

heavy.<br />

4. Economic considerations.<br />

Considering the above, it was decided<br />

that the vertical circulation, staircases,<br />

between the parking decks, the hand<br />

railing to the perimeter wall of the<br />

parking deck, the stair hand rails, the<br />

façade treatment, pergolas, etc., etc.,<br />

would all be designed in steel and <strong>hot</strong><br />

<strong>dip</strong> galvanized.<br />

Not only <strong>hot</strong> <strong>dip</strong> galvanized but left in<br />

the natural state to weather slowly and<br />

adopt the natural colour produced by<br />

a metallurgical reaction between iron<br />

and the coating material, molten zinc.<br />

The newly galvanized steel,<br />

understandably would be bright and<br />

shiny when arriving on site and<br />

initially installed, but over a period of<br />

time this coating would oxidise in the<br />

air and form a ‘dull’ less obvious<br />

protective coating.<br />

Furthermore, a decorative coating over<br />

the <strong>hot</strong> <strong>dip</strong> <strong>galvanizing</strong> was considered<br />

too expensive and once convinced that<br />

the <strong>hot</strong> <strong>dip</strong> <strong>galvanizing</strong> was the<br />

protective coating as well as an<br />

acceptable final product, the client<br />

understood that this form of corrosion<br />

protection and prevention was an<br />

essential factor in the economic<br />

utilisation of structural and decorative<br />

steel.<br />

Facts about Hot Dip Galvanizing,<br />

Practical Guidelines, important extract:<br />

“Provision of the appropriate protective coating<br />

can bring initial savings plus substantial<br />

economies in service, due to the reduction or<br />

elimination of maintenance and lost service<br />

time, and by deferring the replacement date of<br />

structures and equipment.”<br />

The architect soon realised that there<br />

was no limit to what could be done<br />

and hence a combination of <strong>hot</strong> <strong>dip</strong><br />

galvanized steel and hardwood timber<br />

was used extensively.<br />

continued on page 14...<br />

All vertical circulation, staircases between parking decks, are <strong>hot</strong> <strong>dip</strong> galvanized for minimum maintenance.<br />

Volume 9 Issue 3 2012 Hot Dip Galvanizing Today 13