window treatments design pillows slipcovers upholstery

window treatments design pillows slipcovers upholstery

window treatments design pillows slipcovers upholstery

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.CHFmagazine.com<br />

September/October 2006

The Custom Home Furnishings Magazine September/October 2006

Contents September/October 2006<br />

Instructors’ Corner<br />

5 Advice from the Experts<br />

Cover Story…Master Bedrooms<br />

6 Master Bedrooms…Tradition Still Rules<br />

12 Sunburst Canopy<br />

15 Bedding Terminology<br />

34 Gathered Dust Ruffle: Serge & Flip Method<br />

A Sneak Peek Into a Workroom<br />

8 Mar-C's Custom Interior Decorating<br />

Industry Profile<br />

10 Glen Raven Custom Fabrics<br />

Design Ideas<br />

27 Pull-out Section of Design Ideas<br />

Down to Business<br />

38 Treatments Formerly Known as “Hard”<br />

Industry News<br />

39 News from WCAA Chapters<br />

Special Features<br />

40 Do You Need a Business Plan?<br />

41 CPR for the Designer/Workroom Relationship<br />

Extra Features<br />

42 Round Pillow with Decorative Border<br />

51 Knitting & Crocheting…Making a Comeback<br />

Business Therapy<br />

44 Will You Plant Seeds or Beg?<br />

Book Review<br />

46 The E-Myth Revisited<br />

Product Profile<br />

48 Rear Guard Tool Holder<br />

6<br />

Form of the Month<br />

49 Quote/Work Order Request<br />

Step-by-Step<br />

50 The Leading Edge Panel<br />

8 10<br />

The CHF Academy<br />

52 A Better View…Academy Success Story<br />

54 The Latest Career Professional Graduates<br />

55 The CHF Academy Schedule<br />

the custom home furnishings magazine<br />

13900-F South Lakes Drive<br />

Charlotte, NC 28273<br />

Margie Nance, Publisher<br />

Patricia Sprinkle, Editor<br />

Ross Terry, Graphics Artist<br />

SUBSCRIPTIONS<br />

800-222-1415 • 704-333-4636<br />

704-333-4639 FAX<br />

www.CHFmagazine.com<br />

$36 per year, including the CHF Forum<br />

editor@chfmagazine.com<br />

The CHF Magazine Advisory Board<br />

Jill Stanbro, Chairperson<br />

Karen Barnes • Linda Noakes • Amanda Endress<br />

Suzanne Cox-Hudson • Carlette Cormier • Judy Soccio<br />

Dean Fountain • Kelly Geraghty • Rebecca Mack<br />

Susan Kindel • Marilee Smock • Mary Ann Quinn<br />

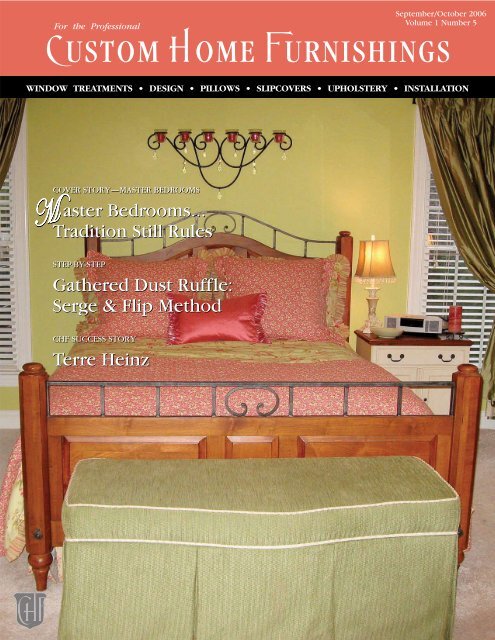

ON THE COVER…<br />

Connie Sikora created this comfortable retreat for her sister<br />

Paula Lempart-Stanfa’s Chapel Hill, NC, home. It features<br />

custom quilting by Prairie Creations. Photo by Tom Stanfa.<br />

Photo courtesy of A Room With A View.<br />

www.CHFmagazine.com<br />

September/October 2006

Associate Editor & Editor’s Journal September/October 2006<br />

from the associate editor<br />

Inspired by Color<br />

You’ll know it when you see it. This is what we<br />

tell our clients when they are searching for that<br />

“perfect” fabric, just the right paint color, or piece<br />

of furniture. The truth is that colors strike a cord<br />

within us that trigger certain feelings.<br />

Fall is my favorite season, and I am truly inspired by the changing<br />

colors of the trees. My entire house is decorated in the colors<br />

of fall. My living room and master bedroom are decorated in<br />

yellow and green. The living room is accented with rust and<br />

the bedroom has raspberry details. My kitchen is done is earth<br />

tones with chocolate brown printed fabric on the <strong>window</strong>s.<br />

I think that we tend to decorate our homes with colors that<br />

we look good in. So if you visit a retail client for the first time,<br />

take a look at her closet. Take mental notes of the overall color<br />

scheme. This will help you steer her in the right direction with<br />

her fabric and treatment selections. Our products are emotional<br />

purchases for our clients. I have learned that draperies are not<br />

“just curtains.” Our clients think of their <strong>window</strong> <strong>treatments</strong><br />

as being a reflection of themselves. If their friends don’t like<br />

them, they will feel like they have failed.<br />

Learning the emotional perspective is essential to selling <strong>window</strong><br />

<strong>treatments</strong> and soft furnishings. You need to understand<br />

that knowing how to engineer the fabrication of a treatment<br />

is half the battle. There are many other things that you need<br />

to know in order to become a successful <strong>window</strong> treatment<br />

sales person. Mary Ann Plumlee has developed a fantastic sales<br />

class at the Academy. Watch the schedule for her class in 2007.<br />

You will leave with a better understanding of how to sell to a<br />

client's emotions.<br />

You have all heard the saying, “The cobbler's children have<br />

no shoes.” You can search the forum and ask, “How many of<br />

us have <strong>window</strong> <strong>treatments</strong> in our own homes?” You will see<br />

that most of us do not. There are many reasons that this is true.<br />

The most common is that we just don’t have time since we are<br />

so busy working on everyone else’s projects. Take some time<br />

to find the colors that inspire you and then surround yourself<br />

with them. Paint your workroom, you will spend a lot of time<br />

there and you should feel happy when you are working.<br />

I hope that you enjoy this issue of the magazine! See you on<br />

the forum.<br />

Connie Sikora<br />

from the editor<br />

Welcoming the Fall<br />

Nothing can beat the days when fall first begins. I<br />

just love the pure enjoyment of the chilly nights<br />

and the breeze that blows during the cooler<br />

days. Fall starts with a time of brilliant colors<br />

and weekends that are packed with fall festivals. It is a time<br />

of renewal. A time to spend raking leaves and cooking up that<br />

first pot of hearty soup. Nature gives us this spectacular season<br />

to renew our spirits and our time outdoors.<br />

Our issue this month starts with great colors, many of them fall<br />

colors on page 6 with our Cover Story on Master Bedrooms.<br />

In keeping with the Master Bedroom theme, Leslie Fehling<br />

has a great step-by-step article on a Sunburst Canopy beginning<br />

on page 12. As always Leslie's work is awesome, and we<br />

appreciate her sending us this article. On page 15 is an article<br />

on Bedding Terminology. And then on page 34 Susan Schurz's<br />

share with you a step-by-step article on a Gathered Dust Ruffle:<br />

Serge and Flip Method.<br />

There are lots of great business articles in this issue. On page<br />

38 Mary Ann Plumlee gives us an insight to Treatments Formerly<br />

Known as Hard. You will not want to miss this article.<br />

And do you need a business plan? Of course, you do. Rebecca<br />

Mack gives you great ideas on how to accomplish this on page<br />

40. A new column this issue is Business Therapy by Suzanne<br />

Cox-Hudson. She asks an important question, “Will You Plant<br />

Seeds or Beg?"<br />

On another note, I would like to address a<br />

personal issue. This September/October issue<br />

will be my last issue as Editor of The Custom<br />

Home Furnishings Magazine. The last three<br />

years I have spent editing and working on the<br />

SewWHAT? Magazine and The CHF Magazine<br />

have been three of the most wonderful<br />

years of my life. I have met many people in this industry who<br />

will remain lifelong friends. I would like to say a special thank<br />

you to the instructors at The Custom Home Furnishings Academy<br />

and my many CHF Network Forum friends. Without each<br />

of you, I would never have succeeded the way I have with this<br />

magazine. And to my special two mentors, Cheryl Strickland<br />

and Margie Nance, thanks doesn't seem quite enough. Best<br />

wishes to each of you for continued success in your business.<br />

Patricia Sprinkle<br />

The Custom Home Furnishings Magazine September/October 2006

Instructors’ Corner<br />

Patricia Sprinkle<br />

Advice from the Experts<br />

Marketing Tactics & Most Profitable Treatments<br />

This issue’s questions for the instructors at The<br />

Custom Home Furnishings Academy were: What<br />

has been your most successful marketing tactic?<br />

and the second questions was What is your most<br />

profitable treatment and why?<br />

~ Patricia Sprinkle<br />

WHAT HAS BEEN YOUR MOST SUCCESSFUL<br />

MARKETING TACTIC?<br />

Jill Stanbro — Swags, Top Treatments, and Embellishments<br />

Instructor: Being a wholesale workroom, I<br />

have never really had to advertise. In the beginning,<br />

I contacted two <strong>design</strong>ers that I knew<br />

about. Through good work, I eventually got<br />

all of their business. From that I then hooked<br />

up with most of my other <strong>design</strong>ers through<br />

the installer. It was his endorsement that was<br />

my best advertising strategy.<br />

Connie Sikora — Sew Like a Pro Instructor: When I decided<br />

that I wanted to concentrate on working “to the trade”, I<br />

went to DesignerFinder.com and pulled a list of <strong>design</strong>ers in<br />

the Chicagoland area. I then wrote a letter of introduction to<br />

about 20 of them. I ended up meeting with four of them and<br />

worked for two for quite some time. Other than that, the best<br />

marketing devise any good workroom can have is her work.<br />

The work speaks for itself and word of mouth is the best<br />

advertising.<br />

Jeanelle Dech — Professional Slipcovers Instructor: Early on,<br />

with a home-based slipcover business, I was always looking<br />

for places to show my work. I offered to create form-fitting<br />

<strong>slipcovers</strong> for two wing chairs in the waiting room of my<br />

OB-GYN's office. Each day 20-30 women passed through. I<br />

placed a small sign on the table that said,<br />

“Believe it or not, these are <strong>slipcovers</strong>!”<br />

and left a stack of business cards. Those<br />

two chairs brought slipcover business<br />

for more than 10 years until the office<br />

closed. They brought at least one job<br />

per month, and more importantly, led to<br />

www.CHFmagazine.com<br />

several whole-house <strong>design</strong> jobs for the doctors and nurses<br />

who worked there.<br />

Susan Schurz — High-end Fabrication Methods Instructor: As<br />

a to-the-trade workroom, I have not needed to<br />

advertise. Word-of-mouth has been my most<br />

successful marketing tactic. In order to keep<br />

positive referrals you must be consistent with<br />

your business practices and the quality of your<br />

product. After that I would say networking<br />

with my local WCAA group has been very<br />

beneficial.<br />

Terri Booser — Workroom Shortcuts, Draperies, and Shades<br />

Instructor: Undoubtedly the most successful<br />

marketing tactic I have ever done is creating my<br />

marketing kit and taking it to task. Attending<br />

conferences and local meetings with this in hand<br />

to showcase my business without feeling I am<br />

“showing off” opened many doors for me.<br />

WHAT IS YOUR MOST PROFITABLE<br />

TREATMENT AND WHY?<br />

Susan Schurz — High-end Fabrication Methods Instructor: This<br />

is difficult to answer, because in a custom market every job is<br />

different. What makes a profitable treatment in my workroom<br />

is often the extras that are added, such as interlining, trims, or<br />

other custom details, and not the specific style.<br />

Jill Stanbro — Swags, Top Treatments, and Embellishments<br />

Instructor: My most profitable treatment is a cornice board, I<br />

can make them quickly and have developed a way to put the<br />

cording on them with no sewing. There is very little cutting<br />

and assembling of the fabric needed, and they nearly always<br />

go together with very little fussing.<br />

Terri Booser — Workroom Shortcuts, Draperies, and Shades<br />

Instructor: The most profitable <strong>window</strong> treatment for me would<br />

have to be anything with embellishments. Why? Because every<br />

time an embellishment is added it adds on to the bottom line. A<br />

banded valance with beaded trim and microcord — cha-ching!<br />

It easily doubles the initial labor cost.<br />

September/October 2006

Cover Story<br />

Patricia Sprinkle<br />

Master Bedrooms<br />

Tradition Still Rules<br />

The bedroom has<br />

historically been<br />

a room for letting<br />

down your guard,<br />

gaining privacy, and experiencing<br />

love and romance. It<br />

has always been a room where<br />

we often find refuge from our<br />

chaotic world. Today is no different.<br />

We all look for a place<br />

where we can find peace and<br />

calm. In the Master Bedroom<br />

we have to please no one but<br />

ourselves. It is a place for<br />

pampering and indulgence.<br />

I can't tell you how many<br />

times I have taken refuge in<br />

the bedroom to steal away a<br />

few minutes to read a good<br />

book, watch a great television<br />

program (that is not a cartoon), work on my<br />

crocheting, or work on my book I am writing<br />

in peace and quiet.<br />

In the Master Bedroom tradition is still the<br />

king because it is so timeless. Interior <strong>design</strong>ers<br />

are selling a lot of sleigh beds and other classic<br />

looks with newer finishes like mocha and<br />

espresso.. Last year I received a sleigh bed for<br />

Christmas. I think it was one of the greatest<br />

gifts I have ever received. I love the traditional<br />

look and how it just warms up the room.<br />

Sandra VanSickle of North Carolina finds that<br />

her clients love to have that “over the top”<br />

custom look in their bedrooms. “They are indulging<br />

in luscious silks, trims, lots of <strong>pillows</strong>,<br />

chandeliers, art work, and beautiful rugs,” said<br />

Sandra. “More and more clients are turning<br />

to custom bedding for their rooms. It allows<br />

them to pick their own theme and place their<br />

individual stamp on their home versus choosing<br />

a store bought set."<br />

From the home of Philippe and Mary Bee Petot in Greensboro, NC, a<br />

traditional look with the gorgeous teal and brown colors that are popular<br />

right now. All fabrics shown are Sunbrella ® decorative fabrics. Photos<br />

submitted by Glen Raven, Inc..<br />

Gillian Wendel of Pinehurst, TX, has also seen an increase in custom made<br />

<strong>window</strong> <strong>treatments</strong> and bed coverings. She has seen that pieced coverlets<br />

The Custom Home Furnishings Magazine September/October 2006

Cover Story<br />

Patricia Sprinkle<br />

have been very successful as they introduce<br />

a truly custom feel to a master suite<br />

that extends beyond the traditional duvet.<br />

Gillian used nine fabrics plus trims for the<br />

pieced coverlet shown on page 7. “The<br />

pieced coverlet made the top of the bed very<br />

interesting,” said Gillian. “In Houston it is<br />

a nice weight. While the colorful mix of this<br />

set is not for the faint of heart, my client is<br />

an artist and was thrilled with the result.<br />

And the opportunity to <strong>design</strong> with multiple<br />

fabrics has pushed me as the <strong>design</strong>er and<br />

workroom to new levels,” stated Gillian.<br />

Terri Booser of Wattsburg, PA, feels that the<br />

Master Bedroom trend is also casual simplicity.<br />

It is includes warm or neutral colors.<br />

“Window <strong>treatments</strong> trends include simple<br />

panels or valances with blinds,” says Terri.<br />

“There is definitely no fuss and no muss."<br />

What makes the Master Bedroom come alive? It would be<br />

great choices in color, fabric, pattern, and accessories. As Gillian<br />

pointed out, the artistic hand really makes a difference.<br />

Pieced coverlets have been successful as they introduce a truly traditional,<br />

custom feel to a master suite. Photo submitted by Gillian Wendel.<br />

considering all the new mattresses are so high, a ready-made<br />

comforter just isn't large enough.”<br />

Flowery, highly feminized master bedrooms are not more<br />

appealing to a man than a bedroom decorated in the colors<br />

of the man's favorite sports team is for a woman. Looks that<br />

are gender-neutral and balance the room are the tradition for<br />

This client wanted to build a coverlet around a tapestry<br />

fabric. Six fabrics were used, and in keeping with the<br />

traditions of neutral colors, monochromatic colors were<br />

used. The different textures made it a visual delight. Photo<br />

Connie Sikora of Indiana has seen that this trend is definitely<br />

true. "People are using more fabric,” said Connie. "I do fuller<br />

bedskirts, breaking on the floor, with lots of fullness. Duvet<br />

covers are big as well as custom-quilted coverlets and several<br />

different sized <strong>pillows</strong>, including Euros, King, and standard.<br />

I think that the custom bedding market is bound to grow,<br />

www.CHFmagazine.com<br />

Creating a bedroom masterpiece is what the client is<br />

looking for. Photo submitted by A Room with a View.<br />

today's master bedroom. Creating a bedroom masterpiece is<br />

all about what the client is looking for and putting that in a<br />

good style and <strong>design</strong>.<br />

September/October 2006

A Sneak Peek Into A Workroom Mar-C's Custom Interior Decorating<br />

Mar-C's Custom Interior Decorating<br />

A Family Tradition<br />

Martha DeMeo learned the art of sewing from<br />

watching her grandmother in the dressmaking<br />

business. When she marred her husband<br />

Rich in 1967, she started doing alterations<br />

and dressmaking. Through word of mouth, this expanded<br />

her business into <strong>design</strong>ing and sewing prom and wedding<br />

gowns and then <strong>window</strong> <strong>treatments</strong> and <strong>slipcovers</strong>. Martha<br />

is basically a self-taught sewer. She has never had any formal<br />

training and learned as she created projects.<br />

She has always enjoyed creating and fabricating interior<br />

decorating <strong>treatments</strong>, and that's how Mar-C's Interior<br />

Decorating started. The name Mar-C's is for Martha, Rich,<br />

and children. Both our children, Christine and Cynthia, helped<br />

in and around the workroom in their younger years. Their<br />

workroom first started in the basement of their rural upstate<br />

New York home. Nothing fancy, just a few machines and a<br />

4'x8' table. Eventually fabric and trim samples were added,<br />

and then in 1994 they relocated to N. Myrtle Beach, SC, to<br />

help care for Martha's ill mother. This is when a dramatic<br />

change took place.<br />

They opened a 1,000 sq. foot retail store and drapery workroom,<br />

basically without any knowledge of running a full-time<br />

retail business. Within two years, we ran out of space and<br />

expanded by another 1,000 sq. feet. The workroom is in<br />

the rear of the first store space, along with the play area for<br />

Martha's 3-year old granddaughter, Trinity. The front is where<br />

Mar-C's is very family oriented. Martha's daughter<br />

Cyndi works in the office.<br />

Martha and Trinity at the sewing machine.<br />

the completed orders and blinds are stored until install. They<br />

also have some in-stock fabrics and accessories in this space.<br />

The other side of the store is used for fabric samples, ADO<br />

display, trim samples, hardware samples, blinds, verticals,<br />

and wallpaper samples. There are two workroom tables in<br />

the front of this side with our photo albums of previous jobs<br />

accumulated from the past 20 years. There is not any wasted<br />

space. (They consider their workroom cluttered, but they know<br />

right where everything is!)<br />

Martha doesn't see her workroom as typical. She is very nontraditional,<br />

casual, and family oriented. Her daughter, Cyndi,<br />

works there and her three children have also been working the<br />

workroom fro the past 10 years. They include Alexandra who<br />

is 10, Zachary who is 8, and Trinity.<br />

The favorite thing in Martha's workroom would have to be<br />

her husband and her granddaughter. “Rich and I have been<br />

working together for 40 years,” said Martha. “I couldn't<br />

do it without him. Trinity is such a joy to have around.” As<br />

Martha sews, Trinity will remove the pins as they come up,<br />

and when hemming, She puts the drapery weights in the hem.<br />

(She calls that a pocket.) Trinity is learning to interact with<br />

many different people and already knows how to sell clients.<br />

As for a favorite item, it would have to be my good old Elna<br />

from the early 1980's. This machine has been used to teach<br />

their children and grandchildren to sew, along with making<br />

many <strong>window</strong> <strong>treatments</strong> in the past. The main purpose for<br />

the Elna now is for tacking drapery pleats. It's small and<br />

portable and can be put in just about anywhere for tacking<br />

and other small jobs.<br />

The Custom Home Furnishings Magazine September/October 2006

A Sneak Peek Into A Workroom<br />

Mar-C's Interior Decorating<br />

As you enter Martha's workroom, the 5'x12' table is to the<br />

right. Brackets for the lining are attached at one end of the<br />

table, the other end has two narrow shelves for storage. Under<br />

the table, there are two shelves that store the fabric they<br />

are working on. There is walking room around the table with<br />

long shelves for storage against the wall. In the back of the<br />

workroom are the machines and more supplies. They have an<br />

old Singer industrial, a Tacsew blindhemmer, a Johnson ruffler,<br />

the Elna, and a few sergers.<br />

Rich at the cutting table.<br />

Martha would like to advise anyone who is interested in starting<br />

a workroom to "jump in and get started.” "If someone asks<br />

you to do a treatment that you haven't yet mastered, go ahead<br />

View of sewing machines.<br />

They have a shelf area behind the machines for storing thread.<br />

Rich built a shelf about 3' down from the ceiling, and this is<br />

where the extra pillow forms are stored. To the left of this is<br />

another shelf for the drapery tapes, Velcro, and buckram. More<br />

hardware is stored on the left side of this space along with the<br />

copier and packing supplies. This is also space for Trinity, which<br />

includes her lunch table, television and nap space.<br />

Although Martha admits that she is not the most organized<br />

person, she definitely knows that she has organized chaos in<br />

the workroom. “We custom make some of the best and most<br />

talked about <strong>treatments</strong> on the beach,” says Martha.<br />

www.CHFmagazine.com<br />

Front display <strong>window</strong>.<br />

Fabric sample books with trim storage on top of the racks.<br />

and try it. If you say you can't do it before you try, you will<br />

never know if<br />

you could have<br />

done it,” said<br />

Martha. “That<br />

has been my<br />

thinking from<br />

the beginning.<br />

If you want to<br />

explore deeper The in-stock fabric storage area.<br />

o c e a n s , y o u<br />

have to first leave sight of the shore. There is nothing that you<br />

can't do if you don't try!”<br />

September/October 2006

Industry Profile<br />

Glen Raven, Inc.<br />

Glen Raven Custom Fabrics<br />

Delivers Good Looks and High Performance with Sunbrella ® Fabrics<br />

Forget what you thought you knew about Sunbrella®; it’s not just<br />

for outdoor decorating anymore. Now available through decorative<br />

jobbers, such as Silver State, Donghia and B. Berger, Sunbrella<br />

Furniture Fabrics feature beautiful color and <strong>design</strong> along with<br />

legendary durability.<br />

Sunbrella offers luxurious textures, jacquards and velvets in a full range of<br />

colors perfect for inside and outside the home. Your clients can rest assured<br />

that virtually any stain can be removed, and Sunbrella will withstand the<br />

rigors of active lifestyles. With the addition of Sunbrella Sheers, Glen Raven<br />

now offers a complete range of looks for your <strong>window</strong> treatment needs, and<br />

you can rest assured that they will not fade, shred, or degrade when exposed<br />

to harsh sunlight.<br />

High Performance Sunbrella ® fabrics shown in <strong>upholstery</strong> and <strong>window</strong> applications in Glen Raven's High<br />

Point showroom. Fabrication and installation by Beth Hodges, Soft Furnishings, Elberton, GA.<br />

10 The Custom Home Furnishings Magazine September/October 2006

Industry Profile<br />

Glen Raven ,Inc.<br />

Sunbrella residential fabrics<br />

offer the same performance<br />

as their outdoor counterparts,<br />

making them ideal<br />

for your clients with children,<br />

pets, bay <strong>window</strong>s or<br />

busy entertainment schedules.<br />

Most stains clean up<br />

with mild soapy water, but<br />

all Sunbrella fabrics are<br />

bleach cleanable.<br />

Sunbrella fabrics debuted in<br />

the early 1960s as an alternative<br />

to the most popular<br />

awning fabric at that time,<br />

cotton. Sunbrella offered<br />

the same rich look of cotton,<br />

but did not fade or<br />

degrade, even in the brightest<br />

sun, and offered years of<br />

care free service.<br />

Boaters soon discovered the<br />

good looks and durability of<br />

Sunbrella fabrics for boat tops<br />

and sail covers. Around the<br />

world today, Sunbrella is the No. 1 fabric choice for power<br />

boaters and sailors, enjoying universal name recognition, synonymous<br />

with quality and durability.<br />

Luxurious Sunbrella Velvet with all of the same performance properties that you've<br />

come to expect from Sunbrella Performance Fabrics. Available in: Terracotta, Vellum,<br />

Cocoa, Wheat, Plum, Antique Beige, Deep Sea. Not pictured: Bay Brown and Herbal.<br />

While Sunbrella was gaining recognition in the great outdoors,<br />

Glen Raven was preparing Sunbrella to come inside the home.<br />

Thanks to intricate jacquard weaving, innovative yarn constructions<br />

and advanced fabric finishes, the <strong>design</strong> and manufacturing<br />

teams at Glen Raven created Sunbrella fabrics that match<br />

the look and feel of fine interior fabrics.<br />

You will also find Sunbrella on the nation’s roadways. Sunbrella<br />

is the leading choice for convertible car tops and is increasingly<br />

popular for recreational vehicles. Fade resistance, durability and<br />

popular colors have made Sunbrella a leader in these market<br />

Glen Raven Custom Fabrics, the makers of Sunbrella fabrics,<br />

next took this winning formula – high-performance fabrics<br />

with the look and feel of cotton – to the outdoor furniture<br />

industry. Market umbrellas and furniture cushions made with<br />

Sunbrella fabrics are fast drying, durable, easy to clean and<br />

beautiful. Over the years, all of the nation’s leading casual<br />

furniture manufacturers have adopted Sunbrella for their premium<br />

furniture lines.<br />

International <strong>design</strong> authorities Joe Ruggiero and Richard<br />

Frinier, along with Sunbrella’s own <strong>design</strong> team, have pushed<br />

the envelope on performance fabrics. Today you will find Sunbrella<br />

throughout the home, from decks, patios and poolside,<br />

to dining rooms, family rooms, bedrooms and even kitchen and<br />

bath. Sunbrella delivers a complete package of enduring color,<br />

exquisite <strong>design</strong>, sumptuous hand and ease of cleaning.<br />

Design and performance innovation continues for Sunbrella<br />

fabrics, focused on providing texture, color and luxury to<br />

interior and exterior spaces, along with legendary durability.<br />

Wherever people demand fabrics that are beautiful, comfortable<br />

and dependable, Sunbrella will be there with fashion right<br />

colors, <strong>design</strong>s, and textures.<br />

Visit www.sunbrella.com, or view Silver State’s extensive<br />

Sunbrella line at www.silverstatetextiles.com.<br />

www.CHFmagazine.com September/October 2006 11

Master Bedrooms<br />

Leslie Fehling<br />

Sunburst Canopy<br />

Makes a Dramatic Statement<br />

A<br />

Sunburst Canopy makes a dramatic<br />

statement in a bedroom,<br />

enhancing and complementing<br />

the drapery <strong>treatments</strong> on a<br />

canopy bed. They are a bit of a challenge<br />

to make, and I recommend working with a<br />

helper to make the whole process go more<br />

smoothly. Your efforts will be rewarded<br />

with an impressive and beautiful finished<br />

product that your customer will love.<br />

CONSTRUCTING THE FRAME<br />

Begin by measure the bed canopy and determine<br />

how the finished sunburst will be<br />

installed. Sometimes it is possible to simply lay<br />

the completed piece on top of the bed frame.<br />

In some cases, however, it is necessary to drop<br />

the sunburst into the canopy opening and support it with 4'<br />

steel mending plates screwed into the sunburst canopy frame,<br />

extending out onto the bed frame and attaching with screws.<br />

For some beds, it is necessary to make cutouts on the corners of<br />

the canopy frame for the bedposts. Measure door openings in<br />

The finished<br />

canopy.<br />

your workroom and at the customer's home to ensure that the<br />

canopy frame will fit through the doors on installation day.<br />

Illustration 1<br />

Illustration 2<br />

12 The Custom Home Furnishings Magazine September/October 2006

Master Bedrooms<br />

Leslie Fehling<br />

Construct a frame of 1"x2" boards as shown in<br />

illustration 1. Use a 1"x10" across the middle with a 5" hole<br />

cut in the center. A test fit on the bed might be a good idea<br />

at this point to prevent any surprises later on. On the canopy<br />

frame, mark the head and foot of the bed, since the bed frame<br />

may not always be perfectly square.<br />

Paint the frame or staple on a layer of polyester batting to<br />

prevent staining from the wood and to give the edges a softer<br />

look shown in illustration 2. Be sure you can still see your head<br />

and foot marks. When constructing the frame, be sure to allow<br />

for the thickness of the batting and the fabric that will be<br />

wrapped around it.<br />

FIGURING YARDAGE<br />

Measure from a corner of the frame<br />

to the center of the 5" hole (as<br />

shown in illustration 1 as A.)<br />

Option 1: If (A + 5") is less than or<br />

equal to the width of your fabric,<br />

then the selvage will be positioned<br />

around the outside edge of the<br />

frame. Allow for 2 to 3 times fullness.<br />

Measure around the outside edge of the frame, multiply<br />

by fullness, and divide by 36 to obtain the yardage amount<br />

needed.<br />

Gather one long edge of the fabric to the correct fullness. Divide<br />

into eight equal sections.<br />

ATTACHING THE FABRIC TO THE FRAME<br />

To divide the circumference of the frame into 8 equal sections,<br />

mark the center of each side, then measure the distance between<br />

marks and place marks halfway between (not on the corners<br />

of the frame.) See illustration 1 on page 12.<br />

Lay the frame on a worktable, top side up, and fasten fabric<br />

in place with large push pins at ¹⁄₈" marks. Place the fabric<br />

about 1-1½" in from the edge. Distribute fullness evenly. See<br />

illustration 3.<br />

Illustration 3<br />

Staple the gathered fabric all around the edges of the frame as<br />

shown in illustration 4.<br />

Option 2: If (A + 5") is greater than the width of your fabric,<br />

you must cut the fabric into lengths of at least (A + 5".) To<br />

figure yardage, measure around the outside edge of the frame,<br />

multiply by fullness, and divide by your fabric width to determine<br />

how many cuts are needed. Multiply the number of cuts<br />

by (A + 5") to get the total length required. Divide by 36 to<br />

convert inches to yards.<br />

PREPARING THE FABRIC<br />

For Option 1: Join the two short ends of the length of the fabric,<br />

right sides together, to form a continuous loop.<br />

Illustration 4<br />

For Option 2: Join cut lengths together, right sides together, to<br />

form a continuous loop.<br />

To reduce bulk in the center of the sunburst, you may choose<br />

to make darts in the fabric. Stitch darts approximately 20"<br />

long, starting at 3" wide and tapering down to 0. If you used<br />

Option 2, place some of the darts on the seams. Take plenty of<br />

darts. It will greatly simplify your work later on, and the dart<br />

seams will not show when the sunburst is finished. They will<br />

be folded into the pleats.<br />

(continued on page 14)<br />

www.CHFmagazine.com September/October 2006 13

Master Bedrooms<br />

Leslie Fehling<br />

Sunburst Canopy (continued from page 13)<br />

GATHERING THE FABRIC INTO THE CENTER<br />

First, divide the fullness by firmly pulling the fabric in from<br />

each corner and stapling just outside the center circle. Then<br />

pull the fabric from each corner and staple. Use ¼" or ³⁄₈"<br />

staples in the beginning, and as in the thickness of the gathers<br />

increases, change to ½" or ⁵⁄₈".<br />

to have only about 6" fullness in each one, take each 6" section<br />

and fold in three or 4 pleats. Put in the final staples. It<br />

works best to do every other section at this point, then do the<br />

final ones. Radiate staples out from the center, like a sunburst,<br />

perpendicular to the circle. See illustration 5.<br />

When you have finished stapling the front, staple down the<br />

fabric on the back side and trim off the excess. See illustration 6.<br />

Check all the pleats on the front and rearrange any that may<br />

need to be tidied up.<br />

MAKING THE ROSETTE<br />

Cut strips 5" wide. Join together, fold in half, and serge the<br />

long edge. Gather 2½xfull. Cut two 6½" circles of buckram<br />

and baste together. Mark concentric circles 1" apart. Sew or hot<br />

glue four circles of ruffles over the marked lines. Attach a 1⁷⁄₈"<br />

covered button in the center by looping tufting twine through<br />

the button shank, then pulling the twin through to the back<br />

side of the buckram and typing it securely. See illustration 7.<br />

Staple the rosette to the 1"x10", hiding the staples under the<br />

ruffles. Make sure it is perfectly centered.<br />

Illustration 5<br />

Now work on one of these sections at a time. Divide each<br />

section in half and staple once at the half point. Then divide<br />

each one of those sections in half. Keep dividing into smaller<br />

and smaller sections. When sections have been broken down<br />

Illustration 7<br />

Illustration 6<br />

FINISHING<br />

Staple blackout lining on the top side of the canopy frame about<br />

½" from the edge. Trim off the excess lining then cover the<br />

14 The Custom Home Furnishings Magazine September/October 2006

Master Bedrooms<br />

Leslie Fehling<br />

staples and the edge of the lining with gimp trim. The finished<br />

sunburst canopy is ready to be installed. See illustration 8.<br />

Illustration 8<br />

Bedding Terminology<br />

There are many choices when it comes to making the bedding<br />

<strong>treatments</strong> for the best bedroom space available. Being able to<br />

explain the differences to your clients is important. We'll take<br />

a look at some of the terms used.<br />

Bedsack: The cover is made to cover the mattress, just like a<br />

fitted sheet. All four corners are stitched down with approximately<br />

4" allowed to go under the mattress. There is elastic<br />

at the corners.<br />

Bedspread: A treatment that entirely covers the bed, hanging<br />

down over the sides to the floor.<br />

Box Pleat: A pleat that is formed on the front side of the fabric<br />

and is flat rather than folded and tacked like pleated drapes.<br />

Canopy: A fabric treatment that is installed above the bed.<br />

Comforter: A reversible throw style that covers the top of the<br />

bed to the headboard and approximately 2" below the mattress<br />

on the sides and the foot.<br />

Corona: A canopy hung from a crown or ring attached either<br />

to a ceiling or to the wall at the head of the bed.<br />

Coverlet: A bed treatment, like a bedspread, but with a shorter<br />

drop (usually to expose a dust ruffle.)<br />

The canopy shown in this article was part of an elaborate bed<br />

ensemble in a historic Victorian home. Contrast-lined swags<br />

and self-lined jabots were Velcro-mounted inside the bed<br />

canopy, and contrast-lined puddled panels were hung from<br />

screw eyes installed in the bottom of the sunburst canopy<br />

frame. Large double-tassel tiebacks and a gathered bedskirt,<br />

along with a purchased comforter and <strong>pillows</strong> completed the<br />

luxurious look of this master bedroom.<br />

Leslie Fehling is the owner of Leslie Fehling<br />

Designs, a home-based workroom in<br />

Prosperity, PA, serving both retail customers<br />

and <strong>design</strong>ers. Leslie holds a BA in art<br />

and has been sewing for most of her life.<br />

In addition to <strong>window</strong> <strong>treatments</strong>, her<br />

business offers custom <strong>slipcovers</strong>, <strong>pillows</strong>,<br />

bedding, and ottomans. She enjoys<br />

using her background in art and quilting<br />

to bring a unique touch to the soft furnishings she creates<br />

for her customers. Leslie is a frequent contributor to The<br />

Custom Home Furnishings Magazine.<br />

Drop: The length from the top of a bed treatment to the floor,<br />

or toward the floor if not floor length.<br />

Dust Ruffle or Bed Skirt: A bed treatment that lies between the<br />

mattress and the box springs and hangs down to the floor.<br />

Duvet: A pillowcase type cover for a comforter with a closure<br />

that is usually a zipper or buttons, but the closure can be other<br />

styles.<br />

Gusset: A flap of fabric that hangs down from the bottom<br />

corner of a bed treatment which as a split corner. It is used to<br />

keep the mattress of box springs from showing.<br />

Pillowcase: A sewing technique used to hide seams by sewing<br />

them with the right sides of the fabric together and then turning<br />

the fabric inside out.<br />

Pillow Sham: A decorative pillow cover that is usually ruffled<br />

or flanged. Shams are used as extra <strong>pillows</strong> on beds to hide<br />

the bed <strong>pillows</strong>.<br />

Reverse Sham: A separate flap of fabric sewn to the top of a<br />

bedspread that folds over the top of the <strong>pillows</strong>, instead of tucking<br />

under the front of the <strong>pillows</strong> like a typical pillow turn.<br />

Tester: The frame above a four-poser bed.<br />

www.CHFmagazine.com September/October 2006 15

16 The Custom Home Furnishings Magazine September/October 2006

CHF Tips & Tricks<br />

Slipcover Solution<br />

By Jeanelle Dech<br />

I like to refer to nightmare jobs as lessons learned. The one I<br />

remember most occurred nearly 12 years ago. Up until that<br />

point I had been doing C.O.M. <strong>slipcovers</strong> out of my home.<br />

This particular job consisted of form-fitting <strong>slipcovers</strong> for<br />

a 3-piece sectional sofa and 45 yards of heavy tapestry. It<br />

was my first significant fabric purchase and was to be the<br />

most profitable slipcover job to date.<br />

We picked up the pieces to begin work — a one-armed<br />

three-seater, a one-armed two seater, a corner piece, and 12<br />

cushions. The cushions came together effortlessly. I was on<br />

a roll. I pin fit the three pieces quickly (using the reverse-pin<br />

technique) and stitched it all in record time. As I went to put<br />

the covers on right side out to admire my work....DUH!! The<br />

three-seater’s arm was on the wrong side! The two-seater’s<br />

arm was on the wrong side! And, even the corner piece did<br />

not fit as it was not symmetrical.<br />

Frantically, I ripped and re-pinned and began stitching again.<br />

With alterations I was able to reuse the three-seater cover<br />

for the two-seater, but it was clear that to complete this job<br />

I would need to order another 14 yards of fabric. That’s not<br />

so bad. Except that when the fabric arrived two weeks later,<br />

the dye lot was off. When I called to replace the 14 yards,<br />

the fabric had been discontinued. The mill had a 30 yard<br />

piece left that matched the 14 yards but nothing that came<br />

close to the initial order.<br />

Well beyond the expected completion date, I used the new<br />

yardage to redo the entire set, including the cushions. So<br />

much for the profit on the fabric and so much for my speedy<br />

work. When all was complete, I think I made less than $.50<br />

per hour.<br />

www.CHFmagazine.com September/October 2006 17

18 The Custom Home Furnishings Magazine September/October 2006

CHF Tips & Tricks<br />

What Ladder and Saw to Buy?<br />

Paree Gregg was looking for a few installation supplies<br />

for her husband and asked for advice on The CHF<br />

Network Forum. She was looking particularly for<br />

a ladder and a good saw. These were suggestions<br />

from two of The CHF Academy Instructors:<br />

Beth Hodges: The best saw to have is a chop saw<br />

that you can plug in somewhere to cut 2" poles. It<br />

cuts perfectly straight. Other than that, we use a<br />

hack saw. Any saw will do. I think it is a personal<br />

preference. Don't bother with those 5" mini saws.<br />

It doesn't reach through the 2" pole.<br />

As for ladders, I highly recommend the Little<br />

Giant. Personally, I have the 22' model, and it is<br />

a perfect installation tool. It folds small enough<br />

to fit in the back of the van. It is not a good idea<br />

to store installation ladders on top of the car or<br />

outside. When the Little Giant is unfolded end to<br />

end, I can reach a second story <strong>window</strong>. I couldn't<br />

install without, but it is heavy for me to carry,<br />

so I keep a 4' ladder in the truck too. I use it for<br />

regular installs.<br />

Mary Ann Plumlee: You can get a mitre box. It is<br />

a rather low tech guide to cut straight across and<br />

angles. It usually comes with a hand saw. It is a<br />

box that your work lays in with slits across that<br />

guide your saw.<br />

www.CHFmagazine.com September/October 2006 19

20 The Custom Home Furnishings Magazine September/October 2006

CHF Tips & Tricks<br />

3 yards per WOM for Panels (up to 90-95)<br />

1.5 yards per Swag<br />

Common Yardages<br />

1.5 yards for Bias = 2" yields 35 yards<br />

3" yields 27 yards<br />

4: yields 17 yards<br />

1.5 yards per tailored pillow sham (Standard/<br />

Queen)<br />

6 yards per comforter/duvet top*<br />

5 yards per tailored skirt (Full/King)<br />

6 yards per tableskirt (up to 107" round)<br />

5 yards per standard shower curtain<br />

*No repeats are considered here.<br />

The CHF Magazine<br />

How To Advertise<br />

The Custom Home Furnishings Magazine is celebrating 14<br />

years as the leading source of inspiration and information<br />

for people in the custom home furnishings industry. Six<br />

times a year workroom enthusiasts, decorators, <strong>design</strong>ers,<br />

installers, slipcoverers, and upholsterers look forward to<br />

a new issue. Each issue is filled with creative <strong>design</strong> ideas,<br />

technical step-by-steps, tricks and tips, extra features, special<br />

features, business articles, product profiles, and much more.<br />

All articles are written by practicing industry experts, as well<br />

as regular contributions by the CHF Academy instructors.<br />

Our 2007 Themes will include: Fabrics/Textiles, Hardware,<br />

Trims, What's New in the Industry, Workroom Equipment,<br />

and Preparing for the Holidays.<br />

If you would like to advertise in the 2007 Custom Home<br />

Furnishings Magazine, call 800-222-1415 (704-333-4636)<br />

for a Media Kit. We will be happy to help you with your<br />

advertising needs.<br />

www.CHFmagazine.com September/October 2006 21

22 The Custom Home Furnishings Magazine September/October 2006

CHF Tips & Tricks…Elements of Style<br />

Tips From Lisabeth Martin at Decorate Now<br />

Just like the exterior of the home, the interior needs a theme<br />

or style. Yet too much of a good thing can be, well, too much.<br />

This section deals with tips on how to make your home your<br />

own using some basic <strong>design</strong> tips.<br />

Get out your favorite magazines and every time you find a<br />

photo that you are drawn to, pull the page out and draw an<br />

arrow to the item that caught your eye. Organize your pages<br />

by room type (kitchens, baths, living spaces, bedrooms, dining<br />

rooms), then go through the pages again. You will see a<br />

pattern begin to emerge as to what elements you are drawn<br />

to. Perhaps it is the center island in the kitchen with the hanging<br />

pot rack? Or the soft tone on tone look of neutrals used<br />

luxuriously in the living room? Or perhaps you are drawn to<br />

dramatic colors and rooms where there are elements of high<br />

contrast? Whatever your style is, taking the time to define it<br />

will help you in your quest to decorate your home.<br />

Modern style isn’t just a room full of spare, clean lines<br />

anymore. Designers delight in unexpectedly mixing up old<br />

and new, straight lines with curvaceous, simple with ornate.<br />

Traditional style no longer means that all the furniture must<br />

come from the same collection. Yet good style does follow<br />

some basic rules:<br />

Rule 1: Too many straight lines need some curves as counterpoint.<br />

In decorating a log home, for example, the horizontal<br />

lines are so prominent throughout the home that <strong>window</strong><br />

<strong>treatments</strong> will benefit from not being quite so geometric. The<br />

hard lines of the log walls need some softness elsewhere in<br />

the room. The counterpoint of softness against the hard lines<br />

makes each element that much more appealing. A luxurious<br />

sofa or a grouping of overstuffed <strong>pillows</strong> may be all that is<br />

needed to make the room more appealing.<br />

Rule 2: Objects in a group have more impact than those<br />

same objects spread around the room. Just as a collection<br />

of candlesticks looks more dramatic when they are grouped<br />

on one table, thus also furniture needs to be in groups. Pull<br />

furniture and chairs into seating groups, allowing enough<br />

walking room between the furniture. Don’t make the mistake<br />

of having the seating arrangement be so spread out that your<br />

guests can’t converse comfortably.<br />

Rule 3: Find the focal point for your room, and emphasize<br />

that. Unless your living room is the size of a hotel lobby, every<br />

room needs one spot that your eye is drawn towards. When<br />

a room has several focal points, the focal points compete<br />

with each other, and the room loses its visual impact and<br />

begins to look disorganized. A fireplace mantle is a natural<br />

focal point. Other focal points can be a large armoire or<br />

entertainment center. Arrange one furniture grouping facing<br />

this focal point. Add art and art objects to add additional<br />

texture and interest to your focal point. Look for more rules<br />

in another issue.<br />

CHF Tips & Tricks<br />

Math Chart<br />

If you use a calculator to do your math problems,<br />

you may find this chart to be helpful. The<br />

fractions go in ascending order.<br />

¹⁄₁₆ = .0625<br />

¹⁄₈ = .125<br />

³⁄₁₆ = .1875<br />

¼ = .25<br />

⁵⁄₁₆ = .3125<br />

³⁄₈ = .375<br />

⁷⁄₁₆ = .4375<br />

½ = .5<br />

⁹⁄₁₆ = .5625<br />

⁵⁄₈ = .625<br />

¹¹⁄₁₆ = .6875<br />

¾ = .75<br />

¹C⁄₁₆ = .8125<br />

⁷⁄₈ = .875<br />

¹⁵⁄₁₆ = .937<br />

The CHF Magazine will begin accepting<br />

classified ads for the 2007 January/February<br />

issue. If you would like to submit an ad, call<br />

800-222-1415 (704-333-4636.<br />

www.CHFmagazine.com September/October 2006 23

CHF Tips & Tricks<br />

Fraction Chart<br />

4.5 inches = ¹⁄₈ yard = .125<br />

9 inches = ¼ yard = .25<br />

12 inches = ¹⁄₃ yard = .333<br />

13.5 inches = ³⁄₈ yard = 3.75<br />

18 inches = ½ yard = .5<br />

22.5 inches = ⁵⁄₈ yard = .625<br />

24 inches = ²⁄₃ yard = .666<br />

27 inches = ½ yard = .75<br />

31.5 inches = ⁷⁄₈ yard = .875<br />

24 The Custom Home Furnishings Magazine September/October 2006

CHF Tips & Tricks<br />

How To Group Accessories and Pictures<br />

Tips From Lisabeth Martin at Decorate Now<br />

For wall displays: Place the heaviest objects at the bottom.<br />

The picture grouping or art grouping should have a rectangular,<br />

triangular, or circular rough shape. Rectangular and<br />

triangular grouping shapes are easier to pull off. Don’t space<br />

the pictures or art too far apart; keep objects close enough<br />

to be visually associated together. This is especially true if<br />

the objects are dissimilar. Vary the sizes, shapes, colors, and<br />

textures used in the group. Keep the center of your grouping<br />

at eye level, except when the display is placed over a sitting<br />

area. In these cases, you can place the group lower on the<br />

wall so that it can be seen better when people are seated. If<br />

pictures or artworks are to be lined up horizontally, then odd<br />

numbers work better than even numbers. 3 paintings hung<br />

at the same height on the wall looks better than just 2 or 4.<br />

Several smaller frames can be substituted for one larger frame,<br />

if they are grouped closely together. Thus, the traditional<br />

large painting behind the sofa can be replaced by a group<br />

of coordinated smaller framed art, as long as the grouping<br />

takes up the same visual space.<br />

For table top displays: Have one item dominate your display,<br />

making sure that the items are appropriately scaled for the<br />

table surface. Avoid items that are so small that they might<br />

get lost in the grouping. Also avoid items that are too large<br />

for the display surface. Odd numbers work better than even<br />

numbers, so 3 or 5 objects work better than 4. Place objects<br />

close enough together so that they look like a distinct grouping.<br />

For example, 3 candles look better grouped together<br />

on one end of a coffee table instead of spread out. Vary the<br />

height of the items. Try raising the height of lamps or vases or<br />

small sculpture by stacking nicely bound books underneath<br />

several of your items.<br />

www.CHFmagazine.com September/October 2006 25

26 The Custom Home Furnishings Magazine September/October 2006

Design Ideas September/October 2006<br />

www.CHFmagazine.com September/October 2006 27

Design Ideas September/October 2006<br />

28 The Custom Home Furnishings Magazine September/October 2006

Design Ideas September/October 2006<br />

From the book<br />

“Sketches for Home Decor”<br />

By Susan Schurz<br />

www.CHFmagazine.com September/October 2006 29

Design Ideas September/October 2006<br />

30 The Custom Home Furnishings Magazine September/October 2006

www.CHFmagazine.com September/October 2006 31

"I think I like it. Can you make one up so I can<br />

see if I really like it or not?"<br />

(From "The Adventures of Curtainlady" by Mary Ann Plumlee)<br />

32 The Custom Home Furnishings Magazine September/October 2006

SUNSHINE FOAM RUBBER COMPANY<br />

~ We Make Furniture More Comfortable ~<br />

CUSTOM CUT FOAM RUBBER!<br />

Send Sunshine your measurements or pattern and we will cut it to that shape in ONE week!<br />

We can fabricate odd shaped <strong>window</strong> seats, dining & kitchen chairs, Feather & Down cushions or <strong>pillows</strong>,<br />

chair & sofa cushions, etc. Your project is our passion!<br />

Sunshine Foam supplies Drapery &<br />

Upholstery Products, such as: Pins,<br />

Batting, Staple Guns, Décor Nails,<br />

Cornice Lining, Tools, Fabrics,<br />

Shirring Tape, Thread, Zipper, Etc.<br />

Call for a FREE Catalog.<br />

Modern & Classical Fabrics,<br />

Faux Leather & Suede,<br />

Leather, Contract Tweed,<br />

Vinyl, and Outdoor Fabrics<br />

are available.<br />

Call for FREE Samples!<br />

1-800-688-7648<br />

Local (513) 681-7300 * Fax (513) 681-5192 * sunshinefoam.com * 4900 Spring Grove Ave. Unit 2. Cincinnati, OH 45232<br />

CHF Tips & Tricks… Types of Foam Rubber<br />

From Sunshine Foam Rubber Company<br />

Pincore Latex - Pincore latex rubber is the most luxurious<br />

foam you can buy. Pincore maintains its firmness and creamy<br />

feel with no sagging and no break down.<br />

High Resilient (H.R.) - Fire retardant, high quality foam.<br />

Frequently used furniture needs this type of foam. Available<br />

in soft, medium, firm, and extra firm densities.<br />

Premium Sunlux - Fire retardant, high quality foam. Excellent<br />

for seat cushions. Available in medium and firm densities. 10<br />

year guarantee.<br />

Prime - Middle grade and most commonly used foam. Available<br />

in soft, medium and firm densities.<br />

Poly - Slightly lower grade than Prime. This foam is best<br />

used for furniture that is seldom used. Available in soft and<br />

medium densities. Super Soft, Poly Rolls, Mattress Topper,<br />

and Bolsters.<br />

Mattress Topper - Can be ordered in almost any type of foam<br />

- soft to firm density in twin to king size.<br />

Church Seating - Church seating foam is High Resilient or<br />

Prime Foam especially for use in church pews. Available in<br />

firm density. Sizing is available.<br />

Automotive - Automotive sew foam is used in automotive door<br />

panels, as well as, arms and backs of furniture. Available with<br />

scrim and Velcro loop backing.<br />

Shredded - Small shreds of foam used for stuffing <strong>pillows</strong> or<br />

back cushions.<br />

Rebond - Extra firm 8 lb. Rebond is very dense polyethylene<br />

foam, mainly used for exercise benches, mats, bus seats,<br />

church seating, etc.<br />

Outdoor - Dri-Fast Outdoor foam is open cell and will not<br />

retain water. Ultimate for boat cushions and lawn-patio<br />

furniture.<br />

Memory-NRG - Energy absorbing and temperature resistance<br />

foam. Used in the Health Care Industry as well as mattress<br />

toppers. Available in soft, medium and firm densities. Custom<br />

order to your size.<br />

www.CHFmagazine.com September/October 2006 33

Step-by-Step<br />

Susan Schurz<br />

Gathered Dust Ruffle Fabrication…<br />

Serge and Flip Method<br />

With this style<br />

of dust ruffle,<br />

the skirt<br />

is attached<br />

to a platform, which will be<br />

installed between the mattress<br />

and box springs. You must<br />

serge the edges for a professional<br />

finish.<br />

HELPFUL TERMS:<br />

Drop: The distance measured<br />

from the top of the box springs<br />

to the floor.<br />

Facing: Strips of material<br />

along the edge to prevent lining<br />

from showing.<br />

Foot: The end of the bed.<br />

Gusset: A Finished piece of<br />

material inserted behind edges where side and foot sections<br />

meet.<br />

Platform: A base of lining to which the skirt is attached. Also<br />

called a deck or a foundation.<br />

Sides: The left and right edges of the bed.<br />

Tabling Allowance: Extra material added to cuts to accommodate<br />

take up or errors.<br />

INSTRUCTIONS:<br />

A. CUTTING:<br />

Lining:<br />

Face Fabric:<br />

.<br />

2.<br />

.<br />

Cut face fabric, allowing for a finished drop plus a 4"<br />

allowance for the hem and a 2" tabling allowance. Solid<br />

colors or non-directional prints can be railroaded. Allow<br />

2½ times fullness. Seam together widths. Note: If a split<br />

and gusset are needed for the foot board, seam together<br />

the sides and foot pieces separately. If no split and gusset<br />

are needed, seam all widths together.<br />

Cut enough 8" strips of fabric to make a facing along the<br />

sides and the foot of the platform. Seam together.<br />

Cut strips for enough welt cord to go around the sides<br />

and the platform.<br />

.<br />

2.<br />

Cut lining for the platform, allowing 6" for the hem and<br />

2" for the tabling allowance. A single width can be used<br />

for twin beds, or seam together two widths for larger beds.<br />

Wide lining or a flat sheet can be used with no seams. Cut<br />

the platform to size, allowing for ½" seam allowance along<br />

the sides and the bottom edges Round off corners at the<br />

foot to fit the box springs.<br />

Cut lining for the drop finished length plus 2" tabling<br />

allowance. Railroad lining if possible. Allow 2½ times<br />

fullness.<br />

B. FABRICATION:<br />

Platform:<br />

.<br />

2.<br />

.<br />

Press in a 3" double hem along the top edge of the platform.<br />

Take strips for facing which have been seam together and<br />

press under a ½" along one side.<br />

Glue baste facing along the edge of the platform. See<br />

illustration #1. Miter facing at corners. See illustration<br />

34 The Custom Home Furnishings Magazine September/October 2006

Step-by-Step<br />

Susan Schurz<br />

#2. Trim away excess fabric under the mitered area.<br />

See illustration #3. Continue around all three sides. See<br />

illustration #4.<br />

Illustration 4<br />

Illustration 1<br />

4.<br />

5.<br />

6.<br />

7.<br />

Top stitch the inside edge of the facing and the hem in<br />

the lining.<br />

Serge outer edges of facing.<br />

Serge outer edges of facing.<br />

Make welt cord and serge the edges. Sew welt cord along<br />

the edge of the facing on the platform. See illustration #5.<br />

(Note: If not welt cord is desired, omit this step.)<br />

Illustration 2<br />

Illustration 5<br />

Drops:<br />

Illustration 3<br />

.<br />

2.<br />

.<br />

Sew together the lining and the face fabric with face of<br />

fabrics together 2" up from the bottom edge. Sew with<br />

the lining on top.<br />

Press 2" seam towards the face fabric. See illustration<br />

#6.<br />

Turn the lining and the face fabric right sides out and press<br />

in 2" hem. See illustration #7.<br />

(continued on page 36)<br />

www.CHFmagazine.com September/October 2006 35

Step-by-Step<br />

Susan Schurz<br />

Gathered Dust Ruffle Fabrication (continued)<br />

Illustration 6<br />

Illustration 8<br />

Illustration 7<br />

Illustration 9<br />

4.<br />

5.<br />

6.<br />

Fold in 1½" double side hem on ends. See illustration #8.<br />

Measure and mark the finished drop from the bottom<br />

edge plus ¾" for seam allowance and take up. Staple, pin,<br />

or glue-baste the top edges together and serge off excess<br />

fabric on the line.<br />

Finish off side hems by blindhemming, hand-sewing, or<br />

using an iron-on hem tape.<br />

Gather drop along the top edge.<br />

Attaching Drops to Platform:<br />

.<br />

2.<br />

Pin drop face down on top of the platform next to cording.<br />

You may need to work in excess material by dividing drop<br />

into equal sections, pinning to platform and gathering up<br />

excess material between pins. Sew drop to platform next<br />

to welt cord.<br />

Flip drop over for finished dust ruffle. See illustration #9.<br />

Adding a Split and Gusset:<br />

.<br />

If a split and gusset are needed between the side and the<br />

foot, fabricate platform and drops as described except<br />

36 The Custom Home Furnishings Magazine September/October 2006

Step-by-Step<br />

Susan Schurz<br />

you will be making<br />

three sections to<br />

fit sides and foot.<br />

Stitch sides and<br />

foot drops to platform,<br />

meeting at<br />

the corners.<br />

with face of fabric and face of lining together and stitch<br />

edges together with a ½" seam allowance along the edges.<br />

See illustrations #10 and #11. Clip corners, turn right sides<br />

out, and press. Mark at desired length, including seam<br />

allowance and serge off excess material. See illustration<br />

#12.<br />

2.<br />

To make the gussets,<br />

cut the face<br />

fabric 8" wide by<br />

drop length plus<br />

4" for the hem and<br />

2" for the tabling<br />

allowance. Cut lining<br />

8" wide plus 2"<br />

tabling allowance.<br />

Sew 2" up from the<br />

bottom edge with<br />

lining and face fabric,<br />

face of fabrics<br />

together. Turn face<br />

fabric away from<br />

lining, allowing for<br />

2" hem. Turn back face<br />

fabric at the bottom edge<br />

Illustration 10<br />

Illustration 11<br />

.<br />

4.<br />

Illustration 12<br />

Sew gussets face down on drops centered over the corner<br />

where drops meet. Slightly gather or clip edges to ease<br />

around corner.<br />

Flip over drops. Gussets will fall behind drops.<br />

Susan Schurz owns Tavern Hill located<br />

in Amelia, VA, a wholesale workroom<br />

since 1988. She specializes in handcrafted,<br />

detailed <strong>window</strong> <strong>treatments</strong> and<br />

accessories. Susan is an instructor for<br />

The Custom Home Furnishings Academy<br />

and is a frequent contributor to The<br />

CHF Magazine.<br />

www.CHFmagazine.com September/October 2006 37

Down to Business<br />

Mary Ann Plumlee<br />

Treatments Formerly Known as “Hard”<br />

Looking at Hard and Soft Treatments<br />

I<br />

keep waiting for someone to do it. I keep thinking it needs<br />

to be done, so I guess it will be me. So I hereby take on the<br />

huge task of renaming the entire industry. Of course, I'm<br />

talking about the twin sisters of <strong>window</strong> <strong>treatments</strong>…one<br />

named Hard and the other Soft. As the owner of a business<br />

who carries both, I've often thought that they were misnamed<br />

somehow, switched at birth so to speak.<br />

The beauty of hard <strong>treatments</strong> is that they are so easy. Anyone<br />

that can read through a manufacturer's price list and brochure<br />

is well on their way to becoming an expert. Add an old blind<br />

that you can autopsy to the mix, and you can know pretty<br />

much all there is to know about blinds inside and out. Other<br />

so called hard <strong>treatments</strong> can be added to a dealer's repertoire<br />

with pretty much the same process.<br />

Even the truly hard treatment,<br />

plantation shutters, can<br />

be learned with relatively short<br />

training, or added by incorporating<br />

a subcontractor.<br />

In contrast soft <strong>treatments</strong> require<br />

mountains of words contained<br />

in copious volumes of<br />

instructive manuals. A I write, I glance at a shelf full of <strong>design</strong><br />

book after <strong>design</strong> book dealing with soft <strong>treatments</strong>, not counting<br />

magazines on top of magazines with articles depicting<br />

the same subject. A good example of this is the SewWHAT?<br />

Magazine started by Cheryl Strickland in 1993. It was in print<br />

for 12 years with each volume containing tricks of the trade,<br />

methods of construction, and styling. One would think that the<br />

subject would be exhausted by now. But not so. A cursory scan<br />

of the associated CHF Forum Network shows over 270,000<br />

threads, featuring still more questions and answers on the<br />

subject. A common saying in the soft side of the industry is,<br />

“You never learn it all.” And after 20 years in this business, I<br />

have to agree.<br />

“When asked to describe what a<br />

workroom does, I often say we're<br />

builders; we're carpenters, only we<br />

use fabric. We're engineers solving<br />

problems; we're mathematicians,<br />

especially in the field of geometry.”<br />

When asked to describe what a workroom does, I often say<br />

we're builders; we're carpenters only we use fabric. We're<br />

engineers solving problems,; we're mathematicians, especially<br />

in the field of geometry. We're people who have to think three<br />

dimensionally. With soft <strong>treatments</strong>, anyone leaving out that<br />

third dimension is in for some nasty surprises. We're also magicians,<br />

making things float in the air or disappear if we have to.<br />

We have to coax fabric to do things it was never intended to<br />

do. We're mind readers and code deciphers, able to interpret<br />

the worst of hen-scratching and stick figures and bring them<br />

to life.<br />

We're women and men with strength, hoisting 50-75 pound<br />

bolts of fabric, wrestling cornice boards into submission, and<br />

dressing down drapes until they purr. Our eyes brighten at the<br />

thought of power tools. The hardware store clerks all know<br />

us because we like to sort through lumber like a pro, and we<br />

know what a number 6 screw is. Grown men come into our<br />

workshops and experience tool envy.<br />

So why don't more of us carry hard <strong>treatments</strong>? I'm convinced<br />

it's because of the name. Most<br />

companies that carry only hard<br />

<strong>treatments</strong> are predominantly<br />

run by men. Most hard treatment<br />

salespersons are men. I think hard<br />

<strong>treatments</strong> are kind of a metaphor<br />

for men. Measure, decide, done.<br />

Whereas the soft treatment side<br />

seems to be dominated by women.<br />

It fits us; it describes us. We're complex; we're detail-oriented;<br />

we want to mull and delve into all the options and enjoy the<br />

beauty, the emotion, and experience of it all. And besides,<br />

aren't hard <strong>treatments</strong> hard? For some of us in the soft side,<br />

they might as well be named — difficult <strong>treatments</strong>, or impossible<br />

<strong>treatments</strong>, because being call hard <strong>treatments</strong> is enough<br />

to keep us away.<br />

If we look at the two halves of the industry, hard and soft, it<br />

seems that the two never meet, except at the retail level. Of<br />

course, hard treatment suppliers don't enter the soft world, and<br />

fabric suppliers don't cross into the hard side. Yet, they are both<br />

in the same industry. Unfortunately, we find ourselves in the<br />

same situation, often at the retail level. We have retailers who<br />

only do hard, and retailers/workrooms who only do soft.<br />

The most important component we have to offer in the custom<br />

<strong>window</strong> treatment industry is customer service. The very best<br />

in customer service is a person at the retail level who is a true<br />

“<strong>window</strong> treatment” expert. There are some functional issues<br />

38 The Custom Home Furnishings Magazine September/October 2006

Down to Business<br />

Mary Ann Plumlee<br />

that can only be met with a hard treatment. By the same token,<br />

there are some ascetic issues that can only be solved by a soft<br />

treatment. Retailers with only one expertise find themselves in<br />

the position of trying to bend the customer to settle for their<br />

solution, whether it is a good fit for the customer or not. The<br />

retailer that can approach the customer as a <strong>window</strong> treatment<br />

consultant, knowing all the available products has a competitive<br />

advantage, and can provide a better service to customers who<br />

are more and more strapped for time. Going to one retailer for<br />

hard <strong>treatments</strong> and then having to deal with a totally different<br />

person for soft <strong>treatments</strong> is not meeting today's customer<br />

needs for convenience. And quite frankly, a retailer who doesn't<br />

have the full array of all <strong>treatments</strong> is not able to make the best<br />

recommendation based upon the customer's needs.<br />

Everything seems to be pointing toward the market moving<br />

toward soft <strong>treatments</strong>. Many of those customers who put in<br />

hard <strong>treatments</strong> in recent year out of a necessity for privacy as<br />

they moved up in the housing market are now ready for soft<br />

<strong>treatments</strong>. Businesses that can provide a mix of both hard and<br />

soft will be in a better position to take advantage of market<br />

trends in the near and long-term future.<br />

So how can the industry as a whole prepare for that future?<br />

Hard coverings manufacturers would be wise to reach out to<br />

the soft side. It doesn't help the hard coverings industry for<br />

drapery people to be pushing only drapes when hard <strong>treatments</strong><br />

are the solution in so many instances. Drapery people need to<br />

know that there's nothing hard about hard coverings except<br />

INDUSTRY NEWS<br />

News from WCAA Chapters<br />

The Central New Jersey Chapter of WCAA meets on the first<br />

Thursday of each month. The November meeting will be held<br />

November 2 at 540 Ridge Road, South Brunswick. The topic<br />

will be Feng Shui and how it impacts <strong>design</strong>. Speaker will<br />

be Jeanette Schwartz. For more information, contact Nicole<br />

Lorber at nlorber@comcast.net. The December meeting will<br />

be held on December 7 at Wegmans, 55 US Route 9 South,<br />

Manalaphan. The topic will be Holiday Party.<br />

The 2006 Chicagoland Chapter holds regular meetings on<br />

the third Thursday of each month, usually from 10:00am-<br />

12:00noon, unless otherwise stated. RSVP to meetings by<br />

contacting Victoria McEligott at 630-922-5919 or email to<br />

the name. Adding hard coverings to a predominantly soft coverings<br />

business strengthens that business. And predominantly<br />

hard coverings retailers that are moving into the soft side need<br />

to know that soft doesn't mean easy. In fact carrying drapes<br />

without knowing the complexity and pitfalls of the drapery<br />

business is one of the easiest ways to loose money that I know.<br />

Hard coverings people learn all you can. The learning curve<br />

is steep.<br />

Meanwhile, I'd like to do some renaming of the industry. For<br />

hard <strong>treatments</strong>, how about “Easy Treatments” (formerly<br />

known as Hard) or “Two Dimensional Treatments”, or “Paper<br />

Turning Money Making Treatments,”, or perhaps “Treatments<br />

That Everybody Could Sell If They Weren't Misnamed Hard.”<br />

And for soft <strong>treatments</strong>, how about “Great Money Making<br />

If You Know Your Stuff” Treatments or the “Never Ending<br />

Choices Treatments.”<br />

I really think I'm on to something here. It'll help us all.<br />

Mary Ann Plumlee started her business in<br />

1985 with a $50 investment and a home sewing<br />

machine on her dining room table. Mary<br />

Ann has built her business through trial and<br />

error, which is an expensive way to learn. She<br />

currently has 13 employees and does wholesale/retail<br />

and commercial work. Mary Ann<br />

is a frequent contributor to The Custom Home Furnishings<br />

Magazine.<br />

toria@wideopenwest.com. The November meeting will be<br />