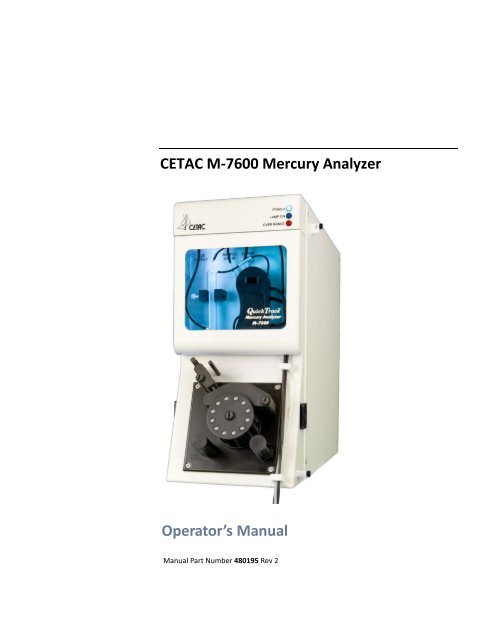

CETAC M-7600 Mercury Analyzer Operator's Manual

CETAC M-7600 Mercury Analyzer Operator's Manual

CETAC M-7600 Mercury Analyzer Operator's Manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>CETAC</strong> M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Operator’s <strong>Manual</strong><br />

<strong>Manual</strong> Part Number 480195 Rev 2

COPYRIGHT<br />

© 2008, 2012 <strong>CETAC</strong> Technologies<br />

480195 Rev 2 , October, 2012<br />

<strong>CETAC</strong> Technologies authorizes its customers<br />

to reproduce, transmit, or store this document<br />

in its entirety, including this page, for the<br />

express purpose of installing, operating, or<br />

maintaining the product described herein.<br />

<strong>CETAC</strong> Technologies<br />

Customer Service & Support<br />

14306 Industrial Road<br />

Omaha, Nebraska 68144, USA<br />

Phone (800) 369-2822 (USA only)<br />

Phone (402) 733-2829<br />

Fax (402) 733-1932<br />

E-mail custserv@cetac.com<br />

REVISIONS<br />

<strong>CETAC</strong> Technologies strives to provide the<br />

scientific community with an unparalleled<br />

combination of effective technology and<br />

continuing value. Modular upgrades for<br />

existing instruments will continue to be a<br />

prime consideration as designs progress.<br />

<strong>CETAC</strong> Technologies reserves the right to<br />

revise this document and/or improve<br />

products described herein at any time without<br />

notice or obligation. Warranty registration<br />

entitles the named owner exclusively to<br />

manual change pages/new editions as they<br />

are published.<br />

TRADEMARK ACKNOWLEDGEMENTS<br />

Windows is a registered trademark of<br />

Microsoft Corporation in the United States and<br />

other countries.<br />

Nafion ® is a registered trademark of DuPont<br />

(E.I. du Pont de Nemours and Company).<br />

Perma Pure is a registered trademark of<br />

Perma Pure LLC.<br />

DuPont, Kapton®, Teflon®, Tefzel® and<br />

Viton® are trademarks or registered<br />

trademarks of E.I. du Pont de Nemours and<br />

Company.<br />

PharMed and Tygon are registered<br />

trademarks of Saint-Gobain Performance<br />

Plastics.<br />

Santoprene is a trademark of Exxon Mobil.<br />

KIMWIPES is a registered trademark and<br />

KIMTECH SCIENCE is a trademark of<br />

Kimberly-Clark Worldwide, Inc<br />

All other marks are the property of their<br />

respective owners.

Contents<br />

1 Introduction .............................................................................................................. 7<br />

Overview.................................................................................................................................... 7<br />

About This Book ..................................................................................................................... 7<br />

Who Should Use This Product ................................................................................... 7<br />

Where to Go for More Information ................................................................................ 8<br />

System Features ..................................................................................................................... 9<br />

System Performance Characteristics .......................................................................... 10<br />

Overview of the <strong>Mercury</strong> <strong>Analyzer</strong> .............................................................................. 11<br />

Supplied Equipment ........................................................................................................... 13<br />

Equipment and Supplies ................................................................................................... 14<br />

Required Equipment and Supplies ........................................................................ 14<br />

Recommended Supplies ............................................................................................. 15<br />

2 Preparing for Installation ................................................................................. 17<br />

Establishing Optimal Operating Conditions ............................................................ 17<br />

Creating the Lab Environment ............................................................................... 17<br />

Choosing a Location ............................................................................................................ 18<br />

Space Requirements .................................................................................................... 18<br />

Work Surface Requirements .................................................................................... 20<br />

Ventilation Requirements ................................................................................................ 20<br />

Power Requirements ......................................................................................................... 20<br />

Unpacking the <strong>Mercury</strong> <strong>Analyzer</strong> ................................................................................. 21<br />

3 Installing the <strong>Analyzer</strong> ....................................................................................... 25<br />

Installation Overview......................................................................................................... 25<br />

Step 1: Position the <strong>Mercury</strong> <strong>Analyzer</strong> and Autosampler.................................. 26<br />

Step 2: Connect the Autosampler Peristaltic Pump to the Rinse Station .... 26<br />

Step 3: Set Up the Autosampler ..................................................................................... 30<br />

Step 4: Connect Power and Data Cables to the Back of the <strong>Mercury</strong><br />

<strong>Analyzer</strong> .......................................................................................................................... 39<br />

Step 5: Connect the Carrier Gas Tubing ..................................................................... 40<br />

Step 6: Install the <strong>Mercury</strong> Trap (KMnO 4) ................................................................ 42<br />

Step 7: Connect the Back of the Autosampler ......................................................... 44<br />

Step 8: Connect to the Host Computer ....................................................................... 45<br />

Summary ......................................................................................................................... 45<br />

Installing a Secondary NIC in Your Own PC ...................................................... 45<br />

Connecting the Communication Cables............................................................... 46<br />

Configuring the Network Metrics .......................................................................... 46<br />

Setting the IP Address for the Secondary NIC ................................................... 50<br />

Changing the Subnet of the <strong>Mercury</strong> <strong>Analyzer</strong>................................................. 51<br />

Connecting a Laptop Computer to the M-<strong>7600</strong> ................................................ 52<br />

Step 9: Install the Gas-Liquid Separator (GLS) ....................................................... 53

M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong> Operator’s <strong>Manual</strong><br />

Contents<br />

Step 10: Connect the Peristaltic Pump on the <strong>Mercury</strong> <strong>Analyzer</strong> .................. 57<br />

Installing the Peristaltic Pump Tubing ............................................................... 57<br />

Installing the Mixing Tee and Drain Tees .......................................................... 59<br />

Step 11: Power On and Verify Communication ...................................................... 63<br />

To Configure the Network Connection ................................................................ 63<br />

To Power On the System for the First Time (PC Configured by <strong>CETAC</strong>) 64<br />

To Power On the System for the First Time (Customer-Supplied PC) ..... 64<br />

To Test the Autosampler ........................................................................................... 68<br />

Step 12: Fill the Rinse Solution Bottle ........................................................................ 68<br />

Step 13: Fill the Reagent Bottle ..................................................................................... 69<br />

Preserving the SnCl 2 ................................................................................................... 69<br />

Step 14: Adjust the Peristaltic Pump Tubing Clamp Tension (Optional) ... 70<br />

Step 15: Check the Reagent Flow ................................................................................. 73<br />

Step 16: Check the Sample Probe Flow ..................................................................... 73<br />

4 Using the <strong>Analyzer</strong> ............................................................................................... 75<br />

Theory of Operation ........................................................................................................... 75<br />

Autosampler .................................................................................................................. 75<br />

QuickTrace M-<strong>7600</strong> Automated <strong>Mercury</strong> <strong>Analyzer</strong> .................................... 76<br />

Software................................................................................................................................... 78<br />

Preparing Reagents and Calibration Standards ..................................................... 79<br />

Gas Parameters .................................................................................................................... 81<br />

Starting the System............................................................................................................. 81<br />

<strong>Mercury</strong> Vapor Lamp Warmup .............................................................................. 82<br />

Turning Off the <strong>Mercury</strong> Vapor Lamp for System Warm-Up ..................... 82<br />

System Warm-Up for Trace or Ultra-Trace Analysis ..................................... 82<br />

System Warm-Up for ppb or Non-Ultra-Trace Analysis ............................... 83<br />

Wetting the GLS .................................................................................................................... 84<br />

Running the Interactive Demo ...................................................................................... 87<br />

Overview of the <strong>CETAC</strong> QuickTrace Software ..................................................... 87<br />

Learning More .............................................................................................................. 88<br />

QuickTrace M-<strong>7600</strong> Startup Summary ................................................................... 89<br />

Setting Baseline Correction ............................................................................................ 91<br />

Keeping an Instrument Log Book .......................................................................... 91<br />

Viewing the Graphs ..................................................................................................... 92<br />

Setting a One-Point Baseline ................................................................................... 92<br />

Setting a Two-Point Baseline .................................................................................. 94<br />

Summary of Gas and Liquid Flows for Analytical Ranges of the<br />

QuickTrace M-<strong>7600</strong> ................................................................................................ 98<br />

Placing the QuickTrace M-<strong>7600</strong> in Standby Mode ......................................... 100<br />

Cold Shutdown .................................................................................................................. 101<br />

Summary of QuickTrace M-<strong>7600</strong> Shut Down .............................................. 101<br />

5 Maintaining the <strong>Mercury</strong> <strong>Analyzer</strong> ............................................................. 103<br />

Maintenance Schedule ................................................................................................... 103<br />

Daily Maintenance (Always Check Before Analysis) .................................... 103<br />

Weekly Maintenance ................................................................................................ 104<br />

Monthly Maintenance .............................................................................................. 104<br />

Yearly Maintenance .................................................................................................. 104<br />

Autosampler Yearly Maintenance....................................................................... 105<br />

Removal or Inspection of the Sample Cell ............................................................. 105<br />

Opening the Optics Access Panel ......................................................................... 105<br />

Removing the Sample Cell ...................................................................................... 107<br />

4

M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong> <strong>Operator's</strong> <strong>Manual</strong><br />

Contents<br />

Cleaning the Cell Windows ........................................................................................... 107<br />

Quick Exposed Surface Cleaning ......................................................................... 107<br />

Dismantling for Total Cleaning ........................................................................... 109<br />

Cell Assembly...................................................................................................................... 109<br />

Cleaning the Gas-Liquid Separator ........................................................................... 112<br />

Changing the Cell Gas Tubing ...................................................................................... 113<br />

Retubing the Gas-Liquid Separator .......................................................................... 115<br />

GLS Inlet........................................................................................................................ 115<br />

GLS Drain ..................................................................................................................... 116<br />

Replacing the Perma Pure ® Dryer Cartridge ........................................................ 117<br />

GLS Overflow Recovery .................................................................................................. 119<br />

Replacing the Hg Lamp Bulb ........................................................................................ 124<br />

When to Replace or Service the Lamp .............................................................. 124<br />

Cleaning the EOFM ................................................................................................... 124<br />

Getting a Replacement Lamp ............................................................................... 125<br />

Caring for the Lamp ................................................................................................. 126<br />

Replacing the Lamp ................................................................................................. 126<br />

Adjusting the Lamp Current ................................................................................. 129<br />

Replacing the Fuse ........................................................................................................... 131<br />

6 Troubleshooting the <strong>Mercury</strong> <strong>Analyzer</strong> .................................................... 133<br />

Troubleshooting Communication Issues ............................................................... 133<br />

Step 1: Check the Cable ........................................................................................... 133<br />

Step 2: Use the IPSetup Tool to Check the Configuration .......................... 133<br />

Step 3: Check the Subnet Configuration Using the Define QuickTrace<br />

Hardware Tool .................................................................................................. 134<br />

Step 4: Check for an IP address conflict ........................................................... 137<br />

If the IPSetup Tool Does Not Find the M-<strong>7600</strong> .............................................. 138<br />

"Subnet of this PC and the M-<strong>7600</strong> are Not Compatible" Error ............. 139<br />

Cannot Zero Instrument ................................................................................................ 140<br />

"Integration Adjustment Reached" Messages ...................................................... 140<br />

Drifting Baseline ................................................................................................................ 140<br />

Low Absorbance or No <strong>Mercury</strong> Response ........................................................... 141<br />

No Liquid or Gas Flow .................................................................................................... 141<br />

No Sample or Rinse Flow ....................................................................................... 141<br />

No SnCl 2 Flow ............................................................................................................. 142<br />

No Drain Flow ............................................................................................................ 142<br />

No Gas Flow or Low Gas Flow .............................................................................. 142<br />

Double Peak with Low Absorbance .......................................................................... 142<br />

Poor Reproducibility ....................................................................................................... 143<br />

Noisy Baseline .................................................................................................................... 144<br />

Bad DL .................................................................................................................................... 144<br />

Sudden Standard Absorbance Rise During Run .................................................. 144<br />

Poor Accuracy .................................................................................................................... 145<br />

Returning the Product to <strong>CETAC</strong> for Service ........................................................ 146<br />

Shipping the Product ............................................................................................... 146<br />

Product Warranty Statement .............................................................................. 146<br />

Returned Product Procedures .............................................................................. 147<br />

Returned Product Warranty Determination ................................................. 147<br />

7 Safety and Regulatory Information ............................................................. 149<br />

Characteristics ................................................................................................................... 149<br />

Environmental Characteristics ............................................................................ 149<br />

5

M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong> Operator’s <strong>Manual</strong><br />

Contents<br />

Electrical Characteristics ....................................................................................... 150<br />

Safety Notices ..................................................................................................................... 151<br />

Replacement Parts .................................................................................................... 151<br />

Chemical Hazards ...................................................................................................... 151<br />

Power Cord Set Requirements .............................................................................. 151<br />

Power Cord Safety Maintenance ......................................................................... 151<br />

Grounding ..................................................................................................................... 152<br />

Mains Disconnect ....................................................................................................... 152<br />

Mechanical Hazards ................................................................................................. 152<br />

Cleaning Instructions ............................................................................................... 153<br />

Operating Environment .......................................................................................... 153<br />

Explanation of Caution and Warning Notices ............................................... 154<br />

Avertissements en Français ......................................................................................... 155<br />

Electromagnetic Interference ..................................................................................... 156<br />

Explanation of Regulatory Marks .............................................................................. 156<br />

8 Glossary ................................................................................................................. 157<br />

6

1 Introduction<br />

Overview<br />

The <strong>CETAC</strong> QuickTrace M-<strong>7600</strong> mercury analyzer measures trace levels of<br />

mercury in aqueous solution by Cold Vapor Atomic Absorption Spectrometry<br />

(CVAAS). CVAAS does not require heating the sample with a flame, plasma, or<br />

furnace. The mercury analyzer’s modular design permits remarkably easy<br />

maintenance access and a reduced countertop footprint. Sturdy construction,<br />

drift-stabilized double beam optics, thermal and electro-optical lamp<br />

stabilization, and an unusually stable “non-foaming” Gas-Liquid Separator (U.S.<br />

Patent #5,792,663) collectively afford exceptional structural integrity and<br />

signal stability. The QuickTrace M-<strong>7600</strong> exhibits a high signal-to-noise ratio<br />

and ultra-trace detection limits for an absorbance system that is fully<br />

compliant with EPA CVAA methods such as 245.7, 245.1, 245.5, SW846 7470<br />

and 7471.<br />

About This Book<br />

This document describes the procedures for installing, using, and maintaining<br />

the analyzer.<br />

This manual covers the following products:<br />

‣ <strong>CETAC</strong> QuickTrace M-<strong>7600</strong> mercury analyzer<br />

Who Should Use This Product<br />

The primary audience for this manual consists of mercury detection and<br />

mercury measurement laboratory managers, chemists, technicians, fieldservice<br />

engineers and owners of the QuickTrace M-<strong>7600</strong> mercury analyzer.<br />

To use this product effectively, you should have a basic knowledge of mercury<br />

analysis, at least a beginning level of computer experience, and a basic<br />

knowledge of chemical handling procedures including the handling of<br />

organomercurials.<br />

Before operating the QuickTrace M-<strong>7600</strong> analyzer, autosampler, or optional<br />

ADX-500 autodilutor, it is important to read this manual, the QuickTrace<br />

Software <strong>Manual</strong>, the Autosampler Operator’s <strong>Manual</strong>, and (if applicable) the<br />

ADX-500 Autodilutor Accessory Operator’s <strong>Manual</strong>.

Operator’s <strong>Manual</strong><br />

Chapter 1: Introduction<br />

Where to Go for More Information<br />

In addition to this manual, you can refer to the following resources:<br />

‣ The QuickTrace Software <strong>Manual</strong> and built-in help<br />

‣ The M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong> PC Setup Guide<br />

‣ The <strong>CETAC</strong> Autosampler Operator’s <strong>Manual</strong><br />

‣ The ADX-500 Autodilutor <strong>Manual</strong> (optional)<br />

‣ U.S. EPA Method 245.1; method for Hg determination in drinking water<br />

‣ U.S. EPA Method 245.7; <strong>Mercury</strong> in Water by Atomic Fluorescence<br />

Spectrometry<br />

‣ U.S. EPA, Office of Solid Wastes. SW846 Method 7470A; <strong>Mercury</strong> in Liquid<br />

Waste (Cold-Vapor Technique)<br />

‣ U.S. EPA, Office of Solid Wastes, SW846 Method 7471B; <strong>Mercury</strong> in Solid or<br />

Semisolid Waste (Cold-Vapor Technique)<br />

‣ American Society for Testing and Methods. ASTM D3223-91; Standard Test<br />

Method for Total <strong>Mercury</strong> in Water<br />

‣ The <strong>CETAC</strong> Technologies Web site: www.cetac.com<br />

‣ <strong>CETAC</strong> Technologies Customer Service and Support:<br />

1 (800) 369-2822 (USA only)<br />

1 (402) 733-2829<br />

1 (402) 733-1932 (Fax)<br />

E-mail: custserv@cetac.com<br />

8

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 1: Introduction<br />

System Features<br />

The QuickTrace M-<strong>7600</strong> incorporates the following features to form an<br />

automated, integrated mercury analysis system.<br />

‣ Computer-controlled four-channel high-performance peristaltic pump<br />

(12-roller pump head).<br />

‣ Ozone-free Hg Lamp. No lamp ventilation is needed.<br />

‣ Thermally controlled Hg lamp housing (for a stabilized Hg vapor lamp).<br />

‣ Stable high performance Gas-Liquid Separator (GLS). (U.S. Patent<br />

#5,792,663). Non-foaming/non-bubbling “thin liquid film” GLS design,<br />

which allows trouble-free direct analysis of blood, urine, and fish tissue<br />

digests as well as standard water and waste analysis.<br />

‣ Rigid, shock and vibration-isolated optical rail (mounting the Hg lamp,<br />

collimator lens, absorption tubes, camera, CCD detector, and A/D<br />

converter).<br />

‣ Precise, self-aligning optical mounts, no optical alignment required,<br />

maximizing the convenience of instrument baseline zeroing. This design<br />

extends maintenance intervals without loss of performance.<br />

‣ Long path (220 mm) absorbance cells.<br />

‣ Hg lamp electro-optical feedback beam utilizing a high-performance solidstate<br />

detector for ultra-fine lamp stabilization.<br />

‣ Fixed optical interference filters, three each (254 ± 2 nm wavelength, 20%<br />

T, 12.7 mm dia.). No moving parts.<br />

‣ Standard Perma Pure ® dryer cartridge eliminates the need for Mg(ClO 4) 2<br />

drying agent.<br />

‣ Stabilized double beam optics - traditional double-beam (sample and<br />

reference) with a CCD detector.<br />

‣ Internal ADC (Analog-to-Digital Conversion).<br />

‣ High-rate data sampling.<br />

‣ Computer controlled system shutdown/standby routines.<br />

‣ Integrated optional autosamplers for accommodation of calibration<br />

standards and up to 720 samples.<br />

‣ Ethernet communications.<br />

‣ Gas exhaust Hg vapor safety trap (solid crystalline KMnO 4).<br />

9

Operator’s <strong>Manual</strong><br />

Chapter 1: Introduction<br />

System Performance Characteristics<br />

‣ Ultra-trace detection limits: < 0.5 ppt at 40 mL / min. carrier gas flow 1 .<br />

(Direct steady state absorbance mode, without pre-concentration by gold<br />

amalgamation).<br />

‣ Wide dynamic linear working range, ≅ 4 orders of magnitude.<br />

‣ Short term precision (%RSD @ 95% Confidence) < 6.0% @ 5 ppt, n=5<br />

‣ Short term precision (%RSD @ 95% Confidence) < 1.2% @ 20 ppt, n=5<br />

‣ Long term precision (%RSD @ 95% Confidence) < 2.7%/h @ 200.0 ppt<br />

‣ 99% Confidence Accuracy @ 5 ppt; ±3.1%<br />

‣ 99% Confidence Accuracy @ 20 ppt; ±4.3%<br />

‣ Sample Throughput < 3.5 min/sample at IDL<br />

‣ Ultra-low drift rates ≤ 300 µAbs/hr (after warm-up) raw uncorrected<br />

analog baseline on-screen drifts.<br />

‣ Ultra-low short-term absorbance noise ≤ 200 µAbs (10 -5 Abs).<br />

‣ 0.1% “raw” Hg lamp stability (single beam output).<br />

‣ Unusually fast washout ≈ 240 sec. from 1ppm Hg, at 1000 mL/min gas<br />

flow.<br />

‣ <strong>Mercury</strong> Response: ≥ 14,000 µAbs / ppb 2 at 100 mL/min carrier gas flow.<br />

1 One hour minimum warm-up using the standard Nafion ® dryer and a gas flow equal<br />

to 40 mL/min along with prescribed tubing and reagents. Using pump speed, uptake<br />

and rinse times specified for standard Nafion ® dryer in Table 4-1 (p. 72), and ≥12 s<br />

integration cycle selected on the "flattest" portion of the peak time profile.<br />

2 Using prescribed tubing, reagents, and pump speed.<br />

10

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 1: Introduction<br />

Overview of the <strong>Mercury</strong> <strong>Analyzer</strong><br />

Power and Status Lights<br />

Perma Pure ® Dryer Cartridge<br />

Gas-Liquid Separator (GLS)<br />

Peristaltic Pump<br />

Figure 1-1<br />

M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong>—Front View.<br />

Sample Probe<br />

Rinse Bottle<br />

Autosampler<br />

(ASX-520 is shown)<br />

Reagent Bottle<br />

Figure 1-2<br />

M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong>—Front View with Autosampler.<br />

11

Operator’s <strong>Manual</strong><br />

Chapter 1: Introduction<br />

Autosampler<br />

Peristaltic Pump<br />

<strong>Mercury</strong> Trap<br />

Autosampler<br />

Power Switch<br />

Electrical<br />

Connectors<br />

M-<strong>7600</strong><br />

Power Switch<br />

Figure 1–2<br />

M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong> —Back View of Complete System.<br />

Auxiliary I/O Ports<br />

Ethernet Port<br />

Auxiliary Input Port<br />

Auxiliary Power<br />

Ports<br />

M-<strong>7600</strong><br />

Power Switch<br />

M-<strong>7600</strong><br />

Power Cord<br />

Figure 1-3<br />

M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong> —Electrical Connectors.<br />

The following components are located on the front of the mercury analyzer<br />

(see Figure 1-2).<br />

‣ POWER Indicator. The top blue LED indicates that the analyzer is<br />

connected to a power source and turned on.<br />

‣ LAMP ON Indicator. Indicates when the internal mercury vapor lamp is<br />

turned on.<br />

‣ OVER RANGE Indicator. Indicates that the internal mercury vapor lamp is<br />

drawing more than the recommended amount of current. This LED will<br />

glow for a few seconds while the mercury lamp warms up when the<br />

mercury analyzer is first turned on and the QuickTrace software is<br />

started or any time the lamp is off and then powered on via software<br />

controls.<br />

‣ Perma Pure ® Dryer Cartridge. Uses a DuPont Nafion ® membrane to<br />

remove humidity from the sample gas.<br />

‣ Gas-Liquid Separator (GLS).<br />

‣ Front Cover. Protects the GLS and dryer cartridge. An LED lamp<br />

illuminates the area behind the cover whenever the mercury analyzer is<br />

turned on.<br />

12

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 1: Introduction<br />

‣ Peristaltic Pump. A four-channel peristaltic pump is built into the front of<br />

the mercury analyzer.<br />

The following components are located on the back of the analyzer:<br />

‣ POWER Switch. Turns power to the M-<strong>7600</strong> mercury analyzer on and off.<br />

This switch also controls power to the autosampler, when powered<br />

through the mercury analyzer.<br />

‣ Gas Ports. Gas inlet and exhaust ports.<br />

‣ <strong>Mercury</strong> Trap. The trap scrubs mercury from the exhaust gas.<br />

The following electrical connectors are located on the back of the analyzer:<br />

‣ Ethernet Port. The Ethernet port is used to interface the mercury<br />

analyzer with the host computer.<br />

‣ Auxiliary Communication Ports. The two AUX I/O ports and one AUX<br />

INPUT port are reserved for use with other <strong>CETAC</strong> instruments.<br />

‣ Power Output Connectors. Provides power for the autosampler and for<br />

an optional auxiliary device.<br />

Supplied Equipment<br />

The following standard components are supplied with the mercury analyzer:<br />

‣ M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong>.<br />

‣ CD. The CD contains:<br />

• QuickTrace software<br />

• This manual<br />

• Other application-specific information<br />

‣ Gas-Liquid Separator.<br />

‣ Perma Pure ® Dryer Cartridge. Uses a DuPont Nafion ® membrane to<br />

remove humidity from the sample gas. The cartridge is pre-installed in the<br />

mercury analyzer.<br />

‣ KMnO 4 Absorbent Trap. This scrubs mercury from the exhaust gas. The<br />

KMnO 4 is not included.<br />

‣ Bottles. One reagent bottle and one rinse bottle are provided.<br />

‣ PCI Ethernet Adapter Board.<br />

‣ Power Cord and Cables. An Ethernet cable, a power cord for the mercury<br />

analyzer, and a power cord for the autosampler are supplied.<br />

Depending on how the system was ordered, the following optional equipment<br />

may be supplied:<br />

‣ Computer. The mercury analyzer may be ordered with a computer which<br />

is pre-configured with the QuickTrace software.<br />

‣ <strong>CETAC</strong> ASX-520/260/130 Autosampler.<br />

‣ <strong>CETAC</strong> ADX-500 Autodilutor.<br />

‣ ENC-500 Enclosure.<br />

13

Operator’s <strong>Manual</strong><br />

Chapter 1: Introduction<br />

WARNING<br />

The computer, autosampler, and optional accessories have their own<br />

manuals (printed or on CD-ROM). Before using the equipment, read those<br />

manuals to understand the precautions you must take to avoid possible<br />

hazards.<br />

Equipment and Supplies<br />

Required Equipment and Supplies<br />

‣ Inert Gas Regulator.<br />

Two-stage, 10-200 psig (70-1380 kPa) secondary pressure gauge, with<br />

plumbing couple for either a cylinder or Dewar capable of delivering 150<br />

psig (1040 kPa).<br />

‣ AC Power Strip.<br />

Surge protected with six outlets, 15-20 A.<br />

‣ Cylinder or Dewar, UHP Nitrogen or Argon Gas.<br />

Ultra-high purity, dry, research grade N 2 or 99.999% purity Ar. The<br />

QuickTrace M-<strong>7600</strong> has a user replaceable 2-micron filter, which<br />

prevents damage from particulates to the internal gas control components.<br />

‣ <strong>Mercury</strong> Standard Solution.<br />

1000 ppm (minimum order quantity).<br />

‣ Hydrochloric Acid Trace Metal Grade (37%).<br />

Trace metal HCl will be used in the preparation of Hg standards, SnCl 2<br />

reagent and in some method applications. If an application is more<br />

demanding, a better grade of acid may be needed (for example, double<br />

distilled).<br />

‣ Nitric Acid Trace Metal Grade (68-70%).<br />

Trace metal HNO 3 will be used in sample preparation, cleaning glassware<br />

(lab glassware and the QuickTrace Gas-Liquid Separator) and added to<br />

the QuickTrace rinse solution to help maintain the cleanliness of the<br />

system during operation.<br />

‣ Stannous Chloride (Crystals, Di-Hydrate).<br />

Two 500g containers minimum order, “suitable for Hg determination.” The<br />

stock SnCl 2 is introduced into the QuickTrace at a steady flow rate and<br />

therefore any mercury contamination will be negated during the<br />

instrument zero.<br />

‣ Potassium Permanganate. Solid, Crystalline.<br />

The least expensive available grade at a minimum quantity is sufficient<br />

unless it is also to be used for oxidative sample preparation. This lowgrade<br />

reagent stock is sufficient to fill a safety trap for retention of Hg<br />

vapor exhaust from the instrument.<br />

‣ 2-propanol. High Purity, “Spectrophotometric” Grade.<br />

2-propanol will be used for cleaning the optical cells and cell windows.<br />

14

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 1: Introduction<br />

‣ KIMTECH SCIENCE KIMWIPES® Delicate Task Wipers.<br />

‣ Additional Chemical Compounds.<br />

The sample preparation procedures of the intended analytical method may<br />

require additional chemical compounds. Refer to published method<br />

specifications.<br />

Recommended Supplies<br />

‣ Volumetric flasks 100 mL class A (TC) six each.<br />

‣ Volumetric flasks 1000 mL class A (TC) two each.<br />

‣ Precision air displacement micropipettes, 10 to 10,000 µL (TD).<br />

‣ Replacement tips for micropipettes.<br />

‣ Disposable plastic dropping pipettes.<br />

‣ Graduated cylinders, 10 and 100 mL.<br />

‣ Polypropylene or polyethylene bottle with Cap, 1 L.<br />

‣ Weighing balance, top loading, 0.1 g readability (or better), any available<br />

capacity will work (1.1 kg capacity is good).<br />

‣ Laboratory scoopula and large spatula.<br />

‣ Stopwatch (for measuring liquid uptake rates).<br />

‣ Stirring rod.<br />

‣ Powder funnel, wide bore stem, small overall size.<br />

‣ Wrenches, adjustable 12" and 6".<br />

‣ Screw drivers:<br />

• 1 small Phillips<br />

• 1 medium Phillips<br />

• 1 long-shank medium flat-blade<br />

• 1 small thin flat-blade<br />

‣ Deionized water.<br />

‣ Flow meter 0 – 1,500 mL/min. with 1 mL/min. readability, calibrated to<br />

user’s choice of carrier gas (Ar or N 2).<br />

15

Operator’s <strong>Manual</strong><br />

Chapter 1: Introduction<br />

This page is intentionally blank.<br />

16

2 Preparing for<br />

Installation<br />

Installing the analyzer requires preparation. Before you install the analyzer,<br />

you should evaluate the physical arrangement of the laboratory to choose a<br />

suitable location. Once you choose a location, you must carefully unpack the<br />

analyzer prior to beginning the installation.<br />

This chapter discusses what requirements must be met when you choose a<br />

location. It also describes how to unpack the equipment before installation.<br />

Establishing Optimal Operating Conditions<br />

The mercury analyzer operates reliably even under less than ideal conditions.<br />

It is not, however, indestructible. Malfunction or damage can occur if specific<br />

operating conditions are not met. Meeting these conditions requires that you<br />

create the proper lab environment, replace analyzer components that wear out<br />

under normal use, and purchase the appropriate supplies for use with the<br />

analyzer.<br />

NOTE<br />

Damage or malfunction that results from unsatisfactory operating conditions<br />

may constitute misuse and abuse and be excluded from warranty coverage.<br />

Creating the Lab Environment<br />

To create satisfactory operating conditions in your lab environment, follow<br />

these guidelines:<br />

‣ Operate the analyzer in a conventional lab environment where the<br />

temperature is 60–90 °F (15–32 °C), the humidity is 20–70%<br />

non-condensing, and the unit is not exposed to excessive flammable or<br />

corrosive materials.<br />

‣ Avoid rough handling of the analyzer. If possible, do not expose the<br />

analyzer to vibration or shock.<br />

17

Operator’s <strong>Manual</strong><br />

Chapter 2: Preparing for Installation<br />

‣ Protect the analyzer from long-term exposure to condensation, corrosive<br />

materials, solvent vapor, continual standing liquids.<br />

‣ Observe the same general electrostatic discharge precautions as with any<br />

other integrated circuit electronic devices. Low humidity environments,<br />

especially when combined with static-generating materials, require<br />

maximum care.<br />

CAUTION<br />

Discharge static buildup and ground to the analyzer base or cabinet before<br />

performing any maintenance. Do not touch or short-circuit bare contacts or<br />

connectors.<br />

‣ Avoid using the analyzer if strong electromagnetic interference or radio<br />

frequency interference is present. Interference fields can cause erratic<br />

operation of the analyzer.<br />

Choosing a Location<br />

Space Requirements<br />

The QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong> System includes the base unit, PC<br />

with monitor, reagent and rinse bottles, and an optional autosampler.<br />

A typical system requires a minimum footprint for countertop installation of<br />

183cm (6’) X 31cm (2’) X 91cm (3’) (W x D x H). A floor space of 1’ (30cm) X 1’<br />

(30cm) is required for the liquid waste receptacle. The space for the waste can<br />

be directly below the analyzer, or directly in front of the lab bench and in line<br />

with the peristaltic pump.<br />

86 cm (34 inches)<br />

183 cm (6 feet)<br />

Figure 2-1 Footprint of QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

with ASX-520 Autosampler.<br />

18

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 2: Preparing for Installation<br />

71 cm (28 inches)<br />

142 cm (56 inches)<br />

Figure 2-2 Footprint of QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

with ASX-260 Autosampler.<br />

71 cm (28 inches)<br />

142 cm (56 inches)<br />

Figure 2-3 Footprint of QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

with ASX-130 Autosampler.<br />

46 cm<br />

(18.1 in)<br />

20 cm<br />

(7.9 inches)<br />

56 cm<br />

(22.0 inches)<br />

Figure 2-4 Dimensions of the QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong>.<br />

The work surface should be at least 61 cm (24 inches) deep if it is accessible<br />

from both front and back. If the work surface is against a wall, it should be at<br />

least 76 cm (30 inches, if possible) deep. If possible, allow at least 15 cm (6<br />

inches) behind the system for cable egress, ventilation, and access to the<br />

power switches.<br />

19

Operator’s <strong>Manual</strong><br />

Chapter 2: Preparing for Installation<br />

Always position the equipment so that it is easy to disconnect the power cord.<br />

Work Surface Requirements<br />

The analyzer must be placed on a sturdy countertop or table. It is not<br />

recommended to place the analyzer on a wheeled cart or folding table.<br />

If the analyzer is to be used in an earthquake zone, choose a location or secure<br />

it so that it will not fall and cause injury or damage during an earthquake.<br />

Ventilation Requirements<br />

During operation, the QuickTrace M-<strong>7600</strong> internally contains trace amounts<br />

of mercury vapor. To prevent inhalation of the vapor, the QuickTrace M-<strong>7600</strong><br />

uses a solid KMnO 4 absorbent trap located on the back of the instrument. This<br />

trap absorbs the mercury vapor prior to final exhaust; therefore no extra<br />

ventilation is required beyond that of a standard laboratory environment.<br />

WARNING<br />

INHALATION HAZARD<br />

Gases exhausting from the QuickTrace M-<strong>7600</strong> cabinet prior to the<br />

external Hg vapor trap (affixed to the rear cabinet panel) contain traces of<br />

mercury vapor and will cause injury if inhaled. Do not run the QuickTrace<br />

M-<strong>7600</strong> unless exhausted gas is properly “scrubbed” or removed. Fill,<br />

maintain, and use the provided KMnO 4 absorbent trap or run a transfer line<br />

to a fume hood.<br />

The ambient temperature should be kept as stable as possible. Locating the<br />

QuickTrace M-<strong>7600</strong> directly in the path of an air conditioner or heater vent<br />

may cause baseline drift, and is not recommended.<br />

NOTE<br />

Due to the likelihood of accelerated damage from corrosion and dust, locating<br />

the QuickTrace M-<strong>7600</strong> in a fume hood with stagnant air automatically voids<br />

the warranty.<br />

Power Requirements<br />

The QuickTrace M-<strong>7600</strong> mercury analyzer includes a built-in switching<br />

power supply which supports line voltages in the range 100-240 VAC at<br />

frequencies of 50-60 Hz. See “Electrical Characteristics” on page 150 for<br />

detailed power requirements.<br />

The autosampler is powered by the M-<strong>7600</strong>'s AUX POWER output. See the<br />

autosampler manual for more details.<br />

The power requirements for the computer can be found on the label affixed to<br />

the bottom of the computer, or in the computer manual which can be found on<br />

the computer CD.<br />

Place the QuickTrace M-<strong>7600</strong> within 1.2 meters of a standard power outlet.<br />

Ensure that you position the analyzer so that the location where the power<br />

supply cord plugs into it is easily accessible (is not blocked) and it can be<br />

20

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 2: Preparing for Installation<br />

quickly disconnected if needed. In case of hazard, the analyzer should be<br />

disconnected from the power source.<br />

Three power outlets may be required, one each for the QuickTrace M-<strong>7600</strong><br />

mercury analyzer, computer, and monitor. (An AC surge protected power strip<br />

with six or more outlets will suffice).<br />

The supplied power cord meets the requirements of the country where the<br />

instrument was purchased. If the instrument is to be used in a country other<br />

than the one specified at the time of ordering, obtain a new power cord set that<br />

meets the requirements of that country.<br />

WARNING<br />

SHOCK HAZARD<br />

This equipment is designed for connection to a grounded (earthed) outlet.<br />

The grounding type plug is an important safety feature. For continued<br />

protection against electrical shock or damage to the instrument, do not<br />

disable this feature.<br />

Do not apply power to the power supply until ready to operate the analyzer.<br />

Unpacking the <strong>Mercury</strong> <strong>Analyzer</strong><br />

Inspect external packaging upon receipt for signs of shipping damage. Inspect<br />

all items during unpacking and notify the carrier immediately of any concealed<br />

damage.<br />

If the system is shipped or removed from storage during cold weather, allow<br />

the packaged equipment to equilibrate to room temperature before opening<br />

and exposing to warm, humid air. It is usually sufficient to provide four to eight<br />

hours for this purpose.<br />

CAUTION<br />

EQUIPMENT DAMAGE FROM CONDENSATION<br />

If condensation forms on or inside the analyzer, allow it to dry thoroughly before<br />

connecting it to a power source and operating it. Failure to do so may cause<br />

equipment damage.<br />

1 Remove the packing checklist from the shipping container, and check off items<br />

against it. Leave accessories in the packing until you are ready to install them.<br />

NOTE<br />

Keep the factory packaging for use in case the product ever needs to be<br />

returned or shipped to another location.<br />

2 Open the box which contains the M-<strong>7600</strong>.<br />

21

Operator’s <strong>Manual</strong><br />

Chapter 2: Preparing for Installation<br />

3 Remove the upper piece of foam.<br />

Figure 2-5<br />

Opening the Box and Removing the Packaging.<br />

4 Ask an assistant to help you lift the M-<strong>7600</strong> from the box.<br />

WARNING<br />

LIFTING HAZARD<br />

Two people are required to lift the M-<strong>7600</strong> when it is in an awkward<br />

position such as in its box. Lifting should be done with a person situated on<br />

either end of the instrument.<br />

Figure 2-6<br />

Lifting the M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong>.<br />

22

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 2: Preparing for Installation<br />

5 Remove the piece of foam from inside the door of the M-<strong>7600</strong>.<br />

Figure 2-7<br />

Removing Foam from the Door.<br />

6 Store the packaging in case you need to ship the mercury analyzer in the<br />

future.<br />

23

Operator’s <strong>Manual</strong><br />

Chapter 2: Preparing for Installation<br />

This page is intentionally blank.<br />

24

3 Installing the <strong>Analyzer</strong><br />

Installation Overview<br />

Figure 3-1<br />

Front View of QuickTrace M-<strong>7600</strong> with Autosampler.<br />

Figure 3-2<br />

Rear View of QuickTrace M-<strong>7600</strong> with Autosampler.<br />

25

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

Step 1: Position the <strong>Mercury</strong> <strong>Analyzer</strong> and<br />

Autosampler<br />

1 Position the mercury analyzer.<br />

Keep in mind the factors listed in “Choosing a Location” on page 18. You will<br />

need easy access to the back of the analyzer as you make the connections.<br />

2 Place the autosampler next to the QuickTrace M-<strong>7600</strong> mercury analyzer.<br />

Leave a 1-centimeter gap so that vibration from the autosampler will not be<br />

transmitted directly to the mercury analyzer, and to facilitate passage of<br />

tubing.<br />

Step 2: Connect the Autosampler Peristaltic Pump to<br />

the Rinse Station<br />

It is easiest to connect the rinse station tubing to the autosampler's built-in<br />

peristaltic pump before other cables and tubing get in the way.<br />

In most cases, rinse solution will be “recycled” by returning it to the rinse<br />

solution bottle. If necessary, rinse solution can be pulled from a fresh bottle<br />

and used solution returned to a waste container.<br />

Note that rinse solution flows up through the rinse station.<br />

Rinse Drain Port<br />

Rinse Intake Port<br />

Figure 3-3<br />

Autosampler Rinse Station.<br />

26

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

1 The tubing from the output of the pump to the rinse station intake port is preconnected<br />

at the factory.<br />

Figure 3-4<br />

Pump Output to Rinse Intake Port.<br />

2 Locate in the completion kit the 6 mm (¼") OD Tygon ® tubing. The tubing will<br />

need to be cut to the appropriate lengths.<br />

3 Cut a 38 cm (15") length of tubing. This will run between the drain port of the<br />

rinse station and the rinse input of the peristaltic pump.<br />

4 Connect one end to the input of the outer pump channel.<br />

The pump rotates counterclockwise, so the inputs are on the top and the<br />

outputs are on the bottom.<br />

Figure 3-5<br />

Pump Input Connection from Rinse Drain.<br />

27

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

5 Connect the other end to the drain of the rinse station.<br />

Remove the rinse station and press the tubing very firmly so that it completely<br />

covers the barb of the fitting. It helps to use your other hand to apply counterpressure.<br />

Figure 3-6<br />

Rinse Station Drain Connection.<br />

Figure 3-7<br />

Replacing the Rinse Station.<br />

28

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

Figure 3-8<br />

Rinse Station in Place.<br />

6 Cut an approximately 102 cm (40 inch) length of tubing to connect the input of<br />

the pump to the bottle of rinse solution. The tubing should be long enough to<br />

reach the bottom of the rinse bottle. This tube will draw rinse solution from<br />

the bottle.<br />

7 Connect one end of this tube to the remaining input channel of the pump.<br />

Figure 3-9<br />

Pump Input Connection.<br />

29

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

8 Cut an approximately 86 cm (34 inch) length of tubing to extend from the<br />

remaining pump output to the bottle of rinse solution. The tubing should<br />

extend a few inches inside the rinse bottle, but should remain above the liquid<br />

surface. This is the rinse solution drain tube.<br />

Figure 3-10<br />

Pump Output Connection and Liquid Flow Direction.<br />

WARNING<br />

SHOCK HAZARD<br />

In the steps which follow, pay attention to keep the tubing below all of the<br />

wires. Move the tubing, if necessary, so that any leaking liquid will not be<br />

directed onto electrical cables or connectors.<br />

Step 3: Set Up the Autosampler<br />

WARNING<br />

Ensure the power cord is not connected before proceeding with<br />

installation.<br />

See the Autosampler Operator’s <strong>Manual</strong>, included on the CD, for additional<br />

instructions and safety information. You may also refer to the printed Z-Drive<br />

Assembly Quick Installation Guide which comes with the autosampler for more<br />

information on installing the Z-drive assembly.<br />

30

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

The Z-drive is driven by a length of cable (line) which is made of solid Nylon<br />

101 (or in some cases, PEEK.)<br />

CAUTION<br />

Do not allow the cable to bend sharply. Avoid pushing up on the slider or pushing<br />

on the Z-drive cable.<br />

CAUTION<br />

Do not tighten the thumbscrews with anything other than your fingers.<br />

1 Locate the Z-drive assembly.<br />

Sleeve (Protects<br />

Z-Drive Cable)<br />

Sample Tube<br />

Z-Axis Slider<br />

Guide Block<br />

Y-Axis Slider<br />

Z-Drive Cable<br />

Sample Probe<br />

Home flag<br />

Figure 3-11 Z-Drive Assembly (Appearance May Vary Slightly Depending on<br />

Autosampler Model).<br />

2 Slide the Z-drive assembly onto the autosampler arm.<br />

Figure 3-12 Sliding the Z-Drive Onto the Arm of the Autosampler.<br />

31

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

3 Slide the Z-drive assembly onto the Y-axis leadscrew nut (the black block<br />

which moves back and forth along the arm). Lift the bushings with your<br />

fingernails to get them over the edge of the leadscrew nut.<br />

Figure 3-13 Lifting the Bushings Over the Edge of the Leadscrew Nut.<br />

4 Secure the Z-drive assembly to the Y-axis leadscrew nut by tightening the<br />

thumbscrews with your fingers. Never use tools to tighten the thumbscrews.<br />

Figure 3-14<br />

Tightening the Thumbscrews.<br />

32

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

5 Slide the cable onto the rotor on the back of the autosampler (Figure 6).<br />

Figure 3-15 Sliding Z-Drive Cable into Rotor Groove.<br />

6 Secure the guide block to the back of the autosampler with 2 black-capped<br />

thumbscrews (Figure 7). Note that it is important to install the guide block in<br />

the correct orientation.<br />

Figure 3-16 Securing Block to Back of Autosampler.<br />

33

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

7 Turn the rotor clockwise as far as it will go. This will raise the Z-drive to its<br />

highest position. (To avoid damaging the drive cable, always raise or lower the<br />

Z-drive by moving the rotor, rather than by pushing or pulling on the Z-drive<br />

itself.)<br />

Rotor Pin<br />

Stator Stop<br />

Figure 3-17<br />

View of Rotor with Z-Drive at Highest Position.<br />

8 Gently move the Z-axis slider until the gap between the slider and cap is<br />

approximately 2 mm (3/32").<br />

With the Z-drive in its highest position, there should be a gap between the Z-<br />

axis slider and the top cap of the Z-drive of approximately 2 mm (~ 3/32 inch).<br />

If this is not the case, see the Autosampler <strong>Operator's</strong> <strong>Manual</strong> for instructions<br />

on how to adjust the Z-drive travel.<br />

2 mm (3/32”)<br />

Figure 3-18<br />

View of Gap Between Probe Bracket and Cap.<br />

34

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

9 Hold the cable flat against the rotor and secure the cable by tightening<br />

thumbscrew on the rotor. Maintain the 2 mm (~ 3/32 inch) gap while the rotor<br />

pin is making contact with the stator stop (full clockwise rotation of rotor).<br />

The thumbscrew should be as tight as possible using just your fingers.<br />

Figure 3-19<br />

Securing Cable to Rotor.<br />

10 Rotate the rotor back and forth to ensure that it moves freely. Ensure that the<br />

full width of the cable is under the clamp.<br />

Clamp<br />

Figure 3-20<br />

Verifying Cable Movement and Cable Clamp.<br />

35

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

11 Insert the clamp into the slot in the Z-drive. Slide the probe into the Z-drive,<br />

through the hole in the clamp, and tighten the clamp with your fingers.<br />

Figure 3-21<br />

Tightening the Clamp Which Holds the Probe to the Z-Drive.<br />

If the clamp doesn't tighten enough to hold the probe in place, reverse the<br />

orientation of the knurled nut:<br />

Threads Visible<br />

Lip Without Threads<br />

Hole for Sample Probe<br />

Figure 3-22<br />

Clamp Oriented Correctly.<br />

12 Loosen the clamp and adjust the position of the probe so that it is about 2 mm<br />

(3/32 inch) above the top of the rinse station when the Z-drive is in its highest<br />

position.<br />

You can use a large coin, such as a U.S. quarter, to help measure this gap. The<br />

exact distance is not critical, but the probe needs to be high enough that it will<br />

not hit anything when it moves from place to place.<br />

36

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

2 mm<br />

Figure 3-23<br />

Probe Position with Z-Drive in Highest Position.<br />

13 Center the probe over the rinse station and rotate the rotor counterclockwise<br />

to lower the probe into the rinse station.<br />

14 Use the provided spiral wrap to secure the sample tube to the Z-drive cable<br />

about 5 cm (2 inches) above the top of the Z-drive. There should be just a little<br />

curve to the free sample tube when the probe is lowered, and a loop when the<br />

probe is raised.<br />

The sample tube should naturally curve away from the probe so that it won't<br />

rub or get caught. If necessary, loosen the probe and rotate it so that the<br />

sample tube looks like the pictures below:<br />

Spiral Wrap<br />

Slight Curve<br />

Away from<br />

Probe<br />

Loop<br />

Figure 3-24<br />

Securing the Sample Tube.<br />

37

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

15 Use the other spiral wrap to secure the sample tube to the cable at its highest<br />

point.<br />

Figure 3-25<br />

Securing the Sample Tube.<br />

16 Moisten a Kimwipes ® wiper with 10% HNO 3 and wipe the probe to remove any<br />

oil. This is needed so that aqueous samples do not adhere to the probe causing<br />

sample-to-sample contamination or rinse contamination.<br />

17 The Z-drive assembly and sample probe are now properly installed on the<br />

autosampler.<br />

38

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

Step 4: Connect Power and Data Cables to the Back<br />

of the <strong>Mercury</strong> <strong>Analyzer</strong><br />

1 Locate the plastic shipping bag labeled “Completion Kit – QuickTrace M-<br />

<strong>7600</strong>.” It contains various power and data cables, small parts, tubing, fittings,<br />

computer CD-ROM, etc.<br />

You will be locating supplies from in kit for throughout the installation process.<br />

It is recommended to leave the parts in this bag, in their original packaging,<br />

until you need them.<br />

2 Place the autosampler power switch in the OFF position.<br />

3 Place the mercury analyzer power switch in the OFF position.<br />

M-<strong>7600</strong><br />

Power Switch<br />

Figure 3-26<br />

Power Switch<br />

4 Connect the line cord to the connector on the back of the mercury analyzer.<br />

If the cord is not of the correct type for your country, contact <strong>CETAC</strong><br />

Technologies. See “Power Cord Set Requirements” on page 151.<br />

Figure 3-27<br />

Power Cord Connected to <strong>Mercury</strong> <strong>Analyzer</strong><br />

5 Connect the power cord into a grounded surge protected power strip.<br />

6 Plug the surge protected power strip into the AC outlet receptacle.<br />

Do not turn on the power switches yet.<br />

39

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

7 Connect the 5-pin end of the autosampler power cable to the back of the<br />

mercury analyzer.<br />

Figure 3-28<br />

Autosampler Power Cable Connected to <strong>Mercury</strong> <strong>Analyzer</strong>.<br />

8 Plug one end of the Ethernet cable into the mercury analyzer.<br />

Figure 3-29<br />

Ethernet Cable Connected to <strong>Mercury</strong> <strong>Analyzer</strong>.<br />

Step 5: Connect the Carrier Gas Tubing<br />

1 In the completion kit bag, find the brass 2-micron gas filter, with associated<br />

brass Swagelok fittings, and a short section of ETFE tubing (attached to the<br />

filter).<br />

2 Determine how far the QuickTrace M-<strong>7600</strong> is located from the gas supply<br />

(UHP nitrogen or argon). Allow a generous service loop of 1/8" nylon tubing<br />

from the roll provided the likely event of system placement changes or<br />

maintenance. This will allow the system to be slid forward for cell maintenance<br />

without disconnecting the gas tubes.<br />

40

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

3 Connect one end of this tube to the gas inlet side of the 2-micron brass filter<br />

and tighten the Swagelok fitting securely.<br />

Figure 3-30<br />

Completed Assembly of Gas Inlet Tubing with Filter.<br />

NOTE:<br />

A 2-micron in-line filter must always be used. The 2-micron filter has been<br />

selected for minimal pressure drop and minimal flow fluctuation. Do not<br />

substitute other filters.<br />

4 Connect the ETFE tube into the bulkhead fitting labeled “GAS INLET.” Make<br />

sure that the flow arrow on the gas filter is pointing in the direction to the gas<br />

in fitting.<br />

Tighten the fitting as tight as you can get it using your fingers. (This fitting<br />

needs to be very secure, but do not use pliers to tighten it.)<br />

Figure 3-31<br />

Carrier Gas Inlet Tubing Connected to <strong>Mercury</strong> <strong>Analyzer</strong>.<br />

41

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

5 Connect the other end of the nylon tube to the gas supply regulator, using ¼"<br />

NPT 1/8" Swagelok fitting provided.<br />

CAUTION<br />

Exceeding 825 kPa (120 psig) gas supply pressure to the QuickTrace M-<strong>7600</strong> may<br />

rupture the bulkhead fittings, causing the unit to malfunction.<br />

CAUTION<br />

Use only “research-grade”, “dry” UHP Nitrogen or Argon. Do not use “welding”<br />

grade gases - these may permanently damage the QuickTrace M-<strong>7600</strong>.<br />

Step 6: Install the <strong>Mercury</strong> Trap (KMnO4)<br />

A tube filled with crystalline potassium permanganate will serve as the<br />

mercury vapor trap. The vapor trap will clean the QuickTrace M-<strong>7600</strong><br />

exhaust vapors, to prevent the release of mercury vapor into the lab<br />

atmosphere.<br />

WARNING<br />

INHALATION HAZARD<br />

Do not operate the mercury analyzer unless the mercury trap is in place<br />

and functioning correctly.<br />

1 In the plastic bag labeled “Completion Kit - QuickTrace M-<strong>7600</strong>,” find the<br />

polyethylene tube with a seven inch (17.8 cm) length of dark Viton ® tubing<br />

attached to one end.<br />

2 Remove one end cap from the polyethylene tubular body. Do NOT remove the<br />

heatshrink wrapped Luer fitting from the end cap.<br />

3 Inspect both end cap interiors to ensure that the ends are lightly plugged with<br />

fine glass wool. If not, lightly pack a small, loose wad of fine glass wool into the<br />

small i.d. section of each cap. Pack enough glass wool to stop the potassium<br />

permanganate from filtering through, but not restrict the gas flow.<br />

4 Put on protective eyewear and gloves.<br />

5 With the glass wool in place, use a powder funnel to fill this tube with dry<br />

crystalline solid potassium permanganate (KMnO 4). While filling, have one end<br />

fully capped, hold the other end straight upward, and use the powder funnel to<br />

guide the KMnO 4 crystals into the tube. Fill to the top, tapping a finger lightly<br />

on the tube to settle the KMnO 4, and finally place the end cap on securely.<br />

WARNING<br />

CHEMICAL BURN HAZARD<br />

Be sure to wear protective eyewear and safety gloves when handling<br />

chemicals.<br />

6 Snap the filled mercury trap into the black holders.<br />

42

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

7 Attach the black Viton ® tube with fitting to the connection labeled “GAS<br />

EXHAUST.”<br />

Figure 3-32<br />

KMnO 4 Absorbent Trap Connected to <strong>Mercury</strong> <strong>Analyzer</strong>.<br />

The mercury vapor trap needs to be cleaned and refilled when the brown color<br />

approaches the open end. This is the formation the MnO 2 as the KMnO 4 is<br />

reduced. The potassium permanganate may last at least one year depending on<br />

frequency of use, except in the unlikely event of a major overflow accident in<br />

the QuickTrace M-<strong>7600</strong>.<br />

NOTE<br />

So long as the KMnO 4 is dry, free flowing (not caked), dark purple crystals, it is<br />

perfectly OK.<br />

WARNING<br />

POISON HAZARD<br />

The mercury vapor trap contains potassium permanganate (KMnO 4 ) and<br />

may contain mercury. Handle and dispose of the used KMnO 4 according to<br />

your laboratory’s procedures and your country’s hazardous waste<br />

regulations.<br />

43

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

Step 7: Connect the Back of the Autosampler<br />

1 Connect one end of the USB cable to the autosampler.<br />

Figure 3-33<br />

USB Cable Connected to Autosampler.<br />

2 Connect the power cable to the autosampler.<br />

This is the cable which was connected in step 7 on page 40. The autosampler<br />

will be powered by the automatic switching power supply within the M-<strong>7600</strong>.<br />

Figure 3-34<br />

Power Cable Connected to Autosampler.<br />

44

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

Step 8: Connect to the Host Computer<br />

The <strong>CETAC</strong> M-<strong>7600</strong> mercury analyzer is controlled by a PC through an<br />

Ethernet connection.<br />

<strong>CETAC</strong> recommends that this PC be equipped with two network cards. One<br />

card is used for communication with your laboratory network, and the other<br />

card is used exclusively for communication with the M-<strong>7600</strong> mercury analyzer.<br />

In most cases, a PC is supplied with the mercury analyzer, and this PC has two<br />

network cards.<br />

NOTE<br />

In most cases, <strong>CETAC</strong> will pre-configure the network cards for your laboratory.<br />

If you were not able to supply the necessary network information to <strong>CETAC</strong>, or<br />

if you will be supplying your own PC, then set up the network cards yourself as<br />

described below. If the PC is already set up, skip to “Step 9: Install the Gas-<br />

Liquid Separator (GLS)” on page 53.<br />

If you wish to use a laptop computer or if you cannot install a secondary<br />

network card, see “Connecting a Laptop Computer to the M-<strong>7600</strong>” on page 52.<br />

The information in this section is also supplied in the <strong>CETAC</strong> M-<strong>7600</strong> <strong>Mercury</strong><br />

<strong>Analyzer</strong> PC Setup Guide which is included with the mercury analyzer.<br />

Summary<br />

Primary NIC<br />

Secondary NIC<br />

Connects to Laboratory network 192.168.0.149 (address of the M-<strong>7600</strong>)<br />

Interface Metric 100 2<br />

Default IP Address Obtain automatically 192.168.0.100 (address of the PC)<br />

Installing a Secondary NIC in Your Own PC<br />

Most PC’s come with a single network interface, but a secondary network<br />

interface card (NIC) can easily be installed in most desktop and tower PCs. To<br />

install the second NIC:<br />

1 Power off the PC.<br />

2 Install secondary network interface card (NIC), following the manufacturer's<br />

instructions.<br />

You will need to set a static IP address for this card, as shown on page 50.<br />

3 Install all of the PC peripherals such as the keyboard, mouse, and monitor.<br />

45

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

Connecting the Communication Cables<br />

Power Cord<br />

Keyboard and<br />

Mouse<br />

Monitor (Cable<br />

Not Shown)<br />

Figure 3-35<br />

PC Before Connection to the M-<strong>7600</strong>.<br />

1 Connect the USB cable from the autosampler to the computer.<br />

2 Connect the Ethernet cable from the mercury analyzer to the computer.<br />

USB to Autosampler<br />

Ethernet to M-<strong>7600</strong><br />

Figure 3-36<br />

PC After Connection to the M-<strong>7600</strong>.<br />

Configuring the Network Metrics<br />

The network metrics for each NIC on the PC must be configured for optimal<br />

communications with the M-<strong>7600</strong> mercury analyzer.<br />

These instructions apply to the Microsoft Windows 7 and Windows XP<br />

operating systems.<br />

46

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

1 Power on the PC.<br />

2 Open the network connection dialog.<br />

WINDOWS 7:<br />

a) Open the Control Panel.<br />

b) Click Network and Internet | View network status and tasks.<br />

Figure 3-37 Network and Internet Settings (Windows 7).<br />

WINDOWS XP:<br />

a) Click Start > Control Panel.<br />

b) Click Network Connections.<br />

You should see two active networks (one for each card.).<br />

3 For each card, click the connection link (circled in red below).<br />

(WINDOWS XP: double-click the connection link.)<br />

Note: The network card connected to the M-<strong>7600</strong> will show No Internet<br />

Access, and probably show up as either an M-<strong>7600</strong> (if preconfigured by<br />

<strong>CETAC</strong>) or otherwise as an unidentified network, as seen in Figure 3-38.<br />

Figure 3-38 Network Connection Dialog for Windows 7.<br />

47

Operator’s <strong>Manual</strong><br />

Chapter 3: Installing the <strong>Analyzer</strong><br />

4 Click Properties.<br />

Figure 3-39<br />

Network Connection Properties Button.<br />

5 Select ‘Internet Protocol Version 4’ and click ‘Properties’.<br />

Figure 3-40<br />

IPv4 Properties Button.<br />

48

<strong>CETAC</strong> QuickTrace M-<strong>7600</strong> <strong>Mercury</strong> <strong>Analyzer</strong><br />