Kemlux II Brochure - Hubbell Industrial Lighting

Kemlux II Brochure - Hubbell Industrial Lighting

Kemlux II Brochure - Hubbell Industrial Lighting

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SPECIFYING HAZARDOUS LIGHTING<br />

Many factors go into specifying hazardous<br />

lighting. Care must be taken in determining<br />

the classification of the hazardous location in<br />

which the fixtures are being installed. Any<br />

qualified inspector, underwriter or fire marshall<br />

can help determine a Classification of an<br />

area. The decisions which must be made are:<br />

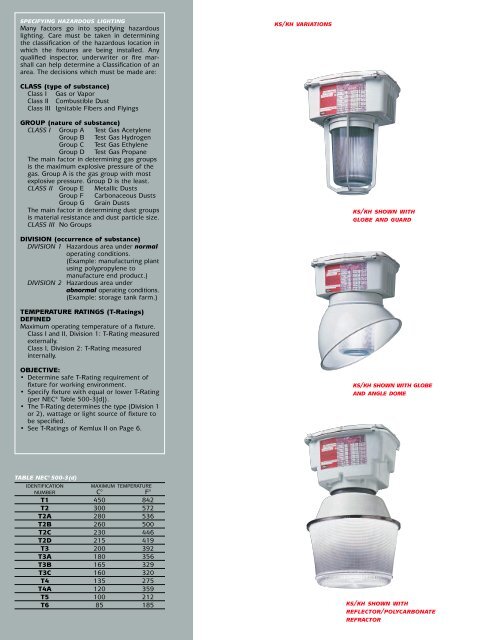

KS/KH VARIATIONS<br />

CLASS (type of substance)<br />

Class I Gas or Vapor<br />

Class <strong>II</strong> Combustible Dust<br />

Class <strong>II</strong>I Ignitable Fibers and Flyings<br />

GROUP (nature of substance)<br />

CLASS I Group A Test Gas Acetylene<br />

Group B Test Gas Hydrogen<br />

Group C Test Gas Ethylene<br />

Group D Test Gas Propane<br />

The main factor in determining gas groups<br />

is the maximum explosive pressure of the<br />

gas. Group A is the gas group with most<br />

explosive pressure. Group D is the least.<br />

CLASS <strong>II</strong> Group E Metallic Dusts<br />

Group F Carbonaceous Dusts<br />

Group G Grain Dusts<br />

The main factor in determining dust groups<br />

is material resistance and dust particle size.<br />

CLASS <strong>II</strong>I No Groups<br />

KS/KH SHOWN WITH<br />

GLOBE AND GUARD<br />

DIVISION (occurrence of substance)<br />

DIVISION 1 Hazardous area under normal<br />

operating conditions.<br />

(Example: manufacturing plant<br />

using polypropylene to<br />

manufacture end product.)<br />

DIVISION 2 Hazardous area under<br />

abnormal operating conditions.<br />

(Example: storage tank farm.)<br />

TEMPERATURE RATINGS (T-Ratings)<br />

DEFINED<br />

Maximum operating temperature of a fixture.<br />

Class I and <strong>II</strong>, Division 1: T-Rating measured<br />

externally.<br />

Class I, Division 2: T-Rating measured<br />

internally.<br />

OBJECTIVE:<br />

• Determine safe T-Rating requirement of<br />

fixture for working environment.<br />

• Specify fixture with equal or lower T-Rating<br />

(per NEC ® Table 500-3[d]).<br />

• The T-Rating determines the type (Division 1<br />

or 2), wattage or light source of fixture to<br />

be specified.<br />

• See T-Ratings of <strong>Kemlux</strong> <strong>II</strong> on Page 6.<br />

KS/KH SHOWN WITH GLOBE<br />

AND ANGLE DOME<br />

TABLE NEC ® 500-3(d)<br />

IDENTIFICATION<br />

MAXIMUM TEMPERATURE<br />

NUMBER C° F°<br />

T1 450 842<br />

T2 300 572<br />

T2A 280 536<br />

T2B 260 500<br />

T2C 230 446<br />

T2D 215 419<br />

T3 200 392<br />

T3A 180 356<br />

T3B 165 329<br />

T3C 160 320<br />

T4 135 275<br />

T4A 120 359<br />

T5 100 212<br />

T6 85 185<br />

KS/KH SHOWN WITH<br />

REFLECTOR/POLYCARBONATE<br />

REFRACTOR