Baronet/HW 110V and 220V Electric Projection Screen ... - Draper, Inc.

Baronet/HW 110V and 220V Electric Projection Screen ... - Draper, Inc.

Baronet/HW 110V and 220V Electric Projection Screen ... - Draper, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Installation/Operating Instructions<br />

<strong>Baronet</strong>/<strong>HW</strong> <strong>110V</strong> <strong>and</strong> <strong>220V</strong> <strong>Electric</strong> <strong>Projection</strong> <strong>Screen</strong> by <strong>Draper</strong><br />

These Installation/Operating Instructions are available in the official language<br />

of the country where you purchase the product. Please contact your<br />

distributor to request a copy.<br />

Vous pourriez dem<strong>and</strong>er les instructions d’installation et d’opération traduises<br />

dans la langue officielle du pays ou vous achetez le produit. Veuillez<br />

dem<strong>and</strong>er à votre distributeur.<br />

Die Gebrauchsanweisung für Installation und Konstruktion sind in der<br />

offiziellen Sprache des L<strong>and</strong>es, indem Sie das Produkt gekauft haben,<br />

vorh<strong>and</strong>en. Fragen Sie die jeweilige Verkaufs-Abteilung.<br />

Caution<br />

Read instructions through completely before proceeding.<br />

Follow instructions carefully. Installation contrary to instructions invalidates<br />

warranty.<br />

<strong>Screen</strong> should be accessible for complete removal should fabric become<br />

damaged or should other service be required.<br />

<strong>Screen</strong> should be installed level (using a carpenter’s level).<br />

Nothing should be fastened to screen dowel or viewing surface.<br />

Operating switch(es) packed separately in screen carton. Do not discard<br />

with packing material.<br />

<strong>Screen</strong> operates on 110-120V AC, 60 Hz. or <strong>220V</strong> AC, 50 Hz. or 60 Hz.<br />

current, depending on model ordered.<br />

NOTE: <strong>Screen</strong> has been thoroughly inspected <strong>and</strong> tested at factory <strong>and</strong><br />

found to be operating properly prior to shipment.<br />

Hanging <strong>Screen</strong><br />

General:<br />

When locating viewing surface <strong>and</strong> checking clearance for screen’s operation,<br />

remember surface is centered in case. H<strong>and</strong>le case carefully to protect<br />

its finish.<br />

Regardless of mounting method, screen should be positively <strong>and</strong> securely<br />

supported so that vibration or even abusive pulling on the viewing surface will<br />

not cause case to work loose or fall. Installer must insure that fasteners used<br />

are of adequate strength <strong>and</strong> suitable for mounting surface chosen.<br />

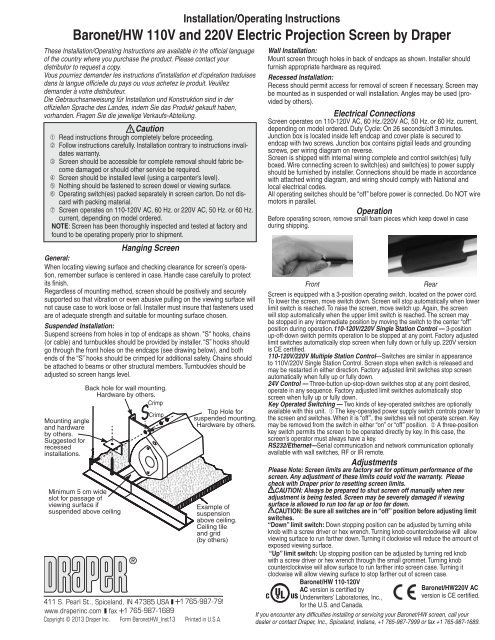

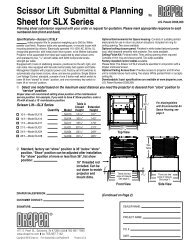

Suspended Installation:<br />

Suspend screens from holes in top of endcaps as shown. "S" hooks, chains<br />

(or cable) <strong>and</strong> turnbuckles should be provided by installer. “S” hooks should<br />

go through the front holes on the endcaps (see drawing below), <strong>and</strong> both<br />

ends of the “S” hooks should be crimped for additional safety. Chains should<br />

be attached to beams or other structural members. Turnbuckles should be<br />

adjusted so screen hangs level.<br />

Mounting angle<br />

<strong>and</strong> hardware<br />

by others.<br />

Suggested for<br />

recessed<br />

installations.<br />

Back hole for wall mounting.<br />

Hardware by others.<br />

Crimp<br />

Minimum 5 cm wide<br />

slot for passage of<br />

viewing surface if<br />

suspended above ceiling<br />

®<br />

Crimp<br />

Example of<br />

suspension<br />

above ceiling.<br />

Ceiling tile<br />

<strong>and</strong> grid<br />

(by others)<br />

Copyright © 2013 <strong>Draper</strong> <strong>Inc</strong>. Form <strong>Baronet</strong><strong>HW</strong>_Inst13 Printed in U.S.A.<br />

Top Hole for<br />

suspended mounting.<br />

Hardware by others.<br />

Wall Installation:<br />

Mount screen through holes in back of endcaps as shown. Installer should<br />

furnish appropriate hardware as required.<br />

Recessed Installation:<br />

Recess should permit access for removal of screen if necessary. <strong>Screen</strong> may<br />

be mounted as in suspended or wall installation. Angles may be used (provided<br />

by others).<br />

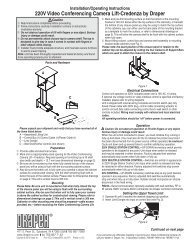

<strong>Electric</strong>al Connections<br />

<strong>Screen</strong> operates on 110-120V AC, 60 Hz./<strong>220V</strong> AC, 50 Hz. or 60 Hz. current,<br />

depending on model ordered. Duty Cycle: On 26 seconds/off 3 minutes.<br />

Junction box is located inside left endcap <strong>and</strong> cover plate is secured to<br />

endcap with two screws. Junction box contains pigtail leads <strong>and</strong> grounding<br />

screws, per wiring diagram on reverse.<br />

<strong>Screen</strong> is shipped with internal wiring complete <strong>and</strong> control switch(es) fully<br />

boxed. Wire connecting screen to switch(es) <strong>and</strong> switch(es) to power supply<br />

should be furnished by installer. Connections should be made in accordance<br />

with attached wiring diagram, <strong>and</strong> wiring should comply with National <strong>and</strong><br />

local electrical codes.<br />

All operating switches should be “off” before power is connected. Do NOT wire<br />

motors in parallel.<br />

Operation<br />

Before operating screen, remove small foam pieces which keep dowel in case<br />

during shipping.<br />

Front<br />

<strong>Screen</strong> is equipped with a 3-position operating switch, located on the power cord.<br />

To lower the screen, move switch down. <strong>Screen</strong> will stop automatically when lower<br />

limit switch is reached. To raise the screen, move switch up. Again, the screen<br />

will stop automatically when the upper limit switch is reached. The screen may<br />

be stopped in any intermediate position by moving the switch to the center “off”<br />

position during operation.110-120V/<strong>220V</strong> Single Station Control — 3-position<br />

up-off-down switch permits operation to be stopped at any point. Factory adjusted<br />

limit switches automatically stop screen when fully down or fully up. <strong>220V</strong> version<br />

is CE certified.<br />

110-120V/<strong>220V</strong> Multiple Station Control—Switches are similar in appearance<br />

to <strong>110V</strong>/<strong>220V</strong> Single Station Control. <strong>Screen</strong> stops when switch is released <strong>and</strong><br />

may be restarted in either direction. Factory adjusted limit switches stop screen<br />

automatically when fully up or fully down.<br />

24V Control — Three-button up-stop-down switches stop at any point desired,<br />

operate in any sequence. Factory adjusted limit switches automatically stop<br />

screen when fully up or fully down.<br />

Key Operated Switching — Two kinds of key-operated switches are optionally<br />

available with this unit. The key-operated power supply switch controls power to<br />

the screen <strong>and</strong> switches. When it is “off”, the switches will not operate screen. Key<br />

may be removed from the switch in either “on” or “off” position. A three-position<br />

key switch permits the screen to be operated directly by key. In this case, the<br />

screen’s operator must always have a key.<br />

RS232/Ethernet—Serial communication <strong>and</strong> network communication optionally<br />

available with wall switches, RF or IR remote.<br />

Adjustments<br />

Please Note: <strong>Screen</strong> limits are factory set for optimum performance of the<br />

screen. Any adjustment of these limits could void the warranty. Please<br />

check with <strong>Draper</strong> prior to resetting screen limits.<br />

CAUTION: Always be prepared to shut screen off manually when new<br />

adjustment is being tested. <strong>Screen</strong> may be severely damaged if viewing<br />

surface is allowed to run too far up or too far down.<br />

CAUTION: Be sure all switches are in “off” position before adjusting limit<br />

switches.<br />

“Down” limit switch: Down stopping position can be adjusted by turning white<br />

knob with a screw driver or hex wrench. Turning knob counterclockwise will allow<br />

viewing surface to run farther down. Turning it clockwise will reduce the amount of<br />

exposed viewing surface.<br />

“Up” limit switch: Up stopping position can be adjusted by turning red knob<br />

with a screw driver or hex wrench through the small grommet. Turning knob<br />

counterclockwise will allow surface to run farther into screen case. Turning it<br />

clockwise will allow viewing surface to stop farther out of screen case.<br />

<strong>Baronet</strong>/<strong>HW</strong> 110-120V<br />

AC version is certified by<br />

Underwriters’ Laboratories, <strong>Inc</strong>.,<br />

for the U.S. <strong>and</strong> Canada.<br />

Rear<br />

<strong>Baronet</strong>/<strong>HW</strong><strong>220V</strong> AC<br />

version is CE certified.<br />

If you encounter any difficulties installing or servicing your <strong>Baronet</strong>/<strong>HW</strong> screen, call your<br />

dealer or contact <strong>Draper</strong>, <strong>Inc</strong>., Spicel<strong>and</strong>, Indiana, +1 765-987-7999 or fax +1 765-987-1689.

STOP<br />

STOP<br />

<strong>Baronet</strong>/<strong>HW</strong> by <strong>Draper</strong> Page 2 of 2<br />

3¼"<br />

(83 mm)<br />

Case Dimensions<br />

Fabric width + 5¾" (146 mm)<br />

3¾"<br />

96 mm<br />

3¼"<br />

(83 mm)<br />

Viewing<br />

Surface<br />

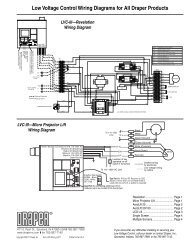

Please Note: Do not wire motors in parallel.<br />

Single Station Control<br />

Junction box at<br />

left end of screen<br />

Internal <strong>Screen</strong> Wiring<br />

White (Common)<br />

Black (Down)<br />

Red (Up)<br />

Green (Motor Ground)<br />

Control<br />

switch Single gang box by others<br />

Blue Min. 4" x 2-1/8" x 1-7/8" deep<br />

Red<br />

Black<br />

Dashed wiring<br />

by electrician<br />

Location of key<br />

operated on-off<br />

switch if furnished<br />

To <strong>110V</strong> AC Line<br />

<strong>Baronet</strong>/<strong>HW</strong> <strong>110V</strong> AC<br />

Multiple Station Control<br />

Junction box at<br />

left end of screen<br />

Red<br />

Red<br />

Red<br />

Black<br />

Black<br />

Internal <strong>Screen</strong> Wiring<br />

White (Common)<br />

Black (Down)<br />

Red (Up)<br />

Green (Motor Ground)<br />

Blue<br />

Blue<br />

Blue<br />

Dashed wiring<br />

by electrician<br />

Wiring Diagrams<br />

Cap off with wire<br />

nut <strong>and</strong> tape<br />

Black Single gang box by others<br />

Min. 4" x 2-1/8" x 1-7/8" deep.<br />

3 shown. More or less equally<br />

feasible.<br />

Location of key<br />

operated on-off<br />

switch if furnished<br />

To <strong>110V</strong> AC Line<br />

Low Voltage, IR Remote or RF Remote (LVC-III)<br />

White or Blue-Common to screen & 110/<strong>220V</strong> AC Neutral<br />

Red-to screen (directional)<br />

Brown-to screen (directional)<br />

Yellow-to 110/<strong>220V</strong> AC-Hot<br />

Black-to 110/<strong>220V</strong> AC-Hot<br />

Green/Yellow (Ground)<br />

Dashed wiring by electrician<br />

Low voltage wiring by others<br />

Eye Port for IR Eye, RF Receiver or LED<br />

Wall Switch. For more than one of<br />

these, a splitter is required.<br />

3 Button Wall Switch<br />

DOWN - Black<br />

COM - White<br />

UP - Red<br />

Aux Port for connecting additional LVC-III<br />

modules (up to six total can be linkedconnect<br />

from Aux to Eye).<br />

110-120V 3-Position Wall Switch<br />

7 mm (2 3/4")<br />

Control<br />

Switches<br />

24v DC<br />

Internal <strong>Screen</strong> Wiring<br />

White/Blue (Common)<br />

Red 110/Black 220 (Up)<br />

Black 110/Brown 220 (Down)<br />

Green/Yellow<br />

(Motor Ground)<br />

To<br />

110/<strong>220V</strong><br />

Line<br />

Location of key<br />

operated on-off<br />

switch if furnished<br />

Control<br />

switch<br />

Dashed wiring<br />

by installer<br />

<strong>Baronet</strong>/<strong>HW</strong> <strong>220V</strong> AC (CE)<br />

Single Station Control<br />

Junction box at CE Approved<br />

left end of screen<br />

Internal <strong>Screen</strong> Wiring<br />

Blue-220v (Common)<br />

Brown-220v (Down)<br />

Black-220v (Up)<br />

Green/Yellow (Motor Ground)<br />

Neutral<br />

L1<br />

220v,<br />

50 Hz.<br />

or 60 Hz.<br />

Junction box at<br />

left end of screen<br />

Neutral<br />

Hot<br />

Multiple Station Control<br />

Not CE Approved<br />

Red<br />

Black<br />

Red<br />

Black<br />

Red<br />

220v, 50 Hz. or 60 Hz.<br />

MC1<br />

Black<br />

Internal <strong>Screen</strong> Wiring<br />

Blue-220v (Common)<br />

Brown-220v (Down)<br />

Black-220v (Up)<br />

Green/Yellow (Motor Ground)<br />

Cap off with wire<br />

nut & tape<br />

Blue<br />

Blue<br />

Blue<br />

Dashed wiring<br />

by installer<br />

See separate Serial Communication-RS232 Instruction sheet for<br />

enabling RS232 with the MC1.<br />

Fuse<br />

Program LED<br />

MC1<br />

White or Blue-Common<br />

Red-to <strong>Screen</strong> (directional)<br />

Black-to <strong>Screen</strong> (directional)<br />

Brown-Hot to AC<br />

Green/Yellow-Ground<br />

Low Voltage Wiring by others<br />

AC Wiring by electrician<br />

RS232 Data FROM Control System<br />

RS232 Data TO Control System<br />

Signal Ground & Manual Switch Common<br />

Manual Switch Down<br />

Manual Switch Up<br />

Eye Port for IR Eye. For RF Receiver or LED<br />

Wall Switch, a Splitter <strong>and</strong> a Power Supply<br />

is required. Plug RF Receiver or LED Wall<br />

Switch <strong>and</strong> Power Supply into splitter, then<br />

run cable from Splitter to MC1 Eye Port.<br />

To AC Line<br />

Internal <strong>Screen</strong> Wiring<br />

White/Blue (Common)<br />

Red 110/Black 220 (Up)<br />

Black 110/Brown 220 (Down)<br />

Green <strong>110V</strong>/<br />

Green/Yellow <strong>220V</strong><br />

(Motor Ground)<br />

Location of key<br />

operated on-off<br />

switch if furnished<br />

<strong>220V</strong> 3-Position, Surface Mount Wall Switch<br />

3.8 cm (1 1/2")<br />

3.5 cm (1 3/4")<br />

3.2 cm (1 1/4")<br />

UP<br />

3"-6" leads<br />

11.8 mm<br />

(4 1/2")<br />

8.6 cm<br />

(3 3/8")<br />

7.8 cm<br />

(3 1/16")<br />

DOWN<br />

www.draperinc.com (765) 987-7999