VPI HIGH VOLTAGE - Von Roll

VPI HIGH VOLTAGE - Von Roll

VPI HIGH VOLTAGE - Von Roll

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

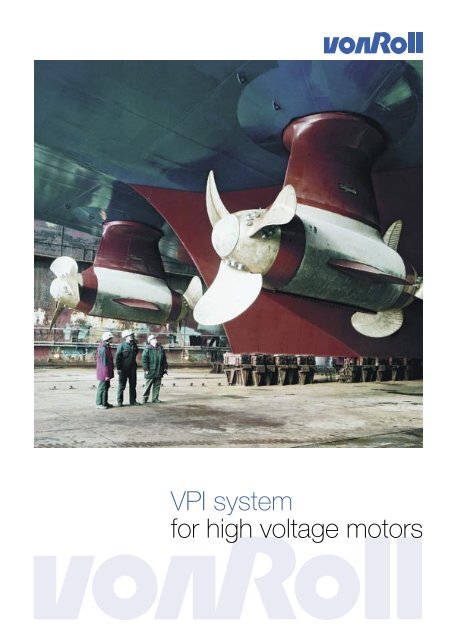

<strong>VPI</strong> system<br />

for high voltage motors

Introduction<br />

<strong>Von</strong> <strong>Roll</strong> is strongly committed to developing materials and processes used in<br />

insulating state-of-the-art electrical high-voltage motors as well as small generators<br />

with equivalent design. We are aware of our customers’ continuously increasing<br />

demand for higher performance and reliability together with low manufacturing<br />

costs.<br />

<strong>Von</strong> <strong>Roll</strong> provides a wide range of process equipment and materials to fi t the<br />

exact requirements of high-voltage motors using both resin-rich (RR) or vacuum<br />

pressure impregnation (<strong>VPI</strong>) technologies.<br />

Insulation materials for high voltage motors<br />

Many different materials are used in constructing a high-voltage coil or bar:<br />

WINDING WIRE (A)<br />

CONDUCTOR INSULATION (B)<br />

STACK CONSOLIDATION (C)<br />

MAIN WALL INSULATION : MICA TAPE (D) + <strong>VPI</strong> RESIN (H)<br />

CONDUCTIVE PAINT OR TAPE (F)<br />

STRESS GRADING PAINT OR TAPE (F)<br />

FINISHING OR SEALING TAPES (E)<br />

BRACING MATERIALS (G)<br />

SLOT WEDGING MATERIALS (I)<br />

Customers enjoy the following advantages:<br />

• Single source for all components<br />

• Proven compatibility for system components<br />

• Testing at <strong>Von</strong> <strong>Roll</strong> for both components and systems<br />

• Single source for technical support<br />

In this document we propose a variety of insulating materials and process<br />

equipment for large generators. The selection is by no means exhaustive. Please<br />

do not hesitate to contact our technicians for further details.

Conductors<br />

For conductors of high voltage coils, <strong>Von</strong> <strong>Roll</strong> offers a complete range of<br />

products:<br />

• Covered wires with impregnated Glass yarn (Silix ® )<br />

• Covered wires with mixed Glass/Polyester yarn (Daglas),<br />

impregnated or not<br />

• Samicafilm-tape covered wires<br />

Samicafilm tape covering on bare or enamelled wires is the preferred conductor<br />

insulation for stator coils due to its large advantages:<br />

• Better corona resistance<br />

• Reduced insulation thickness<br />

• Softer copper enabling an easier workability<br />

• Greater manufacturing flexibility<br />

Samicafilm products are based on <strong>Von</strong> <strong>Roll</strong> Samica ® mica paper impregnated<br />

with modified epoxy resin, reinforced with one or two polyester film backings and<br />

with or without adhesive coating.<br />

Product name<br />

Rated voltage (KV)<br />

13.8<br />

Thickness<br />

(mm)<br />

Weight<br />

(gr/m 2 )<br />

Mica<br />

(gr/m 2 )<br />

Composition<br />

Adhesive<br />

Samicafilm ® F60+ ■ ■ ■ 0.06 76 30 Film / Mica yes<br />

Samicafilm ® F75 ■ ■ ■ 0.075 101 50 Film / Mica no<br />

Samicafilm ® 315.14 ■ ■ ■ 0.09 131 75 Film / Mica no<br />

Samicafilm ® 315.15-11 ■ ■ ■ 0.09 135 75 Film / Mica yes<br />

Samicafilm ® F2 90 ■ ■ ■ 0.09 124 65 Film / Mica / Film no<br />

Samicafilm ® F2 90+ ■ ■ ■ 0.09 126 65 Film / Mica / Film yes<br />

Samicafilm ® tapes are applied butt-lapped or overlapped to the conductor.<br />

<strong>Von</strong> <strong>Roll</strong> supplies both tape and taped conductors to its customers.<br />

Product name<br />

On bare wire<br />

Insulation design<br />

Rated voltage (KV)<br />

Thickness<br />

13.8 unpressed pressed<br />

Adhesive<br />

Samicafilm ® 315.14 2 butt lapped layers ■ 0.36 0.30 no<br />

Samicafilm ® 315.15-11 2 butt lapped layers ■ 0.36 0.30 yes<br />

Samicafilm ® F2 90 3 butt lapped layers ■ ■ 0.54 0.43 no<br />

Samicafilm ® F2 90+ 3 butt lapped layers ■ ■ 0.54 0.43 yes<br />

On enamelled copper grade 2<br />

Samicafilm ® F2 90 1 1/2 lapped layer ■ ■ ■ 0.50 0.43 no<br />

Samicafilm ® F2 90+ 1 1/2 lapped layer ■ ■ ■ 0.50 0.43 yes

The following products in the classical range are used for high-voltage motors.<br />

Product name<br />

Rated voltage (kV)<br />

13.8<br />

Dimensions<br />

Description<br />

Silix ® on bare wire ■ on request Glass lapped wire with or without B-stage overcoat<br />

Silix ® on enamelled wire ■ ■ ■ on request<br />

Daglas on bare wire ■ on request Daglas lapped wire with or without B-stage overcoat<br />

Daglas on enamelled wire ■ ■ ■ on request<br />

VS 220 / VS 240 ■ ■ ■ on request<br />

Polyamide-imide or Polyimide enamelled flat copper<br />

wire insulated with impregnated glass yarns<br />

Yarn coverings are impregnated with varnishes based on epoxy, polyester-imide,<br />

polyamide-imide, silicone or polyimide resins, depending on the thermal class<br />

required. Special “B-stage” varnishes are also available for the conductor stack<br />

consolidation.<br />

<strong>Von</strong> <strong>Roll</strong> offers a wide variety of dimensions to meet<br />

customer needs.

Coil production<br />

<strong>Von</strong> <strong>Roll</strong> is heavily involved in every aspect of high-voltage technology, including<br />

process equipment. For high-voltage motors <strong>Von</strong> <strong>Roll</strong> M Tec has developed a line<br />

of coil-producing machines that use flat-coil technology. This line of equipment<br />

includes the following units:<br />

• Wire dispensing and preparation<br />

• Loop winding<br />

• Taping<br />

• Coil forming<br />

Coil forming machine produced by Vincent Industries<br />

Stack consolidation<br />

Depending on the system, stack consolidation may be included.<br />

Employing Samicafilm with a hot-melt adhesive or glass lapped wires in B-stage<br />

enables rapid consolidation of conductor stacks without the need for additional<br />

consolidation products.<br />

When using Samicafilm without hot-melt adhesive or non-B-stage wires, traditional<br />

hot-press consolidation is preferred. This system can be achieved by overlapping<br />

the stack with Thermopreg 251.78.<br />

<strong>Von</strong> <strong>Roll</strong> standard materials for stack consolidation:<br />

Product name<br />

Form<br />

Rated voltage (KV)<br />

13.8<br />

Thickness<br />

mm<br />

Description<br />

Thermopreg 251.78 Tape ■ ■ ■ 0.1 Impregnated glass cloth<br />

Glass fleece 101.74-07 Tape ■ ■ ■ 0.56 Non impregnated polyester fleece<br />

Glasoflex 261.10-03 Tape ■ ■ ■ 0.5<br />

Damival 15182 / 9030 Resin ■ ■ ■<br />

Impregnated glass fleece with high<br />

resin content<br />

Solventless 2 component epoxy<br />

resin

Main wall insulation<br />

<strong>Von</strong> <strong>Roll</strong> recognizes the problems associated with improving the quality and cost<br />

effectiveness of high-voltage insulation. With Samicapor ® , <strong>Von</strong> <strong>Roll</strong> has developed<br />

a range of vacuum pressure impregnation (<strong>VPI</strong>) mica tapes that satisfy the<br />

requirements of main wall and end-winding insulation, namely:<br />

• High dielectric strength<br />

• Corona discharge resistance<br />

• Fast and easy impregnation<br />

• Resin retention without draining<br />

• Smooth application without creasing<br />

• Both manual and fast-running machine application<br />

• Full compatibility with predefined resin systems<br />

Product name<br />

Rated voltage (KV)<br />

13.8<br />

Thickness<br />

(mm)<br />

Weight<br />

(gr/m 2 )<br />

Mica<br />

(gr/m 2 )<br />

Composition<br />

Resin compatibility and thermal class<br />

Non accelerated<br />

epoxyanhydride<br />

Accelerated<br />

Epoxy <strong>VPI</strong><br />

systems<br />

Polyesterimide<br />

Samicabond<br />

System<br />

Samicapor ®<br />

366.55-10<br />

Samicapor ®<br />

366.58<br />

Samicapor ®<br />

366.58-18<br />

Samicapor ®<br />

366.58-20<br />

Samicapor ®<br />

374.04<br />

Samicapor ®<br />

374.15<br />

Samicapor ® P<br />

315.33<br />

Samicapor ® P<br />

315.45<br />

■ ■ ■ 0.15 200 160 Glass / Mica F<br />

■ ■ ■ 0.15 195 160 Glass / Mica F H<br />

■ ■ ■ 0.15 213 180 Glass / Mica F H<br />

■ ■ ■ 0.17 224 180 Glass / Mica F H<br />

■ 0.18 241 160<br />

■ 0.18 241 160<br />

Glass / Mica /<br />

Fleece<br />

Glass / Mica /<br />

Fleece<br />

■ ■ 0.14 214 160 PET / Mica F<br />

■ ■ 0.14 214 160 PET / Mica F H<br />

F<br />

F<br />

F<br />

<strong>Von</strong> <strong>Roll</strong> has a total commitment to mica<br />

Careful and optimum application of Samicapor ® tapes can be obtained using<br />

<strong>Von</strong> <strong>Roll</strong> M Tec taping machines.<br />

Taping machine by our partner Micamation

Corona protection<br />

All high-voltage machines require electrical stress control measures.<br />

<strong>Von</strong> <strong>Roll</strong> has developed a number of products under the trade name CoronaShield ®<br />

namely:<br />

• Conductive tapes<br />

• Semi-conductive tapes<br />

• Conductive mastics<br />

• Conductive varnishes<br />

• Conductive tapes with Nomex ® technology<br />

These tapes can all be used for:<br />

• Internal corona protection (IGS) - in the conductor stack<br />

• External corona protection (AGS) - within the slot<br />

• End corona protection (EGS) - at the slot end<br />

Product name<br />

Form<br />

Rated voltage (KV)<br />

6 to 13.8 >13.8<br />

Thickness<br />

(mm)<br />

Resistivity<br />

(Ohm Sq)<br />

Description<br />

Conductive tape<br />

215.51<br />

Conductive tape<br />

215.55<br />

CoronaShield ®<br />

250 N 125<br />

Semi-Conductive tape<br />

217.01/217.21<br />

Semi-Conductive tape<br />

217.31<br />

Tape ■ ■ 0.1 200-400<br />

Tape ■ ■ 0.085 200-400<br />

Tape ■ ■ 0.125 250<br />

Tape ■ ■ 0.22 Variable<br />

Tape ■ ■ 0.25 Variable<br />

Based on impregnated non woven<br />

polyester fleece. Not compatible with<br />

Epoxy Anhydrid <strong>VPI</strong> resin<br />

Based on impregnated non woven<br />

polyester fleece.<br />

Non impregnated conductive tape with<br />

Nomex technology<br />

B-Stage semi conductive tape with<br />

different characteristics<br />

Fully cured silicone carbide filled resin tape<br />

impregnated in a non woven fabric.<br />

Conductive and semi conductive tapes

Finishing tapes<br />

The mica tapes used in main wall and overhang insulation contain materials that<br />

can easily be damaged and need to be protected against:<br />

• Moisture<br />

• Mechanical load<br />

• Damage<br />

• Resin flow<br />

• Atmospheric pollutants<br />

Product name<br />

Form<br />

Rated voltage (KV)<br />

< 6 6 to 13.8 > 13.8<br />

Thickness<br />

(mm)<br />

Description<br />

Epoflex ® 324.03 Tape ■ ■ ■ 0.09<br />

Polyester glass fabric with a Polyester film and<br />

reduced binder quantity<br />

Winding and bracing of machines<br />

The simplicity of the winding process for machines with «dry» coils is a recognized<br />

benefit of <strong>VPI</strong> technology. Substantial advantages obtain during the end-winding<br />

bracing and support process. <strong>Von</strong> <strong>Roll</strong> has developed a range of ropes, cords,<br />

and sleeves for «surge ring» intercoil lacing<br />

The main benefits of these products are:<br />

• Class C (glass) and F (polyester) applications<br />

• Compressibility and resilience<br />

• Glass or polyester yarn on the outside<br />

• Wide range of dimensions<br />

• Un-impregnated for use with <strong>VPI</strong>; no further processing<br />

• Impregnated polyester shrink cord for use with RR technologies<br />

Product name<br />

Form<br />

Rated voltage (KV)<br />

< 6 6 to 13.8 > 13.8<br />

Thickness<br />

(mm)<br />

Description<br />

Isocord ® 151.10 Cord ■ ■ ■ From 1.8 to 50<br />

Isocord ® 151.12 Cord ■ ■ ■ From 1.5 to 60<br />

Braided silane E glass yarn outside<br />

with staple glass filler<br />

Braided polyester garn outside<br />

with staple glass filler<br />

Glass or glass polyester cords

Composite materials for high-voltage motors<br />

<strong>Von</strong> <strong>Roll</strong> offers a variety of composite materials that can be delivered as<br />

wedges, sheets, machined parts, or special components that are used<br />

in different sections of a high-voltage rotating machine. The following are<br />

just a selection. Please ask our specialists about additional products.<br />

Product name<br />

Form<br />

Rated voltage (KV)<br />

< 6 6 to 13.8 > 13.8<br />

Stator Slot Insulation<br />

Magnetic stator SW<br />

Rotor Slot Wedges<br />

Commutator<br />

Vetronite ® G-11<br />

Delmat ® Epoxy<br />

68660<br />

Delmat ® Polyester<br />

68420<br />

Commutator<br />

Samicanite 41120<br />

Machined component<br />

or full size sheet<br />

Machined component<br />

or full size sheet<br />

Machined component<br />

or full size sheet<br />

Machined component<br />

or full size sheet<br />

■ ■ ■ ■ ■<br />

■ ■ ■ ■ ■<br />

■ ■ ■ ■<br />

■ ■ ■ ■<br />

Mica Rings Part on design ■ ■ ■ ■<br />

Vetroferrite ® 432.20 /<br />

432.21<br />

Machined component ■ ■ ■ ■<br />

<strong>Von</strong> <strong>Roll</strong> makes composite parts to customer specifications and design

<strong>VPI</strong> resins<br />

There are several families of resins with excellent electrical characteristics when<br />

cured. The factors influencing the final choice of resin used are much more<br />

complex. Important considerations are linked to the characteristics of the design<br />

of the machines, the insulating system choice, the taping and <strong>VPI</strong> processes but<br />

also on more basic parameters. Important criteria include:<br />

• Resin thermal class<br />

• Tank stability<br />

• Storage conditions (cooled or ambient temperature)<br />

• Moisture sensitivity<br />

• VOC (Volatile Organic Compound)<br />

• Impregnating Temperature<br />

• Necessity of rotating curing<br />

• Curing Time<br />

• Total processing time<br />

• Compatibility with mica tapes and the other materials<br />

• Rated voltage<br />

• Dielectrical properties<br />

• Mechanical properties<br />

• Thermal conductivity<br />

• Continuous and maximum peak operating temperature<br />

<strong>Von</strong> <strong>Roll</strong> offers a variety of high performance resins:<br />

Product<br />

Type<br />

Thermal<br />

class<br />

Rated voltage (KV)<br />

< 6.6 6.6 to 15 > 15<br />

Impreg.<br />

temp.<br />

Curing<br />

process<br />

Description<br />

Damisol ® 3340<br />

Polyesterimide<br />

(Samicabond)<br />

H ■ 23°C<br />

8h at<br />

150°C<br />

Highly reactive, yet highly stable<br />

room temperature impregnating<br />

resin. Good results on static curing.<br />

Damisol ® 3032<br />

Polyesterimide<br />

(Samicabond)<br />

H ■ 23°C<br />

8h at<br />

140°C<br />

Highly reactive, yet highly stable<br />

room temperature impregnating<br />

resin. Good results on static curing.<br />

Damisol ® 3308<br />

Polyesterimide<br />

(Samicabond)<br />

H ■ ■ 23°C<br />

8h at<br />

140°C<br />

Highly reactive, yet highly stable<br />

room temperature impregnating<br />

resin. Good results on static curing.<br />

Damisol ® 3309<br />

Polyesterimide<br />

(Samicabond)<br />

H ■ ■ 23°C<br />

8h at<br />

150°C<br />

Highly reactive, yet highly stable<br />

room temperature impregnating<br />

resin. Good results on static curing.<br />

Damisol ® 3313<br />

Polyester/<br />

Epoxy<br />

H ■ ■ 23°C<br />

8h at<br />

150°C<br />

High mechanical properties. Good<br />

results on static curing<br />

Damisol ® 3413<br />

Epoxy/<br />

Anhydride 2K<br />

F ■ ■ 23°C<br />

10h at<br />

150°C<br />

Low viscosity 2 K accelerated<br />

epoxy resin with outstanding<br />

mechanical properties.<br />

Permafil ®<br />

74038<br />

Epoxy 1K H ■ ■<br />

23 to<br />

60°C<br />

8h at<br />

160°C<br />

1K epoxy resin without diluent. Very<br />

low organic emission (VOC

Drying and impregnation<br />

The principles of air drying, controlled rate impregnation, pressuring, and curing of<br />

resin are well understood by <strong>VPI</strong> process users and potential users.<br />

Through M Tec, <strong>Von</strong> <strong>Roll</strong> offers <strong>VPI</strong> systems tailored to meet the needs of all<br />

sectors of the rotating machine industry.<br />

For new equipment or upgrading existing plants, M Tec ensures state-of-the-art<br />

<strong>VPI</strong> technology.<br />

Instrumentation for measuring capacitance, essential for in-line quality control of<br />

impregnation, is built into the systems.<br />

Impregnation unit by our partner Meier Prozesstechnik<br />

Finishing coating<br />

The Damicoat ® range of finishing and overcoat varnishes includes air-drying and<br />

oven- curing solutions. They are all single-component for easy processing by<br />

spray, brush, and even dipping and dip-rolling processes<br />

Product Chemistry Colour<br />

Rated voltage (KV)<br />

< 6 6 to 15 15 to 22<br />

Thermal<br />

Class<br />

Drying<br />

Time<br />

Description<br />

Damicoat ®<br />

2404<br />

Damicoat ®<br />

2407<br />

Alky phenol N/RB/G ■ ■ F 15 - 20h<br />

Alkyd<br />

modified<br />

RB ■ ■ F/H 1 - 2h<br />

Highly chemical resistant overcoat<br />

varnish.<br />

High temperature resistant overcoat<br />

varnish, used up to class H of high<br />

voltage and traction machines.

<strong>Von</strong> <strong>Roll</strong> Switzerland Ltd. • CH-4226 BREITENBACH<br />

www.vonroll.com<br />

All information in this document is subject to the product liability clause as published in the Website www.vonroll.com under legal information.