details - The Andrew Yule Group

details - The Andrew Yule Group

details - The Andrew Yule Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

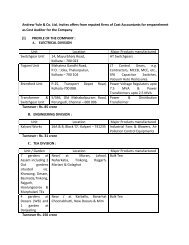

ANDREW YULE & CO. LTD<br />

KARBALLA TEA ESTATE,<br />

TEA DIVISION<br />

P.O. Banarhat, Dist. Jalpaiguri, Pin . 735202.<br />

Sealed Tenders are invited from Contractors located in and around<br />

Jalpaiguri District & having experience in tea garden jobs at Dooars<br />

Gardens, for electrification & commissioning of H.T. 11 KV Overhead line<br />

from Factory to Irrigation Line at Karballa Tea Estate.<br />

Tender form containing <strong>details</strong> of scope of work & other particulars may be<br />

obtained from our web site : www.andrewyule.com<br />

Last date for submission : 26/10/2012<br />

Date & Time of opening<br />

: 27/10/2012 AT 11 A.M.<br />

Application may be addresed to,<br />

Manager,<br />

Karballa Tea Estate<br />

P.O. Banarhat,<br />

Dist. Jalpaiguri,<br />

Pin . 735202.

Tender Form<br />

Anderw <strong>Yule</strong> &Co.Ltd.<br />

KARBALLA TEA ESTATE<br />

PART A page 1 of 1<br />

Karballa Tea Estate requires to draw overhead electrical line for upcoming irrigation<br />

project for its plantation. <strong>The</strong> line has to be drawn from the existing 11 kv line in the<br />

factory compound to the site of irrigation in the field. <strong>The</strong> job is to be inspected at the<br />

garden on any working day (Sunday closed).<br />

<strong>The</strong> Tender Form is bifurcated into two parts. Part- A & Part –B.<br />

<strong>The</strong> 1 st part consists of submitting credentials , technical competence & commercial<br />

terms of the parties. If the credentials, technical competence & commercial terms are<br />

found to be in order then only ‘Part B’ shall be considered where actual rates are to be<br />

given.<br />

Part A & Part B are to be duly filled up & put in two separate envelops superscribed “<br />

Tenders for electrification & commissioning of H.T. 11 KV Overhead line - Part A” &“<br />

Tenders for electrification & commissioning of H.T. 11 KV Overhead line - Part B”.<br />

Both the above envelops should be duly sealed to put in one Single envelop<br />

superscribed “Tender for electrification & commissioning of H.T. 11 KV Overhead line<br />

Part A &B”<br />

Please submit the following <strong>details</strong> .<br />

1. Whether the party has a valid license from electricity authority to work in H.T.<br />

lines - Please mention license number or provide photocopy.<br />

YES/NO<br />

2. Experience in carrying out major H.T. Jobs in reputed Tea Estates in Dooars<br />

(West Bengal). Please provide copy of orders / contracts in support.<br />

YES/NO<br />

3. Numbers of years in business :<br />

4. EMD : Need to be submitted Rs20,000.00 in the form of Demand Draft drawn in<br />

favour of “ <strong>Andrew</strong> <strong>Yule</strong> & Co. Ltd –A/c - Karballa Tea Estate” payable at<br />

Banarhat/Siliguri.<br />

Contd….Pg.2

Commercial<br />

Page 2 of 3<br />

<strong>The</strong> following conditions need to be fulfilled before the applicant is eligible to quote.<br />

(To be filled in by the applicant)<br />

1.Full Postal address of the Firm: __________________________________________<br />

with telephone number<br />

(office, residence & mobile ) _____________________________________________<br />

2.Full Name of the proprietor : ___________________________________________<br />

3. PAN Card Number with photocopy : ____________________________________<br />

4. Bank Account Number & name of the ___________________________________<br />

Bank & address.<br />

(Attach bank certificate regading ___________________________________<br />

Normal operation of your account).<br />

____________________________________<br />

5. a) Please mention VAT registration number ____________________________<br />

b) Please mention CST registration number _____________________________<br />

C) Please mention Service Tax registration number _______________________<br />

(Attach Photocopies in each case)<br />

‣ Terms of Payment<br />

70% on successful commissioning & energisation of the project.<br />

25% within 60 days for the date of energisation. 5% to be released after warranty period<br />

of 1year.<br />

All payment will be made by A/C payee cheque only .<br />

In case of D/D, draft charges to be borne by the party.<br />

‣ Warranty<br />

1 year from the date of energisation against manufacturing defect, poor<br />

workmanship, wiring, fabrication & supply of defective & poor std. of materials.<br />

‣ Electrical Inspector Charges.<br />

<strong>The</strong> project being of Turn key type all the charges related to Electrical Inspection of<br />

central Electrical authority. WBSEDCL visit expenses & all incidental expenses etc are to<br />

be borne by the party.<br />

Contd ….Pg3

Page 3 of 3<br />

Necessary liaison work regarding inspection & obtaining approval from the Central<br />

Electrical Authorities & WBSEDCL will be responsibility of the party.<br />

‣ Unskilled Labour<br />

Unskilled Labour for minimum requirement will be provided by the garden on<br />

approval from garden manager.<br />

‣ Masonry work<br />

Masonry jobs for minimum requirement to be undertaken by the garden.<br />

Free accommodation for your Technicians & others to be provided by the Estate.<br />

<strong>The</strong> entire job has to be completed within 1 month of placing the order.<br />

I agree to accept the above terms & condition.<br />

_______________________<br />

Signature with Office Seal<br />

Date:-<br />

Tender Form : Rs100/- : To be paid in cash while collecting from the garden. In case<br />

of downloads from web-site, it should be paid through Demand Draft to be attached<br />

with this form.<br />

All Demand Drafts to be drawn in favour of “<strong>Andrew</strong> <strong>Yule</strong> & Co. Ltd.-Karballa Tea<br />

Estate”.

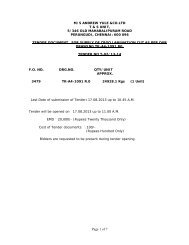

PART B page 1 of 14<br />

<strong>Group</strong> – ‘A’- (i)<br />

Sub : Material for Step-up/ Step-down Sub-station equipments, associated goods<br />

for H.T. Irrigation Job’s from Factory to Section No 16 at your T.E. (45<br />

H.P. x 1 No. Submersible Pump and Booster Motor 50 H.P. x 2 Nos. also<br />

provision for future)<br />

Ser<br />

D E S C R I P T I O N<br />

No<br />

1.a) Supply of 400 Amps. TPN switch fuse unit, type- FN, Make- L & T /<br />

Siemens.<br />

-1 No. ‘M’ @ Rs. ______________ Each<br />

b) Supply of 400 Amps. HRC fuse<br />

- 3 Nos. ‘M’ @ Rs. _____________ Each<br />

c) Supply of Alu. Busbar electrolyte grade, having 400 Amps. capacity,<br />

3 Ph. Neutral, G.I. Bolt, Nut, Washer.<br />

- 1 Set ‘M’ @ Rs. ______________ Each<br />

2.a) Supply of cubicle type, floor mounting MCCB Panel Board having<br />

630 Amps. T.P. MCB with <strong>The</strong>rmal magnate release coil under<br />

voltage release coil, extension operating handle, KWH meter, Amps<br />

& Volts meter, Amps Selector & Volts Selector, C.T. coils, Control<br />

fuses, indicating laps, Busbar, copper wire wiring, fixing<br />

equipments, connection for 400 KVA Step-up Transformer.<br />

- 1 No. (Lot) ‘M’ @ Rs. ________________ Each<br />

b) Supply of cubicle type floor mounting MCCB Panel Board having<br />

400 Amps. T.P. MCCB, 160A. T.P. switch 3 Nos, 125 Amps. HRC<br />

fuse 9 Nos., Busbar supporter, Busbar, Amps. & Volts Meter, Amps<br />

Selector & Volts Selector, C.T. coils, Control fuses, indicating lamps,<br />

Capacitor, MCB, copper wire, copper lugs, fixing equipments, wiring,<br />

connection.<br />

- 1 No. (Lot) ‘M’ @ Rs. ________________<br />

3. Supply of H.T. 11 KV grade, 200 Amps., 250 MVA, 3 Ph., 50 Hz., Oil<br />

switch fuse unit, Type- VLE with rear entry cable box one side &<br />

Kiosk for another side, tapping Box, compound Filling, side inner<br />

plates, Cu. Busbar, H.T. Bushing.<br />

- 2 Nos. ‘M’ @ Rs. __________________ Each<br />

4. Supply of 32/16 Amps. H.T. 11 KV Grade HRC fuse.<br />

- 6 Nos. ‘M’ @ Rs. _______________ Each<br />

5. Supply of Transformer oil (Power Oil).<br />

- 209 Ltr. ‘M’ @ Rs. _________ /Ltr.<br />

6. Supply of M.S. cable adopter box, painting (For VLE switch)<br />

- 4 Nos. ‘M’ @ Rs. ___________ Each<br />

7. Supply of 3 Core x 120 Sq.mm H.T. 11 KV grade XLPE cable.<br />

- 110 Mtrs. ‘M’ @ Rs. ____________ /Mtr.<br />

8. Supply of 3 Core x 120 Sq.mm H.T. 11 KV grade XLPE cable heat –<br />

shrink jointing kits, Alu. Socket, Tapes etc.<br />

a) Indoor type joint<br />

- 6 Nos. ‘M’ @ Rs. ______________ Each<br />

b) Out-door type joint<br />

- 2 Nos. ‘M’ @ Rs. ______________ Each<br />

Materials<br />

(Rs.)<br />

Contd…..Page-2

page 2 of 14<br />

Ser<br />

D E S C R I P T I O N<br />

No<br />

9. Supply of 3.5 Core x 240 Sq.mm 1.1 KV grade XLPE<br />

cable<br />

- 168 Mtrs. ‘M’ @ Rs. ____________ /Mtr.<br />

10. Supply of 3.5 Core x 240 Sq.mm cable end termination,<br />

jointing materials.<br />

- 14 Joints. ‘M’ @ Rs. ___________ Each<br />

11. Supply of H.T. 11 KV grade lighting Arrestor (3 Nos. in<br />

one set) fixing clamp, wire, sockets.<br />

- 2 Sets. ‘M’ @ Rs. _____________ Each<br />

12. Supply of Earthing station materials i.e. 50 mm x 3<br />

mtr. Long G.I. Earth Electrode, char-coal, salt, as per<br />

I.E. Rules.<br />

- 12 Nos. ‘M’ @ Rs. _____________ Each<br />

13.a) Supply of 40 mm x 6 mm G.I. Flat, Hot-deep<br />

Galvanized.<br />

- 190 Kgs. ‘M’ @ Rs. ___________ /Kg.<br />

b) Supply of 25 mm x 6 mm G.I. Flat, Hot-deep<br />

Galvanized.<br />

- 120 Kgs. ‘M’ @ Rs. __________ /Kg.<br />

14.a) Supply of 53 mm rubberized PVC sleeves<br />

- 50’ Ft. ‘M’ @ Rs. __________ /Ft.<br />

b) Supply of 37 mm rubberized PVC sleeves<br />

- 50’ Ft. ‘M’ @ Rs. ____________ /Ft.<br />

15. Supply of 50 mm Earth Funnel with reducer.<br />

- 12 Nos. ‘M’ @ Rs. ____________ Each<br />

16. Providing various sizes G.I. Bolt, Nut, Washer for<br />

earthing Jobs.<br />

- (Lot) ‘M’ @ Rs. ______________ Each<br />

17. Supply of Earth Bus Test link with epoxy Busbar<br />

insulator.<br />

- 2 Sets ‘M’ @ Rs. _____________ Each<br />

18. Supply of Materials for Sub-Station Doors & Windows,<br />

wire net Earth. (Step Up & Step down)<br />

- 2 Sets ‘M’ @ Rs. _____________ Each<br />

19. Supply of 15 KVAr 440 Volts, Delta connected<br />

capacitor, type MPP-H, Enclosure type, 63 Amps. T.P.<br />

MCB enclosure box, 3 Nos. 6 Sq.mm Copper Flexible<br />

wire, PVC Flexible pipe, Cupling joint, copper sockets<br />

etc. (For 60 H.P. motor)<br />

- 3 Sets. ‘M’ @ Rs. _____________ Each<br />

20. Supply of 3” x 20 Ft. long M.S. pipe (for cable<br />

protection)<br />

- 1 Pc. ‘M’ @ Rs. ____________ Each<br />

21. Supply of 12” x 8’ Ft. Long Hume pipe (Factory Road<br />

crossing). - 3 Pcs. ‘M’ @ Rs. _____________ Each<br />

22. Supply of SWG 8 G.I. wire<br />

- 100 Mtrs. ‘M’ @ Rs. ____________ /Mtr.<br />

Materials<br />

(Rs.)<br />

Contd…..Page-3

page 3 of 14<br />

Ser<br />

D E S C R I P T I O N<br />

No<br />

23. Supply of the following sizes 1.1 KV grade XLPE<br />

distribution cable :-<br />

a) 3.5 Core x 70 Sq.mm cable<br />

- 12 Mtrs. ‘M’ @ Rs. ____________ /Mtr.<br />

b) 3 Core x 50 Sq.mm cable<br />

- 30 Mtrs. ‘M’ @ Rs. ____________ /Mtr.<br />

c) 3 Core 25 Sq.mm cable<br />

- 40 Mtrs. ‘M’ @ Rs. ___________ /mtr.<br />

24. Supply of the following sizes 1.1 KV grade XLPE cable<br />

end jointing materials :-<br />

a) 3.5 Core x 70 Sq.mm<br />

- 2 Joints ‘M’ @ Rs. ___________ Each<br />

b) 3 Core x 50 Sq.mm<br />

- 4 Joints ‘M’ @ Rs. ___________ Each<br />

c) 3 Core x 25 Sq.mm<br />

- 8 Joints. ‘M’ @ Rs. ___________ Each<br />

Total<br />

Add : Packing, forwarding, Transporting charges F.O.R.<br />

Garden<br />

Materials<br />

(Rs.)<br />

Add : VAT @ 4%<br />

Grand Total

GROUP – ‘A’- (II) page 4 of 14<br />

Sub : Supply offer for H.T. 11 KV overhead Line from Factory to Sec. No. 116 at<br />

your Karbala Tea Estate<br />

Ser<br />

No<br />

D E S C R I P T I O N<br />

Materials<br />

(Rs.)<br />

1. Supply of 26 ft (8 Mtr) long PCC pole.<br />

- 47 Nos. ‘M’ @ Rs. ___________ Each<br />

2. Supply of M.S. Channel, Angle, Flat, Paint for `V’ Bracket, Top<br />

Adopter, D.P. & T.P. Structure, M.S. frame, clamp saddle etc (soft<br />

quality)<br />

- 2.45 Ton ‘M’ @ Rs. _____________ Per Ton<br />

3. Supply of ¾” x 6 ft long Stay set, Anchore plate, Bow, complete<br />

set.<br />

- 30 Nos. ‘M’ @ Rs. ____________ Each<br />

4. Supply of 6” H.T. Guy Insulator.<br />

- 30 Nos. (Lot) ‘M’ @ Rs. ___________ Each<br />

5. Supply of SWG 7/10 G.I. stay wire, soft quality.<br />

- 150 Kgs. ‘M’ @ Rs. ____________ Per kg.<br />

6. Supply of H.T. 11 KV grade brown glassed Pin Insulator with<br />

stud, bolt, washer, good quality.<br />

- 150 Nos. ‘M’ @ Rs. ____________ Each<br />

7. Supply of H.T. 11 KV grade brown glassed `Disc’ Insulator with<br />

straining clamp, bolt & nuts (Hardware fittings complete set.)<br />

(good quality).<br />

- 36 Nos. ‘M’ @ Rs. _____________ Each<br />

8. Supply of 5/8” x 5 ft long G.I. Earth spike, Bolt & nut.<br />

- 47 Nos. ‘M’ @ Rs. _____________ Each.<br />

9. Supply of 0.030 (Weasel) ACSR Conductor wire (good quality)<br />

- 5500 Mtrs. ‘M’ @ Rs. ____________ Per mtr<br />

10. Supply of H.T. 11 KV GOAB isolator Switch with operating<br />

handle, Square Rod, G.I. pipe (Heavy Duty).<br />

- 2 Sets `M’ @ Rs. ______________ Each<br />

11. Supply of Barbed wire, Anti climbing safety device (for PCC pole).<br />

- 47 Nos. `M’ @ Rs. ____________ Each<br />

12 Supply of SWG 6 G.I. wire soft quality.<br />

- 500 Mtrs. `M’ @ Rs. ______________ Per mtr<br />

13. SWG 8 G.I. wire soft quality.<br />

- 7000 Mtrs. `M’ @ Rs. _____________ Per mtr<br />

14. Supply of G.I. P.G. clamp, size 0.030.<br />

- 42 Nos. `M’ @ Rs. ____________ Each<br />

15. Supply of 11000 Volts, 8” x 6” size Caution plate (English /<br />

Hindi).<br />

- 45 Nos. ‘M’ @ Rs. __________ Each.<br />

16. Supply of 5/8” x 8” long `I’ Bolt, Nut, washer.<br />

- 24 Nos. `M’ @ Rs. ___________ Each<br />

17. Supply of various sizes M.S. Bolt, Nut, Double washer for the Job<br />

(size ½” x 3”, ½” x 2”, ½” x 4”, ½” x 6”, 5/8” x 8”). - Lot. ‘M’ @<br />

Rs. ________________ L.S.<br />

18. Supply of Bricks. - 500 Pcs. ‘M’ @ Rs. __________ Each<br />

Contd…..Page-5<br />

page 5 of 14

Ser<br />

D E S C R I P T I O N<br />

No<br />

19. Supply of Cement.<br />

- 15 Bags `M’ @ Rs. ____________ Per Bag<br />

20. Supply of Sand/pebbles.<br />

- 2 lorry `M’ @ Rs. ____________ Per lorry<br />

Total<br />

Add : Packing, Forwarding, Transporting charges F.O.R. Garden<br />

Materials<br />

(Rs.)<br />

Add : VAT @ 4 %<br />

Grand Total

<strong>Group</strong> – B- (i) page 6 of 14<br />

Sub : Erection offer for Step-up / Step-down Sub-station Electrification work<br />

for H.T. 11 KV Irrigation work (Motor 45 H.P. x 1 No. & 50 H.P. x 2 Nos.)<br />

Sec No. 116 at your Karbala Tea Estate<br />

Ser<br />

D E S C R I P T I O N<br />

No.<br />

1. Being Blue print drawing of H.T. 11 KV Indoor type Step-up & Stepdown<br />

Sub-station equipments. H.T. 11 KV overhead line from<br />

Factory to Irrigation places with SP, DP, TP & 4 Pole position, Single<br />

line diagram Earthing system and submission to the Garden<br />

Authority.<br />

- 1 Job `E’ @ Rs. ____________ Each<br />

2. Being major fabrication arrangement in the Panel Board out-going<br />

switch position for Irrigation, making necessary arrangement,<br />

welding, Angle, Flat, Sheet, Erection of 400 Amps. TPN L &<br />

T/Siemens switch fuse unit.<br />

- 1 Job `E’ @ Rs. ______________ Each<br />

3. Making Alu. Link having 400 Amps. capacity, 3 Phase, Neutral,<br />

bending, drilling of holes, fixing bolt & Nut from Main Bus to Switch<br />

incoming.<br />

- 1 Set. `E’ @ Rs. _____________ Each<br />

4. Fabrication channel, drilling of holes, painting, grouting on ready<br />

trench and installation of 630/400 Amps. TP MCCB Panel Board,<br />

cubicle type, floor mounting, checking meter instruments. (both<br />

side).<br />

- 2 Nos. `E’ @ Rs. _____________ Each<br />

5.a) Making masonry plinth/trench, fabrication M.S. channel grouting,<br />

fixing stopper, and painting. Installation of 400 KVA Indoor type<br />

415/11000 Volts Step-up Transformer and accessories (at Factory<br />

side).<br />

- 1 No. `E’ @ Rs. ____________ Each<br />

b) Erection of 200 KVA Step-down 11000/433 Volts Transformer and<br />

accessories in Sub-station room, fabrication channel, grouting at<br />

pump side.<br />

- 1 No. `E’ @ Rs. ____________ Each<br />

6. Fabrication channel, painting, grouting on trench. Installation of<br />

H.T. 11 KV 200 A, 250 MVA Oil switch fuse unit, type `VLE’ fixing 3<br />

Nos. 11 KV HRC fuse, filling Transformer oil 85 Ltrs. etc (both side).<br />

- 2 Nos. `E’ @ Rs. ___________ Each<br />

7. Fabrication cable adopter box, painting, fixing with H.T. Oil switch,<br />

bottom & side cover for jointing.<br />

- 4 Nos. `E’ @ Rs. _____________ Each<br />

8. Laying of 3 Core x 120 Sq.mm H.T. 11 KV grade XLPE cable in<br />

trench on pole.<br />

- 110 Mtrs. `E’ @ Rs. __________ Per mtr<br />

9. 3 Core x 120 Sq.mm H.T. 11 KV grade XLPE cable heat shrink joint,<br />

crimping lugs, lifting jointing, connection, tapping etc.<br />

a) Out-door type joint. - 2 Nos. `E’ @ Rs. _____________ Each<br />

Erection<br />

(in Rs.)<br />

Contd… Page 7

page 7 of 14<br />

Ser<br />

D E S C R I P T I O N<br />

No.<br />

b) Indoor type joint.<br />

- 6 Nos. `E’ @ Rs. ____________ Each<br />

10. Being High Voltage pressure testing of Sub-station H.T.<br />

equipments, cable and earthing station.<br />

- 1 Job (lot) `E’ @ Rs. ____________ Each<br />

11. Laying of 3.5 Core x 240 Sq.mm 1.1 KV Grade XLPE cable in trench<br />

/ on D.P.<br />

- 168 Mtrs. `E’ @ Rs. ___________ Per mtr<br />

12. 3.5 Core x 240 Sq.mm L.T. XLPE cable gland binding, crimping<br />

socketing, end termination connection.<br />

- 14 Joints. `E’ @ Rs. ____________ Each<br />

13. Erection of H.T. 11 KV Lightening Arrestor (3 Nos. in one set) on<br />

pole structure, connection lugs, wire, G.I. flat as per system.<br />

- 2 Sets `E’ @ Rs. ______________ Each<br />

14. Planning, Supervision after installation, testing & commissioning of<br />

Sub-station equipments, overhead line and energized.<br />

- 1 Job `E’ @ Rs. ________________ Each<br />

15. Making Earthing station from ground level to top as per I.E. Rules<br />

for Transformer Neutral, equipments earth & Lightening Arrester<br />

(Step-up 8 Nos, & Step-down 6 Nos.)<br />

- 12 Nos. `E’ @ Rs. ____________ Each<br />

16. Laying of 25 mm x 6 mm & 40 mm x 6 mm G.I. flat, drilling of<br />

holes, bending, fixing bolt, nut & washer.<br />

- 310 Kgs. `E’ @ Rs. __________ Per kg<br />

17 Laying of 37 mm/ 53 mm PVC sleeves for covering bare G.I. flat for<br />

Transformer Neutral & Lightening Arrestor.<br />

- 100 ft `E’ @ Rs. __________ Per ft<br />

18. Making & grouting earth bus test link for Neutral.<br />

- 2 Nos. `E’ @ Rs. ____________ Each<br />

19. Being H.T. Sub-station room doors and windows earthing,<br />

connection, fixing bolt & nuts.<br />

- 2 Sets `E’ @ Rs. _____________ Each<br />

20. Fabrication M.S. frame, structure, welding, drilling of holes,<br />

painting, grouting, erection of Star / Delta starter, testing &<br />

commissioning.<br />

- 2 Sets `E’ @ Rs. ____________ Each<br />

21. Fabrication M.S. frame, grouting, erection 15 KVAr Capacitor,<br />

enclosure type, 63 Amps. TP MCB with box, laying of 3 Nos. 6<br />

Sq.mm copper flexible wire in PVC flexible pipe, crimping copper<br />

lugs, 4 Nos. coupling joints for 2 Nos. 60 H.P. motor.<br />

- 3 Sets `E’ @ Rs. ___________ Each<br />

22. Laying of the following sizes 1.1 KV grade XLPE distribution cable<br />

in trench / under ground :<br />

a) 3.5 Core x 70 Sq.mm cable.<br />

- 12 Mtrs `E’ @ Rs. __________ Per mtr<br />

Erection<br />

(in Rs.)<br />

Contd.. Page 8

page 8 of 14<br />

Ser<br />

D E S C R I P T I O N<br />

No.<br />

b) 3 Core x 50 Sq.mm cable.<br />

- 30 Mtrs. `E’ @ Rs. _________ Per mtr<br />

c) 3 Core x 25 Sq.mm cable.<br />

- 40 Mtrs. `E’ @ Rs. _________ Per mtr<br />

23. Following sizes cable gland binding, crimping socketing, end<br />

termination connection :<br />

a) 3.5 Core x 70 Sq.mm<br />

- 4 Joints `E’ @ Rs. ___________ Each<br />

b) 3 Core x 50 Sq.mm<br />

- 8 Joints `E’ @ Rs. _________ Each<br />

c) 3 Core x 25 Sq.mm<br />

- 8 Joints `E’ @ Rs. ___________ Each<br />

24. Making Earthing by SWG 8 G.I. wire for M.S. frame, Motor Starter,<br />

Capacitors.<br />

- Lot `E’ @ Rs. _____________ L.S.<br />

25. Laying of 3” x 20ft cable protection pipe.<br />

- 20 ft `E’ @ Rs. __________ Per ft<br />

26. Laying of 12 “ x 8 ft long Hume pipe by digging soil, re-filling.<br />

- 3 Pcs. `E’ @ Rs. ____________ Each<br />

27. Fabrication M.S. frame, grouting on wall/trench installation of<br />

submersible Control Panel Board.<br />

- 1 No. `E’ @ Rs. _____________ Each<br />

Total<br />

Erection<br />

(in Rs.)<br />

Add : Servicing Tax, Education Cess @ 12.36% as per Govt. Rules<br />

Grand Total

GROUP `B – (ii)’ page 9 of 14<br />

Sub : Erection offer for drawing H.T. 11 KV, overhead line from Factory to<br />

Sec. No- 116 for Irrigation line at your Karbala T.E.<br />

Ser<br />

D E S C R I P T I O N<br />

No<br />

1. Route survey of H.T 11KV irrigation overhead line from<br />

factory to Sec. No- 116 Irrigation Line at your Karbala T.E.<br />

– 1.7 KM `E’ @ Rs. ___________ Per KM<br />

2. Erection of 8 Mtr long PCC pole as per WBSEDCL<br />

specification.<br />

- 47 Nos. `E’ @ Rs. ____________ Each<br />

3. Fabrication M.S. Materials `V’ Bracket, top adopter, D.P. &<br />

T.P. pole structure, bracket, GOAB & L.A. structure,<br />

making clamp, saddle, welding, drilling of holes, painting,<br />

fixing on pole.<br />

- 2.45 Ton `E’ @ Rs. ___________ Per Ton<br />

4. Digging, erection of stay set, Anchor plate, Bow, re-filling<br />

after Masonery Dhalai.<br />

- 30 Nos. `E’ @ Rs. ____________ Each<br />

5. Laying of 7/10 SWG stay wire, guy insulator, both end<br />

binding, bow & clamp side binding, straining.<br />

- 30 Nos. `E’ @ Rs. _____________ Each<br />

6. Erection of 11 KV Brown glassed pin insulator with stud,<br />

bolt complete set on pole.<br />

- 150 Nos. `E’ @ Rs. ___________ Each<br />

7. Erection of Brown glassed `Disc’ insulator with straining<br />

clamp, accessories on pole structure.<br />

- 36 Nos. `E’ @ Rs. __________ Each<br />

8. Erection of Earth spike with SWG 6 G.I. wire, binding from<br />

ground to Pole top for Earthing fabricated M.S. structure.<br />

- 47 Nos. `E’ @ Rs. ____________ Each<br />

9. Drawing 0.030 ACSR conductor wire, straining and<br />

sagging, Disc & Pin insulator binding, jumpering<br />

connection.<br />

- 5500 Mtrs. `E’ @ Rs. _________ Per mtr<br />

10. Erection of 4 ply Barbed wire, binding 750 cm around the<br />

pole as per Rules for safety protection, anti-climbing<br />

device.<br />

- 47 Nos. `E’ @ Rs. _________ Each<br />

11. Erection of GOAB isolator switch with fuse, operating<br />

handle on D.P. structure, alignment, connection,<br />

conductor wire as per system. - 2 Nos. `E’ @ Rs.<br />

____________ Each<br />

12. Drawing cradle guard complete with 2 x 8 SWG G.I. wire<br />

for continuous & SWG 8 G.I. wire for cross bracing as an<br />

interval of 2.5 mtr. `I’ bolt fixing, sagging, binding.<br />

- 33 Span `E’ @ Rs. ___________ Each span<br />

13. Erection of 11000 Volts, 8” x 6” Caution Plate on pole.<br />

- 45 Nos. `E’ @ Rs. _____________ Each<br />

Erection<br />

(Rs.)<br />

Contd…….Page10

page 10 of 14<br />

Ser<br />

D E S C R I P T I O N<br />

No<br />

14. Erection of P.G. clamp, size 0.030 ACSR conductor wire<br />

for jumpering joint connection.<br />

- 42 Nos. `E’ @ Rs. ___________ Each<br />

15. Being 0.030 ACSR conductor wire Britannia / twisting<br />

joint etc.<br />

- 12 Nos. `E’ @ Rs. ________ Each<br />

16. Being High voltage pressure testing of H.T. 11 KV<br />

overhead line & accessories & submission of Test report to<br />

the electrical Inspector, Govt. of W.B. , Kolkata for<br />

approval.<br />

- 1 Job ‘E’ @ Rs. _____________ Each.<br />

Total<br />

Erection<br />

(Rs.)<br />

Add : Servicing Tax, Education Cess @ 12.36% as per Govt.<br />

Rules<br />

Grand Total

page 11 of 14<br />

DETAILS OF STATEMENT<br />

A/C – KARBALLA TEA ESTATE<br />

Ser<br />

No<br />

Description<br />

Quoted<br />

Amount<br />

Packing<br />

Charges<br />

VAT/<br />

Service Tax<br />

Total<br />

1. <strong>Group</strong> `A’ (i)<br />

2. <strong>Group</strong> `A’ (ii)<br />

3. <strong>Group</strong> `B’ (i)<br />

4. <strong>Group</strong> `B’ (ii)<br />

5. Transformer 400<br />

KVA/200 KVA (Refer<br />

Annexure I & II)<br />

Grand Total

page 12 of 14<br />

ANNEXURE<br />

A/C- KARBALLA TEA ESTATE<br />

Ser<br />

No.<br />

Description<br />

Sec. No. 116 irrigation motor Submirsal – 45<br />

H.P. x 1 No. & Booster Motor 50 H.P. x 2<br />

Nos.)<br />

1.a) <strong>Group</strong> ‘A’ – (i) Materials cost for Step Up /<br />

Step down, Sub-station equipments and<br />

associated materials.<br />

b) <strong>Group</strong> ‘A’ – (ii) Material offer for H.T. 11 KV,<br />

Over head line and associated goods from<br />

Factory to Sec No – 116<br />

2.a) <strong>Group</strong> ‘B’ – (i) Erection offer for <strong>Group</strong> ‘A’ –<br />

(i) Step up/ Step down sub-station.<br />

b) <strong>Group</strong> ‘B’ – (ii) Erection offer for <strong>Group</strong> ‘A’ –<br />

(ii) H.T. 11 KV O/H Line<br />

3. 400 KVA Step-Up & 200 KVA Step-down<br />

Transformer (Refer Annexure I & II)<br />

Material<br />

Cost<br />

(in Rs.)<br />

Erection<br />

Cost<br />

(in Rs.)<br />

Total<br />

(in Rs.)<br />

Grand Total

page 13 of 14<br />

ANNEXTURE NO – I<br />

TECHNICAL SPECIFICATION OF 400 KVA DW/CU. 415/11000 V. INDOOR TYPE<br />

STEP UP TRANSFORMER AS PER IS 2026.<br />

TECHNICAL SPECIFICATION<br />

400 KVA DW/CU., 415/11000 V. STEP UP TRANSFORMER<br />

400 KVA, 415 V/11000 V., volts step-up Transformer, 3 Phase, 50 Hz., oil immersed, naturally<br />

cooled, core type, double wound with copper conductor, 45/55 C˚ temperature rise in oil and<br />

winding respectively, having ± 2.5 & ± 5% off-circuit trappings on HT to vary HT. High Voltage<br />

side connected in star where as low voltage side connected in Delta, having Vector <strong>Group</strong><br />

reference Y nd- 11, Indoor type, have both side cable end box, complete with following fittings<br />

& accessories.<br />

01. Name, rating and terminal marking plate.<br />

02. Two Nos. Earthing terminals.<br />

03. Two Nos. lifting lugs.<br />

04. Conservator with oil filling hole with cover.<br />

05. Dehydrating silica-gel breather.<br />

06. Oil level gauge.<br />

07. Arcing Horn<br />

08. Drain Valve with plug.<br />

09. Filer valve with plug.<br />

10. Off-Circuit tap changing switch provided with mechanical interlock and position indicator.<br />

11. Cable End Box both side.<br />

12. Cable Termination Facility at LT side.<br />

<strong>The</strong> above Transformer shall be complete with first filling of oil complying with ISS:335<br />

page 14 of 14

ANNEXTURE NO – II<br />

TECHNICAL SPECIFICATION OF 200 KVA DW/CU. 11000/433 V. INDOOR TYPE<br />

STEP DOWN TRANSFORMER AS PER IS 2026.<br />

TECHNICAL SPECIFICATION<br />

200 KVA DW/CU., 11000/433 V. STEP-DOWN TRANSFORMER<br />

200 KVA DW/Cu. 11000/433 V., Step-down Transformer, 3 Phase, 50 cycles, oil immersed,<br />

naturally cooled, core type, double wound with copper conductor, 45/55 dig C temperature rise<br />

in oil and winding respectively, having ± 2.5 & ± 5% off-circuit trappings on HT to vary HT.<br />

High Voltage side connected in Delta whereas low voltage side connected in Star, having Vector<br />

<strong>Group</strong> reference Dyn- 11 with neutral of the secondary winding brought out for earthing.<br />

Indoor type both side cable end box. <strong>The</strong> Transformer shall be complete with following fittings<br />

and accessories.<br />

01. Name, rating and terminal marking plate.<br />

02. Earthing terminals.<br />

03. lifting lugs.<br />

04. Dehydrating silica-gel breather.<br />

05. Oil level gauge<br />

06.. Drain valve and filter valve.<br />

07. Arcing Horn<br />

08. Bushings both on HT & LT side.<br />

09. Explosion vent.<br />

10. Conservator Tank with oil filling hole and drain plug.<br />

11. Cable end Box on both HT and LT side<br />

12. Cable Termination Facility at LT side.<br />

<strong>The</strong> above Transformer shall be complete with first filling of oil complying with ISS:335