Electromagnetic flow meter - GEA Diessel

Electromagnetic flow meter - GEA Diessel

Electromagnetic flow meter - GEA Diessel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

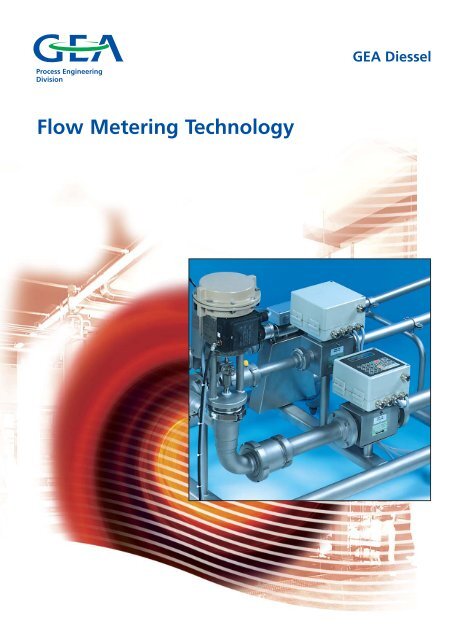

Process Engineering<br />

Division<br />

<strong>GEA</strong> <strong>Diessel</strong><br />

Flow Metering Technology

<strong>Electromagnetic</strong> <strong>flow</strong> <strong>meter</strong><br />

<strong>GEA</strong> <strong>Diessel</strong> is one of the pioneers in the field of the hygienic <strong>meter</strong>ing of liquids for the<br />

food and beverage industry. It was in the mid-1980s that the company started to develop<br />

electromagnetic <strong>meter</strong>ing technology based on the IZM device. Since then, this technology<br />

has almost completely replaced mechanical <strong>meter</strong>s in this market segment.<br />

The electromagnetic unit, which operates in accordance with Faraday's Law of Induction,<br />

has no moving parts that are liable to wear. Even liquids with low conductivity can be<br />

measured reliably. Thanks to their precision, reliability and flexibility, these <strong>meter</strong>ing<br />

devices offer a broad range of possible applications.<br />

Decades of experience and constant further development involving the integration of new<br />

innovative technologies have produced a series of devices that set standards for<br />

the future.<br />

IZML: simple, precise and economical<br />

Practical operation demands the following features:<br />

-precise measurement of the <strong>flow</strong> of liquids within<br />

the production process<br />

-simple installation and rapid commissioning<br />

- no maintenance<br />

- high reliability and a long service life<br />

- economy<br />

Simple and straightforward cleaning ensures that high-value<br />

products can be manufactured under absolutely hygienic<br />

conditions.<br />

Precision, linearity and reproducibility are of course the basic<br />

requirements for <strong>meter</strong>ing devices.<br />

With its technical properties and its economic price, IZML is<br />

in every way the ideal <strong>meter</strong>ing device for the foodstuffs<br />

industry.<br />

IZML is designed to fulfil<br />

all these requirements<br />

The IZML model of electromagnetic<br />

<strong>flow</strong> <strong>meter</strong> supplies<br />

precisely the information that<br />

is required for the control<br />

and regulation of processing<br />

plant. The operator is thus<br />

able to enhance the efficiency<br />

of complex production<br />

facilities at low cost.<br />

IZMS: approved by weights and measures authorities<br />

The IZMS model of electromagnetic <strong>flow</strong> <strong>meter</strong> fulfils almost<br />

every requirement. It offers the most flexible technology for<br />

the most exacting demands.<br />

The electromagnetic <strong>meter</strong>ing principle has proved itself in<br />

industry over decades. It is not affected by the density,<br />

viscosity or temperature of the liquid. Needless to say, the<br />

essential components are made of stainless steel.<br />

Asmooth measuring tube, no internal fittings, no moving<br />

parts: these are the decisive advantages of this <strong>meter</strong>ing<br />

technology.

IZMS has of course been granted type approved by the<br />

German weights and measures authorities PTB, and is thus<br />

able to measure with extreme precision those quantities from<br />

which the amounts payable are calculated.<br />

This device is being used successfully for many applications<br />

relating to milk, beer and other products.<br />

Needless to say, IZMS devices are also made of stainless steel.<br />

Product temperatures of up to 150° C are no problem.<br />

IZMT/R <strong>meter</strong>ing systems for every conceivable<br />

“niche” application<br />

In addition to simply measuring <strong>flow</strong> and volume, the basic<br />

unit of the electromagnetic <strong>flow</strong> <strong>meter</strong> can be flexibly<br />

modified or expanded in such a way as to allow even more<br />

complex functions to be carried out.<br />

•Where a medium has to be pumped from one vessel to<br />

another, the IZMS halts the process automatically when<br />

the desired quantity has been reached<br />

•Even very small quantities are dosed precisely at<br />

intervals of a second<br />

•Packaging statistics are constantly updated and can be<br />

documented on a PC<br />

•Quantities received or delivered are registered in<br />

a printed document - also for official purposes<br />

•For reception and delivery procedures, the customer<br />

numbers and product designations are recorded together<br />

with the <strong>meter</strong>ing data, are stored and printed out as<br />

a report<br />

•Product temperatures may be important; the IZMT<br />

measures and documents them.<br />

•Flow is kept constant at the desired level by the<br />

operation of a regulating valve<br />

•With the aid of a second <strong>meter</strong>, the IZMR is even able to<br />

regulate precisely a pre-determined mixing proportion<br />

•The sampling control provides a regularly distributed<br />

sample for laboratory analysis<br />

•The high precision DI-Master, whose accuracy has been<br />

enhanced yet again, effects the calibration of <strong>meter</strong>s that<br />

operate by the most varied measuring principles, and<br />

provides for “flying” measurement, so that the <strong>meter</strong>s to<br />

be calibrated do not have to be removed from<br />

the production equipment.<br />

Fittings such as the milk pipe as per German standard<br />

DIN 11851, the flange and the clamp allow the device to be<br />

installed in the product pipe in whatever way is desired.<br />

Thanks to the precise recording of even very low <strong>flow</strong> speeds,<br />

starting from 0.03 m/s, a very wide dynamic range is<br />

available.<br />

The easily detachable “MEMbox” memory module provides<br />

for permanent saving of the calibration data.<br />

The integrated keypad and display allow the device to be to<br />

operated easily and reliably.<br />

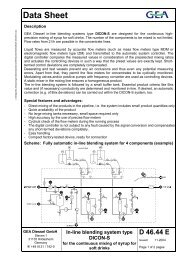

In-line blending system

Applications of <strong>GEA</strong> <strong>Diessel</strong> <strong>flow</strong> <strong>meter</strong>ing<br />

technology<br />

Filling technology<br />

-package filling plant<br />

- keg racking<br />

- post-mix filling<br />

- container filling<br />

- tubular bag filling<br />

- bag-in-box filling<br />

Reception units<br />

- stationary reception of milk from tankers<br />

- collection of milk from farm tanks by tanker<br />

-collection of other liquids by tanker<br />

Delivery units<br />

- filling of tankers with milk<br />

- filling of tankers with beer<br />

- filling of beer containers in pubs, restaurants etc.<br />

from tankers<br />

- delivery of other liquids<br />

Recording of quantities at storage facilities<br />

- management of tank storage facilities<br />

- automatic filling and emptying of storage tanks<br />

- distribution to various processing departments<br />

Batch mixing equipment<br />

-mixing of soft drinks, spirits etc.<br />

-milk standardisation<br />

-production of liquid soaps, cosmetics etc.<br />

- manufacture of bakery products<br />

Blending control systems<br />

- in-line blending of beverages<br />

- in-line blending of yoghurt/curds and fruit<br />

- in-line dosing of wort with yeast<br />

- high-gravity brewing equipment<br />

-blending of alcohol<br />

Dosing plant<br />

- yeast dosing in wort<br />

- enhancing the concentration of cleaning fluids<br />

-dosing of beer with kieselgur (diatomaceous earth)<br />

- dosing of beer, liquid soap with colourings<br />

Process Engineering<br />

Division<br />

<strong>GEA</strong> <strong>Diessel</strong><br />

<strong>GEA</strong> <strong>Diessel</strong> GmbH<br />

Steven 1 . D-31135 Hildesheim . Tel.: +49-51 21/742-0 . Fax: +49-51 21/742-153 . www.diessel.com<br />

701.2.04