Measuring and data technology for milk tankers - GEA Diessel

Measuring and data technology for milk tankers - GEA Diessel

Measuring and data technology for milk tankers - GEA Diessel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Measuring</strong> <strong>and</strong> <strong>data</strong> <strong>technology</strong> <strong>for</strong> <strong>milk</strong> <strong>tankers</strong>Tamper-proof – officially approved – accurateProcess Engineering<strong>GEA</strong> <strong>Diessel</strong>1

Intelligent in-truck computers –ZEVODAT-C1 TM <strong>and</strong> ZEVODAT-flash TMThe ability to record both the quantity<strong>and</strong> the quality of the <strong>milk</strong> <strong>and</strong>to identify the source of each deliveryopens up a whole new range of possibilitiesin the processing chain. Thecontinuous monitoring of both theeach individual reception process <strong>and</strong>of the entire tanker load serves to supportquality <strong>and</strong> tour management.This potential <strong>for</strong> optimisation canbe further enhanced by bi-directional<strong>data</strong> transmission between the tanker<strong>and</strong> the central computer via the internet.These functions, which are availableas extras, allow flexible route planning<strong>and</strong> optimised fleet management.The ZEVODAT-flash TM is a modern,state-of-the-art device, allowing <strong>for</strong> ahigh degree of per<strong>for</strong>mance <strong>and</strong> communicationfunctionality. It is equippedwith GPS as st<strong>and</strong>ard, so that suppliersare automatically identified.This logistical support is further optimisedby the inclusion of an addition alsocket modem <strong>for</strong> GPRS transfer. Thisturns ZEVODAT-flash TM into a <strong>data</strong>transfer device that transmits the co l-lected <strong>data</strong> <strong>and</strong> details of the individualreception procedures in real time.GPRS <strong>data</strong> transfer is a very economictransmission option in day-to-day operation,since the provider charges only<strong>for</strong> the volumes of <strong>data</strong> actually transmitted.Both devices possess OIML certificationin con<strong>for</strong>mity with Direct ive2004/22 EC, <strong>and</strong> so can be used inmeasuring equipment subject toofficial approval pursuant to M. I. D.Highlights of the ZEVODAT-flash TM■ automatic supplier identificiationvia GPS■ identification of the sample bottleby barcode or RFID tag is possible■ remote parameterisation is possible■ intelligent control of meteringsystem <strong>and</strong> pumps is possible■ <strong>data</strong> memory up to 512 MByteis possibleAs a starter version of this <strong>data</strong> captureequipment, we recommend ZEVO-DAT-C1 TM . This device acts as an extensionto the electromagnetic flow meter.It registers <strong>and</strong> stores all in<strong>for</strong>mationthat is relevant <strong>for</strong> the later accountingprocedure <strong>and</strong> transmits it on towherever the <strong>data</strong> is processed. At thesame time, the ZEVODAT-C1 TM cancontrol individual plant components.ZEVODAT-C1 TM4ZEVODAT-flash TMWith this feature our customers are ina position, among other things, to optimisetheir tours in such a way as tosave themselves not only time <strong>and</strong>travelling distance, but fuel as well.The GPRS system has also provedit self in the monitoring <strong>and</strong> loggingof the individual reception procedures<strong>and</strong> of sampling. Any unexpectedchanges in the procedures are immediatelyidentified at the control centre<strong>and</strong> reported back to the driver. Suchearly identification <strong>and</strong> immediateremedying of operator errors is indisputablyan advantage to all those involvedin the procedure.We optimise yourlogistics■■■■Constant monitoring of qualityrelevant<strong>data</strong> ensures traceabilityall the way along the transportchain.GPS satellite navigation simplifiesthe identification of suppliers.The mobile in<strong>for</strong>mation systemusing GSM/GPRS represents anenormous <strong>and</strong> innovative step<strong>for</strong>ward <strong>for</strong> the driver (e.g. in re -spect of route in<strong>for</strong>mation) <strong>and</strong>the customer (e.g. in respect ofthe transmission of laboratory<strong>data</strong>).Thanks to secure <strong>data</strong> transmissionfrom the tanker to the central<strong>data</strong> processing unit, errorsin accounting are prevented.

Tried <strong>and</strong> tested –st<strong>and</strong>-alone samplersQuantity is not the only criterion: Theprice paid <strong>for</strong> the <strong>milk</strong> also dependson its quality. Representative producttesting with reliable identification ofthe supplier is essential. In addition,under EC Directive 178/2002 samplingmust be per<strong>for</strong>med at everystage in order to ensure traceability.<strong>GEA</strong> <strong>Diessel</strong>’s reliable samplers contributeto fulfilling these various re -quire ments.trols <strong>and</strong> regulates the taking of samplesin accordance with time or volumecriteria. They are easy to integrateinto existing systems, <strong>and</strong> are also simpleto extend. They are equipped witha sensor, so that they are able to interrupttime-interval sampling if, <strong>for</strong>example, there is an interruption inreception.All st<strong>and</strong>-alone samplers are designedin such a way as to be able to takeei ther individual or tour samplesSampler <strong>for</strong> multiple samplesFeatures that addvalue in day-todayoperations■It is possible to take two separateClean individual samples via overst<strong>and</strong>-alone sampler■individual samples simultaneously.Sample bottles are filled contin-uously.The trick with representative sam plingis that throughout the entire <strong>milk</strong>reception process, from the first to thelast drop, a constant partial flow isdiverted into the sample bottle.Fully automatic sampler■■■Sample quantities can be regulatedin 0.1 ml steps.low carry-oversuitable <strong>for</strong> bacteriologicalsamplingIn the st<strong>and</strong>-alone versions, these lowmaintenancedevices consist of thesampler <strong>and</strong> a control unit that con-directly from the pipe. The sample ofraw <strong>milk</strong> is then stored in a bottlebearing unique identification.5

Multitasking –fully automated sampling using the SampleGuard TMThe <strong>GEA</strong> <strong>Diessel</strong> SampleGuard TM isthe all-rounder among samplers. Theuse of this fully automated samplerleads to the strictest possible degreeof surveillance. The SampleGuardunseals, opens <strong>and</strong> fills the samplebottle, <strong>and</strong> after sampling closes thebottle which was chosen at r<strong>and</strong>omduring this process. Any tamperingwith the system is reported immediatelyto the surveillance centre– <strong>for</strong> the <strong>data</strong> cont rol unit of theSampleGuard TM device – the ZEVO-DAT-flash TM – not only carries outsurveillance functions but also effects<strong>data</strong> exchange with the control centrein real time contact by GPRS.The SampleGuard TM is not only intelligent,it is also sensitive to an equaldegree: Two sensors monitor the constant<strong>and</strong> continuous filling of thebottles, <strong>and</strong> interrupt immediatelythe sampling <strong>and</strong> <strong>milk</strong> reception inthe event of any fault. Sample bottlesare identified electronically by RFIDtags attached to them. Once filled, theyare kept sealed <strong>and</strong> under surveillancein the refrigerated sample box – absolutelysafe against tampering.SampleGuard TM■■■■■■This you can rely on:The automated reception <strong>and</strong>discharge procedures excludeany possibility of tampering.GPS satellite navigation simplifiesthe identification of suppliers.Representative sampling withunique identification enhancesthe reliability of the laboratoryanalysis <strong>and</strong> the accounting.Thanks to secure <strong>data</strong> transmissionfrom the tanker to the central<strong>data</strong> processing unit, errorsin accounting are prevented.Thanks to the intelligent sensor<strong>technology</strong>, each sample bottleis filled to the same level.Temperature-regulated storageensures that the sample retainsits consistency unchanged untilthe end of the tour.6

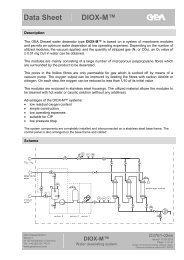

Customer-oriented solutions –sampling <strong>and</strong> upgrade varietiesProductequipmentCustomerrequirement<strong>GEA</strong> <strong>Diessel</strong>solutionOption <strong>for</strong>optimisationautomated extraction of arepresentative sample fromthe farm storage vesseltype PS3i peris taltictime-controlled st<strong>and</strong>alonesampler with display<strong>and</strong> key pad+ recognition of interruptionsin flow throughincorporation of aFlowSwitch sensor+optimised filling, evenduring any interruptionsin receptioninstallation of a sensor orconnection of a switchingcontact in the pipe to theavailable input port ofthe electronic system+ extended samplingto obtain an overallsample during the toursimultaneous takingof an individual sample<strong>and</strong> a tour sampleuse of a second samplinghead or of the dual samplertype PS4i+ automatic capture <strong>and</strong>transmission of supplier<strong>and</strong> tour <strong>data</strong> required<strong>for</strong> accounting purposes+ +storage of all the necessary<strong>data</strong> <strong>and</strong> transmissionto the <strong>data</strong> centreinstallation extended by theaddition of the ZEVODAT-C1 or ZEVODAT-flash<strong>data</strong> capture system+ automatic, accuraterecording of the <strong>milk</strong>quantity by meansof a volumetric measur -ing device+ +automatic determinationof quantity receivedfrom the supplierinstallation of an officially approvedvolumetric measuringdevice (e.g. DIME-M) withair eliminator <strong>and</strong> flow meter+ enhancement of thereception capacity to1,000 – 1,500 l/min.officially confirmed measuringof <strong>milk</strong> quantitiesat high reception speedsweights <strong>and</strong> measuresapproved high-speed measuringdevice with a varietyof pumping combinations+ tamper-proof <strong>milk</strong>collection through fullyautomated sampler+ ++ +sampling device withautomatic presentation<strong>and</strong> sealing of the samplebottlesinstallation of the Sample-Guard sampling deviceSamplingData controlVolumetricmeasuringWeights &measuresapprovedTamper-proofAutomatic7

<strong>GEA</strong> <strong>Diessel</strong> components<strong>for</strong> accurate mobile measurement<strong>and</strong> <strong>data</strong> <strong>technology</strong>■■■■■■■■■■■■■■■■■■PumpAir eliminatorFlow meterTemperature sensorGas bubble detectorSamplerNon-return valveControl unitData capture with voucher printerProcess Engineering<strong>GEA</strong> <strong>Diessel</strong> GmbHSteven 1 · 31135 Hildesheim · GermanyPhone +49 5121 742-0 · Fax +49 5121 742-153info.geadiessel.de@geagroup.com · www.geadiessel.com303.2.09 <strong>Measuring</strong> <strong>and</strong> <strong>data</strong> <strong>technology</strong> <strong>for</strong> <strong>milk</strong> <strong>tankers</strong> / all rights reserved / in<strong>for</strong>m-werbeagentur.de