Monitoring of emerging new seed borne diseases of significance in ...

Monitoring of emerging new seed borne diseases of significance in ...

Monitoring of emerging new seed borne diseases of significance in ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

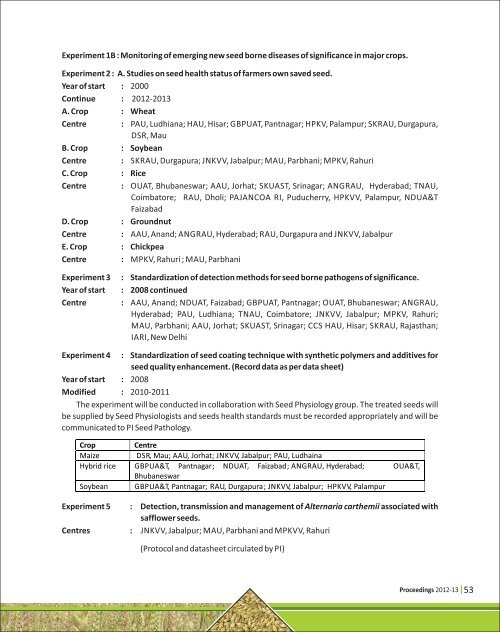

Experiment 1B : <strong>Monitor<strong>in</strong>g</strong> <strong>of</strong> <strong>emerg<strong>in</strong>g</strong> <strong>new</strong> <strong>seed</strong> <strong>borne</strong> <strong>diseases</strong> <strong>of</strong> <strong>significance</strong> <strong>in</strong> major crops.<br />

Experiment 2 : A. Studies on <strong>seed</strong> health status <strong>of</strong> farmers own saved <strong>seed</strong>.<br />

Year <strong>of</strong> start : 2000<br />

Cont<strong>in</strong>ue : 2012‐2013<br />

A. Crop : Wheat<br />

Centre : PAU, Ludhiana; HAU, Hisar; GBPUAT, Pantnagar; HPKV, Palampur; SKRAU, Durgapura,<br />

DSR, Mau<br />

B. Crop : Soybean<br />

Centre : SKRAU, Durgapura; JNKVV, Jabalpur; MAU, Parbhani; MPKV, Rahuri<br />

C. Crop : Rice<br />

Centre : OUAT, Bhubaneswar; AAU, Jorhat; SKUAST, Sr<strong>in</strong>agar; ANGRAU, Hyderabad; TNAU,<br />

Coimbatore; RAU, Dholi; PAJANCOA RI, Puducherry, HPKVV, Palampur, NDUA&T<br />

Faizabad<br />

D. Crop : Groundnut<br />

Centre : AAU, Anand; ANGRAU, Hyderabad; RAU, Durgapura and JNKVV, Jabalpur<br />

E. Crop : Chickpea<br />

Centre : MPKV, Rahuri ; MAU, Parbhani<br />

Experiment 3<br />

Year <strong>of</strong> start<br />

Centre<br />

: Standardization <strong>of</strong> detection methods for <strong>seed</strong> <strong>borne</strong> pathogens <strong>of</strong> <strong>significance</strong>.<br />

: 2008 cont<strong>in</strong>ued<br />

: AAU, Anand; NDUAT, Faizabad; GBPUAT, Pantnagar; OUAT, Bhubaneswar; ANGRAU,<br />

Hyderabad; PAU, Ludhiana; TNAU, Coimbatore; JNKVV, Jabalpur; MPKV, Rahuri;<br />

MAU, Parbhani; AAU, Jorhat; SKUAST, Sr<strong>in</strong>agar; CCS HAU, Hisar; SKRAU, Rajasthan;<br />

IARI, New Delhi<br />

Experiment 4 : Standardization <strong>of</strong> <strong>seed</strong> coat<strong>in</strong>g technique with synthetic polymers and additives for<br />

<strong>seed</strong> quality enhancement. (Record data as per data sheet)<br />

Year <strong>of</strong> start : 2008<br />

Modified : 2010‐2011<br />

The experiment will be conducted <strong>in</strong> collaboration with Seed Physiology group. The treated <strong>seed</strong>s will<br />

be supplied by Seed Physiologists and <strong>seed</strong>s health standards must be recorded appropriately and will be<br />

communicated to PI Seed Pathology.<br />

Crop<br />

Centre<br />

Maize DSR, Mau; AAU, Jorhat; JNKVV, Jabalpur; PAU, Ludha<strong>in</strong>a<br />

Hybrid rice GBPUA&T, Pantnagar; NDUAT, Faizabad; ANGRAU, Hyderabad; OUA&T,<br />

Bhubaneswar<br />

Soybean GBPUA&T, Pantnagar; RAU, Durgapura; JNKVV, Jabalpur; HPKVV, Palampur<br />

Experiment 5 : Detection, transmission and management <strong>of</strong> Alternaria carthemii associated with<br />

safflower <strong>seed</strong>s.<br />

Centres : JNKVV, Jabalpur; MAU, Parbhani and MPKVV, Rahuri<br />

(Protocol and datasheet circulated by PI)<br />

Proceed<strong>in</strong>gs 2012‐13<br />

53

Experiment 6 : Shelf life <strong>of</strong> fungal bio‐ agents <strong>in</strong> treated <strong>seed</strong>s dur<strong>in</strong>g storage<br />

Crop<br />

: Urdbean<br />

Year <strong>of</strong> start : 2010, cont<strong>in</strong>ued<br />

Centres : TNAU, Coimbatore; CRRI Cuttack; JNKVV, Jabalpur; OUAT, Bhubaneswar; MPKV,<br />

Rahuri; MAU, Parbhani<br />

(Protocol and datasheet circulated by PI)<br />

Experiment 7 : Standardization <strong>of</strong> bioprim<strong>in</strong>g for <strong>seed</strong> <strong>borne</strong> pathogens <strong>of</strong> <strong>significance</strong>.<br />

Year <strong>of</strong> start : 2010, title modified 2011<br />

Crop<br />

Centres<br />

Pearl millet : MAU, Parbhani; AAU, Anand; SKRAU, Durgapura<br />

Maize : TNAU, Coimbatore; OUAT, Bhubaneswar<br />

Experiment 8<br />

Year <strong>of</strong> start<br />

(Protocol and datasheet circulated by PI)<br />

: Effect <strong>of</strong> carbondioxide (CO₂) treatment on the management <strong>of</strong> <strong>seed</strong> <strong>borne</strong><br />

pathogens under ambient conditions. (In collaboration with <strong>seed</strong> entomologists)<br />

: 2010‐2011‐ cont<strong>in</strong>ued<br />

Crop (Seed)<br />

Centre<br />

Wheat : SKRAU, Durgapura; MPKV, Rahuri<br />

Paddy : ANGRAU, Hyderabad<br />

Pulse (Green Gram/ Black gram/ Red gram) : TNAU, Coimbatore; OUAT, Bhubaneswar<br />

(Protocol and datasheet circulated by PI)<br />

Experiment 9<br />

Centres<br />

: Correlation <strong>of</strong> various levels <strong>of</strong> <strong>seed</strong> <strong>in</strong>fection by important <strong>seed</strong>‐<strong>borne</strong> fungi on<br />

<strong>seed</strong> germ<strong>in</strong>ation <strong>in</strong> various crops like paddy, soybean, groundnut, castor, sesame,<br />

pearl millet etc (popularly grown crops and <strong>diseases</strong> <strong>of</strong> the region), data sheet will<br />

be supplied by PI Seed Pathology.<br />

: All centres except Jorhat<br />

Experiment 10 : Effect <strong>of</strong> PEMF (Pulsed Electro Magnetic Field) on <strong>seed</strong> health standards <strong>in</strong><br />

different crops (collaboration with physiology group)<br />

Year <strong>of</strong> start : 2012‐2013<br />

Centres : TNAU, Coimbatore and IARI New Delhi<br />

Crop<br />

: Paddy and Sunflower<br />

Experiment 11 : Management <strong>of</strong> <strong>seed</strong>‐<strong>borne</strong> <strong>in</strong>fection <strong>of</strong> Colletotrichum capsaci <strong>in</strong> chilli,<br />

Alternaria porri <strong>in</strong> Onion and A. solani <strong>in</strong> Tomato by way <strong>of</strong> biological <strong>seed</strong><br />

treatment<br />

Centres : GBPUA&T, Pantnagar; SKUA&T, Shr<strong>in</strong>agar; HPKVV, Palampur<br />

Voluntary centre :<br />

Experiment : Identification and management <strong>of</strong> tox<strong>in</strong> produc<strong>in</strong>g <strong>seed</strong> <strong>borne</strong> pathogens <strong>in</strong> rice.<br />

Year <strong>of</strong> Start : 2010 cont<strong>in</strong>ued<br />

Centre : CRRI Cuttack<br />

54 Proceed<strong>in</strong>gs 2012‐13

Additional Programmes for Lead centre<br />

ANGRAU, Hyderabad<br />

Experiment 1. Detection, transmission and management <strong>of</strong> Alternaria carthemi associated with safflower<br />

<strong>seed</strong>s and to develop molecular tools for the study <strong>of</strong> variability <strong>in</strong> the fungus.<br />

Year <strong>of</strong> start : 2008 modified <strong>in</strong> 2012<br />

MPKV Rahuri<br />

Experiment 1. To test the efficacy <strong>of</strong> bio‐ control agents aga<strong>in</strong>st different <strong>seed</strong> <strong>borne</strong> pathogens <strong>in</strong> sesame,<br />

cowpea, and wheat<br />

Year <strong>of</strong> start : 2010, modified <strong>in</strong> 2011, cont<strong>in</strong>ued<br />

OUAT Bhubaneswar<br />

(Lead centre for <strong>seed</strong> <strong>borne</strong> bacterial pathogens)<br />

Experiment 1: Characterization and identification <strong>of</strong> bacterial stra<strong>in</strong>s <strong>of</strong> Xanthomonas oryzae through<br />

morphological,physiological and biochemical methods <strong>in</strong> rice.<br />

Year <strong>of</strong> start : 2009, cont<strong>in</strong>ued<br />

AAU Anand<br />

(Lead centre for <strong>seed</strong> <strong>borne</strong> viral <strong>diseases</strong>)<br />

Experiment 1. <strong>Monitor<strong>in</strong>g</strong> <strong>of</strong> <strong>seed</strong> <strong>borne</strong> viruses <strong>of</strong> peanut, pulses and soybean<br />

Experiment 2. Detection <strong>of</strong> <strong>seed</strong> <strong>borne</strong> viruses through biological and serological techniques.<br />

Experiment 3. Survey and monitor<strong>in</strong>g for cum<strong>in</strong> blight: A <strong>seed</strong> <strong>borne</strong> disease.<br />

Proceed<strong>in</strong>gs 2012‐13<br />

55

D. Seed Entomology<br />

Chairman : Dr. P. K. Borad, HOD, Agrl. Ent. AAU, Anand<br />

Convener : Dr. Amit Bera, PI, CRIJAF, Barrackpore<br />

Recommendations:<br />

1. Emamect<strong>in</strong> benzoate 5 SG @ 40.0 mg/kg <strong>seed</strong> (2 ppm a.i.), Sp<strong>in</strong>osad 45 SC @ 4.4 mg/kg <strong>seed</strong> (2 ppm<br />

a.i.), followed by Flubendiamide 480 SC @ 4.2 mg/kg <strong>seed</strong> (2 ppm a.i.), Indoxacarb 14.5 SC @ 13.8<br />

mg/kg <strong>seed</strong> (2 ppm a.i.) and Thiodicarb 75WP @ 2.7 mg/kg <strong>seed</strong> (2 ppm a.i.) as <strong>seed</strong> protectant<br />

provide effective management <strong>of</strong> storage <strong>in</strong>sects <strong>in</strong>fest<strong>in</strong>g cereals (wheat, pearl millet, paddy, maize<br />

and sorghum) <strong>seed</strong>s under different agro‐climatic conditions except coastal regions without impair<strong>in</strong>g<br />

<strong>seed</strong> germ<strong>in</strong>ation for period <strong>of</strong> 6‐9 months.<br />

2. Emamect<strong>in</strong> benzoate 5 SG @ 40.0 mg/kg <strong>seed</strong> (2 ppm a.i.), Sp<strong>in</strong>osad 45 SC @ 4.4 mg/kg <strong>seed</strong> (2 ppm<br />

a.i.), followed by Indoxacarb 14.5 SC @ 13.8 mg/kg <strong>seed</strong> (2 ppm a.i.), Thiodicarb 75WP @ 2.7 mg/ kg<br />

<strong>seed</strong> (2 ppm a.i.) and Flubendiamide 480 SC @ 4.2 mg/kg <strong>seed</strong> (2 ppm a.i.) as <strong>seed</strong> protectant provide<br />

effective management <strong>of</strong> storage <strong>in</strong>sects <strong>in</strong>fest<strong>in</strong>g pulses (pigeon pea, cowpea, green gram, black<br />

gram, field pea and chickpea) <strong>seed</strong>s under different agro‐climatic conditions except coastal regions<br />

without impair<strong>in</strong>g <strong>seed</strong> germ<strong>in</strong>ation for period <strong>of</strong> 9‐12 months.<br />

3. Seed treatment with diatomaceous earth @ 5g /kg <strong>in</strong> comb<strong>in</strong>ation with desiccant (MgSO 4) @5g/kg<br />

<strong>seed</strong> can provide effective control aga<strong>in</strong>st <strong>in</strong>sect pests <strong>of</strong> wheat, paddy, sorghum, pearl millet without<br />

affect<strong>in</strong>g <strong>seed</strong> viability up to one season except <strong>in</strong> coastal regions.<br />

New Experiment 1 : Studies on the effect <strong>of</strong> <strong>in</strong>secticidal <strong>seed</strong> treatment on <strong>seed</strong> viability dur<strong>in</strong>g storage<br />

under ambient condition.<br />

Objectives:<br />

To evaluate <strong>new</strong>er molecules aga<strong>in</strong>st major storage <strong>in</strong>sect‐pests damag<strong>in</strong>g <strong>seed</strong>s.<br />

Study <strong>of</strong> the storability <strong>of</strong> treated <strong>seed</strong>s.<br />

Year <strong>of</strong> start : 2012<br />

Crop<br />

Wheat<br />

Maize<br />

Pearlmillet<br />

Paddy<br />

Pigeonpea<br />

Cowpea<br />

Mungbean<br />

Chickpea<br />

Black gram<br />

Field pea<br />

Centre<br />

RAU, Durgapura; NDUAT, Faizabad; DSR, Mau<br />

TNAU, Coimbatore; UAS, Bangalore<br />

JAU, Jamnagar; MPKV, Rahuri<br />

OUAT, Bhubaneswar; AAU, Jorhat; NDUAT, Faizabad; ANGRAU, Hyderabad<br />

NDUAT, Faizabad; UAS, Raichur<br />

UAS, Bangalore<br />

RAU, Durgapura; OUA&T, Bhubaneswar; MPKV, Rahuri<br />

ANGRAU, Hyderabad; JAU, Jamnagar; UAS, Raichur<br />

TNAU, Coimbatore<br />

CSAUAT, Kanpur<br />

Treatment:<br />

A. Chemical<br />

1. Emamect<strong>in</strong> benzoate (Proclaim 5 SG) @ 2 ppm (40.0 mg/kg <strong>seed</strong>)<br />

2. Sp<strong>in</strong>osad (Tracer 45 SC) @ 2 ppm (4.4 mg/kg <strong>seed</strong>)<br />

3. Indoxacarb (Avaunt 14.5 SC) @ 2 ppm (13.8 mg/kg <strong>seed</strong>)<br />

4. Rynaxypyr (Coragen 20 SC) @2ppm (0.01ml/kg <strong>seed</strong>)<br />

56 Proceed<strong>in</strong>gs 2012‐13

5. Chlorfenapyr (Intrepid 10 EC)@2ppm (0.02ml/kg <strong>seed</strong>)<br />

6. Novaluron (Rimon 10 EC) @2ppm (0.02ml/kg <strong>seed</strong>)<br />

7. Novaluron (Rimon 10 EC) @ 5ppm (0.05ml/kg <strong>seed</strong><br />

8. Deltamethr<strong>in</strong> 2. 8 EC @ 1.0 ppm (0.04 ml/kg <strong>seed</strong>)<br />

9. Untreated control<br />

B. Packag<strong>in</strong>g Material: Gunny bag‐lets <strong>of</strong> 2 kg capacity<br />

Replications : 3 Design : CRD<br />

Method:<br />

One kg <strong>of</strong> freshly harvested certified <strong>seed</strong> with very high percentage <strong>of</strong> germ<strong>in</strong>ation and low moisture<br />

content (

Replication : 3 Design : Factorial CRD<br />

Method:<br />

One kg <strong>of</strong> freshly harvested certified <strong>seed</strong> with very high percentage <strong>of</strong> germ<strong>in</strong>ation and low moisture<br />

content (

Date <strong>of</strong> Start : 2010<br />

Crop<br />

Sunflower<br />

Pigeonpea<br />

Mustard<br />

Sesamum<br />

Centre<br />

MPKV, Rahuri<br />

UAS, Bangalore<br />

ANGRAU, Hyderabad; NDUAT, Faizabad<br />

TNAU, Coimbatore ; OUAT, Bhubaneswar<br />

Treatments:<br />

Entomophilous crop will be grown <strong>in</strong> 1000 sq. m or more area follow<strong>in</strong>g recommended cultural practice.<br />

T1<br />

Five random plots <strong>of</strong> 3m x 2m will be covered with <strong>in</strong>sect–pro<strong>of</strong> net cages measur<strong>in</strong>g (length =5m,<br />

width=2m) at bud stage to exclude <strong>in</strong>sect's visit to flower <strong>in</strong> order to get self poll<strong>in</strong>ated (SP) <strong>seed</strong>s.<br />

T2<br />

Similarly, there will be five random plots <strong>of</strong> same size to serve as open poll<strong>in</strong>ated (OP) <strong>seed</strong>.<br />

T3<br />

And there will be five random plots <strong>of</strong> same size with partially caged with <strong>in</strong>sect pro<strong>of</strong> nets with 8‐<br />

frame honey bee colony to serve as bee poll<strong>in</strong>ated (BP) <strong>seed</strong>.<br />

The follow<strong>in</strong>g observations are to be recorded:<br />

Observations:<br />

a) Bee visits on 10 plants <strong>in</strong> FN (9‐10 AM) and AN (3‐4 PM)<br />

b) Percent <strong>seed</strong> set and yield under each conditions.<br />

c) Assessment <strong>of</strong> <strong>seed</strong> quality<br />

i. Seed germ<strong>in</strong>ation<br />

ii. Seed vigour<br />

iii. Oil content <strong>in</strong> case <strong>of</strong> oil <strong>seed</strong>s<br />

iv. Deterioration evaluation through accelerated ag<strong>in</strong>g.<br />

d) Record <strong>of</strong> weather condition particularly air temperature, humidity and sunsh<strong>in</strong>e prevail<strong>in</strong>g dur<strong>in</strong>g<br />

flower<strong>in</strong>g period <strong>of</strong> the crop.<br />

However, GOT test should also be performed and reported with other observation.<br />

Experiment 5a. Effect <strong>of</strong> carbon dioxide (CO 2) treatment on the control <strong>of</strong> storage <strong>in</strong>sect pests and the<br />

<strong>seed</strong> quality attributes under ambient conditions.<br />

Year <strong>of</strong> start : 2010<br />

Objectives:<br />

To assess the effect <strong>of</strong> carbon dioxide (CO 2) treatment on the mortality/survival <strong>of</strong> storage <strong>in</strong>sect pest<br />

under ambient conditions.<br />

To monitor effect <strong>of</strong> carbon dioxide (CO 2) treatment on <strong>seed</strong> quality attributes particularly <strong>seed</strong><br />

viability and vigour after 3, 6 and 9 months <strong>of</strong> storage under carbon dioxide (CO 2) atmosphere.<br />

Crop <strong>seed</strong><br />

Wheat<br />

Paddy<br />

Greengram<br />

Pigeon pea<br />

Groundnut<br />

Chickpea<br />

Centre<br />

RAU, Durgapura (Trogoderma); NDUAT, Faizabad (Sitophilus)<br />

ANGRAU Hyderabad (Sitotroga),<br />

TNAU, Coimbarore (Callosobruchus); OUAT, Bhubaneswar<br />

NDUAT, Faizabad (Callosobruchus); ANGRAU, Hyderabad<br />

UAS, Bangalore (Carryedon), TNAU, Coimbatore<br />

MPKV, Rahuri, NDUAT, Faizabad<br />

Proceed<strong>in</strong>gs 2012‐13<br />

59

Treatment:<br />

A. Treatment:<br />

T 1 Normal air treatment (untreated control)<br />

T<br />

2<br />

Carbon dioxide (CO<br />

2) @ 30% <strong>of</strong> the volume<br />

T<br />

3<br />

Carbon dioxide (CO<br />

2) @ 40% <strong>of</strong> the volume<br />

T 4 Carbon dioxide (CO 2) @ 50% <strong>of</strong> the volume<br />

B. Exposure period (P) <strong>in</strong> months:<br />

P 1 03<br />

P 2 06<br />

P<br />

3<br />

09<br />

P4<br />

12<br />

Replication : 3 Design : FCRD<br />

Materials<br />

1. 48 air tight plastic conta<strong>in</strong>ers with provision for air/gas <strong>in</strong>let/outlets;<br />

2. Carbon dioxide (CO 2) gas cyl<strong>in</strong>der with meter<strong>in</strong>g device;<br />

3. CO 2 / O 2 measur<strong>in</strong>g device.<br />

Methods:<br />

Seed <strong>of</strong> a popular crop variety with high germ<strong>in</strong>ation and free from <strong>in</strong>sect <strong>in</strong>festation (fumigate prior<br />

to use to ensure complete kill <strong>of</strong> field <strong>in</strong>festation, if any) should be used <strong>in</strong> the experiment. Fabricate<br />

or purchase airtight plastic conta<strong>in</strong>ers <strong>of</strong> 1 kg capacity with rubber septa on its lid to <strong>in</strong>sert syr<strong>in</strong>ge to<br />

remove air and add (CO 2) <strong>in</strong> proportion to give‐desired level <strong>of</strong> concentration <strong>in</strong> the conta<strong>in</strong>ers by<br />

flush<strong>in</strong>g method with an <strong>in</strong>let and an outlet which will be sealed after release <strong>of</strong> CO 2.<br />

<br />

Fill 500 g <strong>of</strong> <strong>seed</strong> <strong>in</strong> each conta<strong>in</strong>er and put 10 pairs <strong>of</strong> test <strong>in</strong>sects. (Release test <strong>in</strong>sects 10 days prior to<br />

treatment to create uniform level <strong>of</strong> <strong>in</strong>festation <strong>in</strong> all conta<strong>in</strong>ers). To create a particular concentration<br />

(%v/v) for each treatment, calculated volume <strong>of</strong> CO is <strong>in</strong>jected by open<strong>in</strong>g the <strong>in</strong>let for specified time.<br />

2<br />

Turn the conta<strong>in</strong>ers twice upside down to mix <strong>in</strong>tra‐granular gases with CO thoroughly. After<br />

2<br />

completion <strong>of</strong> treatment check the concentration <strong>of</strong> CO 2 with the meter<strong>in</strong>g device. Also check the<br />

concentration periodically to confirm leakage, if any and to plug it. Normally a properly airtight<br />

conta<strong>in</strong>er reta<strong>in</strong>s desired concentration <strong>of</strong> the gas. The temperature and RH will be recorded on<br />

weekly basis.<br />

Observations to be recorded at the end <strong>of</strong> each storage period<br />

Percent damaged <strong>seed</strong> (<strong>in</strong>sect <strong>in</strong>festation).<br />

Germ<strong>in</strong>ation <strong>of</strong> undamaged <strong>seed</strong><br />

Seed moisture content<br />

Number <strong>of</strong> live/dead <strong>in</strong>sects <strong>in</strong> the representative sample<br />

Experiment 5b. Design<strong>in</strong>g <strong>of</strong> large capacity storage b<strong>in</strong> for CO 2 treatment for management <strong>of</strong> <strong>in</strong>sect<br />

pests <strong>of</strong> stored <strong>seed</strong>s<br />

Objective:<br />

To design large conta<strong>in</strong>er to treat CO 2 for management <strong>of</strong> pests <strong>of</strong> stored <strong>seed</strong>s<br />

Year <strong>of</strong> start : 2010<br />

Crop <strong>seed</strong><br />

Centre<br />

Pulse (Green gram or black gram or red gram)<br />

TNAU, Coimbatore<br />

Paddy<br />

UAS, Bangalore<br />

60 Proceed<strong>in</strong>gs 2012‐13

The methodology and design <strong>of</strong> storage b<strong>in</strong> will be standardized for treat<strong>in</strong>g stored paddy / pulse<br />

<strong>seed</strong>s. Required quantity <strong>of</strong> <strong>seed</strong>s will be taken and artificially <strong>in</strong>fested with 100 pairs <strong>of</strong> lesser gra<strong>in</strong> borer<br />

(<strong>in</strong> paddy) and pulse beetle (<strong>in</strong> pulses) 10 days prior to experimentation and then treated with 0 and 50%<br />

CO 2 (<strong>in</strong> two separate conta<strong>in</strong>ers) and the percent <strong>seed</strong> damage due to <strong>in</strong>sect, <strong>in</strong>sect population (live and<br />

dead adults <strong>in</strong> 100g sample), <strong>seed</strong> germ<strong>in</strong>ation and moisture will be recorded at 3, 6 and 9 months after<br />

treatment. The level <strong>of</strong> CO<br />

2<br />

<strong>in</strong> the conta<strong>in</strong>ers will be assessed periodically. The temperature and RH <strong>of</strong><br />

storage room will be recorded on weekly basis.<br />

TNAU, Coimbatore and UAS, Bangalore centre shall design the conta<strong>in</strong>er for stor<strong>in</strong>g 100 kg <strong>of</strong> <strong>seed</strong> <strong>in</strong><br />

collaboration with design eng<strong>in</strong>eer. After the design<strong>in</strong>g <strong>of</strong> the conta<strong>in</strong>er, the concerned centres will<br />

explore for the efficacy <strong>of</strong> CO 2. RAU, Durgapura centre shall evaluate after obta<strong>in</strong><strong>in</strong>g the conta<strong>in</strong>ers from<br />

either <strong>of</strong> the above mentioned two centres by pay<strong>in</strong>g necessary payment towards the cost <strong>of</strong> conta<strong>in</strong>er<br />

Experiment 6: Efficacy <strong>of</strong> <strong>new</strong> <strong>in</strong>secticides as fabric treatment for management <strong>of</strong> cross <strong>in</strong>festation <strong>of</strong><br />

<strong>in</strong>sect pests <strong>of</strong> stored <strong>seed</strong>s<br />

Year <strong>of</strong> start : 2010<br />

Objectives:<br />

To evaluate <strong>new</strong>er molecules as fabric treatment aga<strong>in</strong>st cross <strong>in</strong>festation <strong>of</strong> major storage <strong>in</strong>sectpests<br />

damag<strong>in</strong>g <strong>seed</strong>s.<br />

Study <strong>of</strong> the storability <strong>of</strong> <strong>seed</strong>s <strong>in</strong> treated bags.<br />

Crop<br />

Wheat<br />

Maize<br />

Sorghum<br />

Paddy<br />

Pigeonpea<br />

Chickpea<br />

Mungbean<br />

Groundnut<br />

Centre<br />

CSAUAT, Kanpur; DSR Mau; RAU, Durgapura; JAU, Jamnagar; PDKV, Akola<br />

AAU, Jorhat; UAS, Bangalore<br />

TNAU, Coimbatore<br />

OUAT, Bhubaneswar; NDUAT, Faizabad; PAJANCOA&RI, Karaikal<br />

ANGRAU Hyderabad<br />

MPKV, Rahuri; JAU, Jamnagar,<br />

RAU, Durgapura; OUAT, Bhubaneswar<br />

JAU, Jamnagar; UAS, Bangalore<br />

Treatment:<br />

1. Flubendiamide 100 ppm ai (Fame 480 SC – 0.2ml /litre)<br />

2. Emamect<strong>in</strong> benzoate 100 ppm ai (Proclaim 5SG – 2g /litre)<br />

3. Sp<strong>in</strong>osad 100 ppm ai (Tracer 45 SC ‐ 0.2ml /litre)<br />

4. Deltamethr<strong>in</strong> 100 ppm ai (Decis 2. 8 EC ‐ 3.5ml /litre)<br />

5. Untreated control<br />

Pack<strong>in</strong>g material :<br />

1. Gunny baglet <strong>of</strong> 2 kg capacity<br />

2. Porous HDPE bags <strong>of</strong> 2 kg capacity<br />

3. Cloth bags <strong>of</strong> 2 kg capacity<br />

Replications : 3<br />

Design : FCRD<br />

Methodology:<br />

One kg <strong>of</strong> freshly harvested certified <strong>seed</strong> with high percentage <strong>of</strong> germ<strong>in</strong>ation and low moisture<br />

content (below 10 %) will be taken and fumigated or kept <strong>in</strong> m<strong>in</strong>us 20⁰C for 24h prior to use to ensure<br />

complete kill <strong>of</strong> field <strong>in</strong>festation, if any. Prepare <strong>in</strong>secticidal solution <strong>of</strong> given concentration and spray on<br />

Proceed<strong>in</strong>gs 2012‐13<br />

61

the packag<strong>in</strong>g material with 7.5ml spray fluid for a bag <strong>of</strong> 30 x 40 cm dimension. After shade dry<strong>in</strong>g the<br />

bags, <strong>seed</strong>s will be filled and kept <strong>in</strong> laboratory under ambient condition. Temperature and RH will be<br />

recorded on weekly basis.<br />

Observations:<br />

Every three months for a total period <strong>of</strong> 12 months or loss <strong>of</strong> germ<strong>in</strong>ation below/MSCS which ever is early<br />

a. Seed germ<strong>in</strong>ation<br />

b. Seed moisture<br />

c. Natural <strong>in</strong>sect <strong>in</strong>festation <strong>in</strong> percentage<br />

d. Presence / Absence <strong>of</strong> <strong>in</strong>sects (live and dead)<br />

Experiment‐7: Effect <strong>of</strong> <strong>in</strong>terval <strong>of</strong> <strong>in</strong>secticidal application on storability <strong>of</strong> <strong>seed</strong> under ambient<br />

condition.<br />

Year <strong>of</strong> start: 2011‐12<br />

Objectives:<br />

To evaluate the <strong>in</strong>tegration effect <strong>of</strong> <strong>seed</strong> treatment as well as fabric treatments aga<strong>in</strong>st<br />

<strong>in</strong>festation <strong>of</strong> major storage <strong>in</strong>sect‐pests damag<strong>in</strong>g <strong>seed</strong>s.<br />

To standardize the <strong>in</strong>terval <strong>of</strong> treatment application for effective storage.<br />

Crop<br />

Wheat<br />

Maize<br />

Paddy<br />

Pigeonpea<br />

Mungbean<br />

Centre<br />

DSR Mau; RAU, Durgapura; JAU, Jamnagar; NDUAT, Faizabad<br />

UAS, Bangalore; ANGRAU, Hyderabad<br />

TNAU, Coimbatore; OUAT, Bhubaneswar; AAU, Jorhat PAJANCOA&RI, Karaikal<br />

ANGRAU, Hyderabad; UAS, Bangalore; NDUAT, Faizabad<br />

MPKV, Rahuri; JAU, Jamnagar; TNAU, Coimbatore;<br />

Treatment:<br />

T 1 = Seed treatment with Emamect<strong>in</strong> benzoate (Proclaim 5 SG) @ 2 ppm (40.0 mg/kg <strong>seed</strong>)<br />

T 2 = T 1+Fabric treatment with Emamect<strong>in</strong> benzoate 100 ppm ai (Proclaim 5 SG – 2g /litre) after<br />

two months <strong>of</strong> <strong>seed</strong> treatment<br />

T 3 = T 1+ Fabric treatment with Emamect<strong>in</strong> benzoate 100 ppm ai (Proclaim 5 SG – 2g /litre) after<br />

four months <strong>of</strong> <strong>seed</strong> treatment<br />

T 4 = T 1+Fabric treatment with Emamect<strong>in</strong> benzoate 100 ppm ai (Proclaim 5 SG – 2g /litre) after<br />

six months <strong>of</strong> <strong>seed</strong> treatment<br />

T 5 = T 1+Fabric treatment with Emamect<strong>in</strong> benzoate 100 ppm ai (Proclaim 5 SG – 2g /litre) after<br />

eight months <strong>of</strong> <strong>seed</strong> treatment<br />

T 6 = T 1+T 2+T3<br />

T 7 = T 1+T 2+T4<br />

T 8 = T 1+T 2+T5<br />

T 9 = T 1+T 3+T4<br />

T 10 = T 1+T 4+T5<br />

T 11 = T 1+T 2+T 3+T4<br />

T<br />

12<br />

= T<br />

1+T 2+T 3+T5<br />

T 13 = T 1+ T 3+T 4+T5<br />

T<br />

14<br />

= T<br />

1+T 2+T 4+T5<br />

62 Proceed<strong>in</strong>gs 2012‐13

T<br />

15<br />

= T<br />

1+T 2+T 3+T 4+T5<br />

T 16 = Untreated control<br />

Pack<strong>in</strong>g material: Porous HDPE bags <strong>of</strong> 2 kg capacity<br />

Replications: 2 Design: CRD<br />

Methodology:<br />

One kg <strong>of</strong> freshly harvested certified <strong>seed</strong> with very high percentage <strong>of</strong> germ<strong>in</strong>ation and low moisture<br />

content (

2. Treated bag, non treated lam<strong>in</strong>ation, non treated l<strong>in</strong>er<br />

3. Treated bag, treated lam<strong>in</strong>ation, treated l<strong>in</strong>er<br />

4. Untreated bag (same fabric i.e. PP Bag)<br />

5. Gunny bag (control)<br />

Replication: 3 Design: FCRD<br />

Method: Required quantity <strong>of</strong> freshly harvested certified <strong>seed</strong> (Wheat, Paddy‐ 10 kg ; Maize, Chickpea,<br />

Red gram, green gram‐ 5kg) with very high percentage <strong>of</strong> germ<strong>in</strong>ation and low moisture content (

List <strong>of</strong> Participants<br />

S.No Name Designation Address Telephone No. & Email. address<br />

1. Dr. P. K. Borad Pr<strong>of</strong>essor & Head, Department <strong>of</strong> Entomology,<br />

AAU, Anand.<br />

0919426508347<br />

pkb5458@yahoo.com<br />

2. Dr. A. Bera PI, Seed Ento. CRIJAF, Barrackpore 09732709874<br />

amitbera.iari@gmail.com<br />

3. Dr. A. N. S<strong>in</strong>gh Senior Scientist DSR, Mau 09450725652<br />

arv<strong>in</strong>dnaths<strong>in</strong>gh@gmail.com<br />

4. Dr. R.K. Pandey ASRO (Ent.) Seed Tech Unit<br />

NDUAT, Faizabad, 224229<br />

05270‐262533, 08795885292<br />

pandeyrohit50@yahoo.com<br />

5. Dr. Y.H. Ghelani ASRO (Ent) STR Unit, Pearl Millet Res.<br />

Station, JAU Jamnagar‐ 361006,<br />

Gujarat<br />

0288‐2711793, 098981 41556<br />

yhghelani@rediffmail.com<br />

6. Dr. G.T.<br />

Thirumalaraju<br />

Pr<strong>of</strong>essor (Agrl.<br />

Ento.)<br />

7. Dr. P.K. Behera Associate<br />

Pr<strong>of</strong>essor, Seed<br />

Entomology<br />

AICRP on Seed Technology,<br />

NSP, GKVK, UAS Bangalore‐<br />

560065 Karnataka<br />

STR NSP (Crops) Dept. <strong>of</strong> SST,<br />

OUAT,<br />

Bhubaneswar‐751003,<br />

09845607212<br />

gtr1958@<strong>in</strong>diatimes.com<br />

861231665<br />

pradeepbehera2010@yahoo.com<br />

8 Dr. S.S. Bareth ASRO, STR ARS Durgapura Jaipur 09784628551<br />

sns_str2001@yahoo.com<br />

9. Dr.Mathura Mohan<br />

Goswami<br />

Senior Scientist STR, AAU, Jorhat, 785013,<br />

Assam<br />

094351 83919<br />

mathura.goswami@rediffmail.com<br />

10. Dr. M. Muthuswami Assoc. Pr<strong>of</strong>.<br />

Agril. Ento.<br />

Seed Centre TNAU, Coimbatore 09442616133<br />

mms3@tnau.ac.<strong>in</strong><br />

11. Dr. U. K. Kadam ASRO, STR MPKV, Rahuri 09273531557<br />

kadamuk2010@ rediffmail.com<br />

12. Mr. S. B. Bellad Asst. Pr<strong>of</strong>essor UAS, Raichur 09448305359<br />

belladstech@gmail.com<br />

13. Mr. Prashant S.M. Asst. Seed<br />

Production<br />

UAS, Raichur 09535099680<br />

prashusm@gmail.com<br />

Specialist<br />

14. Dr. V. Bharathi Seed Pathologist ANGRAU, Hyderabad bharathiv@yahoo.com<br />

09440980049<br />

Proceed<strong>in</strong>gs 2012‐13<br />

65

E. Seed Process<strong>in</strong>g<br />

Chairman : Dr. D. C. Joshi, Dean, Agrl. Product Process<strong>in</strong>g & Bio‐energy<br />

Convener : Dr. R.T. Kausal, PDKV, Akola<br />

Recommendation : Nil<br />

Experiment 1 : Optimum sieve size and type <strong>of</strong> screen for grad<strong>in</strong>g <strong>seed</strong>s <strong>of</strong> different crop varieties<br />

and hybrids <strong>in</strong>clud<strong>in</strong>g their parents.<br />

Objective : To standardize the sieve size and type <strong>of</strong> screen for grad<strong>in</strong>g <strong>seed</strong>s <strong>of</strong> different crop varieties<br />

and hybrids <strong>in</strong>clud<strong>in</strong>g their parents.<br />

NSP centre<br />

PDKV, Akola<br />

UAS, Bangalore<br />

UAS, Dharwad<br />

TNAU, Coimbatore<br />

HPKV, Palampur<br />

CSAUT, Kanpur<br />

MPKV, Rahuri<br />

SDAU, SKNagar<br />

UAS, Raichur<br />

CCSHAU, Hissar<br />

AAU, Anand<br />

Crop<br />

Chickpea, Pigeon pea, Paddy<br />

Sunflower, Redgram, Paddy<br />

Soybean, Pigeon pea, Sorghum (Rabi)<br />

Paddy, Blackgram<br />

Wheat, Mustard, Peas<br />

Wheat<br />

Sorghum (Rabi), Chickpea, Pearl millet<br />

Wheat, Greengram, Mustard<br />

Pigeonpea, Soybean<br />

Wheat, Greengram<br />

Wheat, Paddy, Greengram<br />

Treatments:<br />

1. Crop : As above<br />

2. Sieve sizes : 1. Top sieve: (as per MSCS)<br />

2. Grad<strong>in</strong>g sieve:<br />

i) Recommended sieve (as per MSCS)<br />

ii) Two sieves above the recommended sieve<br />

iii) Two sieves below the recommended sieve<br />

Procedure:<br />

Unprocessed <strong>seed</strong> <strong>of</strong> the each crop variety will be procured from reliable source. Recommended size <strong>of</strong><br />

top and bottom sieve will be used along with one or two sieve <strong>of</strong> above size and one or two sieve <strong>of</strong> below<br />

the size <strong>of</strong> recommended grad<strong>in</strong>g sieve. Seed material reta<strong>in</strong>ed over each grad<strong>in</strong>g will be tested for<br />

observation on <strong>seed</strong> quality. Use a two‐screen air cleaner‐cum‐grader. Consider the material rid<strong>in</strong>g over<br />

the grad<strong>in</strong>g screen as product and that s<strong>in</strong>k<strong>in</strong>g through as reject. Brief description <strong>of</strong> the mach<strong>in</strong>e or<br />

experimental set‐up has to be reported.<br />

Observations<br />

1. Recovery and rejection (%)<br />

2. Seed size : Length, breadth and thickness (mm)<br />

3. Germ<strong>in</strong>ation (%)<br />

4. Vigor <strong>in</strong>dex<br />

5. Physical purity (%)<br />

66 Proceed<strong>in</strong>gs 2012‐13

6. 1000/100‐<strong>seed</strong> weight (g)<br />

7. Moisture content (%)<br />

8. Mechanical damage (%)<br />

Experiment 2 : Management <strong>of</strong> mechanical damage at harvest<strong>in</strong>g and thresh<strong>in</strong>g<br />

Objective : To study the management <strong>of</strong> mechanical damage due to different harvest<strong>in</strong>g and thresh<strong>in</strong>g<br />

methods.<br />

NSP Centre<br />

TNAU, Coimbatore<br />

PDKV, Akola<br />

CSK HPKV, Palampur<br />

AAU, Anand<br />

UAS, Raichur<br />

Crop<br />

Paddy<br />

Chickpea, Soybean, Paddy<br />

Soybean<br />

Paddy<br />

Soybean<br />

Harvest<strong>in</strong>g Methods:<br />

1. Traditional method<br />

2. Mechanical methods<br />

Procedure:<br />

The crop will be harvested by different methods i.e traditional and by mechanical. The crop will be<br />

threshed by multi‐crop thresher at 700 rpm <strong>in</strong> case <strong>of</strong> manually harvested / threshed <strong>seed</strong> and the use <strong>of</strong><br />

comb<strong>in</strong>e harvester at 500 rpm and 700 rpm will be tested for <strong>seed</strong> quality parameters <strong>in</strong>clud<strong>in</strong>g<br />

mechanical damage. The field losses will be recorded <strong>in</strong> both the harvest<strong>in</strong>g methods.<br />

Observations:<br />

1. Mechanical <strong>in</strong>jury (%)<br />

2. Germ<strong>in</strong>ation (%)<br />

3. No. <strong>of</strong> abnormal <strong>seed</strong>l<strong>in</strong>g<br />

4. Vigour <strong>in</strong>dex<br />

5. No. <strong>of</strong> ODV Seeds<br />

6. 100‐<strong>seed</strong> weight (gm)<br />

7. Field loss per unit area before and after harvest<strong>in</strong>g<br />

8. Physical purity (%).<br />

Experiment 3: Studies on effectiveness <strong>of</strong> specific gravity separator for removal <strong>of</strong> ODV <strong>seed</strong>s.<br />

NSP Center<br />

TNAU, Coimbatore<br />

PDKV, Akola<br />

UAS, Bengaluru<br />

CCSHAU, Hissar<br />

CSK HPKV, Palampur<br />

PAJANCOA & RI, Karaikal<br />

Crop<br />

Paddy<br />

Paddy<br />

Pigeonpea<br />

Wheat<br />

Wheat<br />

Paddy<br />

Procedure:<br />

The crop <strong>seed</strong> will be processed on a modern <strong>seed</strong> process<strong>in</strong>g plant us<strong>in</strong>g <strong>seed</strong> precleaner, <strong>seed</strong><br />

grader, specific gravity separator arranged <strong>in</strong> series. The ODV <strong>seed</strong>s <strong>in</strong> raw paddy <strong>seed</strong> <strong>in</strong> each lot will be<br />

recorded. Dur<strong>in</strong>g process<strong>in</strong>g, the sample will be collected from the outlet po<strong>in</strong>ts <strong>of</strong> <strong>seed</strong> precleaner, <strong>seed</strong><br />

Proceed<strong>in</strong>gs 2012‐13<br />

67

grader and specific gravity separator. The sample thus collected will be tested for presence <strong>of</strong> ODV <strong>seed</strong>,<br />

germ<strong>in</strong>ation %, Physical purity %, vigour <strong>in</strong>dex, 1000 <strong>seed</strong> weight and moisture content.<br />

Observations:<br />

1. Number <strong>of</strong> ODV <strong>seed</strong>s <strong>in</strong> raw <strong>seed</strong>.<br />

2. Number <strong>of</strong> ODV <strong>seed</strong>s after size grad<strong>in</strong>g.<br />

3. Number <strong>of</strong> ODV <strong>seed</strong>s after specific gravity grad<strong>in</strong>g.<br />

4. Germ<strong>in</strong>ation % <strong>of</strong> raw <strong>seed</strong> and f<strong>in</strong>al product.<br />

5. Seedl<strong>in</strong>g length <strong>of</strong> raw <strong>seed</strong> and f<strong>in</strong>al <strong>seed</strong> product.<br />

6. Vigour <strong>in</strong>dex <strong>of</strong> raw <strong>seed</strong> and f<strong>in</strong>al <strong>seed</strong> product.<br />

7. 1000 <strong>seed</strong> weight<br />

Experiment 4: Evaluation <strong>of</strong> <strong>seed</strong> process<strong>in</strong>g units<br />

NSP Centre<br />

PDKV, Akola<br />

UAS, Bengaluru<br />

CCSHAU, Hissar<br />

CSAUAT, Kanpur<br />

SDAU, SKNagar<br />

MPKV, Rahuri<br />

CSKHPKV, Palampur<br />

UAS Raichur<br />

Area to be covered<br />

Maharashtra (SAUs + Private)<br />

Karnataka (SAUs + Private)<br />

Haryana (SAUs + Private)<br />

Uttar Pradesh (SAUs + Private)<br />

Gujarat (SAUs + Private)<br />

Maharashtra (SAUs + Private)<br />

Himachal Pradesh (SAUs + Private)<br />

Karnataka (SAUs + Private)<br />

Procedure:<br />

The performance <strong>of</strong> <strong>seed</strong> process<strong>in</strong>g plant established <strong>in</strong> SAUs established under the different<br />

projects will be evaluated along with few private plants adjo<strong>in</strong><strong>in</strong>g the area as regard to present status <strong>of</strong><br />

the mach<strong>in</strong>e, performance <strong>of</strong> the mach<strong>in</strong>e, <strong>seed</strong> quality <strong>of</strong> the produce, storage conditions and staff<strong>in</strong>g<br />

pattern etc. (Pr<strong>of</strong>orma will be supplied by the PI).<br />

Observations:<br />

1. Type <strong>of</strong> plant (Make, year <strong>of</strong> purchase and other details)<br />

2. Mach<strong>in</strong>es/Equipments<br />

3. Efficiency <strong>of</strong> mach<strong>in</strong>e<br />

4. Crop processed<br />

5. Process<strong>in</strong>g sequence<br />

6. Staff<strong>in</strong>g pattern<br />

7. Floor area<br />

8. Storage facilities<br />

9. Seed protection measures taken dur<strong>in</strong>g storage<br />

10. Constra<strong>in</strong>ts faced / Difficulties / Problems faced by <strong>seed</strong> <strong>in</strong>dustry.<br />

Experiment 5 : Performance <strong>of</strong> needle separator for separat<strong>in</strong>g <strong>in</strong>sect damage <strong>seed</strong> <strong>in</strong> Cotton <strong>seed</strong>.<br />

Objective : To study the effectiveness <strong>of</strong> needle separator for remov<strong>in</strong>g <strong>in</strong>sect damaged <strong>seed</strong> <strong>in</strong> cotton<br />

<strong>seed</strong>.<br />

Center : PDKV, Akola; TNAU; Coimbatore; SDAU SK; Nagar<br />

68 Proceed<strong>in</strong>gs 2012‐13

Treatments : Crop : Cotton <strong>seed</strong><br />

Unit operation : Raw <strong>seed</strong><br />

↓<br />

Size grader<br />

↓<br />

Specific gravity separator<br />

↓<br />

Needle separator<br />

Procedure:<br />

The <strong>seed</strong> lots <strong>of</strong> cotton will be processed on a normal <strong>seed</strong> process<strong>in</strong>g plant us<strong>in</strong>g needle separator.<br />

The samples will be drawn before process<strong>in</strong>g, after size grad<strong>in</strong>g, after gravity grad<strong>in</strong>g, and after us<strong>in</strong>g<br />

needle separator. The samples thus collected will be tested for follow<strong>in</strong>g <strong>seed</strong> quality characters.<br />

Observations:<br />

1. Mechanical damage (%)<br />

2. Insect damage (%)<br />

3. Germ<strong>in</strong>ation (%)<br />

4. Vigour <strong>in</strong>dex<br />

5. 100‐<strong>seed</strong> weight (gm)<br />

‐1<br />

6. Electrical conductivity (dSm )<br />

List <strong>of</strong> participants<br />

S. Name <strong>of</strong> Scientist Designation & Address Mobile No.<br />

No.<br />

1 Dr. S. Rajendra Prasad Project Director, DSR, Mau 9415108377<br />

2 Dr. D<strong>in</strong>esh Badiyala Pr<strong>of</strong>. & Head, CSK HPKV, Palampur 9816185743<br />

3 Dr.(Mrs.) R Jerl<strong>in</strong> Assoc. Pr<strong>of</strong>., TNAU, Coimbatore 9994282810<br />

4 Dr. R. Siddaraju Assoc. Pr<strong>of</strong>., STR, NSP, UAS, Bengaluru 9880047284<br />

5 Dr. V.S. Mor Asst. Scientist (SST), CCSHAU, Hissar 9255563437<br />

6 Dr. B.S. Ganigara Asst. Seed Production Specialist, UAS, Raichur 9845844075<br />

7 Dr. Ashok Asuti Agriculture Eng<strong>in</strong>eer, Seed Uni t, UAS, Dharawad 9480750848<br />

8 Dr. Parashiva Murthy Assoc. Pr<strong>of</strong>., NSP, UAS, GKVK, Bengaluru 9886038788<br />

9 Sh.Gov<strong>in</strong>dbhi M.Patel Asst. Research Scientist, STR, SDAU, SK Nagar 9898128443<br />

10 Sh. Vijayakumar H.P Scientist, DSR, Mau 9005598429<br />

11 Dr. J.S. Dosh i Asst. Pr<strong>of</strong>. , AAU, Anand 9426419669<br />

12 Dr. J.K. Sharma Nodal Officer (Seed), CSK HPKV, Palampur 9418909960<br />

13 Dr.T. Ramanadane Assoc. Pr<strong>of</strong>., PAJANCOA &RI, Karaikal 9443875443<br />

14 Dr.R.T. Kausal PI, Seed Process<strong>in</strong>g & SRO, STR, Dr. PDKV. Akola 9421794609<br />

Note: The data sheet and pr<strong>of</strong>orma <strong>of</strong> each <strong>of</strong> the above all experiments will be prepared by Dr. R.T Kausal, Dr. (Mrs.) R.<br />

st<br />

Jerl<strong>in</strong> and Dr. T. Ramanadane and circulated to all the centres before 31 May, 2012 for smooth conduct <strong>of</strong> the<br />

experiments<br />

Proceed<strong>in</strong>gs 2012‐13<br />

69

Session ‐ VII<br />

Seed Stakeholders‐Scientists Interaction<br />

Chairman : Dr. J. S. Sandhu<br />

Assistant Director General (Seeds), ICAR, New Delhi<br />

Co‐Chairman : Dr. N. K. Dadlani<br />

Director, NSAI, New Delhi<br />

Rapporteurs : Dr. Geeta Bassi, PAU, Ludhiana<br />

: Dr. Ravi Hunje, UAS, Dharwad<br />

<br />

Date: 16.04.2012<br />

Time: 9.00 A.M.<br />

The session started with open<strong>in</strong>g remarks by Dr J.S.Sandhu. He stressed that public‐ private<br />

partnership is the need <strong>of</strong> the hour for the overall development <strong>of</strong> the Seed sector <strong>in</strong> the country. There<br />

were n<strong>in</strong>e speakers for their presentations but only three made their deliberations.<br />

First speaker was Dr N. K. Dadlani who expla<strong>in</strong>ed <strong>in</strong> details various workable areas for public‐private<br />

partnership <strong>in</strong> Seed Technology. He emphasised that for mov<strong>in</strong>g forward <strong>in</strong> <strong>seed</strong> sector private and<br />

public sector should work <strong>in</strong> harmony and with mutual trust <strong>in</strong> the field <strong>of</strong> <strong>seed</strong> research. He stressed<br />

upon equal partnership <strong>of</strong> both the sector (private and public). He appreciated the contributions<br />

made by public sector and <strong>in</strong>formed that both sectors have realised to work together after the<br />

<strong>in</strong>troduction <strong>of</strong> PPV & FR Act and to compete <strong>in</strong> the global <strong>seed</strong> regime. Commercialisation <strong>of</strong> the<br />

product developed is very essential. So it is necessary to establish a jo<strong>in</strong>t group <strong>of</strong> public and private<br />

sectors to work together to evolve policies <strong>in</strong> contract research, knowledge shar<strong>in</strong>g, jo<strong>in</strong>t technology<br />

development and technology licenc<strong>in</strong>g. There is a need to constitute a small <strong>in</strong>clusive task force to<br />

identify need based areas.<br />

Some researchable suggested areas are:<br />

<br />

<br />

<br />

<br />

<br />

<br />

Newer areas for <strong>seed</strong> production<br />

Decrease the cost <strong>of</strong> <strong>seed</strong> production by <strong>of</strong>f‐ season production<br />

To revisit the isolation distance based on scientific data and experimental evidences.<br />

Development <strong>of</strong> protocol for high quality <strong>seed</strong>s<br />

Economic and effective <strong>seed</strong> dry<strong>in</strong>g and storage protocols<br />

Rationalisation and validation <strong>of</strong> <strong>seed</strong> samples for quality tests<br />

Seed quality enhancement technology.<br />

Second deliberation was made by Dr D.B. Desai, MD Nav Bharat Seeds Gujarat on “Issues related to Seed<br />

Industry <strong>of</strong> Gujarat ” and shared his long association with the <strong>seed</strong> family <strong>in</strong> India. He emphasised:<br />

<br />

<br />

<br />

<br />

<br />

To organise small <strong>in</strong>teractive sessions with farmers and dealers to match the farmer‐ breeder<br />

objective for variety and hybrids development.<br />

To compile the research outcome <strong>of</strong> last 25 years for the benefit <strong>of</strong> all the stakeholders.<br />

Research on cost <strong>of</strong> <strong>seed</strong> production and <strong>seed</strong> supply.<br />

Liberal supply <strong>of</strong> germplasm for use <strong>in</strong> R & D for the private sector.<br />

Representation <strong>of</strong> <strong>seed</strong> association <strong>in</strong> various committees related to <strong>seed</strong>.<br />

To <strong>in</strong>volve private sector <strong>in</strong> <strong>seed</strong> Bank Scheme.<br />

Third speaker Dr. B.N. Basu from H<strong>in</strong>dustan Insecticides Ltd. a Govt. <strong>of</strong> India Undertak<strong>in</strong>g expla<strong>in</strong>ed his rich<br />

70 Proceed<strong>in</strong>gs 2012‐13

experience work<strong>in</strong>g <strong>in</strong> public sector and some association with private sector. He emphasised that there<br />

are several areas for efficient development <strong>of</strong> <strong>seed</strong> sector. He endorsed the comments made by previous<br />

speakers.<br />

Dr. R.K. Chowdhury Former PC (NSP) <strong>in</strong>formed about the revision <strong>of</strong> IMSCS, validation <strong>of</strong> technology<br />

developed by private sector <strong>in</strong> <strong>seed</strong> storage and dry<strong>in</strong>g. He emphasised on liberal and simple rules for<br />

gett<strong>in</strong>g the germplasms by private sector for R&D.<br />

Remarks by Co‐Chair:<br />

<br />

There are areas to work together <strong>in</strong> comb<strong>in</strong>ation <strong>of</strong> vision and capacity <strong>of</strong> both the sectors.<br />

Farmers have become decision makers and ready to pay more for quality <strong>seed</strong>s, therefore best<br />

quality <strong>seed</strong> should reach the end user the FARMERS.<br />

Conclud<strong>in</strong>g Remarks by Chair:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Both public and private sector should work together by mutual understand<strong>in</strong>g their STRENGTHS<br />

and WEAKNESSES for mak<strong>in</strong>g available the quality <strong>seed</strong>.<br />

To build partnership <strong>of</strong> trust and transparency smaller group should meet from both the sectors<br />

frequently.<br />

Identify the complimentary areas to work together.<br />

To br<strong>in</strong>g more area under hybrid rice <strong>in</strong> India by cohesive partnership <strong>of</strong> public and private <strong>seed</strong><br />

players to enhance the quantity vis a vis quality.<br />

To f<strong>in</strong>d alternate areas for <strong>seed</strong> production.<br />

Exposure visit <strong>of</strong> scientists to private <strong>seed</strong> <strong>in</strong>dustries to witness their <strong>in</strong>frastructure and other R&D<br />

programme.<br />

To keep pace with global development, emphasis should be given to HRD.<br />

The session ended with vote <strong>of</strong> thanks by Dr. S. Rajendra Prasad, PD, DSR, Mau.<br />

Proceed<strong>in</strong>gs 2012‐13<br />

71

Session ‐ VIII<br />

Session on Annual Oil<strong>seed</strong> Scheme<br />

Chairman : Dr. J. S. Sandhu<br />

Assistant Director General (Seeds), ICAR, New Delhi<br />

Co‐Chairman : Dr. A.P. S<strong>in</strong>gh<br />

Dy. Commissioner, (TMOP) ISOPOM, DAC, GOI<br />

Rapporters : Dr. (Mrs.) M. S. Uma, UAS, Bangalore<br />

: Dr. P. Ravishankar, UAS, Bangalore<br />

th<br />

At the outset, ADG (Seeds) gave brief account <strong>of</strong> Annual Oil<strong>seed</strong> Scheme started dur<strong>in</strong>g 9 plan, and its<br />

th<br />

objective. While review<strong>in</strong>g its contribution till 11 plan, ADG (Seeds) suggested to monitor the progress <strong>of</strong><br />

AOS and present its status and place it before DAC.<br />

1. Dr. S. Natarajan Sr. Scientist, DSR, Mau presented the progress made under this scheme s<strong>in</strong>ce 2004 till<br />

date. He also presented the problems <strong>of</strong> the centres and f<strong>in</strong>ancial deficits be<strong>in</strong>g encountered by the<br />

centres.<br />

2. On cont<strong>in</strong>uation <strong>of</strong> the scheme, the PD, DSR, Mau expressed that if the scheme is closed, the skilled<br />

man power will be displaced and we may feel shortfall <strong>of</strong> even the breeder <strong>seed</strong>s <strong>in</strong> these corps. ADG<br />

(Seeds) also supplemented the view and emphasized the cont<strong>in</strong>uation <strong>of</strong> the scheme. Dr.<br />

R.K.Chowdhury, Ex PC, NSP op<strong>in</strong>ed that this scheme was started to strengthen oil<strong>seed</strong> production and<br />

to solve specific problems. The same problems still to be addressed and hence reduction <strong>of</strong> manpower<br />

will deter the progress <strong>of</strong> these crops and hence the Govt. may th<strong>in</strong>k <strong>of</strong> f<strong>in</strong>ancial assistance through<br />

any other means. Many other participants stressed upon the importance <strong>of</strong> the scheme and<br />

supported the cont<strong>in</strong>uation <strong>of</strong> the scheme.<br />

3. Dr. A.P. S<strong>in</strong>gh, Dy. Commissioner, (TMOP) respond<strong>in</strong>g to problems, <strong>in</strong>sisted upon to take up the issue<br />

with Secretary, Govt. <strong>of</strong> India along with the progress till date and to modify the scheme along with<br />

tra<strong>in</strong><strong>in</strong>g component and ma<strong>in</strong>tenance breed<strong>in</strong>g.<br />

4. ADG (Seeds) suggested PD, DSR, Mau to review the progress annually, to submit the progress to the<br />

GOI for the past period; a proposal shall be prepared and kept for discussion for the mode <strong>of</strong> operation<br />

and shall def<strong>in</strong>e the targets and deliverables and to review the scheme rigorously. ADG (Seeds)<br />

suggested to redraft the proposal like a <strong>new</strong> scheme and place it for discussion at Govt. level.<br />

5. F<strong>in</strong>ally, PD, DSR, Mau conveyed s<strong>in</strong>cere thank to the Chairman, Co‐Chairman and all the participants<br />

for their active participation.<br />

72 Proceed<strong>in</strong>gs 2012‐13

Session ‐ IX<br />

Plenary Session<br />

Chairman : Dr. Swapan K. Dutta<br />

DDG (CS) ICAR, New Delhi<br />

Co‐Chairman : Dr. A.M. Sheikh<br />

Vice Chancellor, AAU, Anand<br />

Rapporters : Dr. D. Khare, Pr<strong>of</strong>essor, JNKVV, Jabalpur<br />

: Dr. Vijayakumar, H.P, Scientist, DSR, Mau<br />

Date: 16.04.2012<br />

Time: 01.30 P.M.<br />

The session started with welcome address by Dr. S. Rajendra Prasad, Director, Directorate <strong>of</strong> Seed<br />

Research, ICAR Mau. Recommendations <strong>of</strong> various sessions were presented by respective rapporterur. The<br />

proceed<strong>in</strong>gs <strong>of</strong> <strong>in</strong>augural session was presented by Dr. S.R. Dhua, CRRI, Cuttack; Discipl<strong>in</strong>e wise presentation<br />

<strong>of</strong> progress report by Dr. M.S. Bhale, JNKVV, Jabalpur; Inter project l<strong>in</strong>kage by Dr. Rakesh Seth, IARI, Karnal;<br />

Important issues <strong>in</strong> <strong>seed</strong> research by Arun Kumar M.B., IARI New Delhi; Review <strong>of</strong> breeder <strong>seed</strong> production<br />

by Dr. J. Shanthala, UAS, Bangalore and Seed stakeholders‐scientist <strong>in</strong>teraction by Dr. Geeta Bassi, PAU,<br />

Ludhiana. Technical prorgramme <strong>of</strong> 2012‐2013 and recommendations form 2011‐2012 were presented by<br />

respective Project PI's i.e., Seed Production and Certification by Dr. Vilas A. Tonapi; Seed Physiology, Storage<br />

and Test<strong>in</strong>g Dr. S.N. Sharma; Seed Pathology Dr. (Mrs.) K. Vishunavat; Seed Entomology Dr. A. Bera and Seed<br />

Process<strong>in</strong>g Dr. R.T. Kausal.<br />

Important issues emmerged are as follows:<br />

Feasibility <strong>of</strong> SRI <strong>in</strong> <strong>seed</strong> production <strong>of</strong> hybrid and their parents has to be worked out with special<br />

reference to economics that <strong>in</strong>clude f<strong>in</strong>ancial assistance provided by government on SRI, <strong>seed</strong><br />

productivity and its quality before submission <strong>of</strong> recommendation.<br />

Number <strong>of</strong> varieties <strong>in</strong> <strong>seed</strong> multiplication cha<strong>in</strong> may be reduced by awareness prorgramme on<br />

availability <strong>of</strong> alternate <strong>new</strong> varieties. Before submission <strong>of</strong> <strong>in</strong>dent, state government should consult<br />

with the state agricultural university for replacement <strong>of</strong> old varieties.<br />

Denotification <strong>of</strong> old varieties with average performance <strong>in</strong> next CVRC meet<strong>in</strong>g.<br />

Enhancement <strong>of</strong> <strong>seed</strong> replacement rate <strong>of</strong> pulses and oil <strong>seed</strong> with critical monitor<strong>in</strong>g <strong>of</strong> multiplication<br />

rate <strong>in</strong> each class <strong>of</strong> <strong>seed</strong>.<br />

Support on research from private sector <strong>in</strong> PPP mode.<br />

Establishment <strong>of</strong> Referral Seed Test<strong>in</strong>g Laboratory at each zone with central Lab at DSR Mau to work on<br />

DNA f<strong>in</strong>ger pr<strong>in</strong>t<strong>in</strong>g <strong>of</strong> varieties from public and private sector.<br />

Reduction <strong>in</strong> cost <strong>of</strong> <strong>seed</strong> production with special reference to Egyptian clover as <strong>in</strong> Egypt.<br />

Rapid mass scale <strong>seed</strong> production prorgramme on forage and fodder crops has to be launched.<br />

Experiments on vegetable crops have to be addressed only <strong>in</strong> PPP mode.<br />

Identification <strong>of</strong> area for production <strong>of</strong> hybrid <strong>seed</strong> and their parents has to be <strong>in</strong>tensified with<br />

<strong>in</strong>volvement <strong>of</strong> centres where the crop is not cultivated commercially.<br />

In the experiments proposed <strong>in</strong> <strong>seed</strong> physiology, test<strong>in</strong>g and storage available technologies on coat<strong>in</strong>g<br />

and packag<strong>in</strong>g at <strong>in</strong>ternational level should be <strong>in</strong>corporated.<br />

In experiments on <strong>seed</strong> pathology emphasis must be given on scann<strong>in</strong>g <strong>of</strong> <strong>diseases</strong> <strong>in</strong> <strong>seed</strong> by available<br />

mach<strong>in</strong>es.<br />

The XXVII Annual Group meet AICRP‐ National Seed Project (Crops) 2012 ended with vote <strong>of</strong> thanks<br />

proposed by Dr. S. Rajendra Prasad, Project Director, Directorate <strong>of</strong> Seed Research, Mau and Dr. R.N. Pandey,<br />

Nodal Officer (Seed) Anand.<br />

Proceed<strong>in</strong>gs 2012‐13<br />

73

, IGFRI Jhanshi<br />

Constitution <strong>of</strong> <strong>Monitor<strong>in</strong>g</strong> Teams for 2012‐13<br />

Tentative time for monitor<strong>in</strong>g : Kharif Season ‐ Sept. / Oct. 2012<br />

: Rabi Season ‐ Feb. / Mar.2013<br />

Mobile No.<br />

Dr. Udaya Bhaskar, DSR, Mau udaya9252@gmail.com 09557935499<br />

Dr. R. P. S<strong>in</strong>gh, BAU, Ranchi ‐ Convener dsfbau@rediffmail.com 09431701162<br />

74 Proceed<strong>in</strong>gs 2012‐13

Dr.S.Narayanaswamy, UAS, Bangalore<br />

rg_<strong>seed</strong>@rediffmail.com<br />

Dr. Dhandapani, R dandyman2k6@gmail.com<br />

09945926912<br />

09455118227<br />

Proceed<strong>in</strong>gs 2012‐13<br />

75

76 Proceed<strong>in</strong>gs 2012‐13<br />

Address and details <strong>of</strong> Pr<strong>in</strong>ciple Investigator <strong>of</strong> AICRP‐NSP (Crops)

XXVII ANNUAL GROUP MEETING<br />

AICRP ‐ NATIONAL SEED PROJECT (CROPS) 2012<br />

(Venue: Anand Agricultural University, Anand)<br />

14‐16 April 2012<br />

st<br />

1 Day (April 14, 2012)<br />

08.30 ‐ 9.30 : REGISTRATION<br />

09.30 – 11.00 : SESSION I : INAUGURAL SESSION (Venue : University Auditorium)<br />

09.30 Prayer<br />

09.35 Welcome address : Dr. K.B. Kathiria, Director <strong>of</strong> Research, AAU, Anand<br />

09.40 Light<strong>in</strong>g <strong>of</strong> Lamp : By Dignitaries<br />

09.45 Achievements under : Dr. S. Rajendra Prasad, Project Director, DSR, Mau<br />

NSP (Crops)<br />

10.00 Key note address : Dr. J.S. Sandhu, ADG, (Seeds), ICAR, New Delhi<br />

10.10 Release <strong>of</strong> Publications : Dr. S.A. Patil, Chairman, Karnataka Krishi Mission,<br />

Commissionarate <strong>of</strong> Agriculture, Bengaluru<br />

10.15 Felicitation <strong>of</strong> Retir<strong>in</strong>g Scientists : Dr. S.A. Patil, Chairman, Karnataka Krishi Mission,<br />

Commissionarate <strong>of</strong> Agriculture, Bengaluru &<br />

Dr. A.M. Shekh, Vice Chancellor, AAU, Anand<br />

10.30 Inaugural address : Dr. S.A. Patil, Chairman, Karnataka Krishi Mission,<br />

Commissionarate <strong>of</strong> Agriculture, Bengaluru<br />

10.40 Presidential Address : Dr. A.M. Shekh, Vice Chancellor, AAU, Anand<br />

10.50 Vote <strong>of</strong> thanks : Dr. R.N. Pandey, Nodal Officer (STR‐NSP), AAU, Anand<br />

(Rappoteurs: Dr. S.R. Dhua, PS, CRRI, Cuttack & Dr. P.R. Choudhury, Sr. Sci. Seeds Section, ICAR, New Delhi)<br />

11.00 – 11.15 Tea<br />

PROGRAMME<br />

11.15 – 15.10 SESSION II : DISCIPLINE–WISE PRESENTATION OF PROGRESS REPORT<br />

Chairman : Dr. S.A. Patil, Chairman<br />

Karnataka Krishi Mission, Commissionarate <strong>of</strong> Agriculture, Bengaluru<br />

Co‐Chairman : Dr. J.S. Sandhu, ADG (Seeds), ICAR, New Delhi<br />

Rapporteurs : Dr. M.S. Bhale, Sr. Sci., JNKVV, Jabalpur<br />

Sh. Somasundaram G., Scientist, DSR, Mau<br />

Progress <strong>of</strong> Seed Technology Research<br />

Seed Production & Certification : Dr. Vilas A. Tonapi, DSST, IARI, New Delhi<br />

Seed Physiology, Storage & Test<strong>in</strong>g : Dr. S. N. Sharma, RAU, ARS, Durgapura<br />

Proceed<strong>in</strong>gs 2012‐13<br />

77

13.00 ‐ 13.45 Lunch<br />

Seed Pathology : Dr. (Mrs.) Karuna Vishunavat, GBPUAT, Pantnagar<br />

Seed Entomology : Dr. Amit Bera, CRIJAF, Barrackpore<br />

Seed Process<strong>in</strong>g : Dr. R.T. Kausal, PDKV, Akola<br />

Presentation <strong>of</strong> <strong>Monitor<strong>in</strong>g</strong> reports : By all zonal conveners<br />

15.10 – 15.15 Tea<br />

15.15 ‐17.15 SESSION – III: INTER‐PROJECT LINKAGE – CROP IMPROVEMENT<br />

(Review & Suggestions for Quality Seed Research)<br />

Chairman : Dr. R. K. Chowdhury,<br />

Ex‐Coord<strong>in</strong>ator, AICRP‐NSP (Crops) & Member RAC, DSR, Mau<br />

Co‐Chairman : Dr. K. P. Patel, Dean (Agriculture), AAU, Anand<br />

Rapporteurs : Dr. Rakesh Seth, Sr. Scientist, IARI RS, Karnal<br />

Dr. T.N. Tiwari, Sr. Scientist, DSR, Mau<br />

Crop/Area : Speaker<br />

Forage : Dr. S.A. Faruqui<br />

Pulses : Dr. N. Nadarajan<br />

Wheat : Dr.(Mrs.) Indu Sharma<br />

Pearl Millet : Dr. O.P. Yadav<br />

Groundnut : Dr. J.P. Mishra<br />

Sunflower & Castor : Dr. K. S. Varaprasad<br />

Soybean : Dr. S. K. Srivastava<br />

nd<br />

2 Day (April 15, 2012)<br />

09.00‐11.45 SESSION – IV: IMPORTANT ISSUES IN SEED RESEARCH<br />

Chairman : Dr. R. R. Hanch<strong>in</strong>al, Vice‐Chancellor, UAS, Dharwad & Chairman, RAC, DSR, Mau.<br />

Co‐Chairman : Dr. Malavika Dadlani, Jo<strong>in</strong>t Director (Research), IARI, New Delhi<br />

Rapporteurs : Dr. Arun Kumar M.B, Sr. Sci. DSST, IARI, New Delhi<br />

Dr. Dhandapani, R, Scientist, DSR, Mau<br />

1. Application <strong>of</strong> Molecular Tools for Seed Quality Assurance : Dr. K.V. Bhatt<br />

2. Seed Research Avenues <strong>in</strong> Biotechnology : Dr. N. Seetharama<br />

3. Application <strong>of</strong> Pulsed Magnetic Field Tech. <strong>in</strong> Agri ‐sciences : Dr. T. Leelapriya<br />

4. IPR Issues Related to Seeds : Dr. Vilas A.Tonapi<br />

5. New Technologies for Seed Dry<strong>in</strong>g and Storage : Dr. K. Keshavulu<br />

11.45 – 12.00 Tea<br />

12.00 ‐ 12.45 SESSION – V: REVIEW OF BREEDER SEED PRODUCTION AND POLICY ISSUES<br />

Chairman : Dr. J.S. Sandhu, ADG (Seeds), ICAR, New Delhi<br />

Co‐Chairman : Dr. L. V. Subba Rao, Nodal Officer (Seeds), DRR, Hyderabad<br />

Rapporteurs : Dr. S. Natarajan, Sr. Scientist, DSR, Mau<br />

Dr. J.Shanthala, Assoc. Pr<strong>of</strong>. UAS, Bangalore<br />

78 Proceed<strong>in</strong>gs 2012‐13

Presentation <strong>of</strong> Breeder Seed Production by Dr. S. Rajendra Prasad, Project Director, DSR, Mau<br />

Discussions on Breeder Seed Production Issues by Dr. J.S. Sandhu, ADG (Seeds), ICAR, New Delhi<br />

12.45‐ 13.30 Lunch<br />

13.30 ‐ 18.30 : Session VI ‐ F<strong>in</strong>alization Of Recommendations/Technical Programme Formulation For<br />

2012‐13 (Concurrent Session)<br />

Discipl<strong>in</strong>e Chairman Venue Convener<br />

Seed Production & Dr. R. K. Chowdhury,<br />

B.A. College Dr. Vilas A. Tonapi<br />

Certification<br />

Ex‐Coord<strong>in</strong>ator, AICRP‐NSP (Crops) Auditorium<br />

Seed Physiology, Dr.(Mrs.) Malavika Dadlani<br />

Conference Hall, Dr. S.N. Sharma<br />

Storage & Test<strong>in</strong>g Jt. Dir. (R), IARI, New Delhi<br />

Dept. <strong>of</strong> Statistics<br />

Seed Pathology<br />

Dr. R.C. Sharma<br />

Dean, College <strong>of</strong> Horticulture YS<br />

PG Sem<strong>in</strong>ar Hall Dr. (Mrs.) Karuna<br />

Vishunavat<br />

Parmar Uty. Solan<br />

Seed Entomology Dr. P. K. Borad, HOD, Agrl. Ent. AAU,<br />

Anand<br />

Conference Room,<br />

Dept. <strong>of</strong> Agrl.<br />

Economics<br />

Dr. Amit Bera<br />

Seed Process<strong>in</strong>g<br />

rd<br />

3 Day (April 16, 2012)<br />

Dr. D. C. Joshi, Dean, Agrl. Product<br />

Process<strong>in</strong>g & Bio‐energy<br />

Conference Hall,<br />

Dept. <strong>of</strong> Agronomy<br />

9.00 – 11.00 SESSION–VII: SEED STAKEHOLDERS–SCIENTISTS INTERACTION<br />

Dr. R.T. Kausal<br />

Chairman : Dr. J.S. Sandhu, ADG (Seeds), ICAR, New Delhi<br />

Co‐Chairman : Dr. N. K. Dadlani Director, NSAI, New Delhi<br />

Rapporteurs : Dr. Ravi Hunje, Assoc. Pr<strong>of</strong>. UAS, Dharwad<br />

Dr. Geeta Bassi, PAU, Ludhiana<br />

Speakers : 1. Dr. N.K. Dadlani, Director, NSAI, New Delhi<br />

2. Dr. Bhupen Dubey Head, Integrated Bus<strong>in</strong>ess, UPL Group, Mumbai<br />

3. Dr. D. B. Desai, M.D., Navabharath Seeds, Gujarat<br />

4. Dr. R.A. Sherasiya, Director, Gujarat Seed Certification Agency<br />

5. Mr. U.D. S<strong>in</strong>gh, M.D, Gujarat Seed Corporation<br />

6. Dr. B.R. Shah, Director <strong>of</strong> Agriculture, GOG, Gandh<strong>in</strong>agar, Gujarat<br />

7. Dr. B.S. Patel, Director <strong>of</strong> Horticulture, GOG, Gandh<strong>in</strong>agar, Gujarat<br />

8. Dr. T.L. Dholaria, MD, Solar Agro. Pvt. Ltd., Rajkot, Gujarat<br />

9. Dr. Arnab Gupta, INCOTEC<br />

11.00 – 11.15 Tea<br />

11.15‐12.45 : SESSION ‐ VIII Discussions on Issues Related to Annual Oil<strong>seed</strong> Scheme and XII Plan<br />

Proposals <strong>of</strong> NSP<br />

Chairman : Dr. J. S. Sandhu, ADG (Seeds), ICAR, New Delhi<br />

Co‐chairman : Dr. A. P. S<strong>in</strong>gh, Deputy Commissioner, ISOPAM, DAC, GOI, New Delhi<br />

Presentation and Discussion on Issues Related to Annual Oil<strong>seed</strong> Scheme<br />

12.45 – 13.30 Lunch<br />

Proceed<strong>in</strong>gs 2012‐13<br />

79

13.30 ‐ 15.45 : SESSION – IX : PLENARY SESSION<br />

Chairman : Dr. Swapan K. Datta, DDG (CS), ICAR, New Delhi<br />

Co‐chairman : Dr. A. M. Shekh, Vice Chancellor, AAU, Anand<br />

Rapporteurs : Dr. D. Khare, PS, JNKVV, Jabalpur<br />

Shri. Vijayakumar HP, DSR, Mau<br />

A. Presentation <strong>of</strong> Recommendations<br />

Inaugural Session : Dr. S. R. Dhua, Pr.Sci., CRRI, Cuttack<br />

Discipl<strong>in</strong>e wise Presentation<br />

<strong>of</strong> Progress Report : Dr. M. S. Bhale, Sr. Sci., JNKVV, Jabalpur<br />

Inter‐Project L<strong>in</strong>kage : Dr. Rakesh Seth, Sr. Scientist, IARI RS, Karnal<br />

Important Issues <strong>in</strong> Seed Research : Dr. Arun Kumar M.B, Sr. Scientist, DSST, IARI, New Delhi<br />

Review <strong>of</strong> Breeder Seed Production<br />

and Policy issues. : Dr. J.Shanthala, Assoc. Pr<strong>of</strong>. UAS, Bangalore<br />

Seed Stakeholders –Scientists Interaction : Dr. Geeta Bassi, PAU, Ludhiana<br />

B. Technical Recommendations<br />

1. Seed Production & Certification : Dr. Vilas A. Tonapi<br />

2. Seed Physiology, Storage & Test<strong>in</strong>g : Dr. S.N. Sharma<br />

3. Seed Pathology : Dr. (Mrs.) Karuna Vishunavat<br />

4. Seed Entomology : Dr. Amit Bera<br />

5. Seed Process<strong>in</strong>g : Dr. R.T. Kausal<br />

Chairman's Remarks<br />

Vote <strong>of</strong> Thanks<br />

: Dr. S. Rajendra Prasad, Project Director, DSR, Mau<br />

Dr. R. N. Pandey, Nodal Officer (Seeds), AAU, Anand<br />

80 Proceed<strong>in</strong>gs 2012‐13