Impact Damage Mechanisms in Fiber-Metal Laminates - Mechanical ...

Impact Damage Mechanisms in Fiber-Metal Laminates - Mechanical ...

Impact Damage Mechanisms in Fiber-Metal Laminates - Mechanical ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

specimen assembly was then placed <strong>in</strong> the environmental<br />

chamber. Temperature <strong>in</strong> the chamber was raised or lowered<br />

to the desired sett<strong>in</strong>g with the fixture-specimen assembly<br />

be<strong>in</strong>g soaked at that temperature for about 20 m<strong>in</strong>utes to<br />

ensure no <strong>in</strong>itial stress result<strong>in</strong>g from temperature change. A<br />

16 mm- (or 5/8”-) diameter spherical impactor with a weight<br />

of 6.1 kg (or 13.4 lbs) was then dropped from a<br />

predeterm<strong>in</strong>ed height to cause damage. Time histories of<br />

impact load were recorded by a PC-controlled high-speed<br />

A/D converter. After impact the specimen was then carefully<br />

removed from the environmental chamber for post-mortem<br />

<strong>in</strong>spection and photography.<br />

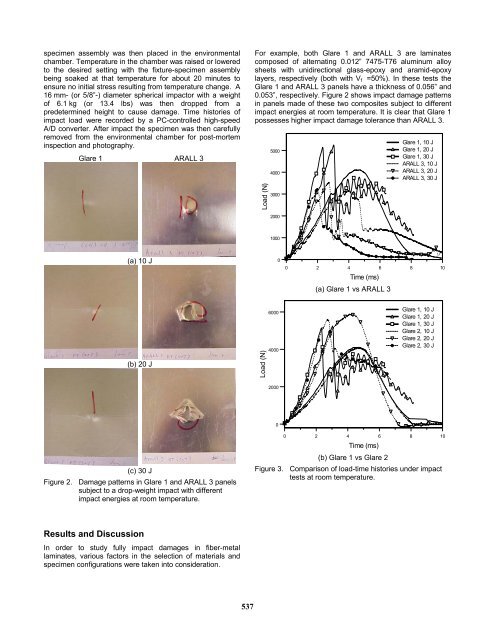

Glare 1 ARALL 3<br />

For example, both Glare 1 and ARALL 3 are lam<strong>in</strong>ates<br />

composed of alternat<strong>in</strong>g 0.012” 7475-T76 alum<strong>in</strong>um alloy<br />

sheets with unidirectional glass-epoxy and aramid-epoxy<br />

layers, respectively (both with V f =50%). In these tests the<br />

Glare 1 and ARALL 3 panels have a thickness of 0.056” and<br />

0.053”, respectively. Figure 2 shows impact damage patterns<br />

<strong>in</strong> panels made of these two composites subject to different<br />

impact energies at room temperature. It is clear that Glare 1<br />

possesses higher impact damage tolerance than ARALL 3.<br />

5000<br />

4000<br />

Glare 1, 10 J<br />

Glare 1, 20 J<br />

Glare 1, 30 J<br />

ARALL 3, 10 J<br />

ARALL 3, 20 J<br />

ARALL 3, 30 J<br />

Load (N)<br />

3000<br />

2000<br />

1000<br />

(a) 10 J<br />

0<br />

0 2 4 6 8 10<br />

Time (ms)<br />

(a) Glare 1 vs ARALL 3<br />

(b) 20 J<br />

Load (N)<br />

6000<br />

4000<br />

Glare 1, 10 J<br />

Glare 1, 20 J<br />

Glare 1, 30 J<br />

Glare 2, 10 J<br />

Glare 2, 20 J<br />

Glare 2, 30 J<br />

2000<br />

0<br />

(c) 30 J<br />

Figure 2. <strong>Damage</strong> patterns <strong>in</strong> Glare 1 and ARALL 3 panels<br />

subject to a drop-weight impact with different<br />

impact energies at room temperature.<br />

0 2 4 6 8 10<br />

Time (ms)<br />

(b) Glare 1 vs Glare 2<br />

Figure 3. Comparison of load-time histories under impact<br />

tests at room temperature.<br />

Results and Discussion<br />

In order to study fully impact damages <strong>in</strong> fiber-metal<br />

lam<strong>in</strong>ates, various factors <strong>in</strong> the selection of materials and<br />

specimen configurations were taken <strong>in</strong>to consideration.<br />

537