Untitled - aaamsa

Untitled - aaamsa

Untitled - aaamsa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ASSOCIATION OF ARCHITECTURAL ALUMINIUM MANUFACTURERS OF SOUTH AFRICA<br />

Trading as the AAAMSA Group<br />

Registration #: 1974/00006/08<br />

Association Incorporated under Section 21<br />

P O Box 7861 1 ST Floor, Block 4<br />

HALFWAY HOUSE<br />

Conference Centre<br />

1685 2 nd Road<br />

Midrand<br />

1685<br />

(011) 805-5002<br />

Fax: (011) 805-5033<br />

e-mail: <strong>aaamsa</strong>@iafrica.com<br />

additional e-mail: sagga@<strong>aaamsa</strong>.co.za<br />

web-site: www.<strong>aaamsa</strong>.co.za<br />

ACKNOWLEDGEMENTS<br />

Aluminium Verlag – Düsseldorf<br />

Fensterbau mit Aluminium – Walter Schmidt<br />

American Architectural Manufacturers Association<br />

Metal Curtain Walls/Windows and Sliding Glass Doors/Aluminium Store Front and Entrances/Skylights and Space<br />

Enclosures<br />

ASTM International E1300<br />

Koninklijk Technicum PBNA<br />

Staalcontructies 43A.VR<br />

South African Bureau of Standards<br />

SANS 10160, SANS 10137, SANS 10400, SANS 204, SANS 613 and SANS 549<br />

Southern African Institute of Steel Construction<br />

Southern African Steel Construction Handbook<br />

Verlag Stahleisen M.B.H. Düsseldorf<br />

Stahl im Hochbau<br />

Building Code Australia<br />

BCA 2007 Volume 1 & 2<br />

W.W. Norton & Company<br />

Window Systems for High Performance Buildings<br />

Lawrence Berkeley National Laboratory<br />

Therm/Windows/Resfen/Optics<br />

National Fenestration Rating Council<br />

Procedure Manuals<br />

Note: This Selection Guide replaces the following AAAMSA Publication which is hereby withdrawn in its entirety:<br />

Selection Guide for Glazed Architectural Aluminium Products – Introducing Energy Efficiency in Fenestration<br />

– June 2008<br />

Any information contained in Selection Guides of earlier dates, which contradicts with data contained in this manual,<br />

is information superseded by this publication<br />

AAAMSA – April 2012<br />

DISCLAIMER<br />

All information, recommendation or advice contained in this AAAMSA Publication is given in good faith to the best of AAAMSA’s<br />

knowledge and based on current procedures in effect.<br />

Because actual use of AAAMSA Publications by the user is beyond the control of AAAMSA such use is within the exclusive<br />

responsibility of the user. AAAMSA cannot be held responsible for any loss incurred through incorrect or faulty use of its<br />

Publications.<br />

Great care has been taken to ensure that the information provided is correct. No responsibility will be accepted by AAAMSA for<br />

any errors and/or omissions, which may have inadvertently occurred.<br />

This Guide may be reproduced in whole or in part in any form or by any means provided the reproduction or transmission<br />

acknowledges the origin and copyright date.<br />

Copyright AAAMSA 2012<br />

Page 3

THE AAAMSA GROUP<br />

The Association of Architectural Aluminium Manufacturers of South Africa (AAAMSA) was founded by eight<br />

companies in July 1974 to foster trade and commerce in relation to those persons associated in the manufacture and<br />

installation of architectural aluminium structures. Its main objective is to promote commercial and group interest.<br />

Association’s Aims:<br />

To be the Professional Organisation within South Africa which is Uniquely Committed to the Disciplines & Standards<br />

of Quality which surround the Manufacture & Installation of Architectural Fenestration Products, Interior Building<br />

Systems, Glass and Glazing, Building Insulation & Associated activities.<br />

TO provide a Forum for the Exchange of Expertise & Interaction between Individuals & Organisations to Create a<br />

Competitive Advantage for the Architectural Aluminium Glass & Insulation Industry.<br />

To communicate to all Stakeholders in the Architectural Aluminium Industry the Register of Accredited Members of<br />

AAAMSA who have Satisfied the Association’s Requirements of Predetermined Standards.<br />

Currently the AAAMSA Group administers, beside the fenestration industry, the glazing material, ceiling and<br />

partitioning and thermal insulation industries represented by the following Associations.<br />

SAFIERA<br />

South African Fenestration<br />

Insulation Energy Rating Association<br />

SAGI<br />

South African<br />

Glass Institute<br />

Fenestration<br />

Industry<br />

Glazing materials<br />

Industry<br />

Thermal Insulation<br />

Industry<br />

Ceiling & Partitioning<br />

Industry<br />

AAAMSA Fenestration SAGGA TIASA SABISA<br />

Association of Architectural<br />

Aluminium Manufacturers<br />

of South Africa<br />

South African Glass<br />

& Glazing Association<br />

Thermal Insulation Association of<br />

Southern Africa<br />

South African Building<br />

Interior Systems<br />

Association<br />

ASDA SASEMA EPSASA<br />

South African Shower Enclosure<br />

Manufacturers Association<br />

Aluminium Stockists &<br />

Distributors Association<br />

Expanded Polystyrene Association<br />

of Southern Africa<br />

SASA<br />

Skylight Association<br />

of Southern Africa<br />

TPMA<br />

Thermal Panel<br />

Manufacturers Association<br />

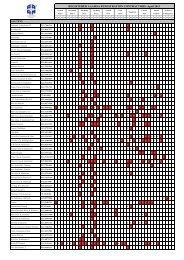

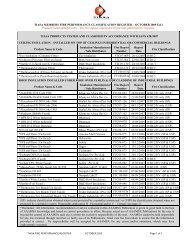

The AAAMSA Group has established in house testing facilities to test certain material properties for Thermal<br />

Insulation and has external testing facilities in Cape Town, Durban, Port Elizabeth and Johannesburg to test<br />

fenestration products in respect of their structural strength, water penetration and air leakage in accordance with<br />

SANS 613. Results of testing by members are bi-monthly updated and published in the Architect & Specificator<br />

magazine to assist specifiers to select appropriate materials and products for projects.<br />

The South African Fenestration and Insulation Energy Rating Association (SAFIERA) facilitate Energy Performance<br />

Testing, conducted at the Association’s Rotatable Guarded Hot Box facility, situated at Unit 28, CSIR, Lynnwood,<br />

Pretoria. The testing is conducted by the Thermal Test Laboratory (TTL) under the auspices of SAFIERA, in strict<br />

accordance with the methods 1 prescribed by the National Fenestration Rating Council (NFRC) of America. SAFIERA<br />

is the South African License holder of the NFRC Rating System and the test results obtained by RGHB testing are<br />

internationally recognized. The thermal Test Laboratory is a SANAS approved independent laboratory. Its<br />

relationship with the AAAMSA Group is as follows:<br />

1<br />

Since U-values (thermal transmittance values) vary for glass, edge-of-glass zone, and frame regions, it can be misleading to compare the U-factors<br />

of windows from different manufacturers if they are not carefully and consistently described. The calculation and testing methods developed by the<br />

NFRC address this concern.<br />

Page 4

The AAAMSA Group also represents material suppliers, manufacturers and installers in the Thermal Insulation<br />

Industry as well as material suppliers, manufactuers and installers of Ceiling & Partitioning and Thermal Panels (cold<br />

rooms/industrialized housing etc.)<br />

For further reading regarding the above please refer:<br />

EPSASA [ www.epsasa.co.za ]<br />

Build an affordable, secure and energy efficient home in two weeks<br />

Expanded Polystyrene (EPS) - The Environmental Truth<br />

Selection Guide introducing Expanded Polystyrene - January 2006<br />

Selection Guide for expanded polystyrene insulation applications - April 2005<br />

Selection Guide for the Recycling of expanded polystyrene - February 2006<br />

The whole truth about Expanded Polystyrene<br />

Large scale fire Test without Sprinklers Video<br />

Large scale fire Test with Sprinklers Video<br />

SABISA [ www.<strong>aaamsa</strong>.co.za ]<br />

General Specification for Drywall Partitions and Lightweight Internal Walls - Second Edition - June 2004<br />

General Specification for Suspended Ceilings - May 2007<br />

TIASA [ www.tiasa.org.za ]<br />

Thermal Insulation Handbook - First Edition - April 2001 Chapter 1<br />

Thermal Insulation Handbook - First Edition - April 2001 Chapter 2<br />

Thermal Insulation Handbook - First Edition - April 2001 Chapter 3<br />

Thermal Insulation Handbook - First Edition - April 2001 Chapter 4<br />

Thermal Insulation Handbook - First Edition - April 2001 Chapter 5<br />

General Specification for Method of Measuring Complete Insulation Installations - January 2001<br />

Thermal Insulation - The Invisible Energy Saver!<br />

Guide for the Construction of Environmentally Comfortable Homes - April 2005<br />

The Guide to Energy Efficient Thermal Insulation in Buildings - August 2010<br />

The Abridged Guide to Energy Efficient Thermal Insulation in Buildings - August 2010<br />

Cellulose Loose-fill Insulation - Installation Guide<br />

Save a Power Station Brochure<br />

Thermal Insulation - A Guide for the Installation of Fibrous Blankets/Mats/Batts - November 2011<br />

The Guide to Radiant Barrier Insulation - Total R-value Calculations for Typical Building Applications<br />

Tiasa Fire Video<br />

TPMA [ www.tpma.org.za ]<br />

Report on the large scale fire propaganda properties of a fire-retarded(FR) Expanded polystyrene(EPS) Core<br />

cold-room systems<br />

General specification for the design of cold store envelopes incorporating prefabricated insulating panels -<br />

September 2006<br />

Large scale "Cold Room" fire test video<br />

Page 5

INTRODUCTION<br />

Since the publication of our Selection Guide for Glazed Architectural Products – June 2008 the legislative<br />

environment of the building industry has dramatically changed.<br />

Government Gazette # 31084 dated 30 May 2008 declared regulations, as set out, to come into operation on 1 October<br />

2008.<br />

Government Gazette # 34463 dated 22 July 2011 declared regulation XA, as set out, to come into operation on 9<br />

November 2011.<br />

The above Gazettes not only introduced Energy Efficiency in Buildings but also compelled participants in the building<br />

industry to reliably demonstrate, or predict with certainty, to the satisfaction of the appropriate local authority, that an<br />

adopted building solution has an equivalent or superior performance to a solution that complies with the requirements<br />

of the relevant part of SANS 10400 (Regulation AZ4 (1)(b)(ii))<br />

This is reinforced by regulation A2 (1)(g) which requires any person intending to erect any building to submit to the<br />

local authority a declaration in the relevant portion of Form 1 contained in SANS 10400-A as to how the applicable<br />

functional regulation (i.e. National Building Regulations) shall be satisfied.<br />

In view of the above it is prudent to include relevant test certificates for the fenestration in the application for approval<br />

of the erection of the building (refer Form 1 of SANS 10400-A)<br />

Tests are conducted in accordance with SANS 613 – Fenestration Products – Mechanical performance criteria which<br />

are applicable to all Fenestration Products irrespective of framing material.<br />

Our Association has therefor commenced encouraging manufacturers of fenestration using framing material other than<br />

aluminium to test and become members of our Association.<br />

This Selection Guide refers to the design, manufacture, finishes, glass, glazing, installation, testing and quality<br />

control of Glazed Architectural Products. It incorporates the 2010/2011 requirements published in National<br />

Building Regulation SANS 10400 Part N, T and XA as well as SANS 10160, 613 and 204.<br />

This Selection Guide has been prepared to assist the Specifier in the first instance to select products that are<br />

sufficiently strong and resistant to water and air infiltration to meet the requirements for the specific job and<br />

related conditions at hand. It also introduces recommendations of the correct usage of glazing materials in<br />

furniture.<br />

This Selection Guide describes the testing of Glazed Architectural Products, irrespective of the framing<br />

material, which is to be conducted in accordance with SANS 613 – Fenestration Products – Mechanical<br />

Performance Criteria. The type testing is fully described in Chapter II of this Selection Guide.<br />

This Selection Guide offers Energy Efficiency solutions for glazed Architectural Products. It will assist the<br />

Specifier, in particular the Architect, to determine suitable glazing solutions to maximize the Energy Efficiency<br />

performance of the building.<br />

Most importantly this Selection Guide offers steps which, when implemented by the Specifier/Client, ensure<br />

that quality end products are installed thus creating confidence that any funding spent on Glazed Architectural<br />

Products is spent responsibly.<br />

This Selection Guide details the testing and simulation of the thermal performance of Glazed Architectural<br />

Products which are conducted in accordance to NFRC protocol and by SANAS accredited test laboratory. The<br />

test and simulations confirm the U-value, Solar Heat Gain Coefficient and Visible Transmittance of the<br />

Fenestration.<br />

This Selection Guide will guide the manufacturer through the relevant SANS standards pertaining to design,<br />

finishes, glass and glazing by means of recommended general practices to ensure reliability of the end products<br />

and compliance with the requirements laid down by the National Building Regulations.<br />

In addition the introduction of the AAAMSA Surface Finishing and Glass & Glazing Certificates will go a<br />

long way in assisting Specifiers to track and record material and services sources long after final handover.<br />

The Certificates may prove invaluable when compiling the relevant maintenance manuals.<br />

The following steps by the Specifier will ensure that quality end products are installed.<br />

Page 6

i) Prior to the commencement of any site work obtain a copy of relevant AAAMSA Performance<br />

Compliance Report for the Architectural System Provider or the Performance Test Certificate (Refer<br />

Chapter II and X) from the Manufacturer/Contractor supplying the Architectural Aluminium Product.<br />

(Note! Only Certificates validated after 15 January 2003 are current).<br />

ii) Obtain the AAAMSA Surface Finishing Certificate confirming that all anodising and/or powder coating<br />

has been processed in strict accordance with SANS 999 and SANS 1796 respectively.<br />

iii) Obtain a powder guarantee of no less than 15 years issued by the powder manufacturer. The specific<br />

conditions contained in this guarantee shall from part of the powder coating process and may only be<br />

applied by an approved powder applicator.<br />

iv) Obtain the AAAMSA Glass & Glazing Certificate confirming that glazing has been installed in<br />

accordance with SANS 10137 ensuring that Safety Glazing Materials have been installed in the mandatory<br />

areas and that each individual pane of Safety Glazing Materials has been permanently marked.<br />

v) Obtain a Warranty from the Manufacturer of the laminated safety glass and/or hermetically sealed glazing<br />

units (SIGU) warranting the products against delamination and colour degradation for a period of not less<br />

than 5 years.<br />

vi) Obtain a SAFIERA Energy Rating Certification for the Glazed Architectural Products confirming U-<br />

value, Solar Heat Gain Value and Visible Transmittance for the products.<br />

Page 7