CHIP COMMON MODE CHOKE COIL HDC0504ST SERIES

CHIP COMMON MODE CHOKE COIL HDC0504ST SERIES

CHIP COMMON MODE CHOKE COIL HDC0504ST SERIES

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>COMMON</strong> <strong>MODE</strong> <strong>HDC0504ST</strong> <strong>SERIES</strong><br />

<strong>CHIP</strong> <strong>COMMON</strong> <strong>MODE</strong> <strong>CHOKE</strong> <strong>COIL</strong><br />

<strong>HDC0504ST</strong> <strong>SERIES</strong><br />

Introductions<br />

The <strong>HDC0504ST</strong> series is wire wound type Common Mode Choke Coil which provides high effective<br />

suppression characteristics without distorting the wave pattern of high speed differential signal interface.<br />

It is suitable for super high speed differential signal such as USB 3.0, HDMI and so on.<br />

Features<br />

*Cut off frequency in differential mode is 8~10GHz<br />

* Operating temperature -40°C to +105°C.<br />

* Excellent solderability and resistance to soldering heat.<br />

* Suitable for flow and reflow soldering.<br />

* Good dimensions, high reliability, and easy surface mount assembly.<br />

Part Number<br />

HDC 0504 S T 600 -S<br />

1 2 3 4 5 6<br />

1<br />

2<br />

Chip Common Mode Choke Coil<br />

Chip Size<br />

CODE L W H UNIT<br />

EIA<br />

0.047<br />

0.039<br />

0.035<br />

Inch<br />

J I S<br />

1.20<br />

1.00<br />

0.90<br />

mm<br />

3<br />

4<br />

5<br />

General Characteristics<br />

Taped In Reel. 3,000pcs/reel.<br />

Typical Impedance at 100MHz<br />

600 = 60 Ω<br />

6 S = USB 3.0<br />

H = HDMI<br />

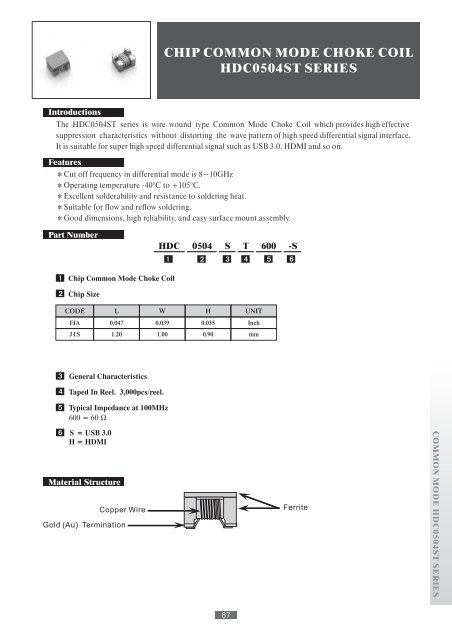

Material Structure<br />

Copper Wire<br />

Ferrite<br />

Gold (Au) Termination<br />

87

<strong>COMMON</strong> <strong>MODE</strong> <strong>CHOKE</strong><br />

WIRE WOUND TYPE<br />

DIMENSION AND CONFIGURATION<br />

0.03mm (ref.)<br />

0.9 max.<br />

0.35 ± 0.1 0.3 ± 0.1<br />

0.35 ± 0.1<br />

0.35 ± 0.1<br />

1.00 ± 0.2<br />

Remark :<br />

: Electrode<br />

( ) : Reference Value<br />

Unit : m/m<br />

1.20 ± 0.2<br />

0.4<br />

0.3<br />

1.10<br />

(1) (2)<br />

0.4<br />

0.45 0.65 0.45<br />

(4) (3)<br />

1.55<br />

RECOMMENDED PCB PATTERN<br />

NO POLARITY<br />

ELECTRICAL SPECIFICATION<br />

HDC0504 <strong>SERIES</strong><br />

Part Number<br />

<strong>HDC0504ST</strong>600-S<br />

<strong>HDC0504ST</strong>900-H<br />

Common Mode<br />

Impedance ( Ω)<br />

at 100MHz<br />

60 typ. (43 min)<br />

Cut-off<br />

Freq.<br />

(GHz)<br />

DC<br />

Resistance<br />

max ( )<br />

Rated<br />

Current<br />

(mA)<br />

Rated<br />

Voltage<br />

(V DC)<br />

Insulation<br />

Resistance<br />

min (M )<br />

10.0 0.40 max. 300 20 max. 100 min<br />

Cut-off<br />

Frequency<br />

(GHz)<br />

10 typ.<br />

90 typ. (65 min) 10.0 0.50 max. 280 20 max. 100 min 8 typ.<br />

1. Impedance is measured in HP4287A at frequency of 100MHz.<br />

2. For 15 °C rise.<br />

88

<strong>COMMON</strong> <strong>MODE</strong> <strong>CHOKE</strong> <strong>COIL</strong>S<br />

HDC0504 (S) <strong>SERIES</strong><br />

INSERTION LOSS Choke impedance Graphic result<br />

Avgs=2 Sys Risc: 50 ps, Date: 2010/05/21 16:12:43 Points=1024<br />

130<br />

Y:Ω<br />

Frequency (MHz)<br />

1 10 100 1000 10000<br />

120<br />

0<br />

Max<br />

110<br />

100<br />

90<br />

80<br />

70<br />

Insertion Loss (db)<br />

1<br />

2<br />

Min<br />

60<br />

50<br />

Base:40.5372 3 ns<br />

Parameter Name:Choke Impedance C1<br />

Scale:200.0 ps/div<br />

Spc Max: 105 Ω<br />

Spc Min: 75 Ω<br />

Max: 102.64 Ohms at 41.7752 ns<br />

Min: 87.85 Ohms at 41.2612 ns<br />

∆Ω:14.79 Avg: 95.24 Ohms<br />

Result:Pass<br />

Ver:3.23<br />

750<br />

USB3.0 Eye Graphic result<br />

Date: 2010/11/11 20:12:42, Resolution: 500x400 pixels<br />

0<br />

-750 Wfrms=500<br />

Base:27.9743ns Scale:33.0 ps/div Ver:3.26<br />

Parameter Name:USB3.0 Eye Aoba<br />

Display Mode:USB3.05Gpbs<br />

dRate: 5 Gbits/s ; 200.0 ps<br />

JGen:OFF<br />

V: 400 mV ; Gain: 0 dB ; Off: 0 mV<br />

Result:pass<br />

89

<strong>COMMON</strong> <strong>MODE</strong> <strong>CHOKE</strong> <strong>COIL</strong>S<br />

<strong>HDC0504ST</strong> (S) <strong>SERIES</strong><br />

INSERTION LOSS<br />

Frequency (MHz)<br />

1 10 100 1000 10000<br />

0<br />

Insertion Loss (db)<br />

1<br />

2<br />

3<br />

90

<strong>COMMON</strong> <strong>MODE</strong> <strong>CHOKE</strong> WIRE WOUND TYPE<br />

RELIABILITY SPECIFICATION<br />

1<br />

Scope<br />

This specification applies to wired wounded chip common mode choke of the following types used in<br />

electronic equipment :<br />

*Material : Ferrite<br />

2<br />

Construction<br />

* Configuration<br />

& Dimension : Please refer to the attached figures and tables.<br />

* Terminals : HDC0504 (S) series shall consist of Ag followed by Nickel, then Gold (Au) plating.<br />

3<br />

Operating Temperature Range<br />

Operating Temperature Range is the scope of ambient temperature at which the common mode choke<br />

can be operated continuously at rated current.<br />

*Temp. Range : - 40 °C to + 85 °C<br />

4<br />

Recommended Soldering Conditions<br />

Peak : 250 +5/-0°C<br />

230°C or higher<br />

180°C<br />

Pre-heating Zone<br />

2 to 6°C/s<br />

3 to 6°C/s<br />

150°C<br />

90 ± 30s<br />

2 to 4°C/s<br />

30 ± 10s<br />

Heating Time<br />

Soldering Zone<br />

5<br />

Characteristics<br />

Standard Atmospheric Conditions<br />

Unless otherwise specified, the standard range of atmospheric conditions for making measurements<br />

and tests are as follows :<br />

* Ambient Temperature : 25°C ± 2 °C<br />

* Relative Humidity<br />

* Air Pressure<br />

: 60% to 70% (RH)<br />

: 86 Kpa to 106 Kpa<br />

91

<strong>COMMON</strong> <strong>MODE</strong> <strong>CHOKE</strong><br />

WIRE WOUND TYPE<br />

RELIABILITY SPECIFICATION<br />

ITEM CONDITION SPECIFICATION<br />

Common Mode<br />

Impedance (Zc)<br />

and Tolerance<br />

Measuring Equipment : HP-4287A or equivalent.<br />

Measuring Frequency : 100 ± 1MHz<br />

Measuring Temperature : 25 ± 5°C<br />

(Refer to Measurement Diagram )<br />

Ω<br />

Ω<br />

Minimum 43 .<br />

Typical : 50~60 .<br />

Electrical<br />

Characteristics<br />

Insulation<br />

Resistance<br />

Dielectric<br />

Withstanding<br />

Voltage<br />

Measuring Voltage : Rated Voltage<br />

Measuring Time : 1 minute max.<br />

(Refer to Measurement Diagram )<br />

Test Voltage : 2.5 times to Rated Voltage<br />

Time : 1 to 5 seconds.<br />

Charge current : 1mA max.<br />

(Refer to Measurement Diagram )<br />

100 MΩ minimum<br />

No damage occurs when the<br />

test voltage is applied.<br />

Rated Current<br />

Test Current : Rated Current<br />

(Refer to Measurement Diagram )<br />

Temperature Rise : ≤ 15°C<br />

DC Resistance<br />

(RDC)<br />

Measured with current of 100mA max.<br />

In case of doubt, measured by four terminal<br />

method. (Refer to Measurement Diagram )<br />

Within Specified Tolerance.<br />

Flexure<br />

Strength<br />

R5<br />

45±<br />

2mm<br />

Pressig jig<br />

10<br />

20<br />

R340<br />

(1-1mm)<br />

Board<br />

45±<br />

2mm<br />

Warp = 2mm<br />

Pressing Speed = 0.5mm/sec<br />

Duration = 5 ± 1 sec<br />

Table 1.<br />

Change In Appearance<br />

Without distinct damage<br />

Change In Common Mode<br />

Impedance :<br />

Within ± 20%<br />

Mechanical<br />

Characteristics<br />

Drop Test<br />

Vibration<br />

(Random)<br />

Components shall be dropped three times on<br />

a concrete or steel board at height of 1 M<br />

naturally at any directions.<br />

Components shall be randomly vibrated at<br />

amplitude of 1.5mm and frequency of<br />

10 - 55 Hz : 0.04 G / Hz, 1 minute at a period of<br />

2 hours in each of the three mutually<br />

perpendicular directions.<br />

Insulation Resistance :<br />

10M<br />

Ω<br />

min<br />

Withstanding Voltage :<br />

No damaged<br />

Solderability<br />

Dip pads in flux and then in a solder bath<br />

at 240 °C ± 5°C for 5 seconds.<br />

A minimum of 80% of the<br />

metalized area must be<br />

covered with new solder.<br />

Resistance to<br />

Soldering Heat<br />

Preheat components at 80 to 120 °C for 1 minute.<br />

Dip components into flux and then into a melted<br />

solder bath at 255 ± 5°C for 5 ± 1 seconds.<br />

Then components are to be tested after<br />

4-48 hours at room temperature.<br />

Meet Table 1.<br />

92

<strong>COMMON</strong> <strong>MODE</strong> <strong>CHOKE</strong><br />

WIRE WOUND TYPE<br />

RELIABILITY SPECIFICATION<br />

ITEM CONDITION SPECIFICATION<br />

Cold<br />

Temperature<br />

Storage<br />

Components shall be stored at temperature of<br />

-40 °C ± 2 °C for 1000 (+48 hours -0 hour).<br />

Then components shall be subjected to standard<br />

atmospheric conditions for 4-48 hours. After that,<br />

measurement shall be made.<br />

Table 1.<br />

Change In Appearance<br />

Without distinct damage<br />

High<br />

Temperature<br />

Storage<br />

Components shall be stored at temperature<br />

of +85 °C ± 2 °C for 1000 (+48 hours -0 hour).<br />

Then components shall be subjected to standard<br />

atmospheric conditions for 4-48 hours. After that,<br />

measurement shall be made.<br />

Change In Common Mode<br />

Impedance:<br />

Within ± 20%<br />

Endurance<br />

Characteristics<br />

Moisture<br />

Resistance<br />

Components shall be stored in the chamber at<br />

40 °C at 90 - 95% R. H. for 1000 (+48 hours<br />

-0 hour). Then components are to be tested<br />

after 4-48 hours at room temperature.<br />

Insulation Resistance:<br />

100M<br />

Ω<br />

min<br />

Temperature<br />

Cycle<br />

Each cycle shall consist of 30 minutes at -40°C<br />

followed by 30 minutes at 85°C with a 10-15<br />

minutes maximum transition time between<br />

temperature extremes. Test duration is 100 cycles,<br />

then components are to be tested after 4-48 hours<br />

at room temperature.<br />

Withstanding Voltage:<br />

No damaged<br />

High<br />

Temperature<br />

With Loaded<br />

(Rated Current)<br />

Components shall be stored at temperature<br />

of +85 °C ± 2 °C for 1000 (+48 hours -0 hour)<br />

with rated current applied.<br />

Then components shall be subjected to standard<br />

atmospheric conditions for 4-48 hours. After that,<br />

measurement shall be made.<br />

93

<strong>COMMON</strong> <strong>MODE</strong> <strong>CHOKE</strong><br />

WIRE WOUND TYPE<br />

RELIABILITY<br />

SPECIFICATION<br />

Measurement Diagram<br />

Terminal to be Tested<br />

When measuring and supplying the voltage, the following terminal is applied.<br />

No.<br />

ITEM<br />

Terminal to be Tested<br />

1<br />

Common Mode Impedance<br />

( Measurement Terminal )<br />

Terminal<br />

Terminal<br />

2<br />

Withstanding Voltage<br />

( Measurement Terminal )<br />

Terminal<br />

Terminal<br />

3<br />

DC Resistance<br />

( Measurement Terminal )<br />

Terminal<br />

Terminal<br />

4<br />

Rated Current<br />

5<br />

Insulation Resistance<br />

Terminal<br />

Terminal<br />

94

PACKAGING INFORMATION<br />

Packing Quantity<br />

TYPE<br />

PCS / REEL<br />

HDC0504 3,000<br />

Ø60<br />

Ø178<br />

1.0<br />

9.0<br />

Dimensions (unit:m/m)<br />

TYPE<br />

Chip<br />

Cavity<br />

Insert<br />

Pitch<br />

Tape<br />

Thickness<br />

Ø1.5 +0.1<br />

- 0<br />

+0.004<br />

(Ø0.059 - 0 )<br />

4±0.1 2±0.1<br />

(0.157±0.004) (0.079±0.004)<br />

1.75±0.1<br />

(0.069±0.004)<br />

T<br />

K<br />

Tolerance<br />

HDC0504<br />

A B F K T<br />

± 0.10mm<br />

1.16 1.41 4.00 0.98 0.23<br />

8±0.3<br />

(0.314±0.012)<br />

A<br />

3.5±0.05<br />

(0.138±0.002)<br />

B<br />

4±0.1<br />

(0.157±0.004)<br />

TAPE DIRECTION<br />

Blank Portions Chip Cavity Leader<br />

Top Tape Strength<br />

The top tape requires a peel-off force of 0.2 to 0.7N in<br />

the direction of the arrow as illustrated below<br />

80mm min<br />

160mm min<br />

o<br />

0 ~ 15°<br />

Top Tape<br />

Direction of tape feed<br />

Base Tape<br />

95