E-AC-10 BKB - Elimko

E-AC-10 BKB - Elimko

E-AC-10 BKB - Elimko

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

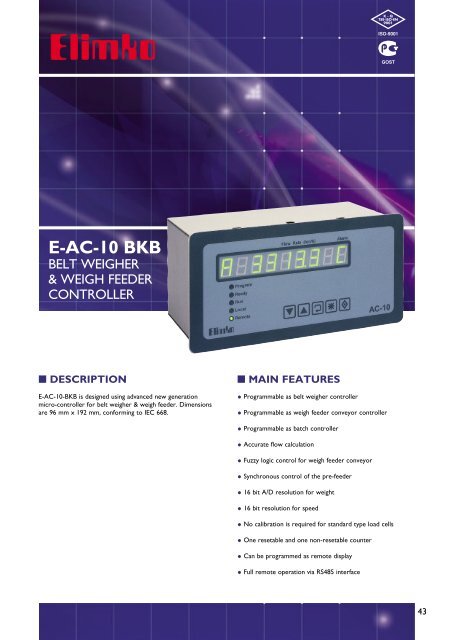

E-<strong>AC</strong>-<strong>10</strong> <strong>BKB</strong><br />

BELT WEIGHER<br />

& WEIGH FEEDER<br />

CONTROLLER<br />

■ DESCRIPTION<br />

E-<strong>AC</strong>-<strong>10</strong>-<strong>BKB</strong> is designed using advanced new generation<br />

micro-controller for belt weigher & weigh feeder. Dimensions<br />

are 96 mm x 192 mm, conforming to IEC 668.<br />

■ MAIN FEATURES<br />

• Programmable as belt weigher controller<br />

•<br />

• Programmable as batch controller<br />

• Accurate flow calculation<br />

•<br />

• Synchronous control of the pre-feeder<br />

• 16 bit A/D resolution for weight<br />

• 16 bit resolution for speed<br />

•<br />

•<br />

• Can be programmed as remote display<br />

Programmable as weigh feeder conveyor controller<br />

Fuzzy logic control for weigh feeder conveyor<br />

No calibration is required for standard type load cells<br />

One resetable and one non-resetable counter<br />

• Full remote operation via RS485 interface 43

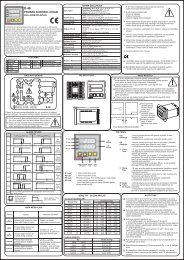

■ TECHNICAL SPECIFICATIONS<br />

Accuracy Class<br />

Display Resolution<br />

A/D Conversion<br />

D/A Conversion<br />

0.5 (flow measurement & control)<br />

4x20 digit display LCD or 9 digit LED<br />

16 bits 50 ms conversion time<br />

16 bits<br />

Flow/Weight Indicator 5 digits up to 60000<br />

Digital Inputs Belt Weigher Weigh Feeder Batch Controller<br />

1. Speed input 24 V pulse 1. Speed input 24 V pulse 1. Speed input 24 V pulse<br />

2. Belt is running 2. Side switches 2. Belt is running<br />

3. Alarm reset 3. Emergency stop 3. Alarm reset<br />

Digital Outputs Belt Weigher Weigh Feeder Batch Controller<br />

1. Totalizer pulse output 1. Totalizer pulse output 1. Motor run<br />

2. Running 2. Running 2. Ready<br />

3. Low flow rate 3. Out off tolerance 3. Out off tolerance<br />

4. Alarm 4. Alarm<br />

Additional Digital Inputs<br />

Analog Digital Outputs<br />

11. Start<br />

12. Interlock<br />

13. Motor Running<br />

14. Motor fault<br />

15. Pre-feeder running<br />

16. Pre-feeder fault<br />

17. Pre-feeder remote<br />

18. Pre-feeder local run<br />

11. Motor Run<br />

12. Pre-feeder run<br />

13. Out of tolerance<br />

14. Speed fault<br />

15. Side switch fault<br />

16. Emergency stop<br />

17. Fault<br />

Analog Inputs 1. Load cell input (up to 4 load cells 350 Ω)<br />

2. 4–20 mA Set point<br />

Analog Outputs<br />

Operating Temperature<br />

Power Supply<br />

Storage Temperature<br />

Weight<br />

1. 4–20 mA Flow rate signal<br />

2. 4–20 mA Control output<br />

3. 4–20 mA Pre-feeder control output<br />

-<strong>10</strong>÷50°C<br />

80–265 V <strong>AC</strong> / 85–375 V DC<br />

20–60 V <strong>AC</strong> / 20–85 V DC<br />

-20÷85°C<br />

1<strong>10</strong>0 gr<br />

44

■ ORDERING GUIDE<br />

E-<strong>AC</strong>-<strong>10</strong>-<strong>BKB</strong> Belt Weigher & Weigh Feeder Controllers<br />

E-<strong>AC</strong>-<strong>10</strong>-<strong>BKB</strong> -W- X - Y - Z<br />

Standard Input & Outputs<br />

3 Digital Inputs<br />

4 Digital Outputs<br />

1 Load Cell Input<br />

1 Set Point Input<br />

• 1 Flow Rate Output<br />

Additional Digital Input & Outputs<br />

None 0<br />

8 Inputs + 8 Outputs 1<br />

Analog Outputs<br />

Flow rate output 0<br />

Flow rate output + 4–20 mA Control output 2<br />

Flow rate output + 4–20 mA Control + Pre-feeder control output 3<br />

Communication<br />

None 0<br />

RS485 MODBUS 1<br />

Power Supply<br />

85–265 V <strong>AC</strong> / 85–375 V DC 0<br />

20–60 V <strong>AC</strong> / 20–85 V DC 1<br />

■ AUXILIARY UNITS<br />

Relay output card<br />

E-RK-<strong>10</strong>8-NA 8 x NO relay outputs 5 A 240 <strong>AC</strong><br />

Weigh Feeder Coordinator<br />

<strong>AC</strong>-<strong>10</strong>-<strong>BKB</strong>-C-0-0-1-0 coordinates the eight feeder to provide concentration.<br />

Communicates with <strong>AC</strong>-<strong>10</strong>-<strong>BKB</strong> via RS485 port therefore all <strong>AC</strong>-<strong>10</strong>-<strong>BKB</strong>’s must have an RS485 com port.<br />

Communication Unit<br />

RS485 / RS232 Converter<br />

E-IB-<strong>10</strong>-485/232<br />

RS485 / USB Converter<br />

E-IB-<strong>10</strong>-485/USB<br />

■ DIMENSIONS<br />

Panel cut-out = 90 x 185 mm<br />

45

■ SCHEMATIC SUMMARY OF WEIGHING EQUIPMENT<br />

* The company’s policy is one of continuous product improvement. We reserve the right to modify the information contained herein without notice.<br />

46