News for JeNseN Customers - Jensen Group

News for JeNseN Customers - Jensen Group

News for JeNseN Customers - Jensen Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2<br />

Design<br />

There are currently two versions of the<br />

Evolution Cube available:<br />

1. Batch processing with a towel size that<br />

corresponds to predefined measurements<br />

2. Mixed processing with a maximum of two<br />

different towel sizes that correspond to<br />

predefined measurements<br />

To be able to run the system as flexibly as possible,<br />

a fold-away transfer table can also be supplied,<br />

which enables manual feeding into the<br />

Tematic Pro towel folding machine. The foldaway<br />

transfer table with feeding belt ensures<br />

operating safety and allows <strong>for</strong> interim feeding<br />

and folding of special laundry items that cannot<br />

be processed using the Evolution Cube.<br />

If the Evolution Cube cannot recognize or grasp<br />

the towel corner <strong>for</strong> some reason, the dropped<br />

laundry item is automatically sent back to the<br />

start of the process via an integrated return<br />

belt, i.e. into the separating hopper. This itemreturn<br />

system means that it is not necessary<br />

to remove towels from the machine by hand.<br />

In effect, the Evolution Cube resolves<br />

its detection or grasping errors itself.<br />

Quality control<br />

One could of course assume that quality control<br />

by means of human inspection during manual<br />

feeding of towels would also be eliminated due<br />

to the rationalization of operating personnel.<br />

In this regard, JENSEN is working on automatic<br />

quality control using a camera system that<br />

identifies damaged or soiled towels and<br />

initiates sorting of these items.<br />

Output<br />

Depending on the towel size and the textile<br />

quality and thickness, the Evolution Cube can<br />

process between 400 and 600 towels per hour<br />

as a daily average. The towels should con<strong>for</strong>m<br />

to the following dimensions:<br />

Minimum size: 900 x 500 mm (35.4 ” x 19.7 ”)<br />

Maximum size: 1200 x 600 mm (47.2 ” x 23.6 ”)<br />

Application<br />

Due to its lack of dependence on operating<br />

personnel, the Evolution Cube is particularly<br />

suited to multi-shift operation. It is naturally<br />

advisable to have a single person monitoring<br />

the overall process when operating multiple<br />

Evolution Cubes. The Evolution Cube is primarily<br />

used in central laundries <strong>for</strong> hospitals and textile<br />

rental companies that process standardized<br />

hotel linen. Currently, the Evolution Cube can<br />

process standardized dry laundry corresponding<br />

to the a<strong>for</strong>ementioned dimensions on a<br />

viable, productive basis. After the next devel-<br />

opmental stage, the Evolution Cube should<br />

meet the requirements of hotel laundries that<br />

process textiles of a different quality and, more<br />

importantly, a wide range of different textiles.<br />

Combination<br />

Laundry items not con<strong>for</strong>ming to the indicated<br />

dimensions, as well as thicker items such as<br />

shower mats, are folded manually using the<br />

Tematic Pro. Hand towels and bath towels<br />

are processed using the Evolution Cube. Pre-<br />

sorting of towels be<strong>for</strong>e the finishing process<br />

can also increase the dryer output. Basically<br />

all dry laundry items should be automatically<br />

fed to the folding stations via a bag conveyor<br />

system, and removed in a precisely stacked<br />

manner by means of a Jenway conveyer belt<br />

system in order to obtain an ideal process<br />

flow. When processing 50% standardized and<br />

50% other types of dry laundry, two Evolution<br />

Cubes, each with one integrated and two freestanding<br />

Tematic Pro folding machines could<br />

1200 mm (47")<br />

be installed. It is not absolutely necessary to<br />

purchase an Evolution Cube together with a<br />

new Tematic Pro if the latter item is already<br />

available in the laundry. The Evolution Cube<br />

can be connected to an existing, recently<br />

produced Tematic Pro; however, in this case<br />

the software must be updated. To achieve<br />

maximum capability, an overhaul of the<br />

existing Tematic Pro is recommended. This<br />

can be per<strong>for</strong>med by JENSEN service technicians<br />

during commissioning.<br />

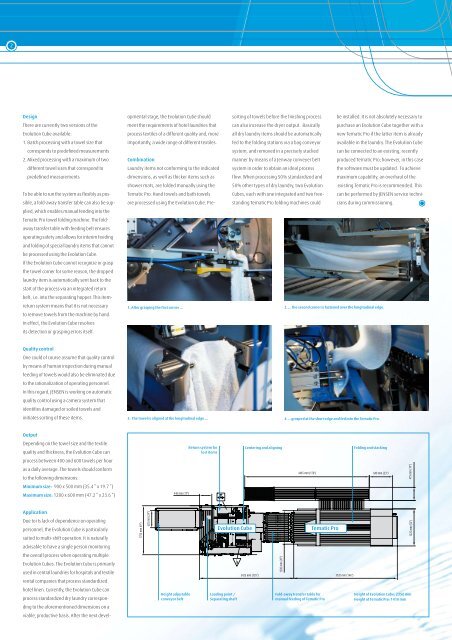

1. After grasping the first corner … 2. ... the second corner is fastened over the longitudinal edge.<br />

3. the towel is aligned at the longitudinal edge … 4. ...grasped at the short edge and fed into the tematic pro.<br />

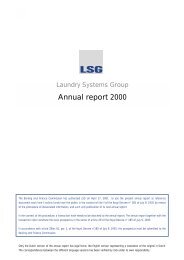

1755 mm 69")<br />

620 mm (24")<br />

440 mm (17")<br />

Height adjustable<br />

conveyor belt<br />

Return system <strong>for</strong><br />

lost items<br />

Centering and aligning<br />

4465 mm (176")<br />

Evolution Cube Tematic Pro<br />

Loading point /<br />

Separating shaft<br />

3425 mm (135") 3720 mm (146")<br />

Fold-away transfer table <strong>for</strong><br />

manual feeding of Tematic Pro<br />

Folding and stacking<br />

840 mm (33")<br />

475 mm (19")<br />

1325 mm (52")<br />

Height of Evolution Cube: 2350 mm<br />

Height of Tematic Pro: 1410 mm