CAVITY WALL TIES - mkm.strawberryadm...

CAVITY WALL TIES - mkm.strawberryadm...

CAVITY WALL TIES - mkm.strawberryadm...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

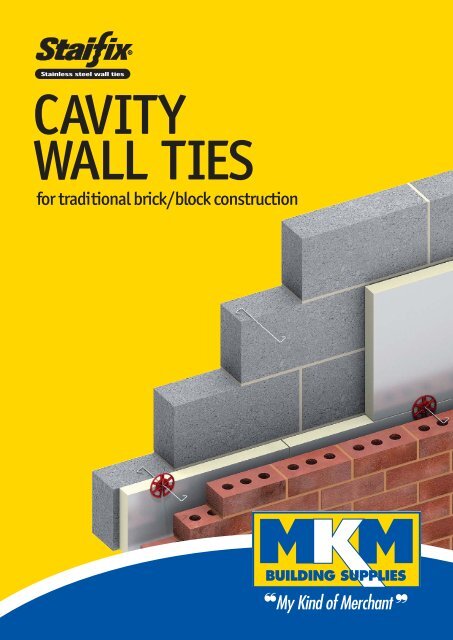

<strong>CAVITY</strong><br />

<strong>WALL</strong> <strong>TIES</strong><br />

for traditional brick/block construction

Stainless Steel<br />

All Ancon and Staifix wall ties are<br />

manufactured from Stainless Steel for<br />

its corrosion resistance and strength.<br />

The use of Stainless Steel means that<br />

no costly remedial measures are required<br />

during the lifetime of the structure.<br />

Approvals<br />

Look for these logos.<br />

These products are<br />

approved by the British<br />

Board of Agrément.<br />

These products meet the<br />

technical requirements of<br />

the National House<br />

Building Council.<br />

These products are Type A<br />

ties and suitable for internal<br />

separating walls to<br />

Approved Document E.<br />

Safety<br />

All Ancon and Staifix wall ties have specially<br />

designed safety ends to reduce the risk of<br />

injury during handling and installation.<br />

Correct Installation<br />

Wall ties should be pressed down in, and<br />

then surrounded by, fresh mortar.<br />

In order to show more details of the<br />

application, mortar has been excluded from<br />

the photography in this literature.<br />

rev. 0508 v.1<br />

MKM acknowledges that any accreditations/certifications are attributed to the brand/manufacturer.<br />

MKM has compiled this booklet from information supplied by manufacturers in good faith and accepts no responsibility for any errors or omissions in this literature.

Cavity Wall Ties<br />

for traditional brick/block construction<br />

Wall ties are an important element in the<br />

stability of cavity walls. The correct<br />

selection, spacing and installation of ties is<br />

essential to avoid damp penetration and<br />

the distortion or cracking of brickwork.<br />

Many factors including cavity width, type<br />

and height of building, and location must all<br />

be considered in the selection of the most<br />

appropriate tie.<br />

BS1243: Metal ties for cavity<br />

wall construction<br />

BS1243 was withdrawn in 2005. Butterfly<br />

and Double Triangle ties to BS1243 do not<br />

meet a current British Standard. Wall ties<br />

should be selected to BS5628-1: 2005<br />

(see page 4).<br />

Pages 4 and 5 provide information on wall<br />

tie selection, density and positioning, tie<br />

length, embedment depths and installation.<br />

3

Wall Tie Selection to BS5628-1: 2005<br />

Maximum<br />

Building Geographical<br />

Type Application Density Height Location<br />

Type 1 Heavy duty tie suitable for 2.5 ties/m 2 Any<br />

3-4 ties/m Height<br />

at unbonded<br />

edges<br />

most building sizes and<br />

types. Not very flexible<br />

and not recommended for<br />

applications where there is<br />

expected to be excessive<br />

differential movement<br />

between leaves<br />

Type 2 General purpose tie for As Type 1 15m<br />

domestic and small<br />

commercial buildings.<br />

May be suitable for<br />

buildings exceeding 15<br />

metres if shown to be<br />

adequate by calculation<br />

Type 3 Basic wall tie generally as As Type 1 15m<br />

Type 2 above<br />

Type 4 Light duty wall tie As Type 1 10m<br />

suitable for box-form<br />

domestic dwellings with<br />

leaves of similar thickness<br />

Type 6* Timber frame tie suitable 4.4 ties/m 2 15m<br />

for domestic houses and<br />

small commercial<br />

developments of up to<br />

3-4 ties/m<br />

at unbonded<br />

edges<br />

four storeys<br />

For complete information refer to BS5628-1: 2005 and BS5268-6: 1: 1996<br />

*Based on BS5268-6: 1: 1996<br />

Suitable for most sites.<br />

However, for relatively<br />

tall or unusually shaped<br />

buildings in vulnerable<br />

areas, the tie provision<br />

should be calculated<br />

Suitable for buildings<br />

on flat sites where the<br />

basic wind speed is up<br />

to 31m/s and altitude is<br />

not more than 150m<br />

above sea level<br />

Suitable for buildings on<br />

flat sites in towns and<br />

cities where the basic<br />

wind speed is limited to<br />

25m/s and altitude is<br />

not more than 150m<br />

above sea level<br />

Suitable for flat sites in<br />

towns and cities where the<br />

basic wind speed does<br />

not exceed 25m/s and<br />

altitude is not more than<br />

150m above sea level<br />

Suitable for flat sites in<br />

towns and cities where the<br />

basic wind speed does not<br />

exceed 25m/s and altitude<br />

is not more than 150m<br />

above sea level<br />

≤ 31m/s<br />

≤ 25m/s<br />

Information taken from BS 6399-2: 1997 Code of<br />

Practice for Wind Loads<br />

Wall Tie Selection to Approved Document E<br />

Type<br />

Application<br />

Type A<br />

Suitable for internal separating walls of new build attached dwellings<br />

up to any height*<br />

For complete information refer to Approved Document E - Resistance to the Passage of Sound<br />

*Restrictions may apply to particularly tall buildings and coastal/exposed sites<br />

Length of Tie and Embedment<br />

Wall ties should be of the correct length to ensure they are properly<br />

embedded in the masonry. Ancon recommends tie lengths which<br />

achieve an embedment of between 62.5mm and 75mm.<br />

A tie, 225mm long, would be the minimum length recommended<br />

by Ancon for a 100mm cavity.<br />

62.5mm + 100mm + 62.5mm = 225mm<br />

The embedment depths for Staifix-Thor Helical thin-joint ties differ<br />

from the information above.<br />

Insulation retaining clip<br />

Multiple drips<br />

4<br />

Embedment<br />

Cavity width<br />

Embedment

Density and Positioning of Ties<br />

Typical Layout of Wall Ties Indicating Maximum Spacing<br />

Standard spacing for cavity brickwork 900mm x 450mm centres in a staggered pattern (2.5 ties per m 2 )<br />

TECHNICAL<br />

INFORMATION<br />

Head restraints<br />

at centres to<br />

suit wind<br />

loading<br />

Horizontal movement joint<br />

450-900mm<br />

Vertical<br />

movement<br />

joint<br />

225mm<br />

450mm<br />

450mm<br />

225mm<br />

450mm<br />

300mm<br />

Usually 225mm<br />

to suit block<br />

courses<br />

300mm<br />

Usually 225mm<br />

to suit block<br />

courses<br />

Debonded<br />

ties at<br />

edges<br />

450mm<br />

225<br />

mm<br />

225<br />

mm<br />

225<br />

mm<br />

900<br />

mm<br />

225<br />

mm<br />

For walls in which both leaves are 90mm or thicker, ties should be used at not less than 2.5 per square metre<br />

(900mm horizontal and 450mm vertical centres). This spacing may be varied by building regulations. Ties should<br />

be evenly distributed over the wall area, except around openings, and should be preferably staggered.<br />

At vertical edges of an opening, unreturned or unbonded edges, and vertical expansion joints, additional ties should<br />

be used. Such ties should be located at 300mm vertical centres, positioned not more than 225mm from the edge.<br />

Installation of Ties<br />

Wall ties should be pressed down in, and surrounded by, fresh<br />

mortar. In order to show more details of the application, mortar has<br />

been excluded from the images in this literature.<br />

To ensure cavity wall ties are effective at tying the leaves together<br />

they should be installed as the inner leaf is constructed and not<br />

simply pushed into a joint.<br />

Ties should be installed with a slight fall to the outer leaf, never<br />

towards the inner leaf as this could provide a path for moisture to<br />

cross the cavity.<br />

The drip part of the tie should point downwards and be positioned<br />

near the centre of the open cavity. Ties with multiple drips, like the<br />

Staifix RT2, can often be positioned centrally as part of the drip will<br />

normally be near the centre of the open section of a partial fill cavity.<br />

Installed ties should be clear of mortar droppings to allow the drip to<br />

function and prevent water from crossing to the inner leaf of masonry.<br />

5

Staifix HRT4 Tie (Type 4/Type A Tie)<br />

Length (mm) Cavity (mm)<br />

200 50-75<br />

225 76-100<br />

Patent Nos. GB 2359831<br />

IE 83574<br />

Application<br />

Type 4 wall tie for use in the external walls<br />

of houses not greater than 10 metres in<br />

height. Type A tie for internal separating<br />

walls of buildings of any height. Please refer<br />

to page 4 for more details.<br />

REPLACES BS1243<br />

BUTTERFLY TIE<br />

Staifix RT2 General Purpose Tie (Type 2 Tie)<br />

Length (mm) Cavity (mm)<br />

200 50-75<br />

225 76-100<br />

250 101-125<br />

Patent Nos. GB 2359831<br />

IE 83574<br />

Application<br />

Type 2 wall tie for use in the external walls<br />

of houses and small commercial<br />

developments not greater than 15 metres<br />

in height. This tie is unsuitable for internal<br />

separating walls of new build attached<br />

dwellings. Please refer to page 4 for more<br />

details.<br />

6<br />

REPLACES BS1243<br />

DOUBLE TRIANGLE TIE

Ancon ST1 Heavy Duty Tie (Type 1 Tie)<br />

Length (mm) Cavity (mm)<br />

200 50-75<br />

225 76-100<br />

250 101-125<br />

275 126-150<br />

300 150*<br />

*With greater embedment to simplify installation<br />

UK Patent Nos. 2 255 358<br />

2 260 348<br />

2 260 349<br />

MASONRY TO MASONRY<br />

<strong>WALL</strong> <strong>TIES</strong><br />

Application<br />

Type 1 wall tie for use in the external walls<br />

of buildings of any height. This tie is<br />

unsuitable for internal separating walls of<br />

new build attached dwellings. Please refer<br />

to page 4 for more details.<br />

REPLACES BS1243<br />

VERTICAL-TWIST TIE<br />

Staifix Universal Insulation Retaining Clip<br />

Application<br />

Insulation retaining clip for use in partial fill<br />

cavities with all* standard Ancon and Staifix<br />

wall ties.<br />

*The TJ Clip should be used with Staifix-Thor Helical TJ2 ties.<br />

Flat Ties<br />

HRT4<br />

RT2<br />

Double Triangle<br />

ST1<br />

7

Staifix Starter Tie<br />

for joining new walls to existing masonry<br />

Application<br />

Screw-in tie supplied with an 8mm nylon<br />

plug for joining new masonry to existing<br />

walls without the need for jointing.<br />

Ideal for the construction of conservatories,<br />

extensions and garden walls.<br />

AVAILABLE<br />

SINGULARLY - NO<br />

JOB TOO SMALL<br />

8

Staifix Starter Tie Installation<br />

1<br />

Starter Ties should be fixed at<br />

225mm vertical centres in a line<br />

central to the new leaf. Drill 8mm<br />

diameter holes, 45mm deep into<br />

the existing wall at an angle of 30˚<br />

to the horizontal.<br />

2<br />

Bend the tie into the bed joint<br />

of the new brickwork. Build the tie<br />

in ensuring it is surrounded<br />

by mortar.<br />

This tie is suitable for use in masonry up to 8 metres in height. For buildings in particularly exposed areas,<br />

especially if the wall is higher than 5 metres or the construction is single leaf, it would be advisable to carry<br />

out a check calculation using the wind code and increase the density of starter ties if necessary.<br />

Staifix Cavity Starter Tie<br />

for the build of a new inner leaf of blockwork<br />

Application<br />

Screw-in tie that simplifies the build of an inner leaf of blockwork within an<br />

existing structure. Supplied with an 8mm nylon plug and a neoprene ‘o’ ring.<br />

Staifix Cavity Starter Tie Installation<br />

IDEAL FOR BARN<br />

CONVERSIONS<br />

Drill an 8mm diameter hole<br />

horizontally into existing outer leaf<br />

of masonry. Position the hole such<br />

that when the tie is installed the<br />

safety end will be located in the<br />

bed joint of the new inner leaf of<br />

blockwork.<br />

Insert the nylon plug. Slide the<br />

neoprene ‘o’ ring on the tie and<br />

screw into the plug. Build the tie<br />

into the inner leaf of blockwork<br />

ensuring it is surrounded by mortar.<br />

9

Staifix Timber Frame Tie (Type 6 Tie)<br />

for fixing masonry to timber frames<br />

To Suit Cavities (mm)<br />

50, 75, 100<br />

Application<br />

Cavity wall tie for use in the construction of<br />

timber-framed buildings up to 4 storeys in<br />

height. Supplied complete with an annular<br />

ring shank nail.<br />

CRANKED, TO<br />

EASE INSTALLATION<br />

10

Installation<br />

1<br />

Position the tie on fresh mortar in<br />

the bed joint of the outer leaf of<br />

masonry with the upstand against<br />

the timber.<br />

2<br />

Hammer the nail, through the hole<br />

in the upstand, into the timber<br />

framework.<br />

3<br />

Build the tie into the bed joint of<br />

the new masonry ensuring it is<br />

surrounded by mortar.<br />

Density of Timber Frame Ties<br />

Timber Frame Ties should be installed at a density of 4.4 ties per<br />

square metre in buildings where the basic wind speed does not<br />

exceed 25m/s (BS6399-2: 1997 Code of Practice for Wind Loads).<br />

The density should be increased to 7 ties per square metre in more<br />

severe situations.<br />

11

References for Bespoke Ancon Wall Ties<br />

Ancon wall ties may be specified and ordered<br />

by using a reference letter for the tail, shank<br />

and head of the tie.<br />

Example using<br />

Reference System<br />

Tail D<br />

Shank P<br />

Head 21<br />

Ancon DP21<br />

wall tie<br />

TAIL<br />

Most can be used<br />

at either end of tie<br />

S _ _<br />

SHANK<br />

_ D _<br />

50<br />

HEAD<br />

10<br />

10<br />

30<br />

30<br />

10<br />

20<br />

8x30mm slot<br />

_ _ V<br />

_ _ U without slot<br />

7mm diameter<br />

hole<br />

_ _ B<br />

_ P _<br />

L<br />

_ _ 21<br />

To fit 21/18<br />

Omega Channel<br />

25mm<br />

L _ _<br />

W _ _<br />

10mm<br />

L<br />

L<br />

P _ _<br />

D _ _<br />

6x60mm welded<br />

dowel<br />

_ V _<br />

_ F _<br />

L<br />

10mm<br />

To suit channel<br />

_ _ 25 To fit 25/14<br />

_ _ 28 To fit 28/15<br />

_ _ 30 To fit 30/20<br />

_ _ 36 To fit 36/8<br />

_ _ 38* To fit 38/17<br />

*Tie will be 25mm wide<br />

_ _ X<br />

7mm diameter<br />

hole<br />

260mm<br />

T _ _<br />

10mm<br />

15mm<br />

15mm<br />

10mm<br />

Y _ _<br />

6x60mm loose<br />

dowel<br />

M_ _<br />

_ H _<br />

105mm<br />

_ _ G<br />

6.5mm<br />

diameter holes<br />

6x60mm loose<br />

dowel<br />

Ancon Remedial Wall Ties<br />

MM63<br />

Lengths 195, 220, 250,<br />

300mm<br />

RM63<br />

Lengths 195, 220, 250,<br />

300mm<br />

AC31<br />

Lengths 175, 200, 225mm<br />

AC31C<br />

Lengths 175, 200, 225mm<br />

HAVE A<br />

QUESTION CALL<br />

0114 238 1 238<br />

Setting tools, resin cartridges, resin guns and mixing nozzles are all<br />

available. Contact Ancon for more details on our range of remedial<br />

wall ties and ancillary products.<br />

12

Staifix-Thor Helical Crack Stitching Kit<br />

for the permanent repair of cracked masonry<br />

500mm<br />

500mm<br />

Wall Slot Bar<br />

Thickness Depth Depth<br />

102mm 30mm 20mm<br />

215mm 40mm 30mm<br />

THE HIGH STRENGTH,<br />

NON-DISRUPTIVE REPAIR<br />

SOLUTION<br />

500mm<br />

500mm<br />

Application<br />

This kit contains all the necessary<br />

components to permanently repair vertical<br />

or stepped cracks in masonry.<br />

•Grout mixing paddle<br />

•Cementitious grout (3 litres)<br />

•Grout applicator gun<br />

•Flat grout nozzle<br />

•Stainless steel helical bar (10 x 1000mm)<br />

•Finger trowel<br />

Notes:<br />

1. This system is also suitable for rendered/plastered walls<br />

2. Vertical spacing is normally every 4 to 6 brick courses<br />

(300 - 450mm), however this should be checked with the<br />

structural engineer<br />

3. Where cracks are within 500mm of corners or reveals, the bar<br />

should be bent and bonded 100mm around the corner<br />

4. If two or more cracks are close together, bars can be lapped.<br />

Laps should be at least 500mm and the bar should extend<br />

500mm from the outer cracks<br />

13

Installation<br />

It is essential that the cause of the cracking is established by a structural engineer<br />

and then eliminated, prior to the installation of this system.<br />

1<br />

2<br />

3<br />

Cut a slot in the mortar joint to the<br />

specified depth that extends just over<br />

500mm each side of the crack<br />

(recommended equipment: Twin-bladed<br />

diamond-tipped wall chaser). Ensure the<br />

mortar is completely removed to reveal<br />

the top and bottom faces of the<br />

masonry. Remove all loose mortar from<br />

the slot and flush with clean water.<br />

Connect the paddle to a power drill,<br />

blend the components of the grout<br />

together in the tub and load into the gun.<br />

Apply a continuous bead (approximately<br />

10-15mm thick) to the back of the slot<br />

using the flat grout nozzle.<br />

Push the helical bar into the face of the<br />

grout, to the depth specified, so that<br />

the bar extends 500mm each side of<br />

the crack.<br />

4<br />

5<br />

Apply a second, continuous bead of<br />

grout to the slot, ensuring the bar is<br />

covered. With the finger trowel, force the<br />

grout back into the slot 10mm from the<br />

surface, and ensure the bar/grout<br />

composite is tightly packed.<br />

Make good the bed joint and fill the<br />

vertical crack with an appropriate filler<br />

or mortar.<br />

14

Helical Nails for Pitched Roofs<br />

European Patent No. 1307303<br />

Super-7 Thor-Helical Nails<br />

Super-7 nails install flush to the<br />

counterbatten. They are manufactured<br />

from stainless steel and are engineered<br />

with the precise Thor-Helical patented<br />

helix, and so provide maximum<br />

corrosion resistance and excellent<br />

holding power. They are stocked in six<br />

standard lengths and meet the technical<br />

requirements of the NHBC.<br />

15

Nail Lengths<br />

Stocked Lengths (mm)<br />

140, 150, 160, 165, 175, 185<br />

Note: Other lengths are available in increments of 5mm<br />

Pack Sizes<br />

Nail Length<br />

Quantity per Box<br />

160mm and under 400<br />

165mm and above 200<br />

Super-7 Alignment Tool<br />

This innovative Alignment Tool vertically<br />

aligns and centres a nail on the<br />

counterbatten to rafter arrangement,<br />

improving build quality.<br />

The tool features a levelling indicator to<br />

identify a vertical plane.<br />

Recommended Nail Length<br />

and Fixing Centres<br />

This information should be calculated<br />

using HeliCalc, a free web-based<br />

program available at www.helicalc.co.uk.<br />

Users simply input details of their site<br />

location and roof construction, and<br />

HeliCalc calculates the length, density<br />

and quantity of Super-7 nails required<br />

for the project. Alternatively, contact<br />

Ancon with your project details.<br />

Note: HeliCalc results are specific to Super-7 Thor-Helical<br />

nails. The data is calculated using a design method, formulated<br />

by Ancon Ltd and independently approved by the Building<br />

Research Establishment, which is applied to the results of a<br />

comprehensive and independent test programme carried out by<br />

CERAM Building Technology. Wind load calculations are to<br />

BS6399: Part 2: 1997. Snow load calculations are to BS6399:<br />

Part 3: 1988. Partial safety factors are from National Annexes to<br />

Eurocodes 0 and 5 and are applied in respect of timber<br />

connections, dead loads, wind loads and snow loads.<br />

Test Results<br />

Test data is available on request.<br />

Patent pending<br />

90˚<br />

Two widths to<br />

accommodate<br />

38mm and 50mm<br />

counterbattens<br />

Top, with level to ensure<br />

correct angle of entry<br />

Eyelet to allow tool<br />

to be secured to<br />

person/structure<br />

Super-7s can be hammered in or<br />

power-driven. SDS drill attachments<br />

are available.<br />

16

Helical Nails for Flat Roofs<br />

Super-8 Headed Helical Nails<br />

Headed helical nails are designed to<br />

secure plywood/insulation composite<br />

roof decks to timber joists. They are<br />

manufactured from zinc coated steel in<br />

two standard lengths which suit panel<br />

depths from 70mm to 126mm. Other<br />

lengths are available on request.<br />

Super-8s should be installed at a rate of<br />

8.6 per square metre, using a hammer.<br />

The 20mm diameter head simplifies<br />

installation.<br />

17

Nail Lengths<br />

Standard Lengths (mm)<br />

135, 165<br />

Note: Other lengths are available on request<br />

Pack Sizes<br />

Quantity per Bag Quantity per Box<br />

25 500<br />

Recommended Lengths<br />

Composite<br />

Panel Depth<br />

70-96mm<br />

96-126mm<br />

Recommended<br />

Nail Length<br />

135mm<br />

165mm<br />

Super-8 nails should achieve a minimum<br />

embedment of 35mm in the joist.<br />

Recommended Axial Spacings<br />

Joist Centres 400mm 600mm<br />

Axial Spacings 400mm x 400mm 600mm x 300mm<br />

400mm<br />

600mm<br />

400mm<br />

300mm<br />

Test Results<br />

Test data is available on request.<br />

18

GREAT PRODUCTS.<br />

GREAT SERVICE.<br />

GREAT PRICES.<br />

FREE LOCAL<br />

DELIVERY<br />

GETTING TO<br />

KNOW MKM<br />

WHO ARE MKM<br />

• The UK’s 8th largest and<br />

fastest growing Builders’<br />

Merchant with an<br />

expanding branch network<br />

• Employing a local ‘hand<br />

picked’ team of experts<br />

WHAT SERVICES CAN<br />

WE PROVIDE<br />

• A fast, friendly, reliable<br />

and efficient counter and<br />

telephone service<br />

• Our team are<br />

knowledgeable and<br />

here to help you get<br />

exactly what you need<br />

OUR PRODUCTS<br />

•A one-stop-shop for all<br />

building, plumbing, timber<br />

and landscape materials<br />

For all your BUILDING, PLUMBING,<br />

TIMBER and LANDSCAPING needs<br />

NEED HELP We have an expert on hand to<br />

help you get exactly what you need<br />

HOW DO I START TRADING<br />

• Call into the branch,<br />

meet our team and<br />

activate an account<br />

There’s an<br />

near you...<br />

OPEN TO TRADE & PUBLIC - MONDAY TO SATURDAY<br />

for your nearest branch call 08701 222 656 or visit www.<strong>mkm</strong>bs.co.uk