hope begins here - College of Engineering - Oregon State University

hope begins here - College of Engineering - Oregon State University

hope begins here - College of Engineering - Oregon State University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2008 Annual Report<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong><br />

<strong>hope</strong> <strong>begins</strong> <strong>here</strong><br />

1

The Vision<br />

Collaborative innovation is<br />

pervasive in the OSU <strong>College</strong> <strong>of</strong><br />

<strong>Engineering</strong>. Student teams thrive<br />

in our culture, and they <strong>of</strong>ten bring<br />

home trophies. Creative energy<br />

crosses disciplines as the greatest<br />

minds in the nation unite to take on<br />

some <strong>of</strong> society’s biggest challenges:<br />

today we are poised for tremendous<br />

impact on multiple aspects <strong>of</strong> energy<br />

independence and engineered<br />

sustainability.<br />

Collaborative innovation happens<br />

easily <strong>here</strong>, but not without the<br />

influence <strong>of</strong> leadership. Leadership<br />

provided when a special person<br />

comes along with an idea and a<br />

vision, a person who just seems to<br />

stand out above the rest. Someone<br />

who sees what could be and devotes<br />

the energy, the <strong>hope</strong>, the enthusiasm<br />

and the leadership it takes to create<br />

a new and better future. Martin<br />

Kelley was such a person.<br />

As much as we believe in the<br />

power <strong>of</strong> collaborative innovation<br />

to develop great engineers and<br />

solve big problems, sometimes we<br />

also need to stop and recognize<br />

the leaders who can make such a<br />

pr<strong>of</strong>ound difference in our colleges,<br />

our universities and our nation. In<br />

this report, you’ll read more about<br />

Martin and the impact his vision and<br />

leadership have had on the <strong>College</strong><br />

<strong>of</strong> <strong>Engineering</strong>. Martin passed away<br />

last summer, but he will always hold<br />

a special place in our hearts.<br />

Martin’s historic gift <strong>of</strong> $20 million<br />

in 2000 was a tipping point in the<br />

history <strong>of</strong> our college. It wasn’t just<br />

the money. It was his vision <strong>of</strong> what<br />

could be and his energy in helping<br />

to bring others on board, to instill<br />

the belief that we really will deliver<br />

the impact <strong>of</strong> one <strong>of</strong> the nation’s top<br />

engineering programs. That donation<br />

has already helped to stimulate<br />

another $100 million in private gifts<br />

and led to many amazing results.<br />

Our faculty has created significant<br />

research programs, including the<br />

National Tsunami Wave Basin,<br />

the <strong>Oregon</strong> Nanoscience and<br />

Microtechnologies Institute and<br />

the Northwest National Marine<br />

Renewable Energy Center. They’ve<br />

launched 11 new companies based<br />

on their research results, and those<br />

companies have already attracted<br />

another $85 million in private<br />

investments.<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong> research<br />

on aging bridge structures helped<br />

save <strong>Oregon</strong>ians $500 million in<br />

bridge repair work — and what<br />

we’ve learned will aid crumbling<br />

infrastructures all over the nation.<br />

The total renovation <strong>of</strong> Apperson<br />

Hall — soon to become Kearney<br />

Hall — is nearing completion. The<br />

number <strong>of</strong> top high school graduates<br />

entering the college has nearly<br />

tripled since Martin’s gift. Our<br />

students are winning national design<br />

competitions, such as the first-place<br />

entry in the 2008 Mars Rover event.<br />

The drive is gaining speed.<br />

As you read this report, you’ll<br />

find many examples <strong>of</strong> advanced<br />

engineering research at OSU. Our<br />

progress and building momentum<br />

are a tribute to a great engineer and<br />

a man with vision. A man who, like<br />

many <strong>of</strong> us, was proud to call himself<br />

an alumnus <strong>of</strong> the OSU <strong>College</strong> <strong>of</strong><br />

<strong>Engineering</strong>.<br />

Ron Adams, Dean<br />

Dean Ron Adams demonstrates<br />

the dancing robotic beaver, one <strong>of</strong><br />

many TekBots designed and built by<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong> students.

Martin<br />

moments<br />

In 2003, when work<br />

began on the building<br />

that would bear his name,<br />

Martin Kelley treated it<br />

like any other construction<br />

project. Every three months,<br />

he toured the site, met<br />

with project engineers and<br />

received budget updates.<br />

“For a while, I was afraid we might<br />

have the largest swimming pool<br />

in <strong>Oregon</strong>,” he joked with guests<br />

at the Kelley <strong>Engineering</strong> Center<br />

grand opening in 2005. “But to say<br />

that I am pleased with the results<br />

would be a huge understatement.”<br />

He had no idea, he added, when he<br />

agreed in 2000 to contribute $20<br />

million to the project, that it would<br />

“be this nice <strong>of</strong> an institution for<br />

group learning.”<br />

Gift sparks additional<br />

investments<br />

Kelley may not have anticipated<br />

something else: the enthusiasm<br />

and sense <strong>of</strong> <strong>hope</strong> he sparked<br />

among other <strong>College</strong> <strong>of</strong> <strong>Engineering</strong><br />

alumni. His vision and philanthropic<br />

leadership became the tipping point<br />

in the college’s success with the<br />

center and the Campaign for OSU –<br />

leading to more than $100 million in<br />

private investments.<br />

Those funds have led to new student<br />

scholarships, faculty endowments<br />

and additional facility improvements,<br />

stemming from the pride and<br />

generosity spurred by Kelley’s<br />

landmark gift.<br />

Five things<br />

stand out about<br />

Martin Kelley,<br />

according to<br />

OSU Foundation<br />

Board chair<br />

Darald W.<br />

Callahan:<br />

“his dedicated<br />

leadership,<br />

incredible<br />

generosity,<br />

humility, great<br />

stories and<br />

sense <strong>of</strong> humor<br />

and <strong>of</strong> course,<br />

that trademark<br />

bow tie.”<br />

The 2008 Annual Report is dedicated to<br />

Martin Kelley (1928-2008), known for his<br />

trademark bow tie and generosity to OSU<br />

— including the $20 million lead gift to<br />

“His vision and philanthropic leadership became the tipping point in the college’s success…”<br />

build the Kelley <strong>Engineering</strong> Center.<br />

2 3<br />

— Ron Adams

“His trademark bow tie is<br />

a clue that he would have<br />

had a successful career as<br />

a university pr<strong>of</strong>essor.”<br />

— Lee Kearney<br />

“He launched the<br />

transformation <strong>of</strong> the<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong>.”<br />

— Ron Adams<br />

Martin<br />

moments<br />

Martin grew up<br />

in Pasadena,<br />

Calif., in a family<br />

that stressed<br />

responsibility,<br />

independence<br />

and a strong<br />

work ethic. This<br />

emphasis on<br />

independence<br />

was one reason<br />

he came to<br />

<strong>Oregon</strong> <strong>State</strong> in<br />

1945 to study<br />

civil engineering.<br />

The “gospel <strong>of</strong> sound<br />

practices”<br />

It may not have been a surprise<br />

to anyone who knew him well.<br />

Rigorous education and training<br />

are keystones, Kelley believed,<br />

to keeping the public trust in<br />

engineering. He loved to mentor<br />

young engineers, and his direct,<br />

easygoing manner, integrity and<br />

commitment to principles made<br />

a lasting impression on them,<br />

according to Lee Kearney, former<br />

colleague and 1963 OSU civil<br />

engineering alum. “He preached<br />

regularly the gospel <strong>of</strong> sound<br />

estimating and engineering<br />

practices. His trademark bow tie is<br />

a clue that he would have had a<br />

successful career as a university<br />

pr<strong>of</strong>essor,” Kearney added.<br />

An accomplished career<br />

After graduating from OSU with<br />

a degree in civil engineering in<br />

1950, Kelley played key roles in<br />

some <strong>of</strong> the world’s most ambitious<br />

construction projects: Quebec’s<br />

James Bay hydropower dams, the<br />

San Francisco Trans-Bay Tube, the<br />

Danish Great Belt Crossing and New<br />

York City’s 63rd Street Tube and<br />

Tunnel Project. Today, millions rely<br />

on his accomplishments in energy<br />

and transportation systems that<br />

light homes, run factories and speed<br />

daily commutes.<br />

Originally anonymous<br />

Kelley retired in 1990 as the vice<br />

president and chief engineer at<br />

the Kiewit Company, one <strong>of</strong> the<br />

nation’s largest construction firms.<br />

His commitment to education<br />

led him to serve with the <strong>Oregon</strong><br />

<strong>State</strong> <strong>University</strong> Foundation Board<br />

<strong>of</strong> Trustees and the <strong>College</strong> <strong>of</strong><br />

<strong>Engineering</strong> Advisory Board.<br />

After meeting with Ron Adams,<br />

who became dean <strong>of</strong> the <strong>College</strong> <strong>of</strong><br />

<strong>Engineering</strong> in 1998, Kelley decided<br />

to launch a renaissance at his alma<br />

mater. “Ron talked about what<br />

he thinks makes things work and<br />

move is people, pr<strong>of</strong>essors and more<br />

students. I agreed with him, but I<br />

said if you’re going to have more<br />

pr<strong>of</strong>essors and people, you’ll need a<br />

place to put them,” Kelley said.<br />

Former OSU president Paul Risser<br />

remembers how Kelley arrived at<br />

the decision to jump-start a new<br />

building. “He and I had several<br />

discussions about the importance <strong>of</strong><br />

engineering, especially in <strong>Oregon</strong>,”<br />

Risser said. “When Martin came to<br />

me to say that he wanted to make<br />

a large gift for the engineering<br />

building, he said it was to be totally<br />

anonymous. In fact, he told me<br />

that if it became known he was the<br />

donor, he would take back the gift.<br />

This was his humbleness.”<br />

A legacy <strong>of</strong> leadership<br />

“The Kelley <strong>Engineering</strong> Center says<br />

to <strong>Oregon</strong> and the nation that OSU is<br />

serious about its mission. It signals<br />

that our aspirations are high and<br />

realistic. Above all else, it announces<br />

loud and clear that OSU is supported<br />

by individuals <strong>of</strong> vision and<br />

determination who care pr<strong>of</strong>oundly<br />

about this nation and this state,”<br />

OSU President Ed Ray said at the<br />

grand opening.<br />

Kelley earned OSU’s highest awards<br />

for his leadership. Among them were<br />

the Lifetime Trustee Award from the<br />

OSU Foundation and the E.B. Lemon<br />

Distinguished Alumni Award from<br />

the OSU Alumni Association.<br />

“I witnessed the sense <strong>of</strong> pride<br />

that he had as he walked through<br />

the building the first time,” says<br />

Terri Fiez, head <strong>of</strong> the School <strong>of</strong><br />

Electrical <strong>Engineering</strong> and Computer<br />

Science. “Last year, he came to the<br />

engineering orientation and brought<br />

some friends to see the building.<br />

He then went out to the ice cream<br />

social with all the new freshmen and<br />

got his picture taken with students.<br />

Again, very proud!”<br />

His contribution was nothing less<br />

than monumental, says Ron Adams.<br />

“He launched the transformation <strong>of</strong><br />

the <strong>College</strong> <strong>of</strong> <strong>Engineering</strong>.”<br />

4<br />

5

Apperson to Kearney<br />

Lee and Connie Kearney<br />

provided the lead gift for<br />

the renovation <strong>of</strong> historic<br />

Apperson Hall.<br />

More than 40 years ago, Lee<br />

Kearney (’63) took classes like<br />

dynamics and fluid mechanics in<br />

Apperson Hall. Back then, the woodframe<br />

building was much like it<br />

was before renovations started last<br />

year, with creaky steps and support<br />

columns in the middle <strong>of</strong> classrooms,<br />

blocking students’ views.<br />

In a few months, the cornerstone <strong>of</strong><br />

<strong>Engineering</strong> Row will emerge with a<br />

new steel structure behind its historic<br />

stone façade. And it will have a new<br />

name: Kearney Hall, in recognition<br />

<strong>of</strong> Lee and Connie Kearney’s lead gift<br />

<strong>of</strong> $4 million toward the $12 million<br />

renovation project.<br />

W<strong>here</strong> the<br />

past and<br />

future meet<br />

Part <strong>of</strong> a strategic plan<br />

A longtime member <strong>of</strong> the <strong>College</strong> <strong>of</strong><br />

<strong>Engineering</strong>’s Advisory Board, Kearney<br />

knew better facilities — in addition<br />

to scholarships, faculty and research<br />

grants — were needed to move the<br />

program forward. Renovating the<br />

100+ year-old Apperson Hall was<br />

part <strong>of</strong> the strategic plan adopted by<br />

the board, Dean Ron Adams and the<br />

department heads.<br />

“We needed to expand our capacity<br />

to produce more graduate engineers,<br />

which are definitely in short supply<br />

in <strong>Oregon</strong> and all over the nation,”<br />

Kearney says. “This project matched<br />

my interest, and I felt it would<br />

allow the continuation <strong>of</strong> our overall<br />

improvement program.”<br />

A collaborative environment<br />

Like the Kelley <strong>Engineering</strong> Center,<br />

the new Kearney Hall will create an<br />

environment for collaboration, with<br />

multiple engineering disciplines<br />

under one ro<strong>of</strong>. Kearney believes this<br />

“collegial atmosp<strong>here</strong>” has helped<br />

the <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> recruit<br />

more top faculty. “When they see<br />

how this group works together,<br />

that’s the deciding factor that makes<br />

it easy for them to come to <strong>Oregon</strong><br />

<strong>State</strong>,” Kearney says.<br />

The nearly total reconstruction<br />

<strong>of</strong> the building — with the steel<br />

structure, those view-blocking<br />

columns are gone — includes<br />

interactive classrooms and a<br />

computerized learning laboratory,<br />

along with space w<strong>here</strong> students and<br />

faculty can collaborate on projects.<br />

“It’s a huge improvement over what<br />

was t<strong>here</strong>,” Kearney says. Bringing a<br />

21st-century learning environment<br />

to one <strong>of</strong> the oldest buildings on<br />

campus is a “nice compromise”<br />

between the past and the future.<br />

The new Kearney Hall<br />

incorporates an entirely new<br />

steel structure and interior<br />

6<br />

behind its historic stone façade.<br />

7

OSU is a national and<br />

international leader in<br />

That research is also<br />

diverse, exploring<br />

multiple pathways to<br />

energy independence. From<br />

harnessing the wind and<br />

waves to highly efficient<br />

solar cells and biodiesel<br />

production, safe nuclear<br />

reactors and hydrogen<br />

fuel cells, OSU researchers<br />

and industry partners are<br />

finding new ways to power<br />

the global economy.<br />

Innovative,<br />

renewable and<br />

sustainable<br />

energy research<br />

Ocean Energy – <strong>Oregon</strong><br />

has become a national and<br />

international leader in the<br />

development <strong>of</strong> wave energy,<br />

the result <strong>of</strong> pioneering<br />

work under lead collaborator<br />

Annette von Jouanne, a<br />

pr<strong>of</strong>essor <strong>of</strong> electrical<br />

engineering. OSU is now home<br />

to the Northwest National<br />

Marine Energy Center, which is<br />

working to make wave energy<br />

production a reality. This<br />

is a vast, largely untapped<br />

energy source that’s clean,<br />

environmentally benign, costeffective<br />

and perpetual.<br />

Biodiesel – Goran Jovanovic,<br />

a pr<strong>of</strong>essor <strong>of</strong> chemical<br />

engineering, is the lead<br />

collaborator on developing<br />

a working prototype <strong>of</strong> a<br />

tiny chemical reactor for<br />

manufacturing biodiesel –<br />

one that is efficient, fast<br />

and portable.<br />

Solar – It wasn’t even<br />

considered at first as one <strong>of</strong><br />

the likely uses, but <strong>College</strong> <strong>of</strong><br />

<strong>Engineering</strong> breakthroughs<br />

in transparent electronics<br />

may find some <strong>of</strong> their first<br />

applications in new solar<br />

energy devices that are up to<br />

four times more cost-efficient<br />

than existing approaches.<br />

Hydrogen – Hong Liu,<br />

an assistant pr<strong>of</strong>essor <strong>of</strong><br />

biological engineering, has<br />

created ways to produce both<br />

electricity and hydrogen gas<br />

from sewage in systems that<br />

may significantly bring down<br />

the cost <strong>of</strong> hydrogen for use<br />

in fuel cells – <strong>of</strong>ten seen as<br />

the fuel for automobiles <strong>of</strong> the<br />

future. And the technology<br />

cleans the water at the same<br />

time.<br />

Wind – OSU was an early<br />

leader in wind energy research<br />

and specializes in assessing<br />

the wind-power potential for<br />

private and public landowners.<br />

Many <strong>of</strong> OSU’s energy research<br />

initiatives are coordinated<br />

through the <strong>Oregon</strong> Built<br />

Environment and Sustainable<br />

Technologies (<strong>Oregon</strong> BEST)<br />

signature research cluster.<br />

Among its goals, <strong>Oregon</strong> BEST<br />

aims to make the state a leader<br />

in clean energy, bio-based<br />

products and green buildings.<br />

“T<strong>here</strong>’s a<br />

culture<br />

shift going<br />

on at OSU.”<br />

Over the past five years, <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> research has spun out 11 new companies and attracted more than $85<br />

million in private investments. Joe Tanous joined the college two years ago to help commercialize OSU innovations.<br />

The strong research programs in<br />

the OSU <strong>College</strong> <strong>of</strong> <strong>Engineering</strong><br />

are increasingly going to work —<br />

creating new products, establishing<br />

new companies and attracting new<br />

investments.<br />

“T<strong>here</strong>’s a culture shift going on<br />

at OSU,” says Joe Tanous, who was<br />

brought to the college two years ago<br />

to serve as innovation liaison. “We’ve<br />

had some great research programs<br />

and accomplishments <strong>here</strong> for a long<br />

time, but too <strong>of</strong>ten they just ended<br />

up on the shelf.”<br />

“We’re not going to let them fall<br />

into that black hole any more,”<br />

he says. “We’re going to get them<br />

commercialized. It’s good for the<br />

faculty, for the students, for the<br />

university and for the public.”<br />

Various tools are available now<br />

to help with the task, Tanous<br />

says, including venture grants,<br />

the facilities <strong>of</strong> ONAMI and other<br />

initiatives designed to get new<br />

findings out <strong>of</strong> the laboratory and<br />

into the commercial marketplace.<br />

The results are starting to show:<br />

Strands is all about “discovery,”<br />

according to OSU computer<br />

scientist Jon Herlocker, who<br />

helped found the company<br />

in 2004. Strands has created<br />

a social recommender engine<br />

that is able to provide real-time<br />

recommendations <strong>of</strong> products<br />

and services through computers,<br />

mobile phones and other Internetconnected<br />

devices.<br />

RedRover S<strong>of</strong>tware, a startup<br />

built on 10 years <strong>of</strong> research by<br />

OSU computer scientists including<br />

Margaret Burnett and Martin<br />

Erwig, provides pioneering new<br />

tools to detect and fix errors in<br />

computer spreadsheets, an issue<br />

that costs billions for companies<br />

around the world.<br />

MTek Energy Solutions is<br />

creating a credit-card sized biodiesel<br />

device that combines vegetable<br />

oil, alcohol and a catalyst in tiny<br />

microreactors to produce biodiesel<br />

fuel. The company is a spinout from<br />

OSU’s leadership in microreactor<br />

technology and original research<br />

by OSU chemical engineer Goran<br />

Jovanovic.<br />

Nanobits is another spinout<br />

from OSU microreactor technology<br />

research. The company is creating<br />

new devices for use in specialty<br />

chemical and nanomaterial<br />

manufacturing. Alex Chang, an<br />

associate pr<strong>of</strong>essor <strong>of</strong> chemical<br />

engineering, is developing<br />

microreactor technology to produce<br />

nanoparticles for drug delivery.<br />

Martin<br />

moments<br />

Martin was a<br />

consummate<br />

teacher and<br />

coach; his<br />

colleagues<br />

thought he<br />

would have<br />

made an<br />

excellent college<br />

pr<strong>of</strong>essor had<br />

he not gone into<br />

engineering and<br />

construction.<br />

8<br />

9

Jose Reyes has led breakthrough<br />

research into small-scale nuclear<br />

power plants that incorporate passivesafety<br />

design features.<br />

Converting economy <strong>of</strong> scale<br />

into the economy <strong>of</strong> small<br />

Martin<br />

moments<br />

Martin believed<br />

he graduated<br />

with a solid<br />

grounding in<br />

the practical<br />

applications <strong>of</strong><br />

engineering.<br />

“I always felt<br />

<strong>Oregon</strong> <strong>State</strong><br />

did a good job<br />

<strong>of</strong> preparing me<br />

for my career in<br />

civil engineering<br />

construction,”<br />

he said.<br />

“We wanted<br />

something small,<br />

really small, and<br />

really safe.”<br />

—Jose Reyes<br />

When Jose Reyes was considering<br />

different types <strong>of</strong> nuclear reactor<br />

designs in the late 1990s, practically<br />

all commercial power reactors were<br />

big. Really big. They embraced the<br />

concept <strong>of</strong> “economy <strong>of</strong> scale,” in<br />

which large reactors that produced<br />

more electricity were the most costeffective.<br />

Reyes had a different vision: the<br />

economy <strong>of</strong> small. So small, in<br />

fact, that a reactor could be built<br />

in a factory, mass produced with<br />

tight quality control and shipped<br />

easily to w<strong>here</strong>ver it was needed.<br />

And that vision ultimately became<br />

the foundation <strong>of</strong> NuScale Power, a<br />

startup firm that is already being<br />

called a “company to watch” by the<br />

Forbes/Wolfe Emerging Tech Report.<br />

“At first, we were thinking primarily<br />

<strong>of</strong> designs that could bring the<br />

benefits <strong>of</strong> nuclear power to remote<br />

locations or developing countries,”<br />

says Reyes, pr<strong>of</strong>essor and head<br />

<strong>of</strong> OSU’s Department <strong>of</strong> Nuclear<br />

<strong>Engineering</strong> and Radiation Health<br />

Physics.<br />

Really small – and really safe<br />

“We wanted something small,<br />

really small, and really safe,” he<br />

says. “Then we had 9-11, and we<br />

realized these same designs could<br />

also be extremely low pr<strong>of</strong>ile,<br />

placed underground and much less<br />

vulnerable to terrorist attack, even<br />

addressing nuclear proliferation<br />

concerns. All the pieces seemed to<br />

come together.”<br />

The idea <strong>of</strong> extremely small nuclear<br />

reactors that could fit on a truck<br />

or railroad car – incorporating the<br />

latest passive safety concepts that<br />

OSU helped pioneer during the<br />

1990s – is now moving closer to a<br />

commercial reality.<br />

The plan is small, modular nuclear<br />

reactor cores that would produce<br />

45 megawatts <strong>of</strong> power each –<br />

enough for about 45,000 homes –<br />

which could be grouped to provide<br />

whatever amount <strong>of</strong> power is needed.<br />

They could be installed incrementally<br />

to minimize up-front investment<br />

costs, speed the completion <strong>of</strong> new<br />

energy facilities and produce large<br />

amounts <strong>of</strong> electricity with no<br />

greenhouse gas emissions.<br />

“We’re creating a design that will<br />

answer many <strong>of</strong> the real obstacles<br />

faced in the construction <strong>of</strong> new<br />

nuclear plants, whether they<br />

relate to safety, cost or ease <strong>of</strong><br />

construction,” says Reyes, who<br />

is also the chief technical <strong>of</strong>ficer<br />

<strong>of</strong> NuScale. “These reactors will<br />

contribute to the renaissance <strong>of</strong><br />

nuclear energy all over the world.”<br />

OSU innovation, plus industry<br />

support<br />

This work started as a collaboration<br />

between OSU, Idaho National<br />

Laboratory and Nexant/Bechtel, with<br />

support in the early 2000s by the<br />

U.S. Department <strong>of</strong> Energy. With a<br />

partnership now in place with Kiewit<br />

Construction, a major power plant<br />

constructor, NuScale Power plans<br />

to take the approach to a working<br />

reality. OSU has three patents on<br />

the technology, and the university<br />

will help test the design. Final<br />

certification may be possible within<br />

five years.<br />

“Cost is important, but safety<br />

in every sense is the real key to<br />

modular reactors,” says Reyes. “This<br />

is a post 9-11 design in which the<br />

reactor core will sit underground<br />

inside a concrete container, with<br />

resistance to air attack by terrorists<br />

one <strong>of</strong> the considerations. All things<br />

considered, it should be the safest<br />

light water reactor ever built.”<br />

“The progress we’ve already made<br />

has been enormous,” he says. “The<br />

future looks bright.”<br />

10<br />

11

The<br />

Diatomic<br />

Trio<br />

Earning three degrees – with a little help from his friends<br />

It’s been a long journey<br />

for Clayton Jeffries. He<br />

went from years <strong>of</strong> work<br />

as a carpet cleaner for his<br />

dad’s business in Bend to<br />

earning three OSU degrees<br />

– a bachelor’s, master’s and<br />

soon a doctorate in chemical<br />

engineering – while helping<br />

to create breakthroughs in<br />

using diatoms, a single-celled<br />

marine life form, in devices<br />

with electronic or biological<br />

applications.<br />

But he wouldn’t have gotten t<strong>here</strong><br />

without a little help from his friends<br />

– the pr<strong>of</strong>essors who believed in his<br />

talents, fellow students who shared<br />

their knowledge and even younger<br />

students whom he now tries to help<br />

as a mentor in his own right.<br />

“We all pull each other up.”<br />

“Guidance and mentoring are just<br />

so important,” says Jeffries, who<br />

always liked science, but didn’t<br />

even start college until five years<br />

after graduating from Redmond<br />

High School. “Your pr<strong>of</strong>essors help<br />

lay out goals, you work closely with<br />

your fellow students, and when you<br />

get far enough along, you try to<br />

give back, help younger students.<br />

We all pull each other up.”<br />

Greg Rorrer, a pr<strong>of</strong>essor <strong>of</strong><br />

chemical engineering, echoes those<br />

sentiments.<br />

“We create the concepts, help guide<br />

our students and get the funding,<br />

but we’d be now<strong>here</strong> without the<br />

talents <strong>of</strong> people like Clayton,”<br />

Rorrer says. “They have a strong<br />

work ethic, youthful energy and the<br />

ability to work with and learn from<br />

their pr<strong>of</strong>essors and peers. This is<br />

really no place for a loner.”<br />

Rorrer and associate pr<strong>of</strong>essor<br />

Alex Chang are making exciting<br />

advances in the use <strong>of</strong> diatoms,<br />

marine life forms that might<br />

be biologically fabricated into<br />

solar cells to produce electricity.<br />

They show promise as unique<br />

biological sensors to detect immune<br />

disease. And their shells have been<br />

incorporated into microelectronic<br />

devices to manipulate broadspectrum<br />

light. With support <strong>of</strong><br />

a $1.3 million grant from the<br />

National Science Foundation, their<br />

research on diatoms has produced 11<br />

publications – just in the past year.<br />

“We need to scale up these systems<br />

to larger applications and test their<br />

reliability,” Chang says. “But some<br />

projects, especially the biological<br />

sensors, are getting pretty close.<br />

And we wouldn’t be making these<br />

advances without all <strong>of</strong> our students,<br />

who have such a passion for their<br />

work.”<br />

Jeffries says he may move eventually<br />

to the private sector or agency<br />

research.<br />

“This bridge between biology and<br />

material science is very interesting,<br />

and t<strong>here</strong>’s still so much we need to<br />

learn,” Jeffries says. “I may go into<br />

private research, but I don’t ever<br />

want to leave behind the type <strong>of</strong><br />

mentoring that exists at OSU. I want<br />

to keep doing that.”<br />

Martin<br />

moments<br />

Martin <strong>of</strong>ten<br />

mentioned his<br />

“bottleneck<br />

theory <strong>of</strong><br />

management:<br />

when t<strong>here</strong> are<br />

problems in an<br />

organization,<br />

the bottleneck<br />

will be found at<br />

the top.”<br />

Ph.D. student Clayton Jefferies (center), together<br />

with his pr<strong>of</strong>essors, Greg Rorrer (left) and Alex<br />

Chang (right), are finding how diatoms — singlecell<br />

marine life forms — might be biologically<br />

fabricated into solar cells to produce electricity.<br />

12<br />

13

Kate Hunter-<br />

Zaworski<br />

opens the<br />

world to<br />

people with<br />

disabilities.<br />

Iused to backpack in the Mt.<br />

Jefferson Wilderness,” reminisces<br />

Marlene Massey <strong>of</strong> Corvallis. “Now,<br />

it’s a challenge just to cross the<br />

street.” Since the results <strong>of</strong> brain<br />

surgery left her in a wheelchair 12<br />

years ago, Massey has depended on<br />

transportation services that can<br />

safely accommodate her Breezy 600.<br />

“<br />

Making it easier for people like<br />

Massey to get around is the mission<br />

<strong>of</strong> OSU’s National Center for<br />

Accessible Transportation (NCAT),<br />

funded by the U.S. Department <strong>of</strong><br />

Education. Under the leadership <strong>of</strong><br />

engineer Katharine Hunter-Zaworski,<br />

experts in biomechanics, ergonomics<br />

and mechanical engineering design<br />

equipment for mass transit systems<br />

— everything from bus lifts to<br />

boarding ramps and a wheelchairaccessible<br />

lavatory in the new Boeing<br />

787 Dreamliner.<br />

For people whose mobility is limited<br />

by physical, sensory or cognitive<br />

impairment, devices such as OSU’s<br />

patented wheelchair “docking<br />

system” that engages automatically<br />

upon boarding can make the<br />

difference between dependence<br />

and self-reliance. Assistive gear lets<br />

people move through the world at<br />

will, come and go on their own terms<br />

and escape solitude and isolation.<br />

Safe, seamless, dignified<br />

Honing the “trip chain”<br />

Three words distill Hunter-<br />

Zaworski’s vision <strong>of</strong> accessible<br />

public transportation: safe,<br />

seamless, dignified. “These words,<br />

these ideas,” she says, “underlie<br />

everything we do.” With partners<br />

such as Boeing, Amtrak, Portland<br />

International Airport, Eugene Transit<br />

and Paralyzed Veterans <strong>of</strong> America,<br />

her team is constantly honing the<br />

“trip chain,” the series <strong>of</strong> movements<br />

that take you from starting point to<br />

destination. For a traveler to arrive<br />

with both body and dignity intact,<br />

each point along the way must be<br />

free <strong>of</strong> hazards, barriers and clumsy<br />

or awkward transfers from, say, a<br />

wheelchair into an airplane seat.<br />

Canadian by birth, Hunter-Zaworski<br />

began her career nearly three<br />

decades ago when she was the<br />

first woman to earn a mechanical<br />

engineering degree at the <strong>University</strong><br />

<strong>of</strong> British Columbia. Today, she and<br />

her team, including colleague and<br />

husband, OSU assistant pr<strong>of</strong>essor<br />

Joseph Zaworski, have relentlessly<br />

pushed the principle <strong>of</strong> “universal<br />

inclusive design.”<br />

Easier access benefits<br />

everybody<br />

Examples abound: lever-style door<br />

handles, which are easier to open<br />

when your arms are full; automatic<br />

garage-door openers, originally an<br />

assistive device for a quadriplegic;<br />

“curb cuts,” built for wheelchairs —<br />

and handy for rolling suitcases and<br />

baby strollers.<br />

The advantages <strong>of</strong> easier access<br />

aren’t just for the 50 million<br />

Americans with disabilities, but<br />

rather to the whole community,<br />

Hunter-Zaworski explains.<br />

The next generation <strong>of</strong> assistive<br />

devices is already on the drawing<br />

board at OSU. Among them are rearfacing<br />

wheelchair restraints, realtime<br />

speech translation, ergonomic<br />

seat cushions and age-in-place<br />

technologies for boomers heading for<br />

retirement.<br />

An ironclad promise<br />

“Some <strong>of</strong> the battles I’ve fought<br />

for accessibility have been hard,”<br />

Hunter-Zaworski says, looking down<br />

at the metal band encircling her<br />

little finger. “But I wear the iron<br />

ring. In Canada, this ring signifies a<br />

pr<strong>of</strong>essional engineer’s responsibility<br />

to protect public safety. I take that<br />

responsibility very seriously.”<br />

14<br />

Kate Hunter-Zaworski leads a team that’s<br />

constantly honing the “trip chain” to<br />

eliminate hazards, barriers and awkward<br />

transfers — so disabled travelers arrive with<br />

both body and dignity intact. 15

Student success<br />

In search <strong>of</strong> a better battery<br />

On the scent<br />

In OSU’s micro- and nanomaterials<br />

lab, Anna Putnam puts<br />

a printed layer <strong>of</strong> lithium iron<br />

phosphate precursor into a tube<br />

furnace, w<strong>here</strong> it decomposes<br />

and forms nanosize gas bubbles.<br />

The result is a nanoporous<br />

material that is suitable for an<br />

electrode in small, lightweight<br />

batteries.<br />

“My first term at OSU,<br />

I struggled in math,”<br />

says Anna Putnam,<br />

a senior in chemical<br />

engineering from<br />

Clackamas. Pressed, she<br />

admits the worst: “I got<br />

a C in vector calculus.”<br />

In the three years since that rude<br />

awakening, nothing less than an<br />

A has darkened Putnam’s grade<br />

report. She has gone on to collect<br />

scholarships like most students<br />

collect songs on their iPods. The<br />

American Electronics Association<br />

Scholarship from Intel, OSU’s<br />

Presidential Scholarship and the<br />

OSU Research Office’s Undergraduate<br />

Research Innovation Scholarship<br />

Creativity grant are among them.<br />

W<strong>here</strong> chemical engineering<br />

meets nanoscience<br />

Today, Putnam has advanced from<br />

the front <strong>of</strong> the class to the front<br />

edge <strong>of</strong> innovation, w<strong>here</strong> chemical<br />

engineering meets nanoscience<br />

and “drop-on-demand” printing<br />

technologies. As a research<br />

assistant for associate pr<strong>of</strong>essor<br />

Alex Chang, Putnam is fabricating a<br />

“nanostructured” electrode for a new<br />

generation <strong>of</strong> lithium ion battery.<br />

An initiative <strong>of</strong> the <strong>Oregon</strong><br />

Nanoscience and Microtechnologies<br />

Institute (ONAMI) in collaboration<br />

with Pacific Northwest National Labs<br />

(PNNL), the project’s ultimate goal is<br />

a revolutionary new battery: smaller,<br />

lighter, faster, tougher.<br />

Reaching the next generation<br />

A star in the <strong>College</strong> <strong>of</strong> <strong>Engineering</strong>’s<br />

K-12 outreach and mentoring<br />

program, Putnam wows high school<br />

girls with her “real and vibrant”<br />

personality. She shows them that it’s<br />

“OK to love math and chemistry, and<br />

that it doesn’t make you a geek!”<br />

says her first-year adviser, pr<strong>of</strong>essor<br />

Willie “Skip” Rochefort, who actively<br />

recruited Putnam to OSU.<br />

When you think <strong>of</strong> computer science,<br />

the first thing that pops into your<br />

head probably isn’t a predator using<br />

environmental cues to find food.<br />

But <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> Ph.D.<br />

candidate Joey Lawrance is focusing<br />

his research on an analogous<br />

situation: programmers using natural<br />

language as a “scent” to navigate<br />

and debug code.<br />

Research wins IBM<br />

scholarship, internship<br />

Lawrance’s dual interest in<br />

computer science and psychology<br />

provides a strong background for<br />

his dissertation research, which<br />

he is currently working on in<br />

collaboration with researchers at<br />

the IBM Watson Research Center in<br />

Hawthorne, N.Y. IBM, recognizing<br />

the significance <strong>of</strong> this work, chose<br />

Lawrance for one <strong>of</strong> its prestigious<br />

Ph.D. Scholarship Awards for the<br />

2008-09 academic year. Besides the<br />

$10,000 scholarship, it also landed<br />

Lawrance an internship at the<br />

Watson Center.<br />

Bug reports help identify<br />

the “scent”<br />

Lawrance’s work involves creating<br />

a model for navigating source<br />

code that will take into account<br />

the frequency with which words<br />

in bug reports appear in source<br />

code. The cues indicated by<br />

these words, provide the “scent,”<br />

Lawrance explains. His research is<br />

investigating whether this scent is<br />

like the cues predators use to find<br />

food in the wild.<br />

“T<strong>here</strong>’s a lot <strong>of</strong> power<br />

and simplicity in the<br />

words that tell people<br />

w<strong>here</strong> to go,” Lawrance<br />

says. “This model<br />

can open the door to<br />

new s<strong>of</strong>tware tools<br />

that quickly guide<br />

programmers to the<br />

code they need to fix.”<br />

Together with his adviser, pr<strong>of</strong>essor<br />

Margaret Burnett, Lawrance has<br />

been collaborating with IBM<br />

researchers for two years. Four <strong>of</strong><br />

his eight refereed papers have been<br />

co-authored with IBM collaborators,<br />

and t<strong>here</strong> are several more in the<br />

pipeline.<br />

Joey Lawrance won a $10,000<br />

scholarship — and an internship at<br />

IBM’s Watson Research Center —<br />

for his research into navigating and<br />

debugging source code.<br />

16 17

An otherworldly<br />

challenge<br />

Two things above<br />

all helped the OSU<br />

Robotics Club win<br />

the 2008 <strong>University</strong><br />

Rover Challenge:<br />

teamwork and a<br />

gasoline-powered<br />

hydraulic engine. The<br />

team’s talents, which<br />

include programming,<br />

mechanical design<br />

and assembly — all<br />

in just five months<br />

— enabled them to<br />

create a vehicle with a<br />

powerful engine that<br />

could handle the harsh,<br />

rocky terrain at the<br />

Mars Desert Research<br />

Station in Utah.<br />

ARCS scholars<br />

Student success<br />

Scholarships can make all<br />

the difference. For four OSU<br />

engineering students, help has<br />

come from the Achievement<br />

Rewards for <strong>College</strong> Scientists<br />

Foundation, Inc. (ARCS), a national<br />

not-for-pr<strong>of</strong>it women’s organization.<br />

Each received a $15,000 three-year<br />

scholarship from the Portland ARCS<br />

chapter.<br />

Motivated by the launch <strong>of</strong> the<br />

Russian satellite Sputnik, three<br />

Southern California women formed<br />

ARCS 50 years ago. Since then, ARCS<br />

has given more than $61 million in<br />

awards to institutions to support<br />

recruitment <strong>of</strong> the best and brightest<br />

students in engineering, science<br />

and medicine. Students can use the<br />

awards for any purpose.<br />

ARCS began its support <strong>of</strong> OSU<br />

students in 2008 and plans to<br />

<strong>of</strong>fer funds to more students in<br />

future years, says Leslie Workman,<br />

president <strong>of</strong> the Portland ARCS<br />

chapter. This fall, ARCS is<br />

supporting a total <strong>of</strong> 37 Ph.D.<br />

students in science and engineering<br />

fields at OSU and <strong>Oregon</strong> Health &<br />

Science <strong>University</strong>.<br />

Putting nuclear energy<br />

on a diet<br />

Graduate student Wade Marcum<br />

is helping to put some <strong>of</strong> the<br />

country’s most advanced nuclear<br />

research reactors on a diet to reduce<br />

proliferation risks. As a Ph.D.<br />

student in OSU’s Department <strong>of</strong><br />

Nuclear <strong>Engineering</strong> and Radiation<br />

Health Physics, he is working on an<br />

initiative that will enable reactors<br />

to function with low enriched<br />

uranium (LEU) fuel.<br />

Marcum grew up in Silverton and<br />

came to OSU as an undergraduate<br />

in mechanical engineering. During<br />

his senior year, he decided to enter<br />

the graduate program in nuclear<br />

engineering. In his research with<br />

assistant pr<strong>of</strong>essor Brian Woods,<br />

he is studying the performance<br />

<strong>of</strong> a molybdenum-uranium alloy<br />

that meets LEU standards and may<br />

enable high-performance research<br />

reactors to operate successfully.<br />

Sarah Oman and Irem Tumer<br />

Marcum’s research is occurring in two<br />

phases. In the first, he is addressing<br />

hydromechanical forces that affect<br />

the fuel. In the second, he will lead<br />

the design and construction <strong>of</strong> a<br />

test facility to examine the function<br />

<strong>of</strong> high-performance reactor fuel in<br />

detail. Someday, he would like to<br />

teach and conduct research at the<br />

university level.<br />

How do you measure<br />

creativity<br />

At OSU, Sarah Oman found the<br />

rigorous challenge and friendly<br />

atmosp<strong>here</strong> she was looking for in<br />

a graduate program. After receiving<br />

her bachelor’s from the <strong>University</strong><br />

<strong>of</strong> Idaho in May, 2008, she met<br />

associate pr<strong>of</strong>essor Irem Tumer in<br />

the School <strong>of</strong> Mechanical, Industrial<br />

and Manufacturing <strong>Engineering</strong>.<br />

She felt welcome in the Complex<br />

Engineered Systems Laboratory,<br />

which Tumer directs. The lab<br />

uses mathematical approaches to<br />

understand and improve integrated<br />

hardware-s<strong>of</strong>tware systems in<br />

aircraft, automobiles and spacecraft.<br />

Oman is considering several areas for<br />

her dissertation topic, such as how<br />

visualization <strong>of</strong> early-stage design<br />

decisions can affect outcomes. She<br />

is also focusing on the intersection<br />

<strong>of</strong> creativity and design, looking at<br />

how creativity can be measured or<br />

analyzed in the design process.<br />

More powerful using<br />

less power<br />

Can the integrated circuits that<br />

paved the way for the computer age<br />

continue to do more with less Jacob<br />

Postman thinks so. The Philomath<br />

native and Ph.D. student in the<br />

School <strong>of</strong> Electrical and Computer<br />

<strong>Engineering</strong> is collaborating with<br />

a Princeton <strong>University</strong> group that<br />

is building chips with improved<br />

performance and reduced power<br />

demand.<br />

Postman works with assistant<br />

pr<strong>of</strong>essor Patrick Chiang in the<br />

school’s well-known analog-mixed<br />

signals group. The graduate<br />

student is designing a 4-core test<br />

chip and plans to produce a 64-<br />

core network-on-a-chip prototype<br />

next year.<br />

After he achieves his goals and<br />

earns a degree, Postman intends<br />

to work abroad, possibly in<br />

Germany or China. Still, the Pacific<br />

Northwest remains home. He <strong>hope</strong>s<br />

to continue doing research, to<br />

create his own company and to<br />

teach in Washington or <strong>Oregon</strong>.<br />

Getting the lead out <strong>of</strong><br />

industrial materials<br />

Finding a lead-free piezoelectric<br />

material that performs well<br />

in electronic sensors and<br />

other devices would make Eric<br />

Patterson’s day. Or maybe his<br />

whole year. The Ankeny, Iowa,<br />

native came to OSU to work on<br />

alternatives to commonly used<br />

electroceramics with pr<strong>of</strong>essor<br />

David Cann in the School <strong>of</strong><br />

Mechanical, Industrial and<br />

Manufacturing <strong>Engineering</strong>.<br />

Eric Patterson and David Cann<br />

Getting the lead out <strong>of</strong><br />

industrial materials has been an<br />

environmental goal for decades, but<br />

no good alternatives currently exist<br />

for piezoelectric materials, which<br />

transform mechanical pressure into<br />

a change in voltage. Ultrasound<br />

devices, microphones, sonar and<br />

ink jet printers are just some <strong>of</strong><br />

the technologies that depend on<br />

piezoelectric materials.<br />

In pursuit <strong>of</strong> his Ph.D., Patterson<br />

is going to fundamentals, in this<br />

case spelled “perovskite.” Materials<br />

in this class <strong>of</strong> piezoelectrics<br />

have unique electronic properties<br />

that vary greatly with changes in<br />

structure. One <strong>of</strong> their strengths<br />

is resistance to fatigue, or the<br />

failure <strong>of</strong> structure under repated<br />

stress. Understanding exactly how<br />

molecular structure affects material<br />

properties such as fatigue is key to<br />

Patterson’s research.<br />

Martin<br />

moments<br />

Although his<br />

$20 million<br />

gift for what<br />

would become<br />

the Kelley<br />

<strong>Engineering</strong><br />

Center was<br />

originally<br />

anonymous,<br />

Martin chose to<br />

step forward in<br />

the <strong>hope</strong> that<br />

“others will be<br />

inspired” to<br />

follow his lead.<br />

And they have.<br />

Brian Woods and Wade Marcum<br />

Jacob Postman and Patrick Chiang<br />

18 19

Internships<br />

Student success<br />

sits on<br />

Solar car hits<br />

the road<br />

Ph.D. students Hai-<br />

Yue Han and Kathy<br />

Van Wormer led a<br />

team <strong>of</strong> more than<br />

two dozen students<br />

who designed and<br />

built a car powered by<br />

more than 400 solar<br />

cells, which produce<br />

around 1.5 hp — less<br />

power than found in<br />

a hairdryer. They then<br />

competed in a 2,400-<br />

mile race from Dallas,<br />

Texas to Calgary,<br />

Alberta, Canada —<br />

the longest solarpower<br />

competition in<br />

the world.<br />

Interns make an impact in the<br />

workforce — and the world<br />

In a world w<strong>here</strong> success is measured<br />

in microns (one-millionth <strong>of</strong> a<br />

meter), Mike Sabo took a giant leap<br />

last summer. At Cascade Microtech’s<br />

corporate headquarters in the Silicon<br />

Forest, the senior in mechanical<br />

engineering from Klamath Falls<br />

helped to eliminate a manufacturing<br />

step and slash production time. He<br />

designed a device that holds circuit<br />

boards securely during automated<br />

soldering. He also helped to redesign<br />

and test a vacuum chuck (clamp) to<br />

specifications <strong>of</strong> 20 microns — less<br />

than the width <strong>of</strong> a human hair<br />

— to prevent tilting during huge<br />

temperature changes.<br />

To outsiders, Sabo’s work on “process<br />

optimization” might be as interesting<br />

as last week’s news. But for Sabo, the<br />

experience — through the Multiple<br />

<strong>Engineering</strong> Cooperative Program<br />

(MECOP) — was unforgettable. “It<br />

gave me a whole different tilt on<br />

the design process,” he says. “In<br />

school, you get some exposure to the<br />

manufacturing side, but it’s hard to<br />

really completely understand it unless<br />

you’ve worked on it. Companies can<br />

really cut costs if things are designed<br />

right the first time.”<br />

Undeniable benefits for<br />

students and industry<br />

Not every intern can claim to have<br />

saved his or her employer money,<br />

but the benefits for companies and<br />

students are undeniable. Students<br />

rub shoulders with working<br />

engineers who <strong>of</strong>ten treat them<br />

as colleagues, not masters <strong>of</strong> the<br />

photocopy room. Companies expose<br />

budding engineers to their products<br />

and culture, building a skilled<br />

workforce in the process.<br />

“We’ve been able to grow in <strong>Oregon</strong><br />

because t<strong>here</strong> is a technology base<br />

<strong>here</strong>,” says Steve VanArsdale, a<br />

1984 OSU graduate and operations<br />

manager for Garmin AT, a division <strong>of</strong><br />

the international GPS company that<br />

makes navigation tools for aviation.<br />

“A good part <strong>of</strong> that base is fed by<br />

the MECOP program. If we had to<br />

attract all <strong>of</strong> our engineers from out<strong>of</strong>-state,<br />

it would be very difficult to<br />

fill our positions.”<br />

Through his internships, Mike Sabo got to see how design decisions can<br />

improve the manufacturing process.<br />

VanArsdale has twice chaired the<br />

board <strong>of</strong> MECOP, a 30-year-old<br />

partnership between OSU, Portland<br />

<strong>State</strong> <strong>University</strong>, the <strong>Oregon</strong><br />

Institute <strong>of</strong> Technology and Pacific<br />

Northwest companies that need<br />

skilled employees who can think<br />

critically and solve problems.<br />

Broad and specialized<br />

experience<br />

Blake Giles, an OSU master’s<br />

student in mechanical engineering,<br />

knows the value <strong>of</strong> internships.<br />

Last summer, pursuing his interest<br />

in renewable energy (he had<br />

previously helped build a solar<br />

power demonstration trailer at<br />

OSU), he worked as an intern for<br />

the newly formed <strong>Oregon</strong> Wave<br />

Energy Trust (OWET).<br />

The Portland native is no stranger<br />

to the sea. He has fished from<br />

Desolation Bay, British Columbia,<br />

to the crabbing grounds <strong>of</strong>f the<br />

<strong>Oregon</strong> coast. When he told OWET<br />

Director Stephanie Thornton <strong>of</strong><br />

his engineering skills and passion<br />

for renewable energy, he began<br />

helping the fledgling organization<br />

get its feet on the ground. He<br />

organized posters for a pr<strong>of</strong>essional<br />

conference and made arrangements<br />

for OWET committees to tackle<br />

issues in wave energy development.<br />

As a student, Giles specializes in<br />

conceptual designs for complex<br />

systems. In plain English, he<br />

combines expertise from different<br />

fields — fluid dynamics, electrical<br />

and chemical engineering and<br />

robotics — to find solutions to<br />

design problems. In contrast,<br />

Giles used his OWET experience to<br />

understand the project management<br />

and research needs <strong>of</strong> an emerging<br />

industry.<br />

How to design wave energy buoys<br />

for survivability and maximum<br />

energy production are important<br />

engineering issues being addressed<br />

at OSU, he adds.<br />

Blake Giles sits on the float that's part<br />

<strong>of</strong> a wave-energy buoy. He used his<br />

internship at the <strong>Oregon</strong> Wave Energy<br />

Trust to gain project management<br />

experience in the emerging renewable<br />

energy industry.<br />

Martin<br />

moments<br />

According to<br />

Martin’s son<br />

Steve, his<br />

parents were<br />

“remarkably<br />

enthusiastic<br />

about education<br />

as a way<br />

<strong>of</strong> creating<br />

opportunity.<br />

With education,<br />

you then have<br />

the ability to be<br />

as successful as<br />

you choose.”<br />

20<br />

21

InternshipsStudent success<br />

A whole lot <strong>of</strong><br />

shaking going on<br />

A team <strong>of</strong> civil<br />

engineering students<br />

— Jeremy Mikkelsen,<br />

Beth McNair, Josh<br />

Leher, Sarah Martin<br />

and Joe Henry — won<br />

first place at the 2007<br />

Undergraduate Seismic<br />

Design Competition<br />

with their balsa wood,<br />

scale-model skyscraper.<br />

“Designing a building<br />

to withstand an<br />

earthquake taught us<br />

about strength and<br />

flexibility,” McNair says.<br />

“Competing and winning<br />

with our design taught<br />

us how our knowledge<br />

can be applied.”<br />

Internship powers her future<br />

For electrical engineering major<br />

Eunice Naswali, an internship is<br />

powering her future dreams. In her<br />

native Uganda, most <strong>of</strong> its electricity<br />

comes from hydropower. The problem<br />

is, during the dry season, t<strong>here</strong>’s not<br />

enough water flow to meet electrical<br />

demand, leading to widespread power<br />

outages. Nor does Uganda have the<br />

infrastructure to get electricity to<br />

remote parts <strong>of</strong> the country.<br />

MECOP internships are essentially<br />

a lottery; the assignments are not<br />

the students’ choice. So Naswali<br />

was thrilled when her second<br />

internship was assigned to Vestas,<br />

the world’s largest manufacturer<br />

Eunice Naswali <strong>hope</strong>s to use<br />

her internship exerience with<br />

wind-turbine manufacturer<br />

Vestas to help bring more<br />

reliable electric power to her<br />

native Uganda.<br />

<strong>of</strong> wind turbines. After completing<br />

her undergraduate degree — and<br />

with plans for graduate school after<br />

that — Naswali <strong>hope</strong>s to return<br />

to Uganda and take what she’s<br />

learned about wind power and other<br />

renewable energy sources to bring<br />

more reliable electric power to her<br />

homeland.<br />

Building for Sustainability<br />

Tristan Wagner graduated from<br />

Portland’s Lincoln High School<br />

in 2004 and went immediately into<br />

the manufacturing business. He<br />

and a group <strong>of</strong> friends made and<br />

sold Adirondack chairs. Even then,<br />

engineering was on his radar. No<br />

doubt his solar cell research at<br />

Portland <strong>State</strong> <strong>University</strong> helped him<br />

get accepted to MIT. It was OSU’s<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong>, though, that<br />

captured his spirit.<br />

The senior in the School <strong>of</strong><br />

Mechanical, Industrial and<br />

Manufacturing <strong>Engineering</strong> (MIME)<br />

has turned academic opportunities<br />

into a rich learning experience. He<br />

studied in Beijing, China in 2005<br />

and interned with Tektronix and<br />

with Benchmark Electronics through<br />

MECOP. As an OpportunityPLUS<br />

student in the <strong>University</strong> Honors<br />

<strong>College</strong>, he is on a fast track to<br />

graduate school and conducting<br />

research on economic replacement<br />

models with associate pr<strong>of</strong>essor<br />

David Kim.<br />

As for the future “Eventually, I would<br />

like to help make manufacturing<br />

processes and companies more<br />

sustainable, and I someday <strong>hope</strong> to<br />

run my own manufacturing company,”<br />

says Wagner.<br />

Left to right: <strong>University</strong> Honors <strong>College</strong> associate dean Bill Bogley, retired dean Joe Hendricks,<br />

Tristan Wagner and David Kim. An OpportunityPLUS student in the <strong>University</strong> Honors <strong>College</strong>,<br />

Wagner <strong>hope</strong>s to run his own manufacturing company using sustainable processes.<br />

Martin<br />

moments<br />

Martin believed<br />

strongly in<br />

the <strong>College</strong> <strong>of</strong><br />

<strong>Engineering</strong>.<br />

“Building a top<br />

engineering<br />

program will not<br />

only help <strong>Oregon</strong><br />

<strong>State</strong>, but it will<br />

also help the<br />

state <strong>of</strong> <strong>Oregon</strong><br />

and the world,”<br />

he said. “It’s a<br />

very worthwhile<br />

goal because<br />

engineering <strong>of</strong> all<br />

kinds provides<br />

solutions to some<br />

<strong>of</strong> the world’s<br />

most complex<br />

problems.”<br />

22 23

Continuing the story<br />

Solving the real<br />

problems<br />

One <strong>of</strong> the things Julia<br />

Petersen likes most about<br />

her job as a validation<br />

engineering manager<br />

at Intel in Hillsboro is<br />

communication. “What<br />

interests me most about<br />

my position is the<br />

opportunity to work across different<br />

departments to improve products and<br />

processes,” Petersen says.<br />

It takes teamwork<br />

Petersen manages a group that<br />

tests motherboards, which means<br />

she needs to coordinate her team’s<br />

efforts with several other teams.<br />

For example, she works with the<br />

developers <strong>of</strong> the Basic Input/Output<br />

System (BIOS) s<strong>of</strong>tware necessary<br />

to run those motherboards to know<br />

which features are available in each<br />

BIOS and that the s<strong>of</strong>tware will be<br />

delivered to her team on time.<br />

Balancing her team’s deadlines with<br />

those <strong>of</strong> the BIOS team takes good<br />

communication skills. “You’re forced<br />

to confront any introversion you have<br />

and put it behind you,” she says.<br />

And Petersen is successful; her<br />

interactions with teams in hardware<br />

engineering, design validation,<br />

materials and quality assurance<br />

are key to running her own group<br />

smoothly.<br />

Internships established the<br />

foundation<br />

The 1988 graduate credits her<br />

internship experiences with providing<br />

a foundation for those skills. “It gave<br />

me the initial experience necessary in<br />

teamwork and relationship building,”<br />

she says.<br />

Not only that, both <strong>of</strong> her internships<br />

gave her real-world engineering<br />

experience. At the food processing<br />

company Lamb-Weston, Petersen<br />

redesigned workstations for better<br />

throughput, eliminating line waste<br />

when it occurred, and discovering the<br />

reason for a high nitrogen count in<br />

wastewater.<br />

At her second internship, Petersen<br />

wrote a program that helped<br />

Weyerhaeuser track the use <strong>of</strong> a<br />

processing chemical on wood chips<br />

that had been sorted by size. Her<br />

program helped Weyerhaeuser realize<br />

how much money and resources it<br />

saved by sorting the chips. Even as<br />

an intern, she was the lead on all <strong>of</strong><br />

these projects.<br />

Mentoring today’s interns<br />

Recognizing the value <strong>of</strong> internship<br />

experience, Petersen has served<br />

on the MECOP board <strong>of</strong> directors,<br />

and she’s also brought a number <strong>of</strong><br />

interns to Intel.<br />

“MECOP interns are given real work.<br />

They need to complete real projects,”<br />

Petersen says. “This program is by far<br />

the best I’ve seen for giving students<br />

experience in the workplace and<br />

expanding their education.”<br />

Valuing versatility<br />

Todd Ittershagen, vice<br />

president <strong>of</strong> Precision<br />

Castparts Corp., a<br />

Fortune 500 company in<br />

Portland, thinks one <strong>of</strong><br />

two things can make a<br />

good manager: the kind<br />

<strong>of</strong> curriculum <strong>of</strong>fered<br />

in OSU’s industrial and<br />

manufacturing engineering program,<br />

or the kind <strong>of</strong> person who decides<br />

to major in it. Either way, flexibility<br />

is key.<br />

“When we look for industrial and<br />

manufacturing engineers, we’re<br />

looking at people who understand<br />

metallurgic, productivity and<br />

financial issues,” says Ittershagen,<br />

who is responsible for operations<br />

at three smaller companies within<br />

Precision Castparts. His engineers<br />

need to understand how to do things<br />

faster and which products to buy<br />

that will cut down on costs. They<br />

constantly need to be looking for<br />

problems and solving them. And<br />

on top <strong>of</strong> that, they need good<br />

communication skills to tie all <strong>of</strong><br />

those tasks together.<br />

Internship leads to job <strong>of</strong>fer<br />

Ittershagen started at Precision<br />

Castparts, which makes metal<br />

forgings, fasteners and castings<br />

primarily for the aerospace industry,<br />

as a MECOP student in 1990. His first<br />

tasks were performing efficiency and<br />

productivity studies on the factory<br />

floor, as well as doing design work<br />

on facility expansion and equipment<br />

placement. He was <strong>of</strong>fered a job<br />

even before he graduated with<br />

an industrial and manufacturing<br />

engineering degree in 1990.<br />

A progressive career<br />

Since then, Ittershagen has done<br />

equipment work, direct supervision,<br />

quality assurance work and design<br />

casting. He’s moved to Michigan,<br />

Virginia, Nevada and Ohio before<br />

coming back to <strong>Oregon</strong>. “It’s been<br />

quite a progression the past 18<br />

years,” he says. “Precision is an<br />

interesting, fast-paced, progressive<br />

company. Every time I’ve thought <strong>of</strong><br />

moving on, they’ve <strong>of</strong>fered me more<br />

responsibility.”<br />

In the future, Ittershagen plans on<br />

working more with MECOP, which<br />

he says not only prepared him for<br />

his work at Precision Castparts, but<br />

also marketed him and provided him<br />

with a network <strong>of</strong> contacts that is<br />

useful even today. “It’s an excellent<br />

program,” he says. “We want to<br />

work with them so we can create a<br />

constant stream <strong>of</strong> new, fresh people<br />

at our company.”<br />

24<br />

25

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong> Advisory Board<br />

Current (December 2008)<br />

James B. Johnson (Board Chair)<br />

President and CEO, Tripwire<br />

Kay E. Altman<br />

CFO, Altman Browning and Company<br />

Fred Briggs<br />

Executive Vice President, Verizon<br />

Communications<br />

JJ Cadiz<br />

Usability Engineer, Micros<strong>of</strong>t<br />

Kevin W. Clarke<br />

Site Manager, Barco Medical Imaging<br />

Systems<br />

Steve Cook<br />

Vice President, CH2M HILL<br />

MECOP Representative<br />

Ron Dilbeck<br />

COO, RadiSys Corporation<br />

James A. Johnson<br />

Vice President and General Manager,<br />

Visual Computing Group, Intel<br />

Lee Kearney<br />

Retired, Kiewit Construction Group Inc.<br />

Mark A. Lasswell<br />

President, OMI Inc.<br />

Sue Laszlo<br />

Transportation Section Manager, HDR<br />

Paul Lorenzini<br />

CEO, NuScale Power<br />

Jeff Manchester<br />

Retired, Fort James Corp.<br />

Tom McKinney<br />

Associate Director, Project<br />

Management Services, Bechtel<br />

Fractals and Trees hangs in the central<br />

atrium <strong>of</strong> the Kelley <strong>Engineering</strong> Center.<br />

Steve Nigro<br />

Senior Vice President and General<br />

Manager, Hewlett-Packard<br />

Jeff Peace<br />

Retired, Boeing<br />

Jim Poirot<br />

Retired, CH2M HILL<br />

Rod Quinn<br />

Director, Process Science & <strong>Engineering</strong>,<br />

Pacific Northwest National Laboratory<br />

Hal Pritchett<br />

Retired, OSU Construction and<br />

<strong>Engineering</strong> Management<br />

Rod Ray<br />

CEO, Bend Research<br />

Scott R. Schroeder<br />

President & CEO, Mega Tech <strong>of</strong> <strong>Oregon</strong><br />

David Skillern<br />

VP <strong>of</strong> Customer Services, Isilon Systems<br />

Milton R. Smith<br />

President, Smith Investments<br />

Randall L. Smith<br />

Vice President, CH2M HILL<br />

Abhi Talwalkar<br />

President & CEO, LSI Logic Corporation<br />

Michael VanBuskirk<br />

Senior Vice President <strong>of</strong> <strong>Engineering</strong><br />

and Operations, Innovative Silicon Inc.<br />

Mike West<br />

VP Technology, Pixelworks<br />

Emeritus Board Members<br />

Larry Chalfan<br />

Executive Director, Zero Waste Alliance<br />

Mark Christensen<br />

President, Global Capital Management,<br />

LLC<br />

Dwayne Foley<br />

Retired, NW Natural<br />

D. W. “Chuck” Halligan<br />

Retired, Bechtel Power Corp.<br />

Ed Hunt<br />

Retired, HUNTAIR<br />

Robert Johnson<br />

Retired, National Semiconductor Japan<br />

Ltd.<br />

Jim Lake<br />

Associate Lab Director, Idaho National<br />

Laboratory<br />

Ted Molinari<br />

Retired, Praegitzer Industries Inc.<br />

Robert L. Polvi<br />

Retired, Bechtel Group Inc.<br />

Jim Street<br />

Retired, Shell Oil Company<br />

Jean Watson<br />

Retired, Chevron<br />

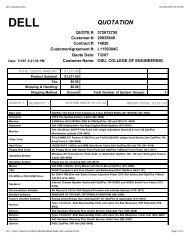

Operational summary<br />

<strong>Oregon</strong> <strong>State</strong> <strong>University</strong> <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> 2007-2008<br />

• Total Revenue: $53.7 million<br />

• Research Expenditures: $28.8 million<br />

• Total Undergraduate Scholarships: $4.9 million<br />

501<br />

2008<br />

Goal<br />

Undergraduate<br />

Degrees<br />

Ted Wilson<br />

Retired HP Fellow & Technology<br />

Work is nearing completion on an entirely new<br />

Director, Imaging & Printing Group,<br />

interior in Kearney Hall. The renovated, historic<br />

Hewlett-Packard<br />

cornerstone <strong>of</strong> <strong>Engineering</strong> Row will house the<br />

School <strong>of</strong> Civil and Construction <strong>Engineering</strong>.<br />

26 27<br />

2008<br />

Actual<br />

560<br />

650<br />

2013<br />

Goal<br />

Number <strong>of</strong> Degrees<br />

152<br />

2008<br />

Actual<br />

150<br />

2008<br />

Goal<br />

Masters<br />

Degrees<br />

150<br />

2013<br />

Goal<br />

Number <strong>of</strong> Degrees<br />

26<br />

2008<br />

Actual<br />

35<br />

2008<br />

Goal<br />

Doctoral<br />

Degrees<br />

39<br />

2013<br />

Goal<br />

Number <strong>of</strong> Degrees<br />

28.8<br />

2008<br />

Actual<br />

30<br />

2008<br />

Goal<br />

Research<br />

Expenditures<br />

39<br />

2013<br />

Goal<br />